• LM-80 refers to a method for measuring the lumen depreciation of

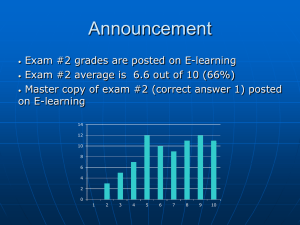

advertisement

LM80 • • • LM‐80 refers to a method for measuring the lumen depreciation of solid‐state light sources, such as LED packages, modules and arrays. Typically, LED component manufacturers each report lumen maintenance data using their own methodology making it vary hard to compare “like for like”. It was developed by the Illuminating Engineering Society of North America (IESNA), to allow people the ability to evaluate and compare the lumen maintenance of LED components from different companies. It is typically a 6000hr test (can be 10,000hrs) that shows depreciation and chromaticity shift over the period at particular operating temperatures 55 degrees, 85 degrees and a third manufacturer defined temperature. TM21 • • • • TM 21 follows on from LM 80 testing and is a method for calculating useful lifetime from the data collected from the LM 80 testing. TM‐21 provides guidelines for using LM‐80 data to estimate the light source lumen maintenance beyond the LM‐80 test period. LM‐80 and TM‐21 are designed to work hand‐in‐hand, with TM‐21 using the LM‐ 80 data, along with in‐situ temperature performance data, to project the lumen maintenance of an LED light source. Typically the claimable life utilising TM 21 method = 6 x LM 80 test time ≥36,000hrs or ≥60,000hrs if the test time is 10,000hrs. TM21 LM79 The LM‐79 test is conducted to gather data relating to the luminaires • Total Luminous Flux • Luminous Intensity Distribution • Electrical Power • Luminous Efficacy (calculation) • Color Characteristics Chromaticity • CCT • CRI The LM79 test requires the complete luminaire to be tested, this also known as Absolute Photometry. Unlike traditional ‘Relative’ photometry, solid state lighting products cannot have their LED’s seperated from the lumnaire due to heat effects. Lifetime and failure rate The light output of an LED module decreases over the lifetime, this is characterized by the L value. L70 = 70% of its initial luminous flux; L90 = 90% of its initial luminous flux; The B value defines the amount of modules which are below the specific L value. L70 B10 = 10% of modules are below 70% of their initial luminous flux L90 B10 = 10% of modules are below 90% of their initial luminous flux The C value defines the percentage of fatally failed modules. F value = B + C L70 F10 = 10% of modules may fail or be below 70% of their initial luminous flux L90 F10 = 10% of modules may fail or be below 90% of their initial luminous flux