DEMONSTRATION SITE - Commissioning

advertisement

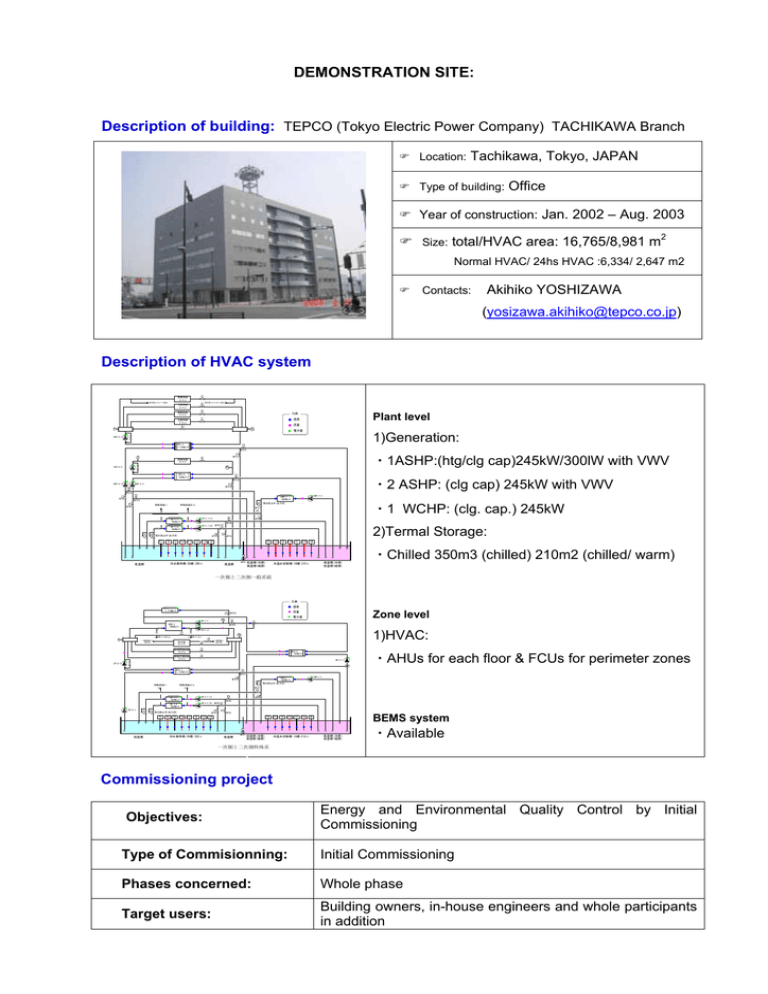

DEMONSTRATION SITE: Description of building: TEPCO (Tokyo Electric Power Company) TACHIKAWA Branch ) Location: Tachikawa, Tokyo, JAPAN ) Type of building: Office ) Year of construction: Jan. 2002 – Aug. 2003 ) Size: total/HVAC area: 16,765/8,981 m2 Normal HVAC/ 24hs HVAC :6,334/ 2,647 m2 ) Contacts: Akihiko YOSHIZAWA (yosizawa.akihiko@tepco.co.jp) Description of HVAC system 南側系統 AHU 指令室AHUへ(温水) 指令室AHUから(温水) 北側系統 AHU 南側系統 FCU 凡例 流量 P TE 電力量 1)Generation: INV CHP-3-1 Plant level 温度 北側系統 FCU WEX-3 3,125MJ/h BFV15 ・1ASHP:(htg/clg cap)245kW/300lW with VWV BFV11 P 西側系統 AHU TE INV CHP-3-2 WEX-4 180MJ/h ・2 ASHP: (clg cap) 245kW with VWV BFV14 INV INV CHP-2-1 CHP-2-2 BFV10 BFV12 BFV8 CHP-1-1 CHR-1 882MJ/h BFV13 特殊系統へ BFV9 INV ・1 WCHP: (clg. cap.) 245kW 落水防止弁(自力式) 特殊系統から BFV1 CP-1-1(1) CR-1-1 882MJ/h BFV6 CP-1-1(2) BFV5 CR-1-2 882MJ/h T9 BFV2 T2 T10 T11 T3 T12 BFV3 T4 T5 冷水専用槽・26槽・350t 低温槽 2)Termal Storage: INV 落水防止弁(自力式) T1 BFV4 INV BFV7 高温槽 低温槽(冷房) 高温槽(暖房) T13 T6 T14 T7 T15 T8 高温槽(冷房) 低温槽(暖房) 冷温水切替槽・18槽・210t ・Chilled 350m3 (chilled) 210m2 (chilled/ warm) 一次側と二次側一般系統 凡例 温度 CT-1 1,170MJ/h 流量 BFV18 Zone level 電力量 TE HP-1-1 INV WCR-1 882MJ/h BFV19 INV CP-1-2 1)HVAC: TE ① P CR-1-2から ② 一般系統から (温水往) CR-1-2へ 一般系統へ (温水還) 指令室 AHU 特殊南側系統 AHU WEX-2 1,350MJ/h 特殊北側系統 AHU HP-2-1 CP-3-1 ・AHUs for each floor & FCUs for perimeter zones WEX-1 1,721MJ/h BFV17 BFV16 特殊系統へ 特殊系統から ① INV CP-2-1 低温槽 T9 CP-1-1(1) CR-1-1 882MJ/h INV CR-1-2 882MJ/h INV T2 BFV4 CP-1-1(2) BFV5 BFV2 T10 T11 INV BFV1 ② 落水防止弁(自力式) T1 CHP-1-1 CHR-1 882MJ/h 落水防止弁(自力式) T3 T12 BFV6 BFV3 T4 冷水専用槽・26槽・350t T5 高温槽 BFV7 低温槽(冷房) 高温槽(暖房) T13 T6 T14 T7 T15 冷温水切替槽・18槽・210t BEMS system T8 高温槽(冷房) 低温槽(暖房) ・Available 一次側と二次側特殊系 Commissioning project Objectives: Energy and Environmental Quality Control by Initial Commissioning Type of Commisionning: Initial Commissioning Phases concerned: Whole phase Target users: Building owners, in-house engineers and whole participants in addition Tools and methods developed Manual tools 要求文書名 要求記述項目 大項目 中項目 細目 2)検討書 2)-1 空調システム検討書 e 部分負荷時運転対応 ・容量制御範囲 システム対応 機器対応 ・その他 f 概略機器仕様決定 ・空調機 ・FCU ・その他 (A) 必要文書・ 記述の有無 (B) (C) (D) (E) 同左内容 文書等の 内容の 是正提案 (必要に 過不足 妥当性 (CA) 応じて 確認 確認 ↓ (設計者による 記述) ○:合格 ○:合格 (発注者・ 文書) ×:不合格 ×:不合格 設計者) ■有り □無し □有り ■無し □有り □無し □有り □無し □有り □無し □有り □無し ○ × ○ × ■有り □無し ■有り □無し ■有り □無し □有り ■無し ○ ○ ○ × ○ ○ ○ × Automatic Cx Tools 検討指示 ・ Development and employmentof procedure documents ・Development and employment of documentation tools requisite at each phase ( Commissioning planning documents determine the framework of each phase of comissioning and, thus, has significant importance.) ・ Development and employment of check-list sheets with grades of items which require the verification at each phase ・This BEMS treats operational data of heat sorce systems, pumps systems (including heat storage tunks), air-conditioning-units, and VAV systems. ・Automatic accumulation of data at intervals of 1 minute,10 minute and 1 hour ・Automatic real-time graphs of the data and the part of calculated data which contribute to check the every-day operational conditions and even function performance tests. ・Coordination of the BEMS functions and forecast estimation system of heat-storage Practical experiences Users interview Occupant Interview ・mostly no troubles Operator Interview ・up until now, no severe troubles ・heat storage operation has proceeded well. Cx actions ・interview with the owner, designers and constructors. ・development and verification of documentation tools ・verification of construction conditions ・verification of TAB results ・execution of function performance tests ・operational data check assisted by BEMS Cx Recommendations Manual 1 2 BEMS assisted 3 4 5 6 Identification of purpose and scope of Cx、role and responsibilities of stakeholders、schedule, distributing information etc(in FPT) development of documentation tools at each phase to organize systematically and documentation tools to distribute information accurately measurement planning of measurement means to verify the owner’s requested performance identification of TAB implementation items and prior check of the site, TAB confirmation of acquiring the data at TAB and execution considering design intents function performance tests prior check (confirming the acquisition of data) operation management organizing documents to convey the design intention to operators development procedure