Analytica Chimica Acta 696 (2011) 84–93

Contents lists available at ScienceDirect

Analytica Chimica Acta

journal homepage: www.elsevier.com/locate/aca

Comparison of near infrared and microwave resonance sensors for at-line

moisture determination in powders and tablets

Claudia C. Corredor ∗ , Dongsheng Bu, Douglas Both

Analytical and Bioanalytical Development, Bristol-Myers Squibb, New Brunswick, NJ, 08901, United States

a r t i c l e

i n f o

Article history:

Received 11 November 2010

Received in revised form 11 March 2011

Accepted 24 March 2011

Available online 15 April 2011

Keywords:

Near infrared (NIR)

Microwave resonance technology (MRT)

Process analytical technology (PAT)

At-line water determination

Powders

Tablets

a b s t r a c t

In this paper we demonstrate the feasibility of replacing KF for water content testing in bulk powders

and tablets with at-line near infrared (NIR) or microwave resonance (MR) methods. Accurate NIR and

MR prediction models were developed with a minimalistic approach to calibration. The NIR method

can accurately predict water content in bulk powders in the range of 0.5–5% w/w. Results from this

method were compared to a MR method. We demonstrated excellent agreement of both NIR and MR

methods for powders vs. the reference KF method. These methods are applicable to in-process control or

quality control environments. One of the aims of this study was to determine if a calibration developed

for a particular product could be used to predict the water content of another product (with related

composition) but containing a different active pharmaceutical ingredient (API). We demonstrated that,

contrary to the NIR method, a general MR method can be used to predict water content in two different

types of blends.

Finally, we demonstrated that a MR method can be developed for at-line moisture determination in

tablets.

© 2011 Elsevier B.V. All rights reserved.

1. Introduction

Water can affect product quality, shelf life, chemical stability

and reactivity of pharmaceutical products [1–3]. The determination

of the water content in active pharmaceutical ingredients (APIs)

and drug products is important to demonstrating compliance with

the pharmacopeia and quality standards [4]. From a manufacturing viewpoint, moisture in APIs and excipients is a critical quality

attribute (CQA) which can impact drug product manufacturing unit

operations such as granulation, conveyance, compaction, drying,

etc. [5–7]. Karl Fischer (KF) titration is a universally acknowledged

method for measuring water in pharmaceutical products. Although

the technique is reliable under careful controlled conditions, it is

time consuming and destructive, requires the handling of organic

solvents, generates waste and in some cases can give erroneous

results due to side reactions with the KF reagent (such as aldol

condensation and redox side reactions) [8]. Although it has the

potential to be interfaced in production processes [9,10], it is generally not considered a high throughput assay owing to required

sample preparation. If water content is determined to be a CQA, it

would be desirable to be able to use an accurate predictive model

with a minimum set of calibration standards to facilitate determi-

∗ Corresponding author. Tel.: +1 732 227 5223.

E-mail address: claudia.corredor@bms.com (C.C. Corredor).

0003-2670/$ – see front matter © 2011 Elsevier B.V. All rights reserved.

doi:10.1016/j.aca.2011.03.048

nations of moisture content as early as possible in the development

of the manufacturing process and for that application to be capable

of being deployed at-line in the process.

Since the publication of the Food and Drug Administration

(FDA) Process Analytical Technology (PAT) guideline: A Framework

for Innovative Pharmaceutical Development, Manufacturing, and

Quality Assurance [11], pharmaceutical companies have undertaken efforts to improve product quality through increased process

understanding and in-process controls rather than solely relying

on end-product testing. These controls are designed in a holistic

manner by embodying ICH Q8, 9 and 10 documents [12–14], which

incorporate risk and quality by design (QbD) into the development

program. An assessment of CQAs of materials in processes leads to

the correct attributes being measured.

Near-infrared (NIR) spectroscopy and microwave resonance

(MR) sensors are analytical approaches used for the timely monitoring of CQAs of materials and the implementation of PAT [15–24].

They are non-invasive techniques that do not require sample preparation and provide real-time data due to their fast acquisition and

processing times. NIR spectroscopy is well suited for measurement of moisture because water shows strong absorption bands

in NIR, most prominent the first overtone of OH stretching at

around 6800–7100 cm−1 (1470–1408 nm) and the combination

band of OH stretching and bending at around 5100–5300 cm−1

(1960–11887 nm). Luypaert et al. reviewed more than 40 applications of NIR for moisture reported until 2007 [16]. Since then,

more applications of NIR spectroscopy for the determination of

C.C. Corredor et al. / Analytica Chimica Acta 696 (2011) 84–93

water in pharmaceutical products have been published [17–20].

Although the major pharmacopoeias have generally adopted NIR

techniques (the European [25] and United States Pharmacopoeia

[26] both contain a general chapter on near-infrared spectrometry and spectrophotometry, respectively), NIR has traditionally not

been considered an amenable technique for quality control (QC

release methods). This may be due to the fact that the NIR method

must be carefully calibrated vs. a reference method, and appropriate reference calibration standards of known moisture content

have to be generated. This calibration phase is time consuming and

requires the use of chemometrics. Due to the time and resources

that have to be invested during the calibration phase, implementation of NIR methods for batch release becomes practical when a

large number of batches of material are to be tested. Additionally, it

could be beneficial to use calibration sets developed with a minimal

number of standards. This would allow the timely implementation

of the NIR method and the release of a batch based on statistical

analysis of hundreds of units.

MR technology is also well suited for quality control and inprocess moisture analysis [27–33]. MR technology is a free-space

technique that allows reflection and transmission measurements in

the microwave frequency region without contact with the sample.

It enables continuous, density independent moisture monitoring of

solid products. MR sensors are based on the interaction of electromagnetic waves with granular or particulate materials. If a product

containing water is passed over a microwave resonance sensor, its

resonance frequency decreases and the half-width of the resonance

curve increases [27,30–33]. The magnitude of these changes can be

correlated to the water content of the samples. The heat increase

for the product to be analyzed is not relevant, as the output in the

measuring field at <10 mW is far below the transmission power of

modern cell phones (1–2 W) [27–30]. Despite the introduction of

MR sensors in the late 1960s as an effective tool for real-time, nondestructive sensing of moisture content in a variety of materials

[33 and literature herein], it was only recently demonstrated the

feasibility and advantages of its use as an on-line PAT tool for pharmaceutical processes [27,28,33]. This could have been the result of

the technical issues and high cost of the first generation of sensors

combined with the past general caution of pharmaceutical companies to the introduction of new probes, due in part to the past FDA

reviewers’ conservatism. Recent developments in solid-state and

planar-circuit technologies provide a variety of commercially available, inexpensive, reliable, and GMP compliant sensors. Contrary to

NIR, MR methods do not necessarily require the use of chemometrics (univariate calibration plots can be developed), making this

technique more amenable for application in cases in which sophisticated chemometric software and expert chemometricians are not

available.

Comparison of at-line NIR and microwave techniques for moisture determination is of great importance, since the basic principles

of their operations are different. For instance, the depth of penetration of NIR light in pharmaceutical powders and tablets measured

in reflectance mode ranges from 0.5 to 2.5 mm (the wide range of

reported depths of penetration can be attributed to several factors

such as wavelength, instrument settings, sample presentation and

physical and chemical properties) ([34,35], and literature therein).

If the depth of penetration is short and the water is not homogeneously distributed in the sample, the NIR determined water would

not be representative of the total water. For example, Dreassi et al.

determined a high percentage error in the water determination in

ranitidine HCl tablets for samples having a water content of less

than 2.5%, when determined by a reflectance NIR method [36].

Contrary to NIR, the stray fields generated in a microwave resonant cavity have penetration depths from 2 to 5 cm, and the water

determined is more representative of the tablet core or the bulk

powder. MR allows the determination of moisture of film coated

85

tablets unlike NIR, where water content must be determined on

uncoated tablets or only measures the coating water content. The

aim of this study is to investigate the use of a microwave sensor for

water determination in powders and tablets and its performance

compared to NIR.

2. Materials and methods

2.1. Materials

Avicel PH102 microcrystalline cellulose (MCC) was purchased

from FMC Biopolymer (Philadelphia, PA, USA). Magnesium stearate

(MgSt), Acetaminophen (APAP) and Hydroxypropyl methylcellulose NF (HPC) were purchased from Sigma–Aldrich (St. Louis, MO,

USA). A proprietary Bristol-Myers Squibb (BMS) active pharmaceutical ingredient was synthesized in house (BMS, New Brunswick, NJ,

USA), and used after purification. Hydranal composite 534805 from

Fluka Analytical. Hydranal Methanol-Dry from Sigma–Aldrich.

Potassium acetate pentahydrate, sodium chloride, magnesium

nitrate hexahydrate were purchased from Sigma–Aldrich.

2.2. FT-NIR instrument

Diffuse reflectance NIR spectra were acquired with an Antaris II®

Fourier-Transform Near Infrared (FT-NIR) analyzer from Thermo

Electron Corp. (Madison, WI), equipped with an InGaAs detector. The software package Result-Integration® accompanying the

FT-NIR instrument was used to acquire the spectra from the instrument. Each spectrum was the average of 64 scans over the range

of 10,000–4000 cm−1 (1000–2500 nm), with 8 cm−1 resolution. All

spectra were recorded through the bottoms of the sample vials

prior to KF titration. Triplicate measurements were made with the

FT-NIR spectrometer. The sample vial was rotated during measurements and inverted in between measurements. Calibration models

were built with partial least squares (PLS) regression, performed

with the Unscrambler® chemometrics software version 9.8 (Camo

Inc., Oslo, Norway). The data was centered prior to analysis.

2.3. Microwave resonance instrument

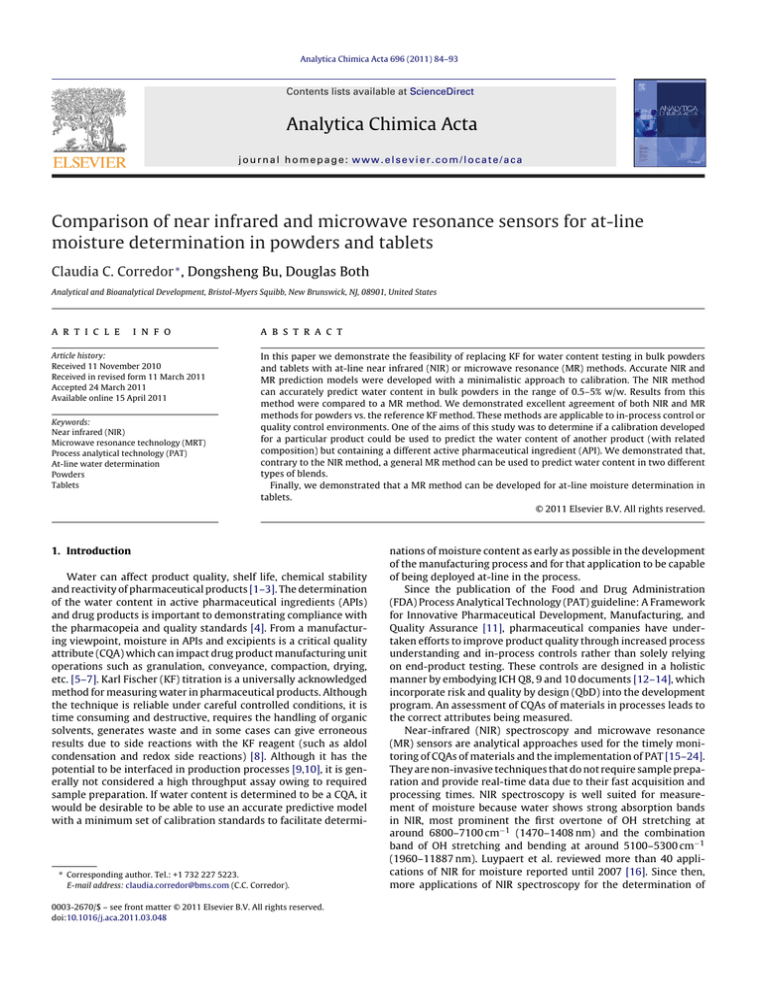

For the at-line determination of water content in powders and

tablets a Sartorius LMA 320PA microwave moisture analyzer (Sartorius Mechatronics, CO, USA), equipped with a LMA 330RE-026

sensor operating at 2.5 GHz was used. This microwave resonance

device works with a high precision resonance method. The resonance frequency of the sensor system is analyzed by continuous

scanning of the microwave frequency. When the field changes its

polarity rapidly, only the water molecules can follow this change

as they are small and have a strong dipole. This movement requires

energy, which is drawn from the electromagnetic field. This loss

of energy, which depends on the number of water molecules, is

detected. When the product containing water is passed over the

sensor, the resonance frequency decreases (due to a decrease of the

wavelength inside the material, f ) and the half-width of the resonance curve increases (due to losses of microwave energy inside

the material B), as shown in Fig. 1.

The mass-independent microwave moisture value (MW) is

given by:

MW = arctan

B

Wm − W0

B

,

= = arctan

A

f

f0 − fm

(1)

where B (also known as B parameter) is the increase of the halfwidth in Hz, f (also known as A parameter) is the shift in the

resonance frequency in Hz, f0 is the resonance frequency of the

empty resonator in Hz, fm is the resonance frequency of the filled

resonator in Hz, w0 is the half-width of the resonance of the empty

86

C.C. Corredor et al. / Analytica Chimica Acta 696 (2011) 84–93

Table 1

Composition of calibration blends in the range of 1–5% w/w.

Fig. 1. Frequency (GHz) vs. scattering transmission coefficient S21 .

resonator in Hz, and Wm is the half-width of the resonance of

the filled resonator in Hz. The ratio of both quantities is virtually

independent of the mass and thus only a function of the moisture

content.

Samples that were used for calibration were available in the

same condition as samples used for validation purposes. The moisture range and ambient conditions used for calibration matched

later measuring conditions. Temperature compensation was not

applied since the temperature of the samples during calibration and

later measurements remained within ±5 ◦ C. Calibration measurements in the NIR and MR sensors were carried out with the same

samples that were used for determining the reference moisture by

KF method. Samples were kept in a closed vial during measurements. After KF and NIR measurements, the microwave resonance

was measured. The MW value used for calibration and measurement was the mean value of three independent measurements. A

compression test was executed prior to the calibration, following

the manufacture recommended procedure [37]. This compression

test should always be used to find out if there are A parameter (frequency difference) or B parameter (width difference) offsets that

have to be taken into account (when A parameter and B parameter differ from the standard A,B = 0 settings) to acquire density

independent MW values. Typically the compression test was run

with samples containing different moistures in the range expected

for the real samples. The compression test provides one regression

line per moisture value. If all regression lines intersect in the 0,0

point, no AB offset has to be manually input in the calibration. If

the regression lines intersect at a different point, the actual A and

B offset parameters should be manually input in the calibration

screen. Temperature was constantly recorded. Data was collected

and processed using TMV-TEWS® software (version 2.0.0.40). The

TMV software controls the MW sensor via a network PC or the unit

touch screen. The software allows the selection of different sensor

modes, measurement of reference standards for daily check calibration, performance of the compression test, and sample temperature

corrections. The corresponding product settings are recorded and

saved and the configuration is used for calibration and measurement of samples.

APAP (%)

MCC (%)

HPC (%)

Water (%)

KFa

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

32.0

56.0

55.0

15.0

55.0

68.0

20.0

35.0

35.0

28.0

73.0

38.0

18.0

58.0

50.0

28.0

68.0

44.0

10.0

60.0

15.0

22.0

65.0

53.0

25.0

57.0

12.5

55.0

75.0

35.0

36.0

70.0

−

−

33.0

24.0

27.0

10.0

15.0

12.0

40.0

12.5

10.0

6.0

8.0

7.0

11.0

3.0

−

−

2.0

1.0

3.0

−

−

−

−

2.5

4.5

1.0

−

−

3.0

2.73

1.78

2.52

3.48

3.70

0.93

2.65

2.17

1.13

4.83

5.05

3.23

3.03

1.44

4.49

2.82

a

KF values correspond to an average of three measurements.

reagent, Hydranal Composite 5 from Fluka Analytical. The solvent

was changed after each triplicate measurement. The performance

of the titration method was checked by determining the water

content of deionized water. Titration conditions were a minimum

extraction time of 1990s, a start and stop drift of 10 L min−1 , a

polarisation current of 50 A and an endpoint detection voltage of

250 mV. Sample masses ranged between 0.15 and 0.30 g.

The reference KF method for blends with water content from

0.2 to 1% w/w was coulometric KF. Coulometric KF measurements

were carried out at a constant room temperature of 16 ◦ C using a

Methrom 756 KF Coulometer controlled with Tiamo 1.2 software

and Hydranal solution (Sigma–Aldrich) for coulometric titrations.

2.5. Samples

For the calibration plot in the range of 1 to 5% w/w, a total of 16

calibration standards consisting of blends of APAP-MCC-HPC were

prepared. The amount of APAP ranged from 15 to 73% w/w, MCC

from 10 to 75% w/w, HPC from 0 to 40% w/w and water from 0 to

4.5% (Table 1). Blends were prepared in a L.B. Bohle minigranulator. Different amounts of APAP, MCC and HPC were added on the

high shear mixer/granulator and mixed for 5 min (Impeller speed:

1800 rpm. Chopper speed: 800 rpm). In some blends (Table 1),

water was added gravimetrically to the dry blend of APAP and

excipients and blended for an additional 5 min.

For the calibration plot in the range of 0.2 to 1% w/w, a total of 11

calibration standards were prepared, following the same procedure

as previously described for the samples with water content in the

1–5% w/w range (Table 2). In these blends the amount of APAP

ranged from 57 to 95%, MCC from 3 to 25%, HPC from 2 to 33% and

water was not added.

Table 2

Composition of BMS API calibration blends in the range of 1–5% w/w.

1

2

3

4

5

6

7

8

9

10

11

2.4. Karl Fischer instrument

The reference KF method for blends with water content from

1 to 5% w/w was volumetric KF. Volumetric KF measurements

were carried out at a constant room temperature of 16 ◦ C using

a 758 KFD Titrino titrator (Metrohm, Switzerland) controlled with

Tiamo 1.2 software and equipped with a titration stand 703 and

a thermostatic titration vessel. The blends were directly added

to the vessel containing approximately 40 mL of dry methanol

(Merck, Darmstadt, Germany) and titrated with a one-component

Sample

a

APAP (%)

MCC (%)

HPC (%)

KFa

80.0

70.0

57.0

59.0

66.0

63.0

92.0

90.0

86.0

95.0

74.0

17.0

10.0

10.0

14.0

19.0

25.0

5.0

8.0

5.0

3.0

23.0

3.0

20.0

33.0

27.0

15.0

12.0

3.0

2.0

9.0

2.0

3.0

0.78

0.43

0.54

0.66

0.84

1.03

0.24

0.34

0.20

0.16

0.93

KF values correspond to an average of three measurements.

C.C. Corredor et al. / Analytica Chimica Acta 696 (2011) 84–93

Table 5

Prediction results for a validation set, using calibration models in Table 1.

Table 3

Composition of calibration blends with BMS API in the range of 1–5% w/w.

Sample

BMS API (%)

MCC (%)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

32.0

15.0

55.0

68.0

35.0

32.0

70.0

18.0

58.0

50.0

55.0

56.0

20.0

38.0

28.0

48.5

68.0

60.0

15.0

22.0

53.0

28.0

15.5

75.0

35.0

36.0

10.0

44.0

65.0

55.0

70.0

38.0

a

HPC (%)

24.0

27.0

10.0

12.0

40.0

10.0

7.0

7.0

11.0

33.0

15.0

6.0

2.0

11.0

Water (%)

1.0

3.0

4.5

3.0

2.0

1.0

0.0

2.5

87

KFa

Pre-processing NIR spectra

Slope

Offset

R2

RMSEP

SEP

2.90

3.64

3.95

1.13

2.16

1.43

5.45

3.10

1.73

4.64

2.71

1.93

2.76

3.45

2.87

4.32

SNV

First derivative

SNV/first derivative

Second derivative

SNV/second derivative

0.94

0.95

0.96

0.95

0.96

0.19

0.14

0.16

0.12

0.20

0.98

0.99

0.98

0.97

0.97

0.20

0.19

0.19

0.22

0.22

0.19

0.19

0.18

0.22

0.21

KF values correspond to an average of three measurements.

The 16 calibration standards consisting of blends of BMS

API-MCC-HPC were prepared in the high shear mixer/granulator

following the same procedure described for the APAP blends

(Table 3). All the blends were stored on tight containers. Moisture was determined by KF method (volumetric KF for blends with

1–5% w/w water content and coulometric KF for blends with 0.2–1%

w/w). KF values correspond to an average of three measurements.

NIR and MW data were collected in a period of no more that 30 min

after the moisture determination.

Tablets of approximately 100 mg weight and 5 mm diameter

were prepared from a blend of APAP (10%), Avicel® 200 (89%) and

magnesium stearate (1%) using a Piccola rotary tablet press (Riva

S. A, Buenos Aires, Argentina) fitted with 8 punch sets. A set of

tablets were exposed to humid air during different time intervals

in order to acquire different levels of moisture content. The relative humidity of the air was either uncontrolled, i.e. ambient air, or

controlled by a saturated salt solutions in sealed desiccators equilibrated at 25 ◦ C. The solutes used in the saturated solutions were

potassium acetate (∼23% RH), magnesium nitrate (∼53% RH) and

sodium chloride (∼75% RH). A set of tablets was placed on an oven.

3. Results and discussion

3.1. At-line moisture determination by near-infrared method

The composition of the blends used for calibration is shown in

Tables 1 and 2. As shown in the Tables, blends with water content

between 1 and 5% w/w contain higher levels of MCC and HPC and

lower level of APAP compared to the blends with water content

between 0.2 and 1% w/w. Due to the quantitative differences of

the two sets, and in order to understand the impact of composition on the NIR spectra and PLS model performance, two different

calibration models were initially developed for each set of blends.

3.1.1. Samples with moisture ranging from 1 to 5% w/w

Fig. 2a shows the NIR spectra of blends of APAP-MCC-HPC

with 1–5% w/w water content after SNV pre-processing. Significant

changes in spectral features of the samples studied were observed

at varying moisture and composition levels. As observed in Fig. 2a,

the NIR spectra of the blends show the two major absorption bands

of water at around 5155 cm−1 and 6895 cm−1 . The absorbance at

these regions increases when the water level increases. These variations in the absorbance spectra are retained in the corresponding

first derivative (Fig. 2b).

Calibration models were developed by correlating the NIR

spectra at the two main spectral regions of water absorption

(7362–6919 cm−1 and 5453–5176 cm−1 ) with water content using

partial least-squares (PLS) regression (Table 4 and Fig. 1a in supplementary material). A randomized design, was employed where the

two major excipients and the water added were varied randomly

with respect to APAP (Table 1). High correlation between major

components was avoided, since component effect on spectral baseline and slope variations due to physical properties were unknown.

Several data pre-processing methods were used and compared,

including Standard Normal Variate (SNV), Multiplicative Scatter

Correction (MSC), first and second derivatives. In the smoothing of

the derivatives (Savitzky-Golay), 21 points window and third order

polynomial were used.

Table 4 summarizes the parameters of the models, including the

slope, offset, correlation coefficient (R2 ), root mean square error of

calibration (RMSEC), and root mean square error of cross validation (RMSECV). PLS figures of merit (selectivity SEL, sensitivity SEN,

detection limit DL and quantification limit QL) were also calculated

for each model [38–40]. In this application, spectra pretreatment

by MSC did not improve the performance of the calibration model,

as previously reported [41] (data not shown).

For all the calibration models shown in Table 4, the slopes and

coefficients of determination (R2 ) are close to one, and the optimal

number of factors is 2. The joint test of significance of intercept and

quadratic term showed that there is no significance of intercept or

curvature at the 95% confidence level for all regression models. The

calibration model constructed using SNV followed by first derivative shows the lowest root mean square error of calibration (RMSEC,

0.14%), lowest root mean square error of cross validation (RMSECV,

0.15%) and best sensitivity (Fig. 1a in supplementary material).

However, since the different calibration models did not greatly

differ and the sensitivity calculated based on Net Analyte Signal

(NAS) is better for models using second derivative, all of them were

used to predict the water content of the samples in an independent

validation set (Table 5). Fig. 1b in supplementary material shows

the NIR predicted water content vs. the reference method (KF) for

independent validation samples in the range of 1–5% w/w. For this

prediction, the best chemometric model in Table 4 was used (SNV

followed by first derivative).

Table 4

PLS calibration models built with different data pretreatments for 1–5% w/w range.

Pre-processing

Slope

Offset

R2

RMSEC

RMSECV

SEN

SEL

DL

QL

SNV

First derivative

SNV/first derivative

Second derivative

SNV/second derivative

0.98

0.99

0.99

0.98

0.98

0.05

0.04

0.03

0.05

0.04

0.98

0.99

0.99

0.98

0.98

0.16

0.15

0.14

0.17

0.16

0.17

0.16

0.15

0.18

0.17

3.16

0.013

0.075

0.001

0.004

0.46

0.59

0.35

0.67

0.36

0.11

0.13

0.18

0.10

0.17

0.33

0.40

0.54

0.30

0.51

88

C.C. Corredor et al. / Analytica Chimica Acta 696 (2011) 84–93

Fig. 2. (a) NIR spectra of blends of APAP-MCC-HPC with different water content (ranging from 1 to 5% w/w) after SNV pre-processing. (b) SNV followed by first derivative

Savitzky-Golay 21 smoothing points of the spectra in (a).

SNV followed by first derivative provided the best prediction

model, with the lowest Standard Error of Prediction (SEP 0.18%

w/w), as shown in Table 5. The RMSEC (0.14% from Table 4) and the

SEP (0.18% from Table 5) are similar, showing that the correlations

are similar for the validation set compared with the calibration set.

Accurate prediction models were obtained with a minimum set of

calibration samples. As previously reported [42], since the magnitude of noise and variability of off-line static samples are greatly

reduced when compared to on-line samples, lower number of calibration samples was required to account for the spectral variability.

The RMSEP and SEP of NIR methods in Table 5 are comparable to

or lower than values for PLS methods reported in the literature

[16,19,20,41,42].

3.1.2. Samples with moisture ranging from 0.2 to 1% w/w

Fig. 3a shows the NIR spectra of blends of APAP-MCC-HPC

with 0.2–1% w/w water content. The absorbance at the 5155 cm−1

and 6895 cm−1 regions increases when the water level increases.

Fig. 3b shows the corresponding first derivative. Calibration models built with different data pretreatment and two spectral regions

(7362–6919 cm−1 and 5453–5176 cm−1 ) for this moisture range

are shown in Table 6. Fig. 2a in supplementary material shows the

calibration model by using SNV followed by first derivative.

The joint test of significance of intercept and quadratic terms

showed that there is no significance of intercept or curvature at the

95% confidence level for all of the regression models. The optimal

number of factors is 3. The calibration model constructed using SNV

followed by first derivative shows the lowest RMSEC (0.036%) and

RMSECV (0.043%). All the calibration models were used to predict

the water content of an independent validation set (Table 7). All

the models were used for prediction, since as previously observed

(Section 3.1.1), they do not greatly differ and the sensitivity is better

for models based on second derivative.

Fig. 2b in supplementary material shows the NIR predicted

water content vs. the reference method (KF) for independent validation samples in the range of 0.2–1% w/w. For the independent

C.C. Corredor et al. / Analytica Chimica Acta 696 (2011) 84–93

89

Fig. 3. (a) NIR spectra of blends of APAP-MCC-HPC with different water content (ranging from 0.2 to 1% w/w) after SNV pre-processing. (b) SNV followed by first derivative

Savitzky-Golay 21 smoothing points of the spectra in (a).

validation set, SNV followed by first derivative provided the best

prediction model, with the lowest SEP (0.052% w/w), as shown in

Table 7. The RMSEP for the reference KF coulometric method was

determined to be 9 × 10–4%.

Since the selected spectral regions and the best signal preprocessing (SNV followed by first derivative) was the same for

both models, and the error of the KF reference methods was determined to be equivalent for both set of samples (no matrix effects

90

C.C. Corredor et al. / Analytica Chimica Acta 696 (2011) 84–93

Table 6

PLS calibration models built with different data pretreatment for 0.2–1% w/w range.

Pre-processing

Slope

Offset

R2

RMSEC

RMSECV

SEN

SEL

DL

QL

SNV

First derivative

SNV/first derivative

Second derivative

SNV/second derivative

0.97

0.97

0.98

0.97

0.98

0.015

0.016

0.010

0.015

0.014

0.97

0.97

0.98

0.97

0.98

0.045

0.042

0.036

0.042

0.040

0.056

0.049

0.043

0.049

0.048

3.75

0.0241

0.021

0.0015

0.012

0.235

0.298

0.289

0.378

0.312

0.045

0.032

0.033

0.03

0.03

0.137

0.096

0.101

0.09

0.08

Table 7

Prediction results for an independent validation set, using calibration models in

Table 6.

Pre-processing

Slope

Offset

R2

RMSEP

SEP

SNV

First derivative

SNV/first derivative

Second derivative

SNV/second derivative

0.91

0.90

0.93

0.85

0.90

0.018

0.033

0.033

0.059

0.049

0.91

0.92

0.96

0.91

0.96

0.078

0.074

0.052

0.079

0.055

0.066

0.067

0.052

0.070

0.053

observed for the volumetric and coulometric KF methods), calibration data from 0.2 to 5% w/w was combined in a single calibration

plot (Fig. 3a in supplementary material, figures of merit are provided in the plot). All independent samples from 0.2 to 5% w/w

were predicted using the general calibration model (Fig. 3b in supplementary material, figures of merit are provided in the plot). This

combined calibration plot can accurately predict water content in

the range of 1–5% w/w. However, the calibration plot in the range of

0.2–1% presents higher sensitivity and selectivity and lower DL and

QL and more accurately predicts samples in this range, compared

to the combined calibration plot.

3.2. At -line moisture determination by microwave resonance

technology

3.2.1. Samples with moisture ranging from 1 to 5% w/w

Similar to NIR, the microwave sensor has to be calibrated against

standard reference methods. Fig. 4a in supplementary material

shows the MR sensor calibration plot using APAP-MCC-HPC blends

with water content between 1 and 5% w/w.

The MW value (given in terms of attenuation and phase shift of

the microwave resonance curve as shown in equation 1 in Section

2.3) was plotted against the water content determined by volumetric KF.

The linear regression revealed the following regression line:

MW = 0.04812 (KF) + 0.01057

(2)

The correlation coefficient for the shown regression line was

found to be 0.992. The joint test of significance of the intercept and

quadratic terms showed that there was no significance of intercept

or curvature at the 95% confidence level. At the measurement conditions specified, the calibration plot is not linear below 1.5% or

above 6.0%.

Fig. 4b in supplementary material shows the comparison of the

reference vs. the predicted moisture values from MR sensor and

NIR, showing the corresponding regression lines. Table 8 shows the

comparison of the prediction results for an independent validation

set by KF, NIR and microwave.

A comparison of the NIR and MR methods is very important

because the principle of water detection is different in both cases.

For instance, the depth of penetration of NIR light in pharmaceutical

powders and tablets measured in diffuse reflectance mode (in the

wavelengths of interest) ranges from 0.25 to 0.5 mm [34,35] while

the stray fields generated in a microwave resonant cavity in the

frequency range of about 2–3 GHz have penetration depths from

2 to 5 cm. MR sensors on the other hand, measures total unbound

water. At frequencies between 2 and 3 GHz, only physically bound

water (including adsorbed water, trapped or liquid-inclusion water

and absorbed water) is determined. Chemically bound water

(water of crystallization) is not monitored as this requires different wavelengths and intensities of the applied microwaves. Careful

consideration of the technique of choice should be paid, particularly

in applications in which anhydrate to hydrate transformation can

take place (such as wet granulation) and the total water is used for

final point determination. The SEP of the KF method was 0.11%. The

relative standard deviation (RSD) of replicate KF determinations of

the same sample was in the range between 0.02 and 0.09% w/w.

These data suggest that a source of the calculated SEP of the NIR

and MR predictions is due to sample non-homogeneity and error

associated with the reference method.

The MR calibration model accurately predicted the water content of an independent validation set. The MR SEP was 0.17%. This

value was similar to the SEP of the NIR method (0.18%). The robustness of the MR calibration model was tested by removing samples

in the calibration set. The calibration model was recalculated after

the reduction, and the water content of the validation test was predicted using the new calibration model. The calibration set could

be reduced to 6 calibration standards with no impact on the prediction results of the independent validation set (Table 8). To ability

to develop calibration plots with low number of standards is beneficial, especially in cases in which the API is in short supply or

expensive. Also, since the MR tool is non-invasive, samples could

be reused for additional analysis. An advantage vs. the NIR method

is that multivariate data analysis is not required. Both NIR and

microwave methods can potentially replace the KF method for the

blends with 1–5 w/w% water content.

3.2.2. Samples with moisture ranging from 0.2 to 1% w/w

Fig. 5a in supplementary material shows the MR calibration plot

using APAP-MCC-HPC blends with water contents between 0.2 and

1% w/w.

The linear regression revealed the following regression line:

MW = 0.0558 (KF) + 0.0031.

Table 8

Comparison of prediction results for an independent validation set for standards

(stds) in Table 1 (1–5% w/w).

Prediction

Slope

Offset

R2

RMSEP

SEP

KF (volumetric)

NIR (14 stds)

NIR (7 stds)

MR (11 stds)

MR (6 stds)

0.97

0.96

0.97

0.93

0.93

0.086

0.16

0.12

0.05

0.07

0.99

0.98

0.97

0.99

0.99

0.10

0.19

0.24

0.17

0.16

0.11

0.18

0.23

0.17

0.15

(3)

The correlation coefficient for the shown regression line was

found to be 0.985. The joint test of significance of intercept and

quadratic term showed that there is no significance of intercept

or curvature at the 95% confidence level. Fig. 5b in supplementary material shows the comparison of the reference vs. the

predicted moisture values from MR and NIR at this moisture range.

Table 9 shows the comparison of the prediction results for an independent validation set by KF, NIR and MR.

C.C. Corredor et al. / Analytica Chimica Acta 696 (2011) 84–93

Table 9

Comparison of prediction results for the three methods for an independent validation set.

Prediction

Slope

Offset

R2

RMSEP

SEP

KF 0.2–1%

(coulometric)

NIR

MR

1.029

−0.018

0.991

0.034

0.0009

0.932

0.980

0.034

0.017

0.963

0.976

0.052

0.037

0.051

0.038

The MR model accurately predicted the water content of an

independent validation set. The MR calibration model performed

better than the NIR method when predicting an independent validation set. The prediction model shows the slope closest to 1.0, the

lowest RMSEP (0.037%), and lowest SEP (0.038%), and is therefore

considered the optimal result.

3.3. Investigation of the feasibility of developing general NIR and

MR calibration plots

The possibility of developing general NIR or MR calibration plots

for different products of related composition but different API was

tested by preparing blends of a proprietary BMS API-MCC-HPC,

as described in Section 2.5. A general calibration plot for blends

with similar excipient composition but different API can potentially

reduce method development time and resources. Fig. 4 shows the

NIR spectra of the BMS API, APAP and blends of BMS API-MCC-HPC

and APAP-MCC-HPC. The spectrum of the BMS API shows characteristic peaks that overlap the absorption in the water regions.

Calibration models using the BMS API-MCC-HPC samples were

developed by correlating the NIR spectra with water content using

PLS regression. As in the case of the APAP blends, a randomized

design was employed to ensure that the component correlation was

minimized and that the PLS solution was specific to water. Similar

to the models developed in Section 3.1, several data pre-processing

methods were used and compared.

For the BMS API-MCC-HPC blends, the best calibration model

used first derivative and loadings in the 7478–6876 cm−1 and

5303–5056 cm−1 regions (slightly different regions that the APAP

method). The slope was 0.98, the correlation coefficient was 0.98,

91

the RMSEC was 0.144%, the RMSEC was 0.16%, and the optimal number of factors was 4. Fig. 6 in supplementary material shows the

prediction results for an independent validation set by using the

best calibration model obtained with the BMS API-MCC-HPC samples and the best APAP model developed in Section 2.5. The best

calibration model developed for the APAP-MCC-HPC blends could

not accurately predict the water content in blends of BMS API-MCCHPC (especially at 2–5 w/w%), although only the API was changed.

Although general NIR water methods have been proposed [20,41],

the development of a universal NIR calibration plot for water in this

case is hindered by the overlap of the API signal in the water region.

Samples of BMS API-MCC-HPC were also used to build a calibration plot in the microwave sensor. Fig. 7a in supplementary material

shows the MR calibration plots using BMS API -MCC-HPC blends

and APAP-MCC-HPC blends. For both materials, MW increases linearly with moisture and the data are superimposed. A small offset

of 0.008% in the regression line of the BMS API was observed with

respect to the APAP regression. The MW values for both types of

blends were plotted against the water content determined by volumetric KF. The linear regression for the general model is:

MW = 0.0455 (KF) + 0.0246.

(4)

The correlation coefficient for the shown regression line was

found to be 0.973. From this equation moisture content in either

material can be determined from a single calibration equation without knowledge of bulk density. The effectiveness of equation 4

in predicting moisture content on an independent validation set

of BMS API-MCC-HPC samples was evaluated (Fig. 7b in supplementary material). As seen in the figure, there is a high degree of

agreement between the set two plots.

Trabelsi et al. demonstrated that moisture content variation in

wheat and soybeans increased linearly and calibration data for both

materials were superimposable, using a microwave sensor operating at 5.8 GHz [32]. As expected, calibration data corresponding

to blends of BMS API-HPC-MCC and APAP-MCC-HPC are superimposable. Excellent agreement of the moisture values determined

by KF and those predicted by the general microwave calibration plot

for BMS API-MCC-HPC blends, demonstrated the utility of a general

microwave calibration model.

Fig. 4. NIR spectra of BMS API (blue), APAP (purple), blend of APAP-MCC-HPC (green) and BMS API-MCC-HPC (for reference to the color information in the figure legend refer

to the on-line version of the article).

92

C.C. Corredor et al. / Analytica Chimica Acta 696 (2011) 84–93

Acknowledgements

3.4. Microwave resonance method for moisture determination in

tablets

The feasibility of developing a MR calibration plot for tablet

cores was tested by preparing tablets of APAP-MCC-Mg stearate

as described in Section 2.5. Tablets to be measured were

loosely filled into a plastic holder fitted in the sensor. The

tablet weight was 100 mg, tablet thickness was 4 mm and tablet

diameter was 5 mm. The microwave sample holder was completely filled with approx. 150 tablets for a sample mass of

approximately 15 g per each moisture point. Temperature was

recorded during the entire measurements. However, temperature correction was not required, since the calibration and

prediction samples were measured at room temperature and the

temperature did not deviate more than ±5 ◦ C. Moisture range

and sample conditions used for calibration matched later measurement conditions. Before developing the calibration plot, a

sensor compression test was run as described by the manufacturer.

Fig. 8a in supplementary material shows the MR sensor calibration plot using APAP tablets with water content between 1.5 and

4.5% w/w. The MW value was plotted against the water content

determined by volumetric KF. The linear regression revealed the

following regression line:

MW = 0.0337 (KF) + 0.0503.

(5)

The correlation coefficient for the shown regression line was

found to be 0.995. At the measurement conditions specified, calibration plot is not linear below 1.5% or above 4.5%.

The repeatability of the method was determined as the relative

standard deviation (RDS) of 10 replicate measurements of the same

sample. An RSD of <1.0% of MW signal was found when the mass

in the sample holder changed no more that ±12%. A higher RSD

of MW signal (2.8%) was observed when the mass in the sample

holder changed in the range of ±12–25%. To maintain the highest

reproducibility, the mass in the sample holder was kept as constant

as possible, by filling the sample holder to the same level before

measurement.

Fig. 8b in supplementary material shows the comparison of the

reference vs. the predicted moisture values from MR. The slope of

the regression line was 1.015. The offset was 0.017. The correlation coefficient was 0.993. The RMSEP was 0.134% and the SEP was

0.117%. These values demonstrate that the MR calibration model

accurately predicted the water content of the independent validation set. The RMSEP and SEP for the tablets were lower than the

corresponding values for the powder blends at the same moisture

levels.

4. Conclusions

MR technology has been shown to be a viable means of moisture analysis for bulk powders and tablets. This study demonstrated

that the MR method for bulk powders in the order of 0.5–5%

w/w gave similar results to the NIR method, without the need of

sophisticated chemometric software and also provides the opportunity to utilize fewer calibration standards. The MR method

accurately predicted the water content of powder and tablets,

when compared to the standard KF method. We also demonstrated that a general microwave calibration plot developed for

a particular product can be used to predict the water content of

a different product with related composition but different APIs.

The feasibility of using a universal calibration model significantly

reduced microwave moisture method development for a second

product.

The authors would like to acknowledge Dan Kopec from Sartorius Mechatronics (Arvada, CO, USA) for the loan of the microwave

sensor and Kevin Macias, for the technical support during the tablet

preparation.

Appendix A. Supplementary data

Supplementary data associated with this article can be found, in

the online version, at doi:10.1016/j.aca.2011.03.048.

References

[1] S. Airaksinen, M. Karjalainen, A. Shevchenko, S. Westermarck, E. Leppanen,

J. Rantanen, J. Yliruusi, Role of water in the physical stability of solid dosage

formulations, J. Pharm. Sci. 94 (2005) 2147–2165.

[2] M.C. Adeyeye, Drug-excipient interaction occurrences during solid dosage form

development, Drugs Pharm. Sci. 178 (2008) 357–436.

[3] C. Ahlneck, G. Zografi, The molecular basis of moisture effects on the physical

and chemical stability of drugs in the solid state, Int. J. Pharm. 62 (1990) 87–95.

[4] United States Pharmacopoeia USP 32-NF 27 on-line. General chapter <921>

Water determination.

[5] O.I. Bravo, R.C. Ferrero, W.M.J. Leon, B.M.R. Jimenez-Castellanos, Solid–water

interaction. I. Study of water-pharmaceuticals interactions, Ciencia y Tecnologia Pharmaceutica 14 (2004) 3–12.

[6] C.R. Dalton, B.C. Hancock, Processing and storage effects on water vapor sorption by some model pharmaceutical solid dosage formulations, Int. J. Pharm.

156 (1997) 143–151.

[7] E. Emery, J. Oliver, T. Pugsley, J. Sharma, J. Zhou, Flowability of moist pharmaceutical powders, Powder Technol. 189 (2009) 409–415.

[8] S. Grunke, Main and side reactions in the Karl Fischer solution, Food Control 12

(2001) 419–426.

[9] P. Lam, M. Nariman, A robust, automated Karl Fischer titration system, Pharm.

Technol. 33 (2009) 52–60.

[10] F. Portala, M. Burkhard, N. Geil, A. Steinbach, On-site water determination: at

line system for Karl Fischer titration, CPP, Chemical Plants + Processing 2 (2009)

76–78.

[11] US food and drug administration September 2004 “Guidance for industry PATA framework for innovative pharmaceutical development, manufacturing, and

quality assurance”.

[12] International Conference on Harmonisation (ICH) Q8: Pharmaceutical Development (May 2006).

[13] International Conference on Harmonisation (ICH) Q9: Quality Risk Management (November 2005).

[14] International Conference on Harmonisation (ICH) Q10: Pharmaceutical Quality

System (June 2008).

[15] L. Maurer, H. Leuenberger, Applications of near infrared spectroscopy in the

full-scale manufacturing of pharmaceutical solid dosage forms, Pharmazeutische Industrie 71 (2009) 672–674 (676–678).

[16] J. Luypaert, D.L. Massart, Y. Vander Heyden, Near-infrared spectroscopy applications in pharmaceutical analysis, Talanta 72 (2007) 865–883.

[17] T.R.M. De Beer, P. Vercruysse, A. Burggraeve, T. Quinten, J. Ouyang, X. Zhang, C.

Vervaet, J.P. Remon, W.R.G. Baeyens, In-line and real-time process monitoring

of a freeze drying process using Raman and NIR spectroscopy as complementary process analytical technology (PAT) tools, J. Pharm. Sci. 98 (2009)

3430–3446.

[18] H. Grohganz, M. Fonteyne, E. Skibsted, T. Falck, B. Palmqvist, J. Rantanen, Role

of excipients in the quantification of water in lyophilized mixtures using NIR

spectroscopy, J. Pharm. Biomed. Anal. 49 (2009) 901–907.

[19] J. Mantanus, E. Ziemons, P. Lebrun, E. Rozet, R. Klinkenberg, B. Streel, B. Evrard,

Ph. Hubert, Moisture content determination of pharmaceutical pellets by near

infrared spectroscopy: method development and validation, Anal. Chim. Acta

642 (2009) 186–192.

[20] H. Grohganz, D. Gildemyn, E. Skibsted, J.M. Flink, J. Rantanen, Towards a robust

water content determination of freeze-dried samples by near-infrared spectroscopy, Anal. Chim. Acta 676 (2010) 34–40.

[21] Y. Roggo, P. Chalus, L. Maurer, C. Lema-Martinez, A. Edmond, N. Jent, A review of

near infrared spectroscopy and chemometrics in pharmaceutical technologies,

J. Pharm. Biomed. Anal. 44 (2007) 683–700.

[22] G. Reich, Near-infrared spectroscopy and imaging: basic principles and pharmaceutical applications, Adv. Drug Deliv. Rev. 57 (2005) 1109–1143.

[23] F.J.S. Nieuwmeyer, M. Damen, A. Gerich, F. Rusmini, K. Voort Maarschalk, H.

Vromans, Granule characterization during fluid bed drying by development of

a near infrared method to determine water content and median granule size,

Pharm. Res. 24 (2007) 1854–1861.

[24] C. Buschmüller, W. Wiedey, C. Döscher, J. Dressler, J. Breitkreutz, In-line monitoring of granule moisture in fluidized-bed dryers using microwave resonance

technology, Eur. J. Pharm. Biopharm. 69 (2008) 380–387.

[25] Near-infrared spectrometry, Chapter 2.2.40, European Pharmacopoeia, 6th ed.,

2010, pp. 60.

C.C. Corredor et al. / Analytica Chimica Acta 696 (2011) 84–93

[26] Near-infrared spectrophotometry, Chapter 1119, United States Pharmacopoeia

USP26NF21, 2003, pp. 2388–2391.

[27] C. Buschmueller, W. Wiedey, C. Doescher, M. Plitzko, J. Breitkreutz, Inline monitoring of granule moisture and temperature throughout the entire

fluidized-bed granulation process using microwave resonance technology: part

I, Pharmazeutische Industrie 71 (2009) 1403–1408.

[28] C. Buschmueller, W. Wiedey, C. Doescher, M. Plitzko, J. Breitkreutz, Inline monitoring of granule moisture and temperature throughout the entire

fluidized-bed granulation process using microwave resonance technology: part

II, Pharmazeutische Industrie 71 (2009) 1614–1620.

[29] R. Knoechel, W. Taute, C. Doescher, Stray field ring resonators and a novel

trough guide resonator for precise microwave moisture and density measurements, Meas. Sci. Technol. 18 (2007) 1061–1068.

[30] S. Trabelsi, A.W. Kraszewski, S.O. Nelson, A microwave method for on-line

determination of bulk density and moisture content of particulate materials,

IEEE Trans. Instr. Meas. 47 (1998) 127–132.

[31] S. Trabelsi, S.O. Nelson, Free-space measurement of dielectric properties of

cereal grain and oilseed at microwave frequencies, Meas. Sci. Technol. 14 (2003)

589–600.

[32] S. Trabelsi, S.O. Nelson, M. Lewis, Microwave moisture sensor for grain and

seed, Biol. Eng. 1 (2008) 195–202.

[33] C. Buschmueller, In-line monitoring of granule moisture in fluidized bed granulators using microwave resonance technology as novel PAT tool. Germany

(2010), Ger. Dissertation 2010 (D0610-1).

[34] Z. Shi, C.A. Anderson, Application of Monte Carlo simulation-based photon migration for enhanced understanding of near-infrared (NIR) diffuse

reflectance. Part I: depth of penetration in pharmaceutical materials, J. Pharm.

Sci. (2010) 2399–2412.

93

[35] M. Saeed, L. Probst, G. Betz, Assessment of diffuse transmission and reflection

modes in near-infrared quantification. Part 2: diffuse reflection information

depth, J. Pharm. Sci. (2011) 1130–1141.

[36] E. Dreassi, G. Ceramelli, P. Corti, P.L. Perruccio, S. Lonardi, Application of

near-infrared reflectance spectrometry to the analytical control of pharmaceuticals: ranitidine hydrochloride tablet production, Analyst 121 (1996) 219–

222.

[37] Compression Test Guide: basic information about AB compression tests of

microwave moisture measurement systems, Sartorius Mechatronics, Arvada,

CO, USA.

[38] A.C. Olivieri, N.M. Faber, J. Ferré, R. Boqué, J.H. Kalivas, H. Mark, Uncertainty

estimation and figures of merit for multivariate calibration, Pure Appl. Chem.

78 (2006) 633–661.

[39] P. Valderrama, J.W.B. Braga, R.J. Poppi, Variable selection, outlier detection, and

figures of merit estimation in a partial least-squares regression multivariate

calibration model. A case study for the determination of quality parameters

in the alcohol industry by near-infrared spectroscopy, J. Agric. Food Chem. 55

(2007) 8331–8338.

[40] S.M. Short, R.P. Cogdill, C.A. Anderson, Determination of figures of merit

for near-infrared and Raman spectrometry by net analyte signal analysis

for a 4-component solid dosage system, AAPS PharmSci. Tech. 8 (2007)

E96.

[41] X. Zhou, P. Hines, M.W. Borer, Moisture determination in hygroscopic drug

substances by near infrared spectroscopy, J. Pharm. Biomed. Anal. 17 (1998)

219–225.

[42] M. Brülls, S. Folestad, A. Sparén, A. Rasmuson, J. Salomonsson, Applying spectral

peak area analysis in near-infrared spectroscopy moisture assays, J. Pharm.

Biomed. Anal. 44 (2007) 127–136.