4. Recrystallization and Melting Points

advertisement

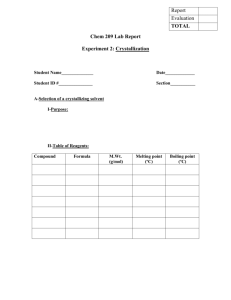

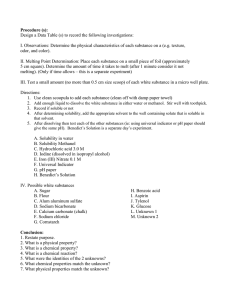

4. Recrystallization and Melting Points PreLab - All PreLabs must be completed before coming to lab. You cannot start any experimental work until the PreLab white pages are turned in! There are no exceptions to this rule! This first experiment is quite lengthy because it involves two techniques, recrystallization and melting point. Therefore, be forewarned that the PreLab is quite extensive and because it’s your first one, will probably take about two hours to do. First, read through the Introduction and all the Experimental sections given in this chapter. Then, read through sections 1 and 2 of Chapter 3 describing the PreLab writing format with examples. Finally, in your lab notebook, using carbonless copies, write an introductory PreLab section for the experiments to be run including: Before coming to Lab 1. A brief Summary of what will be done and why it will be done. 2. Four Learning Objectives or Goals for the experiment. 3. Diagrams of Apparatus. There are no chemical reactions or equations in this experiment. 4. Complete Chemical Data Tables including ALL possible solvents and unknowns used in Procedures 1 to 5, but not Procedure 6. Fill in the data on the Common Shelf Chemical Data Table for the ten solvents designated Chapter 4 in column 3 of that table (including water). On the blank Chemical Data Table, fill in data for the 6 possible organic solid unknowns, phthalic acid, and methylene blue (0.01% solution in water). 5. Do the PreLab Exercise given here. a) If cooling fails to produce crystals, give two methods for inducing crystallization and describe how they work. b) Define immiscible and give one common household example of this phenomenon. c) When choosing a solvent for recrystallization, what factors should be considered? (List at least four criteria for choosing a solvent and explain where appropriate.) d) What is decantation and when should you employ this technique? The PreLab and Final Report for this first experiment will be graded on a ✔, ✔+ , ✔- basis. This means that the report will not be graded in the strict sense, but errors will be indicated and comments for improvement will be given by your TA. Almost everyone will receive a ✔ or 100 points each on the PreLab and Final Report if they do a reasonable job. A few may receive a ✔or 90 points if blatantly sloppy or inferior work is turned in. Also, a few may receive a ✔+ or 110 points if their work is truly exceptional. The intent here is to use these first lab reports as feedback to help your TA communicate to you what he or she is looking for in a typical PreLab and Final Report. It is obviously very important for you to look over your TA’s analysis and comments and discuss any areas you don’t understand so that you are better prepared to do a good job in writing subsequent PreLabs and Final Reports which will be graded more rigorously. The white pages of this section including the Chemical Data Table will be collected by your TA at the beginning of the lab period. Tear out the appropriate Grading Sheet from the back of the Lab Guide in (Appendix A.10) and attach it to the front of the PreLab. The point assignments for each portion of the PreLab are shown below. GRADING FOR RECRYSTALLIZATION/MELTING POINT EXPERIMENT: Possible Points PreLab: Date, Name, Desk #, Experimen t #& Title (abbreviatedafter 1st page),Section& TA Name Summary Goals Reactions and/or Diagra ms of SpecialAppara tus Common Shel f Chemical DataTableand experimentChemicalData Table PreLabExercise Totalfor PreLab 39 8 16 16 20 20 20 100 PreLab Exercise Grading Introduction Chemicals are found everywhere!! Most of chemistry deals with the production of PURE chemicals for use in products we purchase and use everyday. As you look around your kitchen or bathroom you see many of these products. Can you tell which are pure compounds and which are mixtures? You should conclude that most of the foods, cosmetics, cleaning agents or drugs are mixtures. Very likely, the only pure single-compound materials in the kitchen are water (H2O), salt (NaCl), baking soda (Na2HCO3), and sugar (sucrose, C12H22O11). In the bathroom you might have some crystals of Epsom salts (MgSO4) and some liquid rubbing alcohol (2-propanol), but these are about the only common examples. Pills and capsules are all mixtures of a pharmaceutical compound and an inert binder such as starch or gelatin. Many materials are really solutions, for example vinegar (5% acetic acid in water) or hydrogen peroxide (usually 3% in water). Even though most things are mixtures, many are formulated from pure compounds. For example, Anacin is a mixture of pure crystalline aspirin and pure crystalline caffeine mixed with starch and pressed into tablets. The Food and Drug Administration (FDA) sets very rigorous standards for purity of all the chemical components that go into these mixtures or “formulations” sold as consumer products. How do drug firms or the FDA measure the purity of organic compounds used in drugs? More importantly, how do they purify compounds to meet these purity standards? This experiment will answer these questions by demonstrating two common techniques: recrystallization for purifying organic solids and melting point determination for testing the purity of organic solids. Mastering these techniques will be critical to the success of your synthetic experiments in the second half of this course. As with all techniques, mastery means not just learning the motions, but also understanding the underlying principles involved. For this experiment, the principles are: solubility (like-dissolves-like) including its variation with temperature and the melting behavior of mixtures versus pure compounds. Solubility Like-dissolves-like! Italian salad dressing is a classic example of an Most Polar everyday solubility problem. It is clear from Water (H 0) 2 observing the interaction between vegetable oil Acetic Acid (CH3COOH) and water, they are not compatible and do not mix Methanol (CH3OH) well. This phenomenon can be understood by the Ethanol (CH3CH2OH) simple principle “like-dissolves-like”. Only Acetone (CH3COCH3) molecules of similar structure will be soluble in Dichloromethane (CH2Cl2) each other and mix easily. Water (a small polar Chloroform (CH3Cl) molecule) and vegetable oil (a long saturated alkane Ether (CH3CH2OCH2CH3) chain) are very different compounds and thus do Benzene (C6H6) not mix well. However, methanol (CH3OH) or Toluene (C6H5CH3) ethanol (CH3CH2OH) which are small organic Hexane (CH3(CH2)4CH3) molecules containing a functional group that can Ligroin (mix of hydrocarbons) H-bond, are readily soluble in water. We would Least Polar find that the vegetable oil, which contains molecules with large hydrocarbon chains are readily soluble Table 4.1: List of common solvents by in hydrocarbon solvents such as ligroine or paint decreasing polarity. thinner. These are examples of like-dissolves-like. Solubility depends on the polarities and interactions between the solute molecules (the solid to be purified) and the solvent molecules. For recrystallization, a solvent must be picked with a polarity similar to the polarity of the compound you are attempting to purify. In general, the more heteroatoms, such as nitrogen or oxygen, a molecule contains, the more polar the molecule. Table 4.1 lists some common organic solvents in order of polarity. This table can be used to select solvents with polarities closely matching the polarities of your solute. It is quite unlikey that a solvent with polarity that is very different from your solute will work at all, since you need to have a least partial solubility in a solvent for it to be a possible recrytallizing solvent. 40 Solubility (weight in grams of solid dissolved per volume of solvent) The second factor affecting solubility is temperature. The temperature of the solvent directly relates to the amount of material that can be dissolved. One example is making rock candy from sugar. In order to obtain the saturated sugar solution needed to make rock candy, the water is brought to a vigorous boil. More sugar will dissolve in the water when the temperature is increased. This is a very important factor in recrystallization because these differences in solubility at different temperatures will be used to our advantage. The best solvent for any particular recrystallization should only sparingly dissolve the compound at room temperature and easily dissolve the complex at higher temperatures. Figure 4.1 shows the solubility of a typical organic compound in three different solvents as a function of temperature. Temperature plays a large role in recrystallization. C A B Temperature (°C) Figure 4.1: Solubility differences of a solid in three solvents, A, B & C verses temperature. At any given temperature, the compound has a very low solubility in solvent B. Solvent C is exactly the opposite, its solubility is too great at all the temperatures. However, solvent A seems to be a good choice because it has a low solubility at moderate temperatures, and the solubility of the compound changes significantly as the temperature increases. This difference in solubility with small changes in temperature is an ideal solvent for recrystallization. By understanding the solubility principles and the temperature factors involved, recrystallization can be a useful method for purifying solid organic compounds in the laboratory. This easy, convenient, and inexpensive purification technique can be used to remove small amounts of impurities from solid compounds. Essentially the process of recrystallization breaks down into five simple steps: • • • • • • Choosing a suitable solvent Dissolving the compound in a minimum amount of solvent Removing insoluble and/or colored impurities Crystallization Collecting and washing the collected solids Drying the crystals. 1. Choosing a Suitable Recrystallization Solvent The success of a recrystallization is based on the amount of pure solid crystals that can be obtained using this technique. Ideally one would like to obtain 100% of the original weight of material. This is rarely possible, but recovery of 80 to 90 % of the original weight can be obtained if: 1) the “correct” solvent is chosen and 2) the recrystallizing technique is carried out correctly. Selecting an appropriate recrystallization solvent is the first and normally the most difficult step in the purification process. A successful recrystallization depends on the solubility differences between the substance and the impurity. Recrystallizing a known substance makes 41 Six easy steps to recrystallization. A Problem! choosing a solvent of similar polarity easier. Reference textbooks, such as the Handbook of Chemistry and Physics, can be used to find information on the solubility of organic compounds. If the material you will be recrystallizing is unknown, than the process of choosing a solvent is not as straight-forward and is mainly trail and error. Dissolve the unknown compound in a variety of solvents, heat and observe the results. Based on the principle of “like-dissolves-like”, which solvent, benzene or water, would be a better candidate solvent for recrystallizing naphthalene? Which solvent would be better for benzoic acid? * O Solids: C OH Napthalene Benzoic Acid Solvents: O H Benzene H Water There are also several practical concerns when choosing a recrystallization solvent. For obvious reasons, the solvent should not react with the solute. The solvent must have a boiling point lower than the melting point of the compound. If the boiling point of the solvent is higher than the melting point of the solid it will tend to “melt” instead of dissolve. This will lead to a very poor crystallization. Chemists use the term “oiling out” to describe when a solid turns to an oil instead of well-defined crystals. Oils are hard to handle and often difficult to crystallize. By choosing a different recrystallization solvent, oiling out can normally be avoided. In addition, a non-toxic, inexpensive, volatile and nonflammable solvent is the best choice. However, since most solvents do not fit all these requirements, as the chemist you will have to find the best compromise for your specific recrystallization. In an ideal system, the compound should be completely soluble in the hot solvent and quite insoluble in the cold solvent and the impurities should be soluble at all temperatures. This ideal situation is never obtainable. A single solvent system is always the best for recrytallization, but sometimes this cannot be found and therefore a two solvent system may be necessary. When choosing a two solvent system, the two solvents must be miscible. Miscible means capable of being mixed in all proportions. Table 4.2 summarizes the miscibility of some common solvents. Notice that with only one exception (can you find it?) organic solvents are miscible with each other, but many are not miscible with water. Some typical two solvent systems include; ethanol-water, methanol-water, acetone-ligroin, ethanol-toluene and acetic acid-water. (Notice that each of these combinations are miscible.) When using two solvents, it is best to find one solvent that will completely dissolve the compound to be recrystallized at high temperatures and the second that dissolves it poorly at high temperatures. Dissolve the compound in a minimum amount of the good solvent (dissolves compound well at the boiling point), then add the bad solvent (dissolves the compound poorly) dropwise until the solution becomes slightly cloudy. Reheat the solution until clear and then cool slowly. Upon cooling, the compound should crystallize. If you are having problems crystallizing the compound, reheat and add more of the poor solvent. The complex should eventually precipitate, although this can often lead to the production of an oily non-crystalline mass. The Answer! * Benzene would be a better choice for recrystallizing naphthalene. Both of these compounds are nonpolar organic molecules and the naphthalene should dissolve readily in hot benzene. Water would be a better solvent for organic molecules having polar substituents such as alcohol groups (sugar) or carboxylic acid groups (benzoic acid). 42 Miscibility Acetic acid Acetone Benzene Chloroform Dichloromethane Ethanol Ether Hexane Ligroin Methanol Toluene Water Miscible means capable of being mixed. Acetic Acid Acetone Benzene Chloroform Dichloromethane Ethanol Ether Hexane Ligroin Methanol Toluene Water M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M M I M M M M M M M M M M I M M M M M M M M M M I M M M M M M M M M M M M M M M M M M M M M I M M M M M M M M I M I M M M M M M M M M M I M M M M M M M I M M M M M M M M M M M M M I M M I I I M I I I M I - Table 4.2: Miscibility of Common Solvents (M = miscible, I = immiscible) 2. Dissolving the Compound Once a suitable single solvent or solvent pair has been found, the impure material is dissolved in the solvent with heat. The most common mistake when dissolving the compound is adding too much solvent. For an easy purification, adding the minimum amount of hot solvent is essential. The minimum amount is completely dependent on the quantity of material and the solubility of that material in the solvent used. If the compound’s identity is known, the solubility data can be used to calculate the approximate amount of solvent needed. For example, when recrystallizing phthalic acid, use the data in Table 4.3. Water 0.5414 0.7025 18.0 100 Ethanol 11.715 27.478 Other 0.6915, Ether 20.421, MeOH insol, CHCl3 Table 4.3: Solubility data for phthalic acid (in grams of solute per 100 mL of solvent.) The superscripts refer to temperature in °C. This solubility data can be found using the Beilstein Crossfire searching program or the Handbook of Chemistry and Physics (CRC). Later in this chapter, we will use this data to understand the more quantitative aspects of recrystallization. This data is convenient for a known complex, but if your substance is unknown or has been synthesized for the first time, this data would not be available. In this case, the amount of solvent needed to dissolve the compound is determined experimentally. Begin with just enough solvent to cover the material and heat. Once the solute-solvent mixture comes to a boil, continue to add hot solvent. (Heating a small amount of the recrystallization solvent at the same time will avoid cooling the solution when adding additional solvent.) If a good recrystallization solvent was selected, the solid will completely dissolve at the solvent’s boiling point. The substance is completely dissolved when the solution is translucent. If the complex is white, then it will be a clear translucent solution. However, if the compound is yellow, then the solution will be a 43 Use Beilstein or the CRC to find solubility data. Use boiling chips or a boing stick to avoid bumping!! translucent yellow solution. Recognizing when the solid just dissolves completely is very important. DO NOT add too much solvent. This will cause problems when attempting to collect the solid. The goal when heating this mixture is to create a saturated solution in hot solvent. (Just like our rock candy example.) By creating a completely saturated solution, the less soluble compound will crystallize upon cooling. If an appropriate solvent was selected, your compound will crystallize with ease. Too much solvent will hold more solid on cooling and it may not crystallize. However, if too much solvent is added, there is a simple solution. Heat the solution to the boiling point and evaporate some of the solvent to reduce the volume of the solution. It is very easy to add too much solvent while learning to recrystallize organic compounds. This is a way to correct your mistakes without starting over or wasting material. One practical aspect of dissolving the compound in heated solvent is how to avoid a phenomenon called “superheating” or “bumping”. Superheating is when the temperature of the solvent reaches a temperature greater than that of the boiling point of the solvent. When this occurs, the solvent will very rapidly and sometimes violently bump or splash. Bumping is the sudden explosive boiling of the liquid near the bottom of the flask. Avoid bumping by using a Teflon boiling chip (small white chips found on the Common Shelf) or a wooden boiling stick (also found on the Common Shelf). These two methods allow the solution to heat evenly and boil smoothly. 3. Removing Insoluble and Colored Impurities Pipet filtration of insoluble particles. Once a hot saturated solution is obtained, there may still be some remaining particles, including dirt, sand, or insoluble impurities. If these particles are dense and settle to the bottom, the liquid can often be poured off or decanted from the solid. If they don’t settle to the bottom, there are several methods to remove these insoluble materials. When working on small scale, pipet filtration is a good method. To make a filter pipet, carefully stuff a small portion of cotton (Common Shelf) into a disposable glass pipet as shown in Figure 4.2. Some chemists also add about 1/2” of silica or alumina. Pour in dilute solu tio n Silica gel or alumina plug or layer on top of cotton Figure 4.2: Pipet filtration for insoluble materials. Cotton used to collect insoluble materials Reaction tube to c olle ct mother liquor Transfer the hot solution into the filter pipet with another pipet. The insoluble materials collect in the glasswool. Be careful though; since the filter pipet cools the solution, crystallization can occur inside the pipet. One method to avoid precipitation inside the pipet is to heat some pure recrystallization solvent to the boiling point and run this hot solution through the pipet first. This will increase the temperature of the pipet and glasswool decreasing the chance of precipitation. Another way to insure that the compound will not crystallize inside the pipet is to use extra solvent and create a more dilute solution. This will decrease the chance of crystallization at cooler temperatures. After collecting the dilute solution, you will have to evaporate the extra solvent to initiate crystallization. If you are working on a larger scale, use the hot filtration apparatus shown in Figure 4.3. As in the microscale pipet filtration, it is essential to have the entire flask and funnel heated. This can be accomplished by heating a small amount of recrystallization solvent in the bottom of the Erlenmeyer flask. This allows the vapor to rise warming the flask, funnel, and filter paper. If the 44 entire apparatus is not warm, the product will crystallize along the inside of the filter paper. These filtration methods will remove insoluble materials from the solution. However, if you have soluble colored impurities, Norit® pellets can be used to remove them. Norit® is the commercial name for activated carbon. When mixed with the solution, the colored materials physically absorb onto the Norit® pellets. You may have to heat the mixture and repeat the procedure more than once. (Note that even very small quantities of colored impurities can produce highly colored solutions.) The benefit of using the Norit® pellet form of activated carbon instead of finely powdered charcoal when removing colored impurities is that the pellets can then be easily removed by pipet or gravity filtration as described above. In other words, the soluble colored impurities stuck to the Norit® pellets are now an easily removable insoluble impurity. Remember, however, that some of your product will be absorbed so don’t use too much Norit. Obviously filtration and/or treatment with activated carbon are only necessary when there are insoluble or colored impurities present. Most recrystallizations will not require either step. Heating the entire hot filtration apparatus is essential to the process. Figure 4.3: Hot filtration set-up 4. Crystallization Once you have obtained a clear saturated solution in hot solvent free of insoluble or colored impurities, it is time to crystallize your solid product. Crystallization can sometimes occur within seconds and other times it may take days. A perfect crystal needed for X-ray crystallography requires very slow crystallization in order to obtain a crystal large enough to analyze. It should also be mentioned that crystallization is different from precipitation. Precipitation is defined as the formation of a solid product from a reaction that separates from solution. Precipitation normally occurs very rapidly and results in very fine crystals. Crystallization is similar to precipitation in that you separate a solid from the remaining solution; however, no chemical reaction occurs and crystallization normally refers to the slow growth of crystals. Slow crystal growth yields purer crystalline formations. There are three ways to initiate crystallization; cooling, scratching and seeding. Slow cooling is the easiest method and works in most cases. Simply allow the hot saturated solution to cool slowly without agitating or disturbing the solution in any way. Allow the hot solution to cool to room temperature by placing the flask on a book or paper towel, then move it to the cooler bench top and finally put it in a beaker of ice. Setting a beaker on an insulating surface such as a book or placing a test tube in a beaker of glasswool will slow the heat losses and the cooling process. The slower the solution cools, the more likely it will form perfect crystals which can exclude the impurities since these will not fit in the crystal structure. Alternatively, you may cool the solution slowly to room temperature and then place the solution in the refrigerator until 45 Slow colling leads to the best crystals. the next lab period. (Note: All solutions placed in the refrigerator must be in capped and labeled containers!) This slow cooling process normally yields beautiful crystals. Sometimes it is difficult to obtain crystals even after the solution is cooled in an ice bath. In this situation crystallization can be induced by scratching the inside of the beaker or flask with a glass stirring rod. This will produce microscopic fragments of glass that may act as surfaces on which crystal growth can begin. If slow cooling and scratching does not produce crystals, crystallization may be induced by seeding. Seeding is accomplished by taking a small crystal from the original solid and dropping it into the solution. This will provide a nucleation site for similar crystals to grow. This method works well if you are having problems with a solid that separates without crystallization or “oils” out. However, by adding some of the original material, you are inevitably increasing the amount of impurity in the resulting solid. Seeding is normally used only as a last resort. One crystallization method that is not encouraged is evaporation. Naturally, if you are having trouble crystallizing a solid, evaporating the solvent completely will recover the material. However this method has defeated the purification process. Not only have you recovered the pure material, but also the impurities. When this is done, the recrystallization procedure must be carried out again. 5. Collecting and Washing the Crystals The filtration method used depends largely on the amount of crystals collected. Wash your crystals with care! The filtration method used to separate the crystals from the remaining solution and “collect” the solid depends largely on the amount of crystals and solution. For recrystallizations involving 1 g to 100 g or more, gravity filtration through filter paper can be used. For recrystallizations involving at least 0.1 g up to 100 g or more, organic chemists use a fast and effective filtration method called vacuum filtration. But for the small quantities of 10 - 100 mg in a few mL of solution, pipet filtration is quick and effective. The first method, gravity filtration is used when there is at least a half a gram of large, welldefined crystals. A glass funnel fitted with fluted filter paper is used to collect the crystals. With very large amounts of solid, this process can consume a lot of time. A quicker and more efficient method for this same quantity of material is vacuum filtration. Vacuum filtration is probably the most common filtration type used by chemists. The funnel used for this method called a Hirsch funnel if small or a Buchner funnel if large. These funnels have a large flat plate inside which can either be made from ceramic materials that contains lots of small holes through it or from a porous polyethylene disk. To use these funnels, a round piece of filter paper of a matching diameter is placed over the perforated or porous plate. The Hirsch or Buchner funnel is put into a vacuum filter flask with a rubber adapter in between to assure a vacuum tight seal. The filter flask has a connecting tube or “side arm” which is connected to the house vacuum or water aspirator. Wet the filter paper with a small amount of solvent or recrystallization solution to prohibit loss of product under the filter paper. Once the vacuum is turned on, the filter paper is sucked down on the plate so that it seals uniformly. The crystals and solution are swirled or agitated and quickly poured onto the filter funnel. The vacuum quickly draws the liquid through the filter paper disk, leaving the crystals behind. Any crystals remaining behind in the beaker are scraped out with a spatula and/or washed out with some of the recrystallizing solution from the filter flask or with small amount of cold recrystallizing solvent. This step requires great care. Using too much solvent that is not cold enough can dissolve a lot of solid product, thus decreasing your recovery and yield significantly. 46 Figure 4.4: Vacuum filtration apparatus using a Hirsch funnel. One variation on a traditional vacuum filtration apparatus is shown in Figure 4.5. The mother liquor is the filtrate or liquid left behind after removing solids from a solution. In this set-up, the mother liquor is collected in a clean beaker and can be used again. Often during a recrystallization, the first collection process will not crystallize all the material from the solution. By collecting the filtrate, the remaining crystals can be retrieved. After the first filtration, concentrate the mother liquor by evaporating the solvent to approximately half the original volume. Upon cooling, additional crystals, called a second crop, may appear. Filtration method used to obtain a second crop of crystals. Figure 4.5: Bell Jar with vacuum filtration used to collect the mother liquor. To use this set-up, first apply a light coating of stopcock grease to the bottom edge of the bell jar. Seat the Hirsch funnel in a rubber filter adapter and place in the top of the bell jar. Connect the side arm of the bell jar to the house vacuum using heavy-walled vacuum tubing. Pour the solution carefully onto the filter. Once you have collected the solid, turn off the vacuum and allow air to leak slowly into the jar. Carefully disconnect the tubing being careful not spill the contents of the filter apparatus or beaker. If there is not sufficient time to concentrate the mother liquor by evaporation, than simply setting the beaker in the back of the hood for slow evaporation. This will often yield crystals without effort. If crystals are obtained from this second crop, the crystals may not be as pure as the first crop because there were a higher percentage of impurities present during the second attempt. A melting-point determination can be used to determine the purity of both crops. For small quantities of materials, pipet filtration is the preferred method. Figure 4.6 shows the pipet filtration method for collecting solid products. When you have solid material leftover in a reaction tube or small test tube, there will be less product loss if you remove the solvent and leave the solid behind. This can be easily achieved by pipet filtration. Select a pipet with a Square tip pipet perfectly square tip (when looked at from the side), and without chips on the tip. Push out all the air by squeezing the pipet bulb. Slowly lower the pipet into the solution and ease your way to the very Figure 4.6: Pipet Filtration of Solid Product. 47 Pipet filtration of a solid product. Pipet filtration takes practice and patience. bottom of the reaction tube. Once the pipet tip is squarely and firmly pressed against the bottom of the tube, slowly release the pipet bulb while keeping the pipet tip pressed against the bottom of the tube. The solvent will be slowly drawn up into the pipet and the product should remain behind. Initially you may see a small amount of product move up the pipet. Don’t panic! This is a normal loss for this technique. This technique is a little trickier than vacuum filtration and normally requires some practice. Practice with some inert materials from the Common Shelf, such as sodium sulfate and hexane. The separation is easier if you have big, chunky crystals. Very fine crystals will be difficult to separate using this method. After the crystals have been successfully separated from the solvent, washing the crystals with cold recrystallization solvent will put the finishing touches on your purification. This will wash away any last traces of soluble impurity that have been left on the surface of the crystals. It is essential to use cold solvent; hot or room temperature solvent will dissolve too many of your crystals. If you used gravity filtration or vacuum filtration to collect the crystals, drop the cold liquid directly onto the crystals with a pipet. If you performed a pipet filtration, add the cold solvent directly to the tube while immersing it in ice, stir the solvent and then remove the solvent using pipet filtration as you did before. Careful pipet filtration will increase your percent recovery of the product. 6. Drying the Crystals Air Drying Vacuum Drying The easiest way to dry the collected crystals is to be patient and allow nature to take its course. Leave the crystals in a container open to the air in your desk. Over a period of a few days, depending on the boiling point of the solvent, they will dry. If there is not sufficient time to allow this slow drying process or if you are using test tubes, reaction tubes or solvents with higher boiling points, such as toluene or water, there are several other methods including vacuum drying or using a stream of nitrogen. Pressing the solid between pieces of filter paper or paper towel is a simple way to remove a major proportion of a solvent. Vacuum drying can be easily accomplished with the desk equipment provided. If your product is in a reaction tube from a pipet filtration, you can connect the yellow thermometer adapter to the reaction tube and then on to a piece of thick-walled rubber tubing using the cut off barrel from a 1-mL plastic syringe. Connect the tubing to the house vacuum and allow it to dry. (Figure 4.7) Alternatively, the reaction tube can be pushed directly into the opening of the thick-walled tubing. Eveaporation is speeded up by clamping the reaction tube in a beaker of warm water. This method should only be used to dry residual solvent. Using a vacuum to remove large amounts of solvent will be slow and could eventually destroy the vacuum pumps. Figure 4.7 Vacuum drying solids in a reaction tube. Nitrogen For volatile or low boiling solvents, placing your product under a stream of nitrogen may be sufficient to dry your product. Each hood has its own nitrogen line. The outlet should be fit with a plastic pipet attached to the nitrogen line by a piece of Tygon tubing. Simply place the end of the plastic pipet over the solid to be dried or directly into the reaction tube. Be careful not to “blow” all the product away with a very fast flow rate. Drying your product under a stream of nitrogen works very well for very volatile solvents such as ether and dichloromethane. 48 Melting Behavior of Mixtures vs. Pure Compounds Once you have purified the solid by recrystallization, its purity can be verified by determining its melting temperature which is commonly called a melting point, but is really a melting range. To better understand this behavior, the theory of melting point determination must be examined. Butter is a mixture of many different types of fat or triglyceride molecules. When stored at 5°C in a refrigerator, it is fairly solid. On warming to room temperature (~ 25°C) it becomes soft and if allowed to stand in the warm sun (40°C), it will turn to a liquid. Thus, this mixture of organic compounds “melts” over a very broad range of temperatures. Pure water containing only one type of molecule, H2O, freezes (if we remove heat from the liquid) or melts (if we add heat to the solid) at a single temperature, 0°C, which is defined as the melting point (mp) of pure water. Until all the solid ice is melted to liquid water, the temperature will remain at 0°C no matter how hard we heat the container. What would happen if we add an impurity, such as salt, to water? Everyday experience with the effects of spreading salt on highways and sidewalks tells us that the melting temperature of a water-salt mixture is lower than 0°C causing the ice to melt as it dissolves the salt. This behavior is called melting point depression. Hopefully you are familiar with this from general chemistry. Of the 18 million organic compounds known today, only a few thousand are liquid or gaseous organic compounds. The remainder are all solids, many of which will melt from just above room temperature to about 350°C. Above this temperature, organic compounds just decompose and char rather than melt. (Also, the glass in a thermometer starts to get red hot and soften.) Solids with normal melting behavior are in the molecular weight range from 59 (e.g., acetamide CH3CONH2, mp 79-81°C) to roughly 1500 ( e.g. the antibiotic bacitracin, C66H103N17O18S, mp 221-225°C). Notice that while we talk about melting point and use the abbreviation mp for it, we almost always report a melting temperature range of a few degrees as seen in the examples just cited. This is an anachronism that chemists have perpetuated and we will continue this peculiar habit. As with water, we should expect that adding impurities to organic compounds would lower their melting point also. In addition we observe that the melting range is broadened. Even small amounts of impurities, ~1%, will lower and broaden the melting temperature range. This behavior of solids is consistent and can therefore be used as a test of whether we have a pure compound or one mixed with some impurities. Thus, a melting point (really melting range) determination is a quick and simple test of a compounds purity and drug companies will use this and other analyses to assure the purity of any drug compounds they produce. For example, the true melting point range for caffeine is 234 - 237 ° C. If the caffeine is obtained directly from tea and is not purified, the observed melting point is much lower. In fact, crude caffeine extracted from tea bags melts as low 180 - 220 ° C. This melting range is significantly different from the true melting point and can be used to determine that it is impure. There are over 18 million organic compounds known today. Melting Point (Range) Determination The melting point or freezing point of a compound is the physical state change from a solid to a liquid or a liquid to a solid respectively. Each pure organic compound has a characteristic melting point or range. This determination can be used to correctly identify and/or demonstrate the purity of the compound. In addition to traditional melting points, compounds can sometimes decompose before actually melting. Instead of a solid clearly turning into a liquid, the solid may turn gray, brown or black at a certain temperature. This does not mean that you have obtained the wrong compound, just that this particular compound is not stable at the observed temperatures. Saccharin for example does not melt, but decomposes at 229°C. This is symbolized as 229 d. This may happen to some of the compounds you purify throughout the semester. 49 Not all compounds melt. Melting Point Depression. Purity can be determined by evaluating the melting point range. When an impurity is soluble in the compound, the melting point will be depressed. Figure 4.8 is a Melting Point Composition Diagram that shows how the melting temperatures are affected in a two component mixture. Either component may be regarded as an impurity in the other component. MP in °C of pure A MP in °C of pure B Increasing Melting Temperature Et Ep Mole percent of A Mole percent of B 100 0 50 50 0 100 Figure 4.8: Melting Point Composition Diagram of a Two Component Mixture. Solids must be free of solvent in order to obtain an accurate melting point. The left and right y-axis intercept the known melting temperatures for pure compound A and pure compound B respectively. However, upon mixing A with B, the melting temperature of the mixture is decreased. The amount the melting point is depressed is a function of the molar percent of each component and can be read directly from the diagram. There are two special points on this diagram. The first is the Eutectic temperature, designated by Et. This is the lowest temperature at which the mixture will begin to melt. The Eutectic point, Ep is the mole percentage where the mixture of two compounds are dissolved equally in each other. At this particular point, even though the mixture is not pure, it will appear to have a sharp melting point. As discussed earlier, a sharp melting point indicates a pure material. A broad melting point is normally a mixture of compounds. The Eutectic point is an exception to this rule and can lead to misidentification of the sample. It should also be noted that insoluble impurities, although very undesirable, will not affect the melting point. One example of an insoluble impurity would be a piece of sand. The sand will have not affect on the melting point. If you are determining the melting point of a known compound, the results can be compared to literature values. Aldrich catalog has an enormous amount of physical data for organic compounds including melting points. Use these and other sources to verify your melting points. However, if the compound is unknown or has been synthesized for the first time, the melting range may still help in determining the purity of the substance. The melting point range is the temperature at which the solid begins to melt to the temperature when the solid has completely been converted into a liquid. Melting points should always be recorded as a range. As previously mentioned, the purer the compound is the narrower the melting point range. In contrast, the more impure the compound is the broader the melting point range. Melting point ranges can vary, but a good range is typically 1-3 °C. Poor ranges can be as broad as 20°C. One of the biggest and most common mistakes when obtaining a melting point, is not allowing the sample to dry completely. Traces of solvent in the sample act just as any other impurity. It will depress the melting point and broaden its range. This will lead to incorrect identification of the unknowns you will be recrystallizing in this chapter. Another common mistake is to heat the sample too fast. In general it is best to heat the sample slowly, no faster than 2°C per min in the range of the melting point. Use this rate to expedite the use of the few melting point units we have. 50 In our laboratory, we use two different types of melting point apparatuses: Mel-Temps, located at the end of every other laboratory bench, and Thomas Hoover’s located at the North end of Lab 205. Both are electrically heated melting point apparati. The directions for the Thomas-Hoover and Mel-Temp Melting Point Apparati can be found in Step 3 of the experiment found in this chapter. Since both the Mel-Temp and the Thomas Hoover machine use thermometers, it is very important to calibrate the thermometers. Obviously, the identification of your unknown will be incorrect if the thermometer reading is wrong. This is a very common and serious mistake during the determination of unknown samples. Please check to see that the thermometer is giving accurate temperature readings by recording the temperatures of boiling water and ice. It is a simple and straight-forward test you must complete before the melting point determination. One advantage of a melting point analysis is the very small amount of sample needed to obtain good results. Each machine uses glass capillary tubes to obtain the melting point. To load to capillary, take a few milligrams of the material to be analyzed and push the solid together on a watch glass or other clean surface. Use the open end of the capillary tube (found in your desk equipment) and push the open end onto the pile of solid material. Once a small portion of the compound is in the tube, turn the capillary over and rap the tube gently on the desk top to pack the sample in the botton. Be careful not to break the tube accidentally. Even though the tubes are small, the glass can be very dangerous and puncture the skin very easily. While rapping on the desktop, the compound (if thoroughly dry) will move to the closed end of the tube. If this does not occur, drop the mp capillary through a 3 foot long plastic tube held vertically on the benchtop. These plastic tubes can be found clamped to the side shelves. You only need a few millimeters of sample in the end of the tube. Too much sample will lead to uneven melting and possibly increase the range of your melting point. Insert the tube, closed-end down, into the Mel-Temp or Thomas Hoover, heat it slowly, and observe the melting point range. Although melting points can be used as an identification tool, there are many compounds that have coincident melting points. There may be an occasion when you have two compounds that have the same melting point. They could be the same compound or it may be a coincidence. A mixed-melting point determination can verify whether they are the same compound or two different compounds. Mix equal amounts of the two solids and determine the melting point of this mixture. If the mixed-melting point is the same for both the mixed materials and the individual compounds, they are the same compounds. However, since mixtures of different materials melt at lower than either compound, if the combined melting point is depressed compared to the individual samples, then the materials are not the same. This simple method can easily verify if these compounds with the same melting point are the same. 51 Mel-temps & Thomas Hoovers only 1 to 2 mm of sample in mp capillary Mixed-melting points. 52 Recrystallization Experiments Procedures 1,2, and 3 provide challenging tests of your experimental and observational skills. You will be given a small amount of an impure unknown organic compound whose identity can be determined from its melting point. However, since its melting point is depressed by impurities, you will need to purify the compound by recrystallization before the melting point determination. Procedure 4 involves a more quantitative analysis of solubility in cold and hot solutions. Procedure 5 demonstrates how colored impurities might be removed from an organic solid. Procedure 6 shows how the melting point can be used to help identify an unknown solid. All students should complete Procedures 1, 2 & 4 in the first lab. Procedure 3, determination of unknown melting points and Procedure 5, decolorization can be done in the following lab period. Procedure 6 may be done in subsequent labs or in the instrument room. In order to use your time efficiently, whenever possible try to do more than one operation or experiment at a time. Procedure 1 • Finding a Suitable Recrystallization Solvent for your Unknown You will use a sand bath, not a Bunsen burner or steam bath, to heat solvents. As soon as you arrive and while you’re waiting for your TA to collect your PRELAB pages, fill your heating mantle half full of sand, mount it to a ring stand in your hood, and plug it into the heating controller (often called a varistat or powerstat) which is mounted on the outside of the hood. Plug the controller into the electrical socket above the bench and set the dial to 50. To effect smooth boiling and avoid explosive boiling or bumping of the solvent when heating it, be sure to use boiling sticks (wooden applicator sticks). Boiling sticks also can serve as stirrers. Your instructor will provide you with approximately 100 mg of an impure unknown organic solid (record the number of your unknown immediately into your lab notebook) which is one of the six compounds shown below: CH3 O O C OH 1 o-Toluic Acid m.p. 104-107°C CH3 NOTE: Set up and heat your sand bath as soon you arrive in lab. Unknown Compounds CH2 C OH m-Toluic Acid m.p. 109-113°C 2 3 O Fluorene m.p. 114-116°C O C NH 2 4 E-Stilbene m.p. 122-124°C 5 Benzamide m.p. 127-130°C OH 6 E-Cinnamic Acid m.p. 133-134°C Solubility Test You will test the solubility of your unknown in different solvents as follows: Weigh out between 8 and 13 mg (0.008 to 0.013g) of your unknown and transfer it to a tared reaction tube or micro test tube. (This is about the amount that can be picked up on the last half inch of the sharply pointed end of your stainless steel micro-spatula.) Using a Pasteur pipet, add to this solid about 0.25 mL of distilled water. You can use the graduations on the side of the reaction tubes to estimate the 0.25 mL of solvent. 53 Graduated Reaction Tube Refluxing Alternatively, use your 1 mL x 1/100 mL pipette to measure out liquid volumes less than 1 mL. To draw liquids into the pipet in a controllable manner, attached your 2.5-mL plastic syringe to the pipet with a small rubber connector available on the Common Shelf. (Ask your TA for a demonstration if you are unsure of how to use the rubber connector.) Volumes can be approximate for the solubility tests; for 0.25 mL of water, for example, you can use a volume between 0.20 and 0.30 mL. Agitate the tube vigorously for 10-30 sec by hitting or tapping the bottom with your fingers, or by crushing the large crystals with a stirring rod. If the solid dissolves, the unknown is too soluble in the solvent and the solvent can be eliminated as suitable for recrystallization. If the solid does not dissolve after mixing for a short period, place a boiling stick (wooden applicator) in the tube and push the bottom of the tube part-way down into the hot sand of your sand bath. The solvent should start to boil within 10-30 seconds. If the boiling becomes too vigorous, pull the tube partially out of the sandbath. Continue gently boiling the solvent for about a minute, noting how the vapors condense on the tube walls and run back down into the liquid. This is called refluxing. Carefully observe the mass of crystals while you’re refluxing the liquid. If the solid dissolves, place the tube in a small beaker of ice water for one or two minutes to cool the solution. If you observe solid crystals coming out of solution you have found a suitable solvent for recrystallization. Go directly to Step 2 and recrystallize your unknown according to the instructions there. Always make careful observations. Note: Be alert to the difference between melting and dissolving! Compounds that melt just above the boiling point of water when pure may melt just below the boiling point of water when small amounts of impurities are present (the maximum solvent temperature in these experiments is approximately that of the boiling point of the solvent). Solids that melt but do not dissolve will form two immiscible liquids in the tube; upon crystallization, little impurities will stay in the solvent, so the degree of purification of the solid from this step will be rather small. If refluxing in the solvent leads to an observable decrease in the mass of the solid, but not complete dissolution, try adding more solvent, a few drops at a time, heating the solution to boiling (refluxing) for 30 to 45 seconds after each addition to see whether all of the solid dissolves. If it finally does, place the tube in an small ice-filled beaker for one or two minutes to cool the solution. If you observe solid crystals coming out of solution you have found a suitable solvent for recrystallization. Go directly to Step 2 and recrystallize your unknown according to the instructions there. If the mass of solid remains unchanged after one or two minutes in the refluxing solvent, then the unknown is obviously insoluble in both cold and hot solvent, and the solvent is unsuitable for recrystallization. Set the tube aside. With a clean tube, carry out the solubility test procedure as described above with another 8 to 13 mg sample of your unknown and a different solvent. Try the other extreme in solvent polarity, for the second test, ligroin (ligroin is the common name for a mixture of hexane and cyclohexane isomers with boiling points between 60 and 90°C). If this doesn’t work, try a solvent with polarities intermediate between water and ligroin such as methanol. If you don’t find a suitable recrystallization solvent in 3 or 4 trials, talk with your instructor. Cleaning Up Cleaning Up Place organic solvents and solutions of the compounds in the Nonhalogenated Organics Disposal container. Dilute the aqueous solutions with water and flush down the drain. Procedure 2 •• Microscale Recrystallization of your Unknown Having found a suitable solvent for recrystallization in Step 1 above, recrystallize the remainder of your unknown as follows: 54 Obtain approximately 80 mg of your unknown solid by weighing your unknown on the electronic balance. Transfer the weighed unknown into a tared reaction tube. (See the Checkin instructions in the back of the laboratory notebook for information on how to permanently mark tare weights on your reaction tubes, if they haven’t been marked already.) Make sure you have about 5 mg of the impure solid left to be used in a melting point determination in Step 3. Use the plastic funnel from your red glassware kit can be used as a powder funnel to make the transfer of the solid into the narrow neck of the reaction tube easier. If you do not have 80 mg, you’ll have to obtain more from the stockroom. Please be sure to tell the stockroom personnel your unknown number if you need more. Obtain the weight of your unknown. To the solid in the tube, add about 1.0 mL of the solvent you’ve found to be suitable for recrystallization, place a boiling stick in the tube and heat to refluxing in the sand bath. If the solid has not completely dissolved after a minute of boiling, add additional solvent, 5 or 6 drops at a time, bringing the solution back to a gentle reflux for a brief period after each addition. Be sure to allow time for as much undissolved solid to go into solution as possible at the boiling point of the solvent. After all the solid has dissolved, set the tube into a test tube rack and allow the solution to cool slowly. This will lead to slower crystal growth, yielding larger, more perfect, and purer crystals. While this is cooling, put approx. 0.5 mL fresh recrystallization solvent in a small test tube and cool in an ice bath. You will use this later to wash your purified crystals. After about five to ten minutes of slow cooling, crystals should have started to form. If they haven’t scratch the inside wall of the tube with a glass stirring rod. When you are sure that the solution is close to room temperature, cool it further by placing the tube in a small beaker of ice. After a few minutes in ice, if necessary, break up any solid crystalline mass that may have formed and rap the reaction tube bottom on a book or paper towel to force the liquid to the bottom. Remove the solvent using the pipet filtration method described in Figure 4.6 and demonstrated to you by your instructor. Add 6 to 10 drops of previously-cooled pure solvent to the crystals in the ice bath and agitate to wash the crystals. Remove this wash solvent using the pipet filtration method. Scratch or Seed If your recrystallization solvent was water, you should remove a small clump (about 5 mg, just enough to fit on the tip of the spatula) of crystals and place them on an open watch glass in your locker so that they can dry thoroughly by the next lab period. They will be used to obtain and accurate melting point. If it was ligroin or other more volatile solvent, the solids can be left in the open reaction tubes in your locker until the next lab period and weighed directly in the tube (subtracting the tare weight of the tube). This will reduce losses in of solid during transfers which can be a problem at microscale. Alternatively, you can speed up the removal of the residual solvent adhering to the solids by applying vacuum to the reaction tube while warming in a beaker of warm water as shown in Figure 4.7. Your compound must be dry to determine the correct melting point. When dry, simply weigh the tube containing the sample and subtract the reaction tube tare weight as determined previously. Calculate and report the percent recovery in your final report. A small portion of this solid will be used to determine the melting point of your purified unknown in Step 3. Cleaning Up Place organic solvents and solutions in the halogenated or nonhalogenated organics waste container, whichever is appropriate. Dilute the aqueous solutions with water and flush down the drain. Carry your sandbath to the side shelf and dump the HOT! sand back into the sand supply bowl. Do NOT dump it in the waste bins. Procedure 3 • Melting Points of Your Impure and Recrystallized Unknown In this experiment, you will determine the melting temperature ranges of both your impure unknown and your recrystallized, pure unknown. These will be determined using melting point capillary tubes (found in your locker) and one of the “Mel-Temp” electrically heated melting point apparati found on the shelf above your desk (1 per 4 students) or “Thomas-Hoover” type found on the side shelves. (Please don’t move the ones on the side shelves.) Two students can 55 Cleaning Up use one Thomas-Hoover apparatus at the same time, since 4 melting point tubes can be placed in the heating oil bath of this apparatus, and the melting points determined for all 4 samples by heating from low temperature, say 70°C, to high temperature, say over 130°C, in one pass. It should take 20-30 min for each temperature “scan”, including the time necessary for the apparatus to cool down. All students should be able to determine their mp’s in one three-hour lab. Your unknown must be solvent free. Loading the melting point capillary. It is of utmost importance that your sample be thoroughly dry and free from all traces of solvent before trying to determine its melting point. Otherwise, the solvent, like any other impurity, will cause the melting point to be depressed, and you won’t obtain an accurate melting point. Normally, most solvents evaporate completely from crystals in an open reaction tube in the two to five days between labs, but higher boiling solvents such as water (bp 100°C) and toluene (bp 110°C) may require drying on an open watch glass for a day. If your solid still seems wet and sticky after this period of time, you may have to allow additional time for drying by leaving it open in your locker for another few days, or you may have to speed up the evaporation process by applying vacuum. Assuming your crystals are dry, proceed as follows: Remove a few mg of the purified unknown and place it on a watch glass. If it is lumpy, grind it into a fine powder using the flat end of a spatula. Push the crystals into a small pile and then push the open end of a melting point capillary tube into the crystals so that some solid is forced into the opening of the tube. The sample is then shaken down into the closed end of the capillary either by: 1) wrapping the capillary tube with a paper towel and rapping sharply onto a hard surface; or by: 2) dropping it down a 2 to 3-ft length of 5-10 mm I.D. tube onto a hard surface. (there are a few of these tubes on the side shelves) If necessary, push more crystals into the open end and pack it down into the closed end so that you have no more than 2-3 mm column of solid at the bottom of the mp. tube. In a second melting point capillary, load a small amount of the unrecrystallized and impure unknown that you retained from Step 2 in the snap-top plastic vial. Mark the tubes so they can be differentiated. only 1 to 2 mm of sample in mp capillary When a melting point apparatus is available, check that it has cooled to below 70°C. Then you (and another student in the case of the Thomas Hoover units) can insert two samples and take their melting points using one of the following procedures, depending on the melting point apparatus. Be sure to bring your notebooks with you to the mp apparatus so that you can record the mp data Mel-Temp Melting Point Apparatus Procedure Mel-Temp Turn the power on, but turn the heating rate control dial all the way counter-clockwise to zero. If the temperature of the aluminum block is more than 70°C as read on the thermometer, wait for it to cool see the temperature on the thermometer rise. At this point you need to keep an eye on both the mp tubes (to watch for any signs of melting) and the thermometer (to monitor the rate at which the temperature is rising). [It helps to have chameleon eyes!] You may need to adjust the heating rate control dial so that the temperature does not rise too rapidly. It is best to heat the samples slowly, no faster than 1°C per min. However, it is possible to get useable mp’s heating at 2 to 3°C per minute, and to expedite the use of the few mp units we have, try this faster rate. Watch the samples, and when you start to see any one of them start to melt, record the temperature. When the solid in 56 Figure 4.12: Mel-Temp Apparatus a particular tube has completely melted, record this temperature also (87-88°C, for example). Once both samples have melted, you should have recorded melting ranges for each. Turn the heating rate control dial to zero and turn off the power. Cooling of the aluminum block can be expedited by holding a moist (not sopping wet!) paper towel on it, but be careful not to burn your fingers. Thomas-Hoover Melting Point Apparatus Procedure Turn the power on, if it isn’t already. Turn the heating rate control dial all the way counterclockwise to zero. Make sure the stirrer speed control dial is set at a little more than half of full speed. If the temperature of the oil bath is more than 70°C as read on the thermometer, wait for it to cool below this. Once below 70°C, you and another student can place your two mp tubes gently into the holes above the oil bath. Now start heating the oil by turning the heating rate control dial to about 3. After a moment, you should start to see the temperature on the thermometer rise. At this point you need to keep an eye on both the mp tubes (to watch for any signs of melting) and the thermometer (to monitor the rate at which the temperature of the oil bath is rising). [It helps to have chameleon eyes!] You may need to adjust the heating rate control dial so that the temperature does not rise too rapidly. It is best to heat the oil bath slowly, no faster than 1°C per min. However, it is possible to get useable mp’s heating at 2 to 3°C per minute, and to expedite the use of the few mp units we have, try this faster rate. Watch all the samples, and when you start to see any one of them start to melt, you or your co-worker should record the temperature and the position of the tube, for example #3 (from right) - 86.5°. If that is one of your partner’s tubes, it would be nice if you could let them watch the tubes while you keep tabs on the temperature and rate of heating and then change places again when yours starts to melt. When the solid in a particular tube has completely melted, record this temperature also (87-88°C, for example). Once all samples have melted, you should have recorded melting ranges for each. Turn the heating rate control dial to zero, but do not turn off the power or stirrer, since stirring helps to cool the oil bath down faster. Figure 4.13: Thomas Hoover Apparatus Mixed Melting Points Proof that an unknown compound is identical to known compound can be obtained by taking a mixed melting point. If two organic solids are thoroughly mixed together, two possibilities are observed: 1. If they are identical, the mp will be unaffected. 2. If they are different, each acts as an impurity in the other, and the mp will be considerably depressed. For example, you could verify that your unknown is fluorene by grinding it together with an authentic sample of fluorene using a glass rod on a watch glass. If the melting point is still 114116°C, your unknown is indeed fluorene; if lower, it must be something else. Occasionally, the melting point range of your purified unknown is still more than a few degrees and in between two possibilities. If this is the case, ask you TA to provide you with small amounts of pure samples of each of the possibilities, grind a small amount of your unknown together with each, and take the mp’s. Your unknown is then identical to the authentic compound that doesn’t effect the mp of your unknown when mixed with it. 57 Thomas-Hoover If your mp data isn’t definitive, try this! Quantative aspects of recrystallization. Procedure 4 • Macroscale Recrystallization of Phthalic Acid The more quantitative aspects of recrystallization will be studied using phthalic acid. Using the Beilstein Crossfire as a reference the following solubility data (in grams of solute per 100 mL of solvent) can be summarized. The superscripts refer to temperature in °C: Water 0.5414 0.7025 18.0100 Ethanol 11.715 27.478 Other 0.6915, Ether 20.421, MeOH insol, CHCl3 Table 4.3: Solubility data for phthalic acid (in grams of solute per 100 mL of solvent). The superscripts refer to temperature in °C. The large difference in solubility in water as a function of temperature suggests this as the solvent of choice. The solubility in alcohol is too high at room temperature. Ether is difficult to use because it has such a low boiling point and boils away rapidly; the compound is insoluble in chloroform (insol. CHCl3). Crystallize 1.0 g of phthalic acid from the minimum volume of water, using the above data to calculate the required volume. (This calculation should appear in your Observation and Data Section.) Add the solid to a 25-mL Erlenmeyer flask and then, using a Pasteur pipet, add the amount of water calculated above to the flask from a full 10-mL graduated cylinder. A boiling stick (a wooden applicator stick) facilitates even boiling and will prevent bumping. After a portion of the water has been added, gently heat the solution to boiling on a shallow sand bath or a hot plate. (A hot plate can be shared between 3 or four people.) As soon as boiling begins, continue to add water in small portions, heating to boiling each time, until all the solid just dissolves. Record the total amount of water used to do this. Place the flask on a book or other insulator and allow it to cool undisturbed to room temperature, during which time the crystallization process can be observed. Slow cooling favors larger and purer crystals. While this is taking place, set up for suction filtration by clamping your 25 mL filter flask to a ring stand, and connecting the vacuum hose from the house vacuum outlet to the side arm of the filter flask. Place the white plastic Hirsch funnel into the filter flask and cover the porous disc with a 1.3 cm filter paper disc from the Common Shelf (see Figure 4.4) The filter paper keeps the porous plastic frit from getting clogged with small particles. Open the vacuum valve and place the palm of your hand firmly over the top of the Hirsch funnel to see if you can feel a vacuum. If you don’t, there may be an air leak or the vacuum system isn’t working properly. Consult your TA if you can’t figure out the problem. An alternative filtration method is also demonstrated above in Figure 4.5. Collecting the purified crystals. Don’t forget to collect a second crop of crystals. Once cooled close to room temperature, cool the flask in an ice bath with occasional swirling. If the crystals have formed a solid mass, break this up with a spatula or boiling stick. Swirl to make sure everything is in suspension and then pour the solid-liquid slurry into the Hirsch funnel. The water solution should be rapidly sucked through the filter. Rinse out any crystals remaining in the flask into the Hirsch funnel with about 1 mL of ice water. Press down on the crystals in the Hirsch funnel with a spatula to squeeze out as much water as possible. Using a stainless steel spatula, scrape the crystals and filter paper disc out of the funnel onto a tared beaker or onto a tared watchglass. Remove the 1.3-cm filter paper disc and discard it. Allow the crystals to dry in your locker until the next lab period and then weigh them. For your Final Report, compare the calculated volume of water with the volume of water actually used to dissolve the acid. Also, calculate the percent recovery of dry, recrystallized phthalic acid. 58 More phthalic acid crystals (a second crop) can be obtained from the filtrate (mother liquor) by concentrating the solution. Pour the filtrate from the first crystallization above into a 100-mL beaker and either let the solution evaporate in your desk until the next laboratory period or boil the solution to at least half the volume. Collect the second crop of crystals by suction filtration, wash the crystals with about 1 mL of ice water, and air dry the crystals on tared watch glass until the next lab period. Weigh the watchglass and determine the yield and percent recovery based on the original sample of phthalic acid. Obtaining a second crop. The technique used for recovering the second crop of crystals is a general approach in synthetic chemistry. Occasionally, you may find that you’ve formed an unsaturated solution that is so dilute, that you have to boil away a lot of solvent before it becomes concentrated enough that cooling gives a supersaturated solution. You may also find that upon crystallization, there is a great loss of product; as long as you do not throw out your product, the solvent can always be removed and repeat the crystallization procedure using less solvent. Cleaning Up Cleaning Up Phthalic acid crystals can be recycled in the specially marked recycle containers on the hooded side shelves. Please don’t put filter paper in the recycling bottle. The water solutions from the phthalic acid recrystallization can go down the drain. Phthalic acid is not considered toxic to the environment. Carry your sandbath to the side shelf and dump the HOT sand back into the sand supply bowl. Do NOT dump it in the waste bins. (Why is this a bad idea?) Procedure 5 • Removing Colored Impurities Using Activated Carbon Decolorization Into a reaction tube place 1.0 mL of a 0.01% solution of methylene blue dye. Add to the tube a few pieces (8 or 10) of pelletized Norit decolorizing charcoal. Shake, and observe the color over a period of a minute or two. Add a boiling stick, heat the contents of the tube to boiling (reflux) and observe the color by holding the tube in front of a piece of white paper from time to time. How rapidly is the color removed at room temperature versus heating to higher temperature? If the color is not removed after heating for a minute or so, add more pelletized Norit charcoal, a few pieces at a time, until the color does disappear. Cleaning Up Place the Norit in the waste bin (the nonhazardous solid waste container.) The water solutions can go down the drain. Cleaning Up Procedure 6 • Spectral Unknown melting point Melting Point Determination of your Spectral Unknown Obtain the melting point of your spectral unknown. Assume that the sample is pure and does not need to be recrystallized. You do not necessarily need to do this during the two lab periods scheduled for this recrystallization/melting point technique experiment. If the melting point apparati are tied up, you can take your melting point during the distillation technique lab periods or in the instrument room any time it is open. If you plan to do it outside your regularly scheduled lab time, put your unknown sample tube in a labeled ziplock bag (available on the Common Shelf) and place it by the melting point apparatus in the instrument room or carry it with you. Use only as much sample as necessary. Remember that you need most of your sample for NMR and IR analysis. Once you have determined the melting point, look at the Unknown Possibilities by Melting Point list located on the Web at: http://courses.chem.psu.edu/chem36/HTML/Experiments/Unknown_Lists/Unknown.html In you Final Report, give the name and draw the structures for all compounds that have melting points within plus or minus 5 °C of your spectral unknown’s melting point. 59 Final Report Follow the guidelines given below in the Summary for In-Lab and Post-Lab Points to write a thorough discussion of recrystallization, solubility, and melting point determination. Include all in-lab observations and data and calculations or answers to questions shown in bold to the above experiments. Answer the PostLab Questions below. PostLab Questions Grading PostLab Questions: 1) Under what circumstances might it be necessary to use a mixture of solvents to carry out crystallization? What characteristics should these two solvents have? 2) What is the effect of an insoluble impurity, such as sodium sulfate, on the observed melting point of a compound? 3) Strictly speaking, why is it incorrect to speak of a melting point? A copy of the In-Lab and Post-Lab portions of the Recrystallization/Melting Point Grading Sheet is givenbelow Summary of In-Lab and Post-Lab Points for Final Report OBSERVATION /DATA - Accuracy and completeness 8 Solubility test data; Weighing data; Melting point data, Calc ulated water volume for Phthalic Acid Recrystalliz ation, Decolorizing Ex data and observations RESULTS/DISCUSSION -Overall organiz ation, readability, completeness. 10 Identification of Unknown withxplana e tion 12 Yield and % recovery for unknown 8 Yield and % recovery of phthalic acid (firstcrop) 8 Yield and % recovery of phthalic acid (secondcrop) 4 Calculatesolubil ity of phthalic acid in hot waterfromyour data and Tab le 4.3 8 Discuss ion of th e volumeof water used vs calc ulated 8 Solution decoloriz ation results and discussion 6 SpectralUnknownmeltingpoint and pos siblecompounds ' names andstructures 8 PostLab Questions 12 60 8