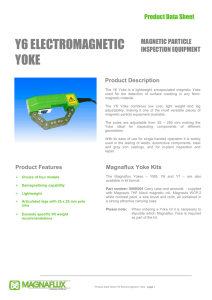

Handbook for Magnaflux Y6 Electromagnetic Yoke - Nov 11

advertisement

Y6 YOKE KITS In kit form, the Y6 Yoke is supplied complete with black magnetic ink, white contrast paint and a wire brush and duster, all housed in a strong attractive carrying case. A light source, attached to one leg of the Y6 Yoke, is activated by the magnetic field and switches on automatically during testing. Ideal for darker corners. Light source for Y6 Yoke – part number 002L115. HANDBOOK FOR MAGNAFLUX Y6 ELECTROMAGNETIC YOKE L-10 MAGNETISING COIL Developed for testing shafts, spindles and similar components. Features: Ideal for inspecting for transverse cracks Components are magnetised and demagnetised with the same coil 110V operation Wet or dry Magnetic Particle Inspection (MPI) method can be used Footswitch provides continuous control PART NUMBERS: 001Y022, 001YO20, 001Y004 Magnetic particle colours available: Dry method – grey, black, red Wet method – black, red, fluorescent Handbook for Magnaflux Y6 Electromagnetic Yoke PREPARED INKS Certificate of Conformity Y6 Yoke Serial number: Certified that the above item conforms to and meets the requirements of the following: EC Directives Specifications 73/23/EEC 89/392/EEC 91/368/EEC 89/336/EEC (Emissions) 92/31/EEC (Emissions) ASME V ART7 ASTM E-709 ASTM E-1444 EN-ISO 9934-3 MIL-STD-271 Certificate is issued under the auspices of the Equipment Product Manager (2011): Flash point (°C min) (PMCC) Viscosity @ 21°C (cS) Specific gravity Particle size (µm) Settlement volume (%V/V) (as supplied) 93 3.45 0.81 7 to 25 0.12 93 3.45 0.81 2 to 25 0.25 93 3.45 0.81 0.6 to 2.5 2.5 Magnaglo 410HF* A prepared ink consisting of Magnaglo MG410 in a high flash kerosene of low odour Magnaglo 14HF* A prepared ink consisting of Magnaglo 14A in a high flash kerosene of low odour Magnavis 7HF* A prepared ink consisting of Magnaflux 7C in a high flash kerosene of low odour *Available in both aerosol and bulk format DRY POWDERS 1 Grey Maximum working temperature 315°C Magnaflux (A Division of ITW Ltd), Faraday Road, South Dorcan Industrial Estate, Swindon, Wiltshire, SN3 5HE, UK. Tel: +44 (0)1793 524566 Fax: +44 (0)1793 490459 Email: sales@magnaflux.co.uk www.magnaflux.com MAGNETIC FIELD RISK Persons susceptible to strong magnetic fields, including those with pacemakers, are advised not to use or approach this equipment without seeking professional advice. 3A Black Maximum working temperature 230°C 8A Red Maximum working temperature 175°C WCP-2 White Contrast Paint Magnaflux dry powders offer a range of colour to give good contrast on as wide a variety of finishes as possible. In the event of contrast not being ideal for inspection, a thin layer of Magnaflux WCP-2 White Contrast Paint can be applied prior to testing. All powders are of closely controlled particle size and shape and have desirable magnetic properties. For best results application should be as a cloud applied near the surface while the current is flowing. Excess powder settling out can be blown off. Magnaflux WCP-2 is a quick-drying white contrast paint which can be applied as a thin coating prior to testing where enhanced contrast is required. SPECIFICATIONS Magnaflux, Magnaglo and Magnavis concentrates, prepared inks and dry powders meet the requirements of ASTM E-1444 with oil suspended inks and concentrates meeting AMS specifications, plus appropriate industrial and Government specifications, Certifications are available on request. TECHNICAL SPECIFICATION 50 110 115 230 50 50 60 50 12 12 AC 15 3.5 3.5 2.3 DC 8.5 8.5 2.5 Weight (Kg) lifted at 140mm pole spacing AC 10.5 10.5 10.5 10.5 DC 32.0 32.0 Part number 001Y022 001Y004 001Y020 AC Tangential Field Strength in kA/m at the central point between the poles on a 500 x 250 x 10 mm steel plate Pole spacing 35mm 12kA/m 140mm 2kA/m 250mm 1.4kA/m USING THE Y6 YOKE AC voltage (V) Frequency (Hz) DC voltage (V) Supply current (A) in air The light source and leg assembly, which is activated by the magnetic field, is switched on automatically during testing. Ideal for dark corners. Part number: 002L115. Note 1: This Yoke can be supplemented by a magnetising coil for inspecting mounted spindles, rear axles and other light parts for transverse cracks only. Note 2: Fluorescent magnetic ink with high intensity black light improves the sensitivity of both the Y6 Yoke and L10 Magnetising Coil 1. 2. 3. CERTIFIED TEST WEIGHTS Available for both AC and DC. AC Test Weight (4.5Kg) DC Test Weight (18Kg) Place the Yoke on the workpiece perpendicular to the direction of the cracks. Double jointed articulated legs can be moved in two directions at each joint. You can then adjust the spacing between the legs from about 25 to 250mm and contour the feet to produce a good flat contact point on parts with irregular shapes. Trigger the switch, apply the inspection medium, either wet or dry, and surface crack indications form immediately. You can proceed rapidly in a series of steps each finding cracks in a 150 x 150mm area. WARNINGS Part Number: 026T018B Part Number: 026T018A 4. 5. DO NOT smoke while performing NDT DO NOT operate the Y6 Yoke for longer than 3 seconds ON followed by 10 seconds OFF, that is a 23% duty cycle If the Yoke is too hot to hold in the bare hand it is a sign that the duty cycle has been exceeded. Wait for the Yoke to cool before continuing. DO NOT use any means to permanently operate the Yoke switch DO NOT use the supply cable to pull, lift or carry the equipment When the Yoke is switched OFF the magnetic attraction to the tested component will be weakened and either the part or the Yoke could fall and cause injury Laminar magnetic iron provides maximum efficiency with light weight. The trigger switch is easily operated without changing hand positions. As magnetic contact exists only between the Yoke and the test piece, the switch, completely enclosed by a rubber gasket, is the only break in the electrical circuit. Thus arcing on the part itself is impossible. SAFETY DATA FLAMMABILITY The Y6 Yoke is intended to be used in conjunction with appropriate chemicals as a Non Destructive means of Testing (NDT) for defects, such as cracks, on a wide range of manufactured components. Some chemicals may produce a flammable atmosphere at the point of use and it is important that the testing is carried out in a well ventilated place and that all sources of ignition are excluded. Good quality NDT chemicals such as Magnaflux magnetic inks and powders are formulated to minimise the risk of a flammable atmosphere when correctly used. ELECTRICAL Ensure that the protective conductor (earth) is continuous from the Y6 laminations through suitable connections to the electrical supply. Recommendations: PARTS LIST Item 1 2 3 4 5 Description Cable, 3 core Bush Leg/foot assembly Switch kit: Switch Rubber cover Insulated metal cover Screws Cable cover Part number 001C065 014B027 70617A3 Quantity 3.75 metre 1 2 005K026 1 MAINTENANCE Before using the Yoke: 17771A3 1 WARNING DO NOT REPLACE ANY PARTS RECOMMENDED BY MAGNAFLUX. A Residual Current Circuit Breaker (RCCB) or Earth Leakage Circuit Breaker (ELCB) should be used if the Yoke supply is greater than 50V If the switch area of the Yoke becomes wet with kerosene or water it should be disconnected from its supply until the area has dried In damp conditions select either a 42V or 48V Yoke, or a 110V Yoke operated from a supply that is centre tapped to earth (55V-0-55V) If the Y6 shows signs of malfunctioning or if cracks appear in the casing, the Yoke should be removed from service immediately and examined by a qualified electrician. Cracking is usually caused by dropping the Yoke or by twisting the articulated legs. WITH OTHER THAN THOSE Ensure it is physically undamaged Ensure the cable is free from cuts which expose the wiring Tighten the articulated joints if they are excessively loose It is a legal requirement in many countries that the electrical safety of equipment is checked periodically, commensurate with use, but at least once a year. The basic tests required are to check the condition and effectiveness of the electrical insulation and the continuity of the protective conductor (earth). These tests can be performed using as Portable Appliance Tester (PAT) or Portable Appliance Checker (PAC).