Molecularly Stretchable Electronics

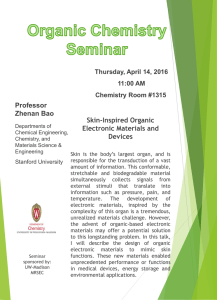

advertisement