PARALOID KM-1 Acrylic Impact Modifier

advertisement

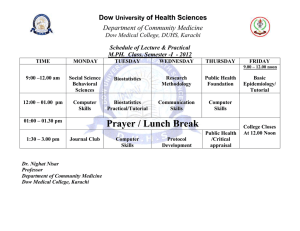

Technical Data Sheet PARALOID™ KM-1 Acrylic Impact Modifier For Weatherable Vinyl Building Applications Regional Product Availability • Europe Description PARALOID™ KM-1 Acrylic Impact Modifier belongs to the new generation of The Dow Chemical Company acrylic impact modifiers (AIMs) designed to outperform existing vinyl additives across a range of processing conditions. This new powder modifier provides outstanding impact and rheological performance properties. This unique combination of properties affords conventional AIMs users the opportunity to switch to PARALOID KM-1 Acrylic Impact Modifier with minor or no adjustment to existing formulations. In addition, the core shell structure of this new modifier has been designed to offer an improved impact strength efficiency satisfying all standards, across a range of processing conditions. Key Attributes Key properties provided by PARALOID™ KM-1 Acrylic Impact Modifier are as follows: • No stress built-up • Consistent surface finish (Gloss) • Low post-extrusion shrinkage • Reduced or no plate-out • High impact strength • Good resistance to compaction • Unparalleled weathering performance Impact Strength EN12608 STANDARD (ISO 179-1/1eA) Impact strength under plane strain conditions is regarded as a reliable indicator of brittleness for a given formulation, following a linear elastic fracture mechanism on pressed plate. This property is customarily measured with the Single V-notch Impact test (ISO 179-1/1eA). To pass the test, a calendered/pressed formulation must withstand a minimum energy of 20 kJ/m². Results conducted with this procedure demonstrate that PARALOID™ KM-1 Acrylic Impact Modifier provides improved impact strength under plane strain conditions. As shown in the graph on the following page, PARALOID KM-1 Acrylic Impact Modifier at 6 or 7 phr displays similar or superior impact effectiveness as other acrylic impact modifiers (Fig. 1). Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow PARALOID™ KM-1 Acrylic Impact Modifier / Dow Plastics Additives ®TM Page 1 of 7 Form No. 874-00921-0810 Impact Strength (continued) Figure 1: EN 12608 Standard RAL STANDARD (DIN 53753: Double V-notch Charpy impact test) In some countries, reference is made to the RAL-GZ 716/1 Standard. This RAL Standard specifies the use of a double-V notch Charpy impact test (DIN 53753) to measure the impact strength of extruded vinyl profiles under plane stress conditions. A minimum energy of 40 kJ/m² is necessary to satisfy the Standard’s requirements in this regard. Evaluations conducted with this procedure confirm the good efficiency of PARALOID™ KM-1 Acrylic Impact Modifier relative to competitive modifiers (Fig. 2). At low level, PARALOID KM-1 Acrylic Impact Modifier provides enough impact resistance to satisfy the standard. Figure 2: RAL standard Process Characteristics Brabender Rheology PARALOID™ KM-1 Acrylic Impact Modifier yields a slightly slower fusion but similar fusion temperature, compared to conventional AIMs. Equilibrium torque is comparable to conventional AIMs (Figure 3). This feature was ascertained in Brabender rheology testing conducted at 180°C and 50 rpm with a charge weight of 59 grams. Figure 3: Brabender Rheology Data Loading phr Pb stabilized formulation Competitive AIM 6 PARALOID KM-1 6 Fusion time (sec.) Fusion Temp ºC Fusion Torque (nm) 72 77 166 166 16.7 20.2 Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow PARALOID™ KM-1 Acrylic Impact Modifier / Dow Plastics Additives Equilibrium Torque (nm) 31.6 31.5 ®TM Page 2 of 7 Form No. 874-00921-0810 Extrusion Processing Characteristics In trials conducted with large parallel or conical twin-screw extruders, vinyl formulations containing PARALOID™ KM-1 Acrylic Impact Modifier exhibit processing characteristics similar or slightly delayed fusion to vinyl formulated with conventional AIMs (Fig. 4). These extruder data reflects the slightly slower fusion observed for PARALOID™ KM-1 Acrylic Impact Modifier in a Brabender test. Figure 4: Extrusion Characteristics Loading phr Pb stabilized formulation Competitive AIM 6 PARALOID KM-1 6 Competitive AIM 7 PARALOID KM-1 7 Density g/cc Screw Torque A Melt Pressure Z1 MPa Melt Temp. ºC 0.671 0.673 0.668 0.671 3.59 3.43 3.64 3.58 1.1 0.7 1.3 1.0 169 166 171 170 Gloss Properties As a result of the outstanding rheological and impact properties described above, PARALOID™ KM-1 Acrylic Impact Modifier based formulations delivers very good gloss to vinyl profiles (Fig. 5) compared to competitive AIMs. Figure 5: 60° Gloss Percentage Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow PARALOID™ KM-1 Acrylic Impact Modifier / Dow Plastics Additives ®TM Page 3 of 7 Form No. 874-00921-0810 Color Properties As slight temperature adjustment could be required to optimize the PARALOID™ KM-1 Acrylic Impact Modifier efficiency in vinyl profiles, color characteristics remains fully comparable to competitive modifiers (Fig. 6). Figure 6: b* value Weatherability The weathering resistance of vinyl depends on a number of factors in the formulation, notably the polymer grade, the chemical type and concentration of the stabilizer, and the nature of the pigmentation. All acrylic polymers, specially developed by The Dow Chemical Company for vinyl impact modification, have proven their outstanding weathering resistance and color stability over many years. Rigid vinyl products, when properly stabilized, pigmented and modified with PARALOID™ acrylic impact modifiers, show excellent color durability and retention of mechanical properties. Accelerated weathering tests were carried out with a Xenontest weatherometer for 4000 hours. The tests were performed on window profiles in a Pb stabilized vinyl formulation. The results highlight the excellent long-term durability of PARALOID KM-1 Acrylic Impact Modifier (Fig. 7 and 8). Figure 7: Color Stability (Delta b*) Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow PARALOID™ KM-1 Acrylic Impact Modifier / Dow Plastics Additives ®TM Page 4 of 7 Form No. 874-00921-0810 Figure 8: Color Stability (Delta E*) Packaging and Handling Packaging Powder Characteristics PARALOID™ KM-1 Acrylic Impact Modifier Funnel flowability, mm 20 Minimum ignition energy, mJ 200–300 Minimum ignition temperature, ºC 420 Layer ignition temperature, ºC > 400 KST Class/Value (bar.m/s) Class 1 / 120 Particle size: On 0.600 mm, maximum On 0.250 mm, maximum Trough 0.045 mm, maximum 7 60 25 Handling Considerations Under certain conditions all organic powders can form explosive mixtures with air. PARALOID™ KM-1 Acrylic Impact Modifier is no different in this respect and has been classified as belonging to the dust explosion class ST1. Risks of this nature can be minimized by careful plant design. To ensure safe handling, the appropriate safety regulations should be observed. We recommend that the prospective users determine the safe handling procedures necessary for the user’s applications before manufacturing products. A Material Data Safety Sheet, outlining hazards and handling methods, is available on request from your local Dow Chemical Plastics Additives sales office. Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow PARALOID™ KM-1 Acrylic Impact Modifier / Dow Plastics Additives ®TM Page 5 of 7 Form No. 874-00921-0810 Formulations Window Profile Ca/Zn Stabilized (K68) S-PVC K68 100 Ca/Zn-Stabilizerpack 4–6 Titanium Dioxide 5 Calcium Carbonate 5–8 PARALOID™ KM-1 6.0 PARALOID K-125 ER 0.5 Window Profile Pb Stabilized (K68) S-PVC K68 Pb-Stabilizerpack Titanium Dioxide Calcium Carbonate PARALOID™ KM-1 PARALOID K-175 ER PARALOID K-125 ER Handling Precautions 100 4–6 4 5–8 6.0 0.5 0.5 Before using this product, consult the Material Safety Data Sheet (MSDS)/Safety Data Sheet (SDS) for details on product hazards, recommended handling precautions and product storage. CAUTION! Keep combustible and/or flammable products and their vapors away from heat, sparks, flames and other sources of ignition including static discharge. Processing or operating at temperatures near or above product flashpoint may pose a fire hazard. Use appropriate grounding and bonding techniques to manage static discharge hazards. CAUTION! Failure to maintain proper volume level when using immersion heaters can expose tank and solution to excessive heat resulting in a possible combustion hazard, particularly when plastic tanks are used. Storage Store products in tightly closed original containers at temperatures recommended on the product label. Disposal Dispose in accordance with all local, state (provincial) and federal regulations. Empty containers may contain hazardous residues. This material and its container must be disposed in a safe and legal manner. It is the user's responsibility to verify that treatment and disposal procedures comply with local, state (provincial) and federal regulations. Contact your Dow Plastics Additives Technical Representative for more information Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow PARALOID™ KM-1 Acrylic Impact Modifier / Dow Plastics Additives ®TM Page 6 of 7 Form No. 874-00921-0810 Product Stewardship Dow has a fundamental concern for all who make, distribute, and use its products, and for the environment in which we live. This concern is the basis for our product stewardship philosophy by which we assess the safety, health, and environmental information on our products and then take appropriate steps to protect employee and public health and our environment. The success of our product stewardship program rests with each and every individual involved with Dow products–from the initial concept and research, to manufacture, use, sale, disposal, and recycle of each product. Customer Notice Dow strongly encourages its customers to review both their manufacturing processes and their applications of Dow products from the standpoint of human health and environmental quality to ensure that Dow products are not used in ways for which they are not intended or tested. Dow personnel are available to answer your questions and to provide reasonable technical support. Dow product literature, including safety data sheets, should be consulted prior to use of Dow products. Current safety data sheets are available from Dow. Contact: North America: 1-800-441-4369 Asia: 800-7776-7776 Europe: 800-3-694-6367 South America: +55-11-5188-9000 http://www.dow.com Notice: No freedom from any patent owned by Dow or others is to be inferred. Because use conditions and applicable laws may differ from one location to another and may change with time, Customer is responsible for determining whether products and the information in this document are appropriate for Customer's use and for ensuring that Customer's workplace and disposal practices are in compliance with applicable laws and other government enactments. The product shown in this literature may not be available for sale and/or available in all geographies where Dow is represented. The claims made may not have been approved for use in all countries. Dow assumes no obligation or liability for the information in this document. References to “Dow” or the “Company” mean the Dow legal entity selling the products to Customer unless otherwise expressly noted. NO WARRANTIES ARE GIVEN; ALL IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE ARE EXPRESSLY EXCLUDED. Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow PARALOID™ KM-1 Acrylic Impact Modifier / Dow Plastics Additives ®TM Page 7 of 7 Form. 874-00921-0810