FS UnoTM Ground Mount Installation Manual

FS Uno

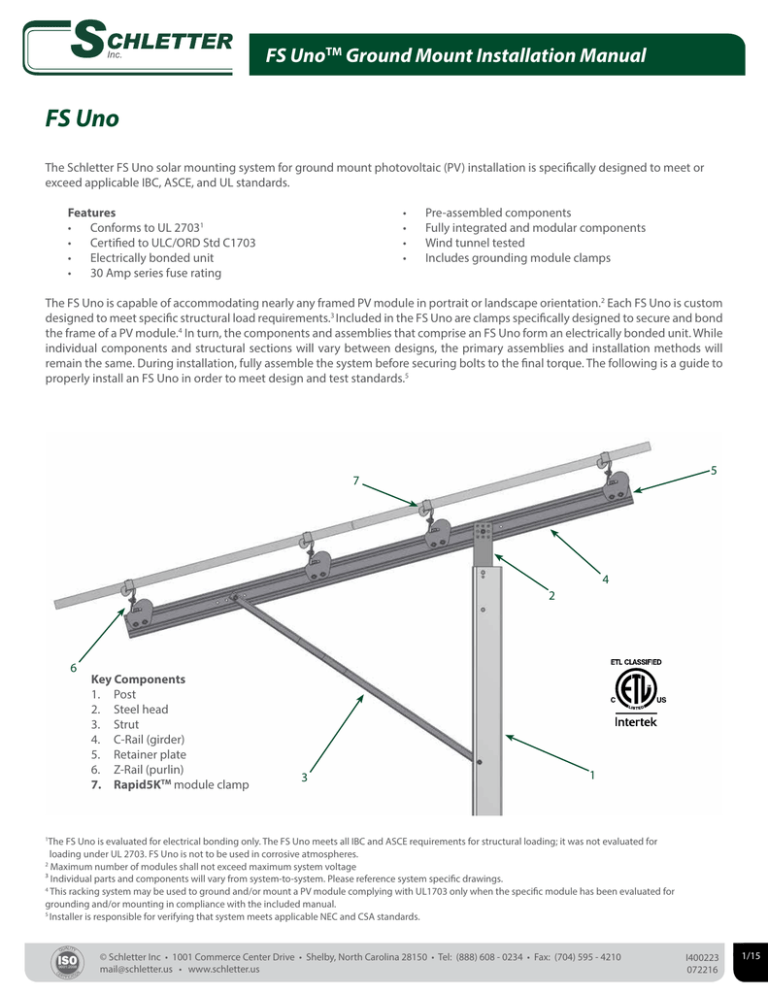

The Schletter FS Uno solar mounting system for ground mount photovoltaic (PV) installation is specifically designed to meet or

exceed applicable IBC, ASCE, and UL standards.

Features

• Conforms to UL 27031

• Certified to ULC/ORD Std C1703

• Electrically bonded unit

• 30 Amp series fuse rating

•

•

•

•

Pre-assembled components

Fully integrated and modular components

Wind tunnel tested

Includes grounding module clamps

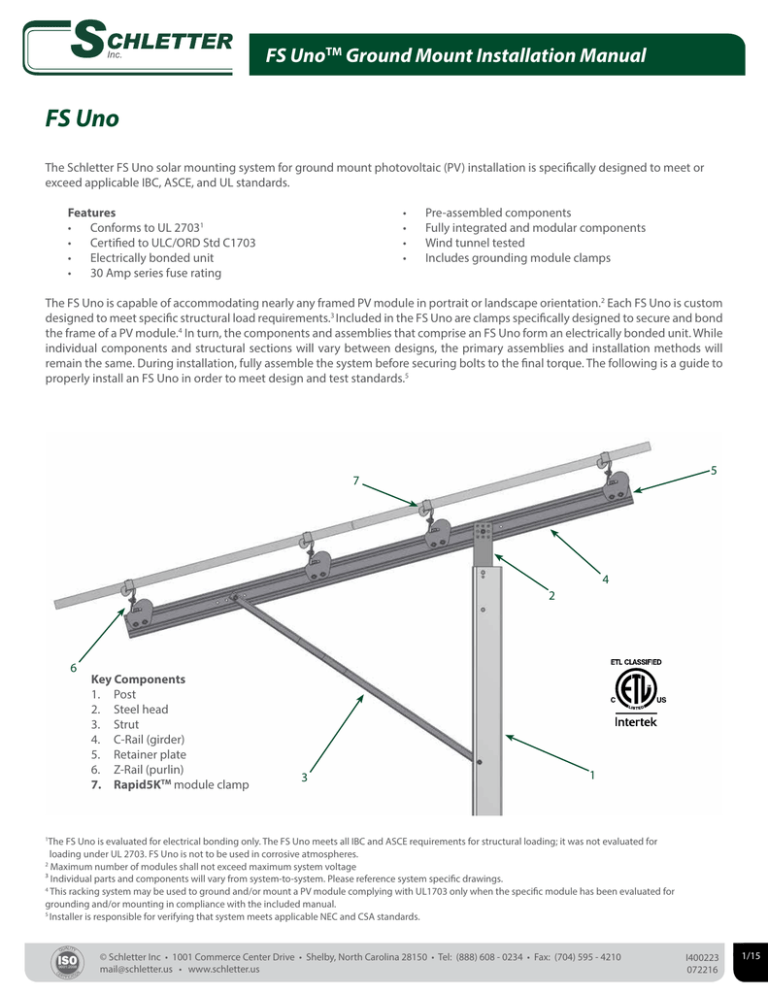

The FS Uno is capable of accommodating nearly any framed PV module in portrait or landscape orientation.2 Each FS Uno is custom

designed to meet specific structural load requirements.3 Included in the FS Uno are clamps specifically designed to secure and bond

the frame of a PV module.4 In turn, the components and assemblies that comprise an FS Uno form an electrically bonded unit. While

individual components and structural sections will vary between designs, the primary assemblies and installation methods will

remain the same. During installation, fully assemble the system before securing bolts to the final torque. The following is a guide to

properly install an FS Uno in order to meet design and test standards.5

5

7

4

2

6

Key Components

1. Post

2. Steel head

3. Strut

4. C-Rail (girder)

5. Retainer plate

6. Z-Rail (purlin)

7. Rapid5KTM module clamp

3

1

The FS Uno is evaluated for electrical bonding only. The FS Uno meets all IBC and ASCE requirements for structural loading; it was not evaluated for loading under UL 2703. FS Uno is not to be used in corrosive atmospheres.

2

Maximum number of modules shall not exceed maximum system voltage

³ Individual parts and components will vary from system-to-system. Please reference system specific drawings.

4

This racking system may be used to ground and/or mount a PV module complying with UL1703 only when the specific module has been evaluated for grounding and/or mounting in compliance with the included manual.

5

Installer is responsible for verifying that system meets applicable NEC and CSA standards.

1

ALITY

QU

ISO

N

9001:2008

CE

R T I F I C AT I O

© Schletter Inc • 1001 Commerce Center Drive • Shelby, North Carolina 28150 • Tel: (888) 608 - 0234 • Fax: (704) 595 - 4210

mail@schletter.us • www.schletter.us

I400223

072216

1/15

FS UnoTM Ground Mount Installation Manual

Sample Drawings

Specific drawings are provided for each project. Key information included on these drawings is as follows:

1. Design Criteria

4. Array Tilt

6. Post Embedment

2. Notes Section

5. Array Dimensions

7. Footing Size (if applicable)

3. Module Dimensions

1

2

4

3

5

7

6

8

9

11

10

12

2

14

13

15

16

17

DESIGN CRITERIA:

2009 EDITION OF THE INTERNATIONAL BUILDING CODE, WITH LOCAL AMENDMENTS.

15305 [602169 in]

A

8200 [32213

16 in]

550 [2158 in]

A

30 [1163 in]

1

7100 [27912 in]

SPLICE

992 [39161 in] TYP

5 [163 in]

(30 [1163 in])

B

FINISHED GRADE

FRONT ELEVATION

SCALE 1 : 30

A

E

95 [3 3

413 [16 1

4

4

in]

825 [32 1

in]

1650 15 2

[64

16 in] TY

P

694 [27 5

16 in]

4

F

830 [32 11

16

8

in]

825 [32 1

in]

75 [2 15

16

15°

4

496 [19 1

3

[62 8

84

15

in]

in]

in]

in]

a. SEMI-HOLLOWS AND HOLLOWS SHALL BE 6105-T5, 6005A-T6, OR 6005-T5

b. SOLIDS SHALL BE 6063-T6

STEEL:

1: ALL BOLTS AND WASHERS SHALL BE 304 STAINLESS STEEL CLASS 2 (A2-70).

2. ALL NUTS SHALL BE 316 STAINLESS STEEL CLASS 2 (A4-70)

3. ROLL FORMED STEEL RAILS AND GIRDERS SHALL BE HSLA-F GRADE 70 G165 ASTM A653

4. ROLL FORMED STEEL POSTS AND STRUTS SHALL BE SAE J2340

348 [1311

16 in]

6

1603 [6318 in]

3000 [11818 in]

I

E

TORQUE:

TORX BOLT FOR RAPID 2+ MODULE CLAMPS IS 14 N-M (10.5 FT-LBS)

M6 AND 1/4" BOLT TORQUE IS 6 N-M (4.5 FT-LBS)

M8 AND 5/16" BOLT TORQUE IS 14 N-M (10.5 FT-LBS)

M10 AND 3/8" BOLT TORQUE IS 30 N-M (23 FT-LBS)

M12 AND 1/2" BOLT TORQUE IS 50 N-M (37 FT-LBS)

M16 AND 5/8" BOLT TORQUE IS 121 N-M (89 FT-LBS)

M20 AND 3/4" BOLT TORQUE IS 244 N-M (180 FT-LBS)

F

NOTE: RECOMMENDED SPEED FOR INSTALLATION OF SELF-DRILLING 1/4" DIAMETER

SCREWS IS 1200-1800 RPMS.

MODULE SIZE:

RACKING SYSTEM DESIGNED FOR MODULE SIZE: 1650mm x 992mm x 40mm

VERTICAL MODULE GAP: 23 mm

HORIZONTAL MODULE GAP: 5 mm

FOUNDATIONS:

1. FOUNDATION DESIGN IS BASED UPON GEOTECHNICAL REPORT/TESTING REQUIREMENTS

BY TERRACON; PROJECT NO: TO BE DETERMINED.

ALL CONSTRUCTION SHALL CONFORM TO THE REQUIREMENTS OF THE GEOTECHNICAL REPORT.

GEOTECHNICAL TEST LOADS: UPLIFT (Tension) = 4.09 kips, LATERAL (Shear) = 1.20 kips

2. THE STRUCTURAL ENGINEER IS NOT RESPONSIBLE FOR ANY GEOTECHNICAL ASPECTS OF

THIS PROJECT. IF THE INSTALLER NOTICES ANY SOIL THAT HAS DIFFERENT DRIVING

CHARACTERISTICS THAN EXISTED FOR TESTED DRIVEN POSTS, CONTACT THE ENGINEER

IMMEDIATELY.

NOTE:

THE POST EMBEDMENT DEPTH IS PRELIMINARY AND SHALL BE VERIFIED BY THE STRUCTURAL

ENGINEER OF RECORD PRIOR TO CONSTRUCTION. BASED UPON ON SITE TESTING BY THE

GEOTECHNICAL ENGINEER.

ISOMETRIC VIEW

SCALE 1 : 40

POST EMBEDMENT DEPTH

IS PRELIMINARY

SEE NOTES

D

ALUMINUM:

1. ALL ALUMINUM SHALL CONFORM WITH THE LATEST ALUMINUM DESIGN HANDBOOK.

2. ALL ALUMINUM SECTIONS SHALL BE:

FINISHED GRADE

H

C

Y

L

N

O

933 [3611

16 in]

1200 [4714 in]

1397 [55 in]

1050 [41165 in]

2

2094 [82167 in]

ING

L

P

M

SA

2

413 [16 1

G

5

W

A

R

ED

3

3305

[130 1

8 in]

2650

[104 5

16 in]

2480 5

[97 in]

in]

B

GENERAL:

1. THE STRUCTURAL CONSTRUCTION DOCUMENTS REPRESENT THE FINISHED STRUCTURE.

THEY DO NOT INDICATE THE METHOD OR SEQUENCE OF CONSTRUCTION. THE

CONTRACTOR SHALL BE RESPONSIBLE FOR AND PROVIDE ALL MEASURES NECESSARY TO

PROTECT THE STRUCTURE DURING CONSTRUCTION. SUCH MEASURES SHALL INCLUDE,

BUT NOT BE LIMITED TO, BRACING, SHORING FOR LOADS DUE TO CONSTRUCTION

EQUIPMENT, ETC. THE STRUCTURAL ENGINEER SHALL NOT BE RESPONSIBLE FOR THE

CONTRACTOR'S MEANS, METHODS, TECHNIQUES, SEQUENCES FOR PROCEDURE OF

CONSTRUCTION, OR THE SAFETY PRECAUTIONS AND THE PROGRAMS INCIDENT THERE TO

(NOR SHALL OBSERVATION VISITS TO THE SITE INCLUDE INSPECTION OF THESE

ITEMS). THE CONTRACTOR SHALL BE RESPONSIBLE FOR THE DESIGN AND

IMPLEMENTATION OF ALL SCAFFOLDING, BRACING AND SHORING.

2. WHERE REFERENCE IS MADE TO VARIOUS TEST STANDARDS FOR MATERIALS, SUCH

STANDARDS SHALL BE THE LATEST EDITION AND/OR ADDENDA.

D

2240 [88163 in] TYP

A

WIND DESIGN:

DESIGN BASED UPON WIND TUNNEL TEST REPORT # RC 1127/0611_1e

BASIC WIND SPEED = 90 MPH (3 SECOND GUST).

EXPOSURE: C

Iw = 1.0

INSTALLATION TOLERANCES:

LATERAL POST PLACEMENT IS ±5.0"

TOTAL LATERAL DEVIATION OF POSTS WITHIN AN ARRAY IS ±5.0"

POST HEIGHT VARIATION TOLERANCE IS ±0.40"

POST VERTICALITY TOLERANCE <2.0° IN ALL DIRECTIONS

POST ROTATIONAL TOLERANCE <±7.0°

ARRAY TILT ANGULAR TOLERANCE ±1.0°

C

933 [3611

16 in]

LOADS:

MODULE DEAD LOAD = 2.38 PSF

SNOW LOAD = 0 PSF (BASED ON 30 PSF GROUND SNOW LOAD)

Is = 1.0 Ce = 0.9 Ct = 1.2 Cs = 1.0

G

H

I

SECTION A-A

SCALE 1 : 20

987 [3878 in]

2216 [8714 in]

J

J

NO. DRAWN:

0

1

2

3

4

K 5

6

7

8

CHECKED: REVIEWED: APPROVED:

REVISIONS:

New Drawing

Client:

Ground Mount FS Uno 2V x 15 15°

Drawing Number:

Project Site:

Racking Structure

1001 COMMERCE CENTER DR. | SHELBY, NC 28150

TEL: (704) 595 - 4200 | Fax: ( 704) 595 - 4210

EMAIL: MAIL@SCHLETTER.US

WWW.SCHLETTER.US

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

Dimensions and Specifications

JOB NUMBER: v

ISSUED BY: SCHLETTER INC.

PROPRIETARY AND CONFIDENTIAL

PRELIMINARY

10

11

12

13

10

11

12

13

SHEET: 1 of 2

UNLESS THIS DRAWING IS SIGNED

AND SEALED BY A LICENSED

STRUCTURAL ENGINEER, IT IS

A PRELIMINARY DESIGN AND SHALL K

NOT BE USED FOR CONSTRUCTION.

v.01

SCALE:

14

SEE DRAWING VIEWS

14

15

16

17

15

16

17

A

A

ID

B

A

B

C

D

F

2650

[104 5

16 in]

2530 5

[99 in]

8

789 [31 1

16

1811

[71 5

in]

16 in]

1705 1

[67 in]

8

C

875 [34 7

16

in]

471 [18 9

15°

16

in]

50 [1 15

16 in] TY

P

50 [1 15

16 in]

D

1050 [41165 in]

B

1

C

E

F

D

6

571 [22 1

7

2

3

[62 8

84

15

14

in]

W

A

R

ED

L

P

M

SA

3000 [11818 in]

5

1950 [7613

16 in]

H

3

ING

in]

12

G

ITEM

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

GIRDER TABLE

DESCRIPTION

CONFIGURATION

GIRDER LENGTH (mm)

2650

'A' CLAMP SPACING ON MODULE (mm)

825

'B' CLAMP SPCING BETWEEN MODULES (mm)

830

'C' RAIL CANTILEVER BOTTOM (mm)

571

'D' RAIL CANILVER TOP (mm)

789

'F' OFFSET PURLIN TOP (mm)

70

DESIGN

STANDARD

40 X 60 (FORMED)

STRUT TYPE

LENGTH OF STRUT (mm)

1584

NUMBER OF GIRDERS ASSEMBLIES

7

9

14

6

15

13

5

11

8

1

13

PART NUMBER

143018-008-300-105

000010-203

943612-030

943922-012

943912-012

141C04-02650

144982-01584

943612-085

144901-08200

144901-07100

144999-013

144999-003

100000-040

100000-003

100000-140

QTY

7

7

21

14

35

7

7

14

4

4

4

28

4

56

4

PARTS LIST

DESCRIPTION

Post, Universal, 8, M12, Galvanized, L=300cm A= 105cm

Steel Head, FS Uno / FS Uno100, M12, Galvanized, A

Screw, Hex Head, M12x30mm, DIN 933, 304 SS

Washer, Large Diameter, M12, DIN 9021, 304 SS

Nut, Flange, Serrated, M12, DIN 6923, 316 SS

Rail, C, FS Uno, 4 Rail, Gen3, Assy, A, L=2650mm

Strut, Formed, M12, 40x60, T=3mm, A, L=1584mm

Screw, Hex Head, M12x85mm, DIN 931, 304 SS

Rail, Z, FS Uno / FS Duo, G165, L= 8200 mm

Rail, Z, FS Uno / FS Duo, G165, L= 7100 mm

Splice, FS Uno / FS Duo, Gen 3, Kit

Wedge, Retainer Plate, FS Uno / FS Duo

End Clamp, Rapid5K, Grounding, FS Uno, Left, 40mm

Mid Clamp, Rapid5K, Grounding, FS Uno, 38-42mm

End Clamp, Rapid5K, Grounding, FS Uno, Right, 40mm

B

C

Y

L

N

O

D

E

9

F

10

G

7

7

5

4

8

6

H

4

ISOMETRIC VIEW

SCALE 1 : 40

2

1

15

I

SUPPORT TRIANGLE

SCALE 1 : 12

DETAIL B

SCALE 1 : 5

I

DETAIL D

SCALE 1 : 5

DETAIL C

SCALE 1 : 5

J

J

NO. DRAWN:

0

1

2

3

4

K 5

6

7

8

1

ALITY

QU

ISO

9001:2008

CE

R T I F I C AT I O

N

2/15

CHECKED: REVIEWED: APPROVED:

New Drawing

REVISIONS:

Client:

Ground Mount FS Uno 2V x 15 15°

Drawing Number:

Project Site:

Racking Structure

1001 COMMERCE CENTER DR. | SHELBY, NC 28150

TEL: (704) 595 - 4200 | Fax: ( 704) 595 - 4210

EMAIL: MAIL@SCHLETTER.US

WWW.SCHLETTER.US

2

3

4

5

6

7

8

9

Details and Parts List

ISSUED BY: SCHLETTER INC.

PROPRIETARY AND CONFIDENTIAL

10

JOB NUMBER: v

11

12

PRELIMINARY

13

SHEET: 2 of 2

UNLESS THIS DRAWING IS SIGNED

AND SEALED BY A LICENSED

STRUCTURAL ENGINEER, IT IS

A PRELIMINARY DESIGN AND SHALL K

NOT BE USED FOR CONSTRUCTION.

v.01

SCALE:

14

SEE DRAWING VIEWS

15

16

17

© Schletter Inc • 1001 Commerce Center Drive • Shelby, North Carolina 28150 • Tel: (888) 608 - 0234 • Fax: (704) 595 - 4210

mail@schletter.us • www.schletter.us

I400223

072216

FS UnoTM Ground Mount Installation Manual

Installation Tools

•

String line with wood line blocks for foundation post installation

•

Permanent marker

•

Tape measure

•

Rubber mallet for wedge

•

Two (2) foot carpenter’s square for girder-to-

purlin connection

•

Torpedo level or protractor

•

Wrench and/or socket for all

bolted connections

•

Torque wrench

•

Ratchet and/or rechargeable power drill

17 mm

19 mm

•

Hex head wrench for standard clamps

•

Torx® bit (TX40) for Rapid5KTM

module clamps

6 mm

TX40

ALITY

QU

ISO

N

9001:2008

CE

R T I F I C AT I O

© Schletter Inc • 1001 Commerce Center Drive • Shelby, North Carolina 28150 • Tel: (888) 608 - 0234 • Fax: (704) 595 - 4210

mail@schletter.us • www.schletter.us

I400223

072216

3/15

FS UnoTM Ground Mount Installation Manual

Foundation Post Installation

1. Survey Proposed Site

•

Review final drawing. Drawing will include

information vital to the proper installation of

the foundation posts such as the embedment

depth, post-to-post spacing, and

installation tolerances.

•

Please note: Schletter does not provide

construction layouts.

•

4 inches

For longer racks, intermediate stakes may

be required.

Tolerance

•

Posts are installed vertically.

•

Installation tolerances:

Lateral post placement is ±5.0”

Total Lateral deviation of posts within an

array is ±5.0”

Post height variation tolerance ±0.50”

Post verticality tolerance <2.0° in

all directions

Post rotational tolerance <±5.0°

•

For East-West slopes greater than 5° contact

your Schletter representative.

Maximum 5°

4” Maximum

Embedment depth

E-W slope

±.5”

±5°

Rotation

Lateral cantilever

ALITY

QU

ISO

9001:2008

CE

R T I F I C AT I O

N

4/15

Elevation difference between

adjacent post

Support distance

© Schletter Inc • 1001 Commerce Center Drive • Shelby, North Carolina 28150 • Tel: (888) 608 - 0234 • Fax: (704) 595 - 4210

mail@schletter.us • www.schletter.us

I400223

072216

FS UnoTM Ground Mount Installation Manual

2. Post Installation

•

Position each post at respective installation

locations based on the completed stake-out

(use a forklift).

•

Position the hydraulic ram (GAYK) at the

installation location and lift the post into

position beneath the ram head.

•

Level hammer using bubble level on

hydraulic ram.

•

Level mast of hydraulic ram.

•

Level post using a torpedo level.

•

Advance the post approximately two feet into

the subsurface then re-check level.

•

Advance the post to the embedment depth

as shown on the final drawing.

•

Position string lines: bottom string line is

used for correct placement of post; top string

line indicates the correct embedment depth:

string is run from the top of the first post to

the top of the last post.

•

When installing subsequent posts, ram until

the hammer head touches the top string line.

ALITY

QU

ISO

N

9001:2008

CE

R T I F I C AT I O

Mark each post location using soil nails

with flagging

Position posts on marked locations

(use a forklift)

Ram two posts at opposite ends of array

for string line

Use string line as guide to determine

correct placement and depth of posts

Position hydraulic ram and lift post into

position beneath ram head

Hammer head touching top string line

indicates correct depth is reached

© Schletter Inc • 1001 Commerce Center Drive • Shelby, North Carolina 28150 • Tel: (888) 608 - 0234 • Fax: (704) 595 - 4210

mail@schletter.us • www.schletter.us

I400223

072216

5/15

FS UnoTM Ground Mount Installation Manual

Mounting the Individual Assembly Groups

1. Install of Optional Post Splice

•

Verify torque on all bolts.

•

Splices are used to extend the length of

a post.

•

Splice location will vary depending

on project.

•

Consult project specific drawings.

Install shim plates between post and splice tubing using 3/4” bolts, nuts,

and washers (front view of post)

4

3

2

1

D

D

2. Attach Steel Head

•

Once the head assembly is aligned, verify

the torque of the bolts.

•

B

A

C

C

B

B

Head piece attaches to inside right of

the post.

ISSUED BY: SCHLETTER INC. - PROPRIETARY AND CONFIDENTIAL

All rights reserved. Reproduction of any kind only with the express, written consent of the Co: Schletter Inc.

STATUS:

WorkInProgress

DRAWN BY:

christopher.schatz

A CHECKED:

kg/m or kg/sq m:

DESIGN STATUS DATE:

RT PART #:

CREATION DATE:

WEIGHT:

OLD PART # :

N/A

DESCRIPTION / PROJECT / CUSTOMER:

11/25/2014

CHECKED DATE:

MFG:

MFG APPROVAL DATE:

APPROVED:

ENG APPROVAL DATE:

Align steel head to the inner side of

the post and fasten using M12 bolts,

and nuts (front view of post)

PART NUMBER:

FS UNO Head Mount

SIZE:

C

3rd ANGLE PROJECTION

4

SCALE: AS SHOWN AREA: N/A

TOLERANCES:

MATERIAL:

A

Mounted head assembly with multiple

holes for adjustment flexibility (rear

view of post)

# REVISION

SHEET: OF

3

REV BY DATE

NOTE:

RDC # APPROVED

2

1

DETAIL A

SCALE 1 / 2

3. Mount Girders

•

Steel head has multiple bolt holes to

allow for adjustment.

•

Do not fully tighten the bolt on the steel

head. The connector must be loose for

mounting the strut.

Feed the M12 bolts through the pre-punched hole in the girder and tighten

loosely with nut and washer to the steel head

ALITY

QU

ISO

9001:2008

CE

R T I F I C AT I O

N

6/15

© Schletter Inc • 1001 Commerce Center Drive • Shelby, North Carolina 28150 • Tel: (888) 608 - 0234 • Fax: (704) 595 - 4210

mail@schletter.us • www.schletter.us

I400223

072216

FS UnoTM Ground Mount Installation Manual

4. Install Strut

•

Attach strut to girder and post with

provided M12 hardware.

•

The strut must be slotted into the open

side of post.

•

Once all connections are in place, tighten

bolts according to torque specifications.

5. Install Overcurrent Protection Device

(grounding)

•

Shares bolt that connects strut to post.

•

Remove serrated flange and install

grounding lug, torque to specification.

•

Accomodates stranded or solid copper

wire (14 gauge to 2 gauge).

•

Must use bare copper wire to connect

to the grounding lug. If using insulated

grounding wire, remove at least

two inches of insulation to expose

copper wire.

6. Mount Purlins

•

Strut to girder connection

with M12 hardware

Install one end of strut to connector on girder and

the other end to post, secure connections but do not

tighten

Loosen or remove top portion of grounding

lug and insert grounding wire into

appropriate groove

Z-Rail (purlin) must be mounted at a 90°

angle to the girder.

•

The distances between purlins must be

observed as specified in the

project drawing.

•

Use rubber mallet to drive in the wedge.

•

Retainer plate has slotted holes

for adjustment.

ALITY

QU

N

9001:2008

CE

R T I F I C AT I O

Grounding wire must extend through

grounding lug by at least 1/4”

Wedge

Insert purlins into pre-assembled

retainer plates

ISO

Strut to post connection

with M12 hardware

Hammer in the wedge

© Schletter Inc • 1001 Commerce Center Drive • Shelby, North Carolina 28150 • Tel: (888) 608 - 0234 • Fax: (704) 595 - 4210

mail@schletter.us • www.schletter.us

I400223

072216

7/15

FS UnoTM Ground Mount Installation Manual

7. Splice Connection

•

Mount splice on the front side of

the purlin.

•

Consult system specific drawings for

splice locations.

•

Torque to specification.

Side view

Secure splice connection with M12 bolt and washer, and M12 nut

8. Listing Requirement

•

IMPORTANT! Listing requires that every

girder be labeled.

•

If girder has no label, contact your

Schletter representative.

Label should appear on inside of girder.

ALITY

QU

ISO

9001:2008

CE

R T I F I C AT I O

N

8/15

© Schletter Inc • 1001 Commerce Center Drive • Shelby, North Carolina 28150 • Tel: (888) 608 - 0234 • Fax: (704) 595 - 4210

mail@schletter.us • www.schletter.us

I400223

072216

FS UnoTM Ground Mount Installation Manual

9. Grounding Path

Grounding Clamp

Retainer Plate

Purlin (Z-Rail)

Module Frame

Purlin Splice

Steel Head

Post

Strut

ALITY

QU

ISO

N

9001:2008

CE

R T I F I C AT I O

© Schletter Inc • 1001 Commerce Center Drive • Shelby, North Carolina 28150 • Tel: (888) 608 - 0234 • Fax: (704) 595 - 4210

mail@schletter.us • www.schletter.us

I400223

072216

9/15

FS UnoTM Ground Mount Installation Manual

Optional Accessories

1. Bonding Jumper

•

Electrically bonds adjacent systems

forming a continuous ground path.

•

Connects directly to purlin.

•

Available in 6-inch to 48-inch lengths.

Minimum length for FS Uno is 12 inches.

•

Install bonding jumper on pre-punched holes at end of purlin using M12

bolt and washer, and M12 nut

Used for expansion joints or other breaks

in racking system.

2. Cable Management

•

If cable management was ordered with

the system, place before

installing modules.

•

Combiner box mount is installed against

exterior end of foundation post as shown

in image (combiner box not included).

•

For a more detailed cable management

installation see:

Cable Tie and Edge Clip (149023-004)

4

3

Cable Management

Installation Guide

44

33

4

D

D

LENGTH

LENGTH

D

D

22

2

4

WIDTH of

WIDTH of

of COMBINER

239.0

WIDTH

239.0

COMBINERBOX

COMBINER

BOX

BOX

WIDTH

WIDTH of

of

COMBINER

COMBINER

BOX

WIDTH of

LENGTH

BOX

COMBINER

BOX

3

239.0

2

C

239.0

239.0

WIDTH of

COMBINER

BOX

7

9

2

239.0

6

77

5

99

4

7

22

77

9

66

99

55

6

44

66

9

2

5

4

55

44

6

5

33

3

55

11

1

33

D

5

3

11

4

9

2

6

5

5

1

4

3

C

1

C

C

C

8

10

88

C

8

10

88

10

10

8

10

B

2

22

D

5

55

1

CC

10

10

BB

D

D

3

239.0

7

C

B

D

1

DD

5

C

LENGTH

LENGTH LENGTH

LENGTH

C

C

1

D

LENGTH

LENGTH

LENGTH

C

1

11

3

7

CC

11

22

239.0

LENGTH

C

2

33

WIDTH of

COMBINER

BOX

LENGTH

LENGTH

LENGTH

LENGTH

D

1

3

44

D

DD

2

4

8

10

FRONT

VIEW

B

B

SCALE 1 : 10

SIDE VIEW

ASSEMBLY VIEW

SCALE 1 : 10

SCALE 1 : 6

B

FRONT VIEW

SIDE VIEW

ASSEMBLY VIEW

FRONT VIEW

VIEW

SIDE VIEW

VIEW

FRONT

SIDE

SCALE 1 : 10

SCALE 1 : 10

ASSEMBLYSCALE

VIEW 1 : 6

ASSEMBLY

VIEW

SCALE 11 :: 10

10

SCALE 11 :: 10

10

SCALE

SCALE

SCALE 11 :: 66

SCALE

FRONT

VIEW

SIDE

VIEW

B

FRONT VIEW

ASSEMBLY

SIDE VIEW

ASSEMBLY VIEW

VIEW

SCALE

1

:

10

SCALE

1

:

10

SCALE 1FRONT

: 10 VIEW

SCALE

11 :: 66

SCALE 1 SIDE

: 10 VIEW

SCALE

NOTE:

ISSUED BY: SCHLETTER INC. - PROPRIETARY

AND CONFIDENTIAL

ASSEMBLY

VIEW

PARTS LIST

All rights reserved. Reproduction of any kind only with the express,

written1consent

SCALE

: 10 of the Co: Schletter Inc.

SCALE 1 :1.10MAXIMUM COMBINER BOX PLUS

SCALE 1DESCRIPTION

:6

ITEM QTY PART NUMBER

B

BB

B

B

B

B

MATERIAL

MASS

CREATION DATE:

kg/m or kg/sq m: TOLERANCES: MATERIAL:

RT PART #:

lbs. PER KIT

8/5/2013

NOTE:

1

1 143008-000

Post, 8, Custom, Galvanized

SAE J2340

ISSUED BY: SCHLETTER INC. - PROPRIETARY AND CONFIDENTIALCONTENTS WEIGHT = 100

PARTS LIST

CHECKED DATE:

2. PARTS

REFLECTS1.2MAXIMUM

KITS, AS COMBINER

AllISSUED

rights reserved.

Reproduction

of any

kind onlyFRONT

with the

express,

written consent of the Co: Schletter

Inc. LIST

VIEW

SIDE

VIEW

NOTE:

NOTE:

ISSUED

BY: SCHLETTER

SCHLETTER

INC.

PROPRIETARY

AND

CONFIDENTIAL

BY:

INC.

-- PROPRIETARY

AND

CONFIDENTIAL

2

2BOX

123001-001

Rail, DN0, Custom

6105-T5

PLUS

WEIGHT:

ASSEMBLY VIEW

PARTS LIST

LIST

PARTS

ITEM QTY PART NUMBER

MATERIAL

DESCRIPTION

MASS

CREATION

DATE:

All rights

rights

reserved.

Reproduction

any kind

kind

only with

with

the

express,

written consent

the or

Co:

Schletter

Inc.

All

Reproduction

only

the

express,

the

Co:

Schletter

OLD

PART # : ofof any

DRAWN

BY:reserved.

SHOWNSCALE

ABOVE

kg/sq

m: Inc.

TOLERANCES:

MATERIAL:

RT

PART

#: written

MAXIMUM

COMBINER

BOX

PLUS

SCALE

1consent

: 10 ofofkg/m

COMBINER

BOX

PLUS

1 :1.1.10MAXIMUM

2lbs.000009-555

Angle,

40x40,

T=4, L=200, 2 Slots 41x11mm1 : 6

6105-T5

0.157MATERIAL

kg

CONTENTS

WEIGHT

=3 100

PER KIT

ITEM QTY

PART

NUMBER

QTY PART

DESCRIPTION

MASS

ITEM

MATERIAL

DESCRIPTION

MASS

1 NUMBER

1 143008-000 SCALE

Post, 8, Custom,

Galvanized

SAE J2340

Dillon.HurleyTITLECREATION

CREATIONDATE:

DATE: 8/5/2013

/ PROJECT

/ CUSTOMER:

DRAWN BY:

BY: CUSTOMER:

DRAWN

STATUS:

kg/m

or

kg/sq

m:

TOLERANCES:

MATERIAL:

RT

PART

#:

kg/m

or

kg/sq

m:

NOTE:

TOLERANCES:

MATERIAL:

RT

PART

#:

ISSUED

BY:

SCHLETTER

INC.

PROPRIETARY

AND

CONFIDENTIAL

4

4

119025-00200

Threaded

Rod,

3/8"-16

UNC,

304

SS,

Grade

B8,

L=200mm

304

SS

0.109

CONTENTS

WEIGHT

=

100

lbs.

PER

KIT

CONTENTS

100REFLECTS

lbs. PER KIT2 KITS, AS

A

A

CHECKED

DATE:

2.WEIGHT

PARTS =LIST

NOTE:

8/5/2013

ISSUED

BY: SCHLETTER

INC. - PROPRIETARY AND

CONFIDENTIAL

8/5/2013

PARTS

LIST

143008-000

Post, 8,

8, Custom,

Custom,

Galvanized

SAEkg

J2340 6105-T5

11

11 143008-000

Post,

SAE

J2340

WorkInProgress

Dillon.Hurley

2

2 123001-001

Rail, Galvanized

DN0,

Custom

Dillon.Hurley

WEIGHT:

CHECKED: All rights reserved.

Reproduction of any kind only with the express, written

consent of the Co: Schletter Inc.

PARTS

LIST

1.

MAXIMUM

BOX

PLUS

000000-000

MFG APPROVAL DATE:

TORQUE:

5

8AS

0.015 kg

Flange,

Serrated,

3/8"-16

UNC,

316 SS

316 SS

All rights

reserved.

Reproduction of any OLD

kind only

with

express, written consent of the Co:

Schletter Inc.

CHECKEDDATE:

DATE:

2. PARTS

PARTS

LIST

REFLECTS

KITS,

AS943912-001

CHECKED

2.

REFLECTS

22 KITS,

PART

# the

: WEIGHT:

SHOWN

ABOVECOMBINER

MFG:

1.LIST

MAXIMUM

COMBINER

BOX

PLUS22 Nut,

ITEM

PART

NUMBER

MATERIAL

DESCRIPTION

MASS

123001-001

Rail,

DN0,

Custom

6105-T5 6105-T5

22 123001-001

Rail,

DN0,

Custom

3 QTY

2 000009-555

Angle, 40x40, T=4, L=200,

2 Slots 41x11mm 6105-T5

0.157

kg

WEIGHT: kg/m or kg/sq m: TOLERANCES:

CHECKED: DRAWN BY:

CHECKED:

CREATION DATE:

ITEM

PART

NUMBER

MATERIAL

QTY

DESCRIPTION

MASS

NOTE:

MATERIAL:

RT

PART

#:

CUSTOMER:

M6

AND

1/4"

BOLT

TORQUE

IS

6

N-M

(4.5

FT-LBS)

CREATION

DATE:

ISSUED

BY:

SCHLETTER

INC.

PROPRIETARY

AND

CONFIDENTIAL

CONTENTS

WEIGHT

=

100

lbs.

PER

KIT

6

4

943919-126

3/8"

16

UNC,

ASME-B18.2.2,

316

SS

Nut,

Square,

316

SS

0.013

kg

DRAWN

BY:

OLD

PART

#

:

OLD

PART

#

:

TITLE

/

PROJECT

/

CUSTOMER:

SHOWN

ABOVE

kg/m or kg/sq m: TOLERANCES: MATERIAL:

SHOWN

ABOVE

RT PART #:

8/5/2013

143008-000

Post,

Custom,

Galvanized

SAE

J2340

WEIGHT = 100 lbs. PER KIT33 22 000009-555

000009-555

Angle, 40x40,

40x40,

T=4,8,

L=200,

Slots

41x11mm

6105-T5

0.157 kg

kg 0.109 kg

Angle,

T=4,

Slots

41x11mm

0.157

Dillon.Hurley

411

411 119025-00200

Threaded

Rod,223/8"-16

UNC, 304 SS,PARTS

Grade LIST

B8,6105-T5

L=200mm 304

A STATUS:

A

Assembly

Combiner

Box Mount,

M10

All Directions,

rights reserved.

Reproduction

of any

kind only with the express, written consent

the Co:

Inc.

M8ofAND

5/16"Schletter

BOLT TORQUE

ISCONTENTS

14 N-M (10.5 FT-LBS)

8/5/2013

143008-000

Post,

8,L=200,

Custom,

Galvanized

SAESS

J2340

CUSTOMER:

CUSTOMER:

Dillon.Hurley

WorkInProgress

1.LIST

MAXIMUM

BOX PLUS

ENG APPROVAL

DATE:

7 COMBINER

4 2943914-010

0.013 kg

Nut,

Square,

M10,

DINThreaded

557, 316

SS

316 SSB8,

CHECKED

DATE: // PROJECT

2. PARTS

TITLE

PROJECT

CUSTOMER:

TITLE

// CUSTOMER:

STATUS: CHECKED:

APPROVED:

ITEM

PART

NUMBER

QTY

DESCRIPTION

MASS

123001-001

Rail,

DN0,

6105-T5

119025-00200

Rod,

3/8"-16

UNC,

304 SS,

SS,

Grade

L=200mm

304 SS

SS

0.109 kg

kgMATERIAL

44

44 119025-00200

Threaded

Rod,

UNC,

304

Grade

B8,

L=200mm

304

CHECKED

DATE:DATE:

WEIGHT:

000000-000

MFG APPROVAL

PARTS

LIST REFLECTS

REFLECTS

2 KITS,

KITS, AS

AS

522

822 943912-001

0.015

M10 AND

BOLT TORQUE

ISTORQUE:

302.N-M

(23 FT-LBS)

CREATION

DATE:

Nut,

Flange,

Serrated,

3/8"-16

UNC,

316

SS

316

SS 0.109

AA STATUS:

AA kg

# REVISION

BY DATE

DRAWN BY:

MFG:

123001-001

Rail,3/8"-16

DN0, Custom

Custom

6105-T5

kg/m or kg/sq

m: 3/8"

TOLERANCES:

MATERIAL:

RT PART

#:

WorkInProgress

WEIGHT:

CHECKED:

WorkInProgress

CONTENTS

WEIGHT

= 100

lbs.

PER

KIT

8 IS 6 N-M

4 943921-010

Washer,

304

SS

316

SS 41x11mm 0.004 kg

OLD

ABOVE

8/5/2013

M12 AND 1/2" BOLTTORQUE:

TORQUE ISSHOWN

50

FT-LBS)

M6N-M

AND(371/4"

BOLT TORQUE

(4.5

FT-LBS)

1125,

1 Flange,

143008-000

Post,

8,UNC,

Custom,

Galvanized

SAE

336 M10,

224 DIN

000009-555

Angle,

40x40,

T=4,

L=200,

22ASME-B18.2.2,

Slots

6105-T5

0.157

000000-000

MFG

APPROVALDATE:

DATE:

Dillon.Hurley

TORQUE:

943912-001

0.015

kg J2340

000000-000

APPROVAL

Nut,

Flange,

Serrated,

3/8"-16

316

SS

316

SS

55

88 943912-001

kg

Nut,

Serrated,

3/8"-16

316

SS

PART NUMBER:

OLD PART

PART ## ::

943919-126

3/8"

16

UNC,

316 316

SS SS

Nut,

Square,

316

SS 0.015

0.013

SIZE: MFG

CROWN:

SHOWN

ABOVE

ASSEMBLY NUMBER

MFG:

MFG:

000009-555

Angle,

40x40,

T=4,-UNC,

L=200,

Slots

41x11mm

6105-T5

0.157 kg

kg

CUSTOMER:

CHECKED

DATE: / PROJECT

2.

PARTS

LIST

REFLECTS

2

KITS,

AS

9

4

129010-001

KlickIn,

M10

Polyamide

(Nylon)

0.002

kg

Assembly

Directions,

Combiner

Box

Mount,

M10

TITLE

/

CUSTOMER:

M8

AND

5/16"

BOLT

TORQUE

IS

14

N-M

(10.5

FT-LBS)

M16

AND

5/8"

BOLT

TORQUE

IS

121

N-M

(89

FT-LBS)

CUSTOMER:

STATUS:

M6

AND

1/4"

BOLT

TORQUE

IS

6

N-M

(4.5

FT-LBS)

C

M6

AND

1/4"

BOLT

TORQUE

IS

6

N-M

(4.5

FT-LBS)

NOTE:

000000-000

ISSUED

BY:

SCHLETTER

INC.

PROPRIETARY

AND

CONFIDENTIAL

2

2

123001-001

Rail,

DN0,

Custom

6105-T5

47

44 119025-00200

Rod,

3/8"-16

UNC,

304316

SS,

Grade

L=200mm

304

WEIGHT:

CHECKED:

ENG APPROVAL DATE:

943919-126

3/8"Square,

16 UNC,

UNC,

ASME-B18.2.2,

316

SS

Nut, Square,

Square,Threaded

316

SS PARTS

0.013 kg

kg 0.109

66

44 943919-126

3/8"

-- 16

ASME-B18.2.2,

Nut,

316

SS

0.013

TITLE / PROJECT / CUSTOMER:

943914-010

0.013 kg

Nut,

M10,

DIN 557,

316

SS

316 SS

A

A

APPROVED:

119025-00200

Threaded

3/8"-16

UNC,

SS,SS

Grade B8,

B8,

L=200mm

304

SS

0.109

kg

LIST

WorkInProgress

A STATUS:

A

SUBCONTRACTOR:

ANDwritten

3/4" BOLT

IS

244

N-M

FT-LBS)

M20

M10

AND(180

3/8"

BOLT

IS 30

N-M

(23 FT-LBS) Screw,4Hex Head,

Assembly

Directions,

Combiner

Box #Mount,

Mount,

M10

Assembly

Combiner

Box

M10

M8ofAND

AND

5/16"

BOLT

TORQUE

ISTORQUE

14

N-M10(10.5

(10.5

FT-LBS)

4FT-LBS)

943610-020

M10x20mm,

DIN

933,

304Rod,

SS

304304

SS

0.024

kg

OLD

PART

: of any

BY TORQUE

DATE

All Directions,

rights

reserved.

Reproduction

kind only with the#express,

consent

the Co:

Schletter

Inc.

M8

5/16"

BOLT

TORQUE

IS

14

N-M

REVISION

SHOWN

ABOVE

WorkInProgress ENG

3

2

000009-555

Angle,

40x40,

T=4,

L=200,

2

Slots

41x11mm

6105-T5

0.157

kg

1.

MAXIMUM

COMBINER

BOX

PLUS

ENGAPPROVAL

APPROVALDATE:

DATE:

000000-000

MFG APPROVAL DATE:

TORQUE:

5

8

943912-001

0.015

kg

Nut,

Flange,

Serrated,

3/8"-16

UNC,

316

SS

316

SS

7

4

943914-010

0.013

kg

Nut, Square,

Square,Nut,

M10,

DIN

557,

316125,

SSNUMBER

316 SS

SSDESCRIPTION

7

4 943914-010

Nut,

M10,

DIN

557,

316

SS

316

943921-010

Washer,

M10,

DIN

304 SSUNC, 316 SS

0.004 kg

APPROVED:MFG:

APPROVED:

CUSTOMER:

M12

ANDTORQUE

1/2" BOLT

TORQUE

ISFT-LBS)

50 N-M (37 FT-LBS)

AREA:

1PART

000000-000

MFG APPROVAL

DATE:

58

84 943912-001

ITEM

PART

MATERIAL

Flange,

Serrated,

3/8"-16

316 SS 0.013 kg 0.015

SHEET:

OF NUMBER:

SCALE: AS SHOWN

QTY

M10m:

AND TORQUE:

3/8"

BOLT

TORQUE

ISTORQUE

30 N-M

N-M (23

(23

M10

AND

3/8"

IS

30

CREATION

DATE:

SIZE:

CROWN:

BY DATE

DATE

ASSEMBLY

NUMBER

REVISION

MFG:

## REVISION

BY

TITLE

/ PROJECT

/ 1CUSTOMER:

DRAWN

BY:

M6BOLT

AND

1/4"

ISISCONTENTS

6FT-LBS)

N-MN-M

(4.5 FT-LBS)

kg/m or kg/sq

TOLERANCES:

MATERIAL:

RT PART

#:

4 Washer,

4KIT119025-00200

Threaded

Rod, 3/8"-16

UNC, 304316

SS,316

Grade

L=200mm

304

0.109 kg

943919-126

SS

Nut,

Square,

3/8"

-- 16

SS

WEIGHT

=966100 44lbs.129010-001

PER

943921-010

Washer,

M10,

DIN

125,

SS

SS B8, 316

0.004

kgSS 0.013

88

44 943921-010

M10,

DIN

SS

SS

kg

A STATUS:

KlickIn,

M10304

Polyamide

(Nylon)

0.002 kg

M16

ANDTORQUE

5/8"BOLT

BOLT

TORQUE

121

FT-LBS)

M6BOLT

AND

1/4"

BOLT

IS26FT-LBS)

N-M (4.5(89

FT-LBS)

4

3 Box

1 Post,

M12 AND

AND 1/2"

1/2"

TORQUE

ISTORQUE

50 N-M

N-M (37

(37

8/5/2013

M12

IS

50

C

000000-000

WorkInProgress

943919-126

3/8"143008-000

16 UNC,

UNC, ASME-B18.2.2,

ASME-B18.2.2,

316 316

SSGalvanized

Nut,

Square,

316

SS 0.004

0.013

kg

1125,

1304

8, Custom,

SAE J2340 A

Dillon.Hurley

PART NUMBER:

NUMBER:

SIZE: CROWN:

CROWN:

PART

SIZE:

ASSEMBLYNUMBER

NUMBER

Assembly

Directions,

Combiner

ASSEMBLY

M8BOLT

AND

5/16"

TORQUE

IS FT-LBS)

14

N-M

(10.5

000000-000

DATE: Directions,

ENG

APPROVAL DATE:

SUBCONTRACTOR:

TORQUE:

5 KlickIn,

8AS943912-001

0.015 kg

Assembly

Combiner

Box Mount,

Mount, M10

M10

ANDTORQUE

3/4" BOLT

244

N-M

(180FT-LBS)

FT-LBS)

M20

Nut,

Flange,

Serrated,

3/8"-16

UNC,

316

SS (Nylon)

316

M8BOLT

AND

5/16"

BOLT

TORQUE

IS 14

N-M

(10.5

FT-LBS)

77

943914-010

0.013

Nut,

M10,

DIN

SS

316

129010-001

KlickIn,

M10Screw,

Polyamide

(Nylon)

0.002

kgSS 0.024

99 REFLECTS

44 129010-001

M10

kg

CHECKED

DATE:

10

44 2943610-020

M10x20mm,

933,

304

SSPolyamide

304

2.N-M

PARTS

LIST

KITS,

M16 AND

AND 5/8"

5/8"

BOLT

ISTORQUE

121 N-M

N-M (89

(89

FT-LBS)

M16

IS

121

FT-LBS)

MFG:

APPROVED:

000000-000

CC DATE:MFG APPROVAL

000000-000

ENG APPROVAL

943914-010

0.013 kg

kg

Nut, Square,

Square,

M10,

DIN 557,

557, 316

316DIN

SS

316 SS

SS 0.002

2 Hex 2Head,

123001-001

Rail,

DN0,

Custom

6105-T5

M10

ANDTORQUE

3/8"

ISTORQUE

30

(23

CHECKED:

## REVISION

APPROVED:

M6BOLT

AND

1/4"

BOLT

IS 6FT-LBS)

N-M

(4.5 FT-LBS)

1 OFWEIGHT:

1BY

M10

ANDTORQUE

3/8"

BOLT

TORQUE

ISSHOWN

30FT-LBS)

N-M (23

FT-LBS)

SCALE: AS SHOWN AREA: OLD PART # : SHEET:

SUBCONTRACTOR:

AND 3/4"

3/4"

BOLT

TORQUE

IS

244

N-M

(180

FT-LBS)

M20 AND

SUBCONTRACTOR:

BOLT

IS

244

N-M

(180

M20

6

4

943919-126

3/8"

16

UNC,

ASME-B18.2.2,

316

SS

Nut,

Square,

316

SS

0.013

kg

BY DATE

DATE

REVISION

8

4

943921-010

Washer,

M10,

DIN

125,

304

SS

316

SS

0.004

kg

10

4

943610-020

Screw,

Hex

Head,

M10x20mm,

DIN

933,

304

SS

304

SS

0.024

kg

10

4

943610-020

Screw,

Hex

Head,

M10x20mm,

DIN

933,

304

SS

304

SS

0.024

kg

ABOVE

M12 AND 1/2"

IS TORQUE

50 N-M (37 FT-LBS)

8

4 943921-010

Washer,

125, 304 SS Angle, 40x40, T=4, L=200, 2316

SS41x11mm 0.004 kg

3 M10,

2 DIN

000009-555

6105-T5

PART

SIZE:

CROWN:

Assembly

Directions,

Combiner

Box

Mount,

ASSEMBLY NUMBER

M8BOLT

AND TORQUE

5/16" BOLT

14 N-M (10.5 FT-LBS)

M12 AND 1/2"

BOLT

TORQUE

IS 50 N-M (37ISFT-LBS)

4

1Slots

AREA:

1 M10 3

AREA:

CUSTOMER:

11 OF

SHEET:

OF

SCALE:

ASAPPROVAL

SHOWN

SHEET:

SCALE:

SHOWN

PART NUMBER:

NUMBER:

SIZE:

CROWN:

ENG

DATE:

ASSEMBLY

NUMBER AS

7

4 943914-010

0.013 kg

316 SS

99 2 44 129010-001

KlickIn,

M10Nut, Square, M10, DIN 557, 316 SS

Polyamide

(Nylon)

kg

M16 AND 5/8"

BOLT

IS TORQUE

121 N-M (89

FT-LBS)

TITLE

/ PROJECT

/ 1CUSTOMER:

APPROVED:

C

000000-000

129010-001

KlickIn,

Polyamide

(Nylon)B8,0.002

0.002

kg

4 M104 119025-00200 Threaded Rod, 3/8"-16

UNC,

304 SS, Grade

L=200mm

304 SS

M10

ANDTORQUE

3/8" BOLT

IS 30

N-M 2(23

M16 AND 5/8"

BOLT

TORQUE

IS 121 N-M (89

FT-LBS)

A STATUS:

# REVISION BY DATE

2 FT-LBS)

C

44

33

11

000000-000

WorkInProgress

SUBCONTRACTOR:

BOLT

IS TORQUE

244 N-M (180

M20 AND 3/4"

8

4 943921-010

Washer,

M10, DIN 125, 933,

304 SS

316 SS

0.004 kg

10

44 943610-020

Screw,

M10x20mm,

304

304

SS

M12

ANDTORQUE

1/2" BOLT

IS 50FT-LBS)

N-M (37 FT-LBS)

SUBCONTRACTOR:

BOLT

TORQUE

IS

244 N-M (180

FT-LBS)

M20 AND 3/4"

MFGCROWN:

APPROVAL DATE:

10

943610-020

Screw,5 Hex

Hex 8Head,

Head,

M10x20mm, DIN

DIN

304 SS

SS

304UNC,

SS 316 SS 0.024

0.024 kg

kg

PART NUMBER:

TORQUE:

943912-001

Nut,933,

Flange,

Serrated, 3/8"-16

316 SS

SIZE:

ASSEMBLY NUMBER

MFG:

AREA: 000000-000

SHEET: 1 OF 1

SCALE:

SHOWN

9 FT-LBS)

4 129010-001

KlickIn, M10

Polyamide (Nylon) 0.002 kg

M16 AND 5/8" BOLT TORQUE

IS 121

N-MTORQUE

(89 FT-LBS)

SCALE: AS

AS C

SHOWN AREA:

M6 AND 1/4"

BOLT

IS 26 N-M (4.5

000000-000 SHEET: 1 OF3 1

6

4 943919-126

316 SS

Nut, Square, 3/8" - 16 UNC, ASME-B18.2.2,

316 SS

44

1

SUBCONTRACTOR:

IS 244BOLT

N-M TORQUE

(180 FT-LBS)

M20 AND 3/4" BOLT TORQUE

3 Box Mount, M10

943610-020

Screw, Hex Head, M10x20mm, DIN 933, 304 SS 1

304 SS

0.024 kg

Assembly Directions, Combiner

M8 AND 5/16"

IS2 14 N-M10(10.5 4FT-LBS)

ENG APPROVAL DATE:

7

4

943914-010

Nut,

Square,

M10,

DIN

557,

316

SS

316 SS

APPROVED:

SHEET: 1 OF 1

SCALE: AS SHOWN AREA:

M10 AND 3/8" BOLT TORQUE IS 30 N-M (23 FT-LBS)

# REVISION BY DATE

8

4 943921-010

Washer, M10, DIN 125, 304 SS

316 SS

4

1

M12 AND 1/2" BOLT TORQUE IS 50 N-M (372FT-LBS)

PART NUMBER: 3

SIZE: CROWN:

ASSEMBLY NUMBER

9

4 129010-001

KlickIn, M10

Polyamide (Nylon)

M16 AND 5/8" BOLT TORQUE IS 121 N-M (89 FT-LBS)

C

000000-000

SUBCONTRACTOR:

M20 AND 3/4" BOLT TORQUE IS 244 N-M (180 FT-LBS)

10

4 943610-020

Screw, Hex Head, M10x20mm, DIN 933, 304 SS

304 SS

SHEET: 1 OF 1

SCALE: AS SHOWN AREA:

4

3

2

1

B

DRAWN BY:

Dillon.Hurley

CHECKED:

Attach combiner box to foundation post

ISO

9001:2008

CE

R T I F I C AT I O

N

10/15

ALITY

QU

© Schletter Inc • 1001 Commerce Center Drive • Shelby, North Carolina 28150 • Tel: (888) 608 - 0234 • Fax: (704) 595 - 4210

mail@schletter.us • www.schletter.us

MASS

0.157 kg

0.109 kg

0.015 kg

0.013 kg

0.013 kg

0.004 kg

0.002 kg

0.024 kg

A

I400223

072216

FS UnoTM Ground Mount Installation Manual

Module Mounting

20 mm

1. Position Modules

•

Purlins are positioned according to

module dimensions.

•

End clamps are positioned approximately

20 mm from the end of the purlin.

Position end clamps approximately

20 mm from end of purlin

Modules are positioned on the purlins according

to specified dimensions

2. Secure Modules

•

Verify that the module clamp is fully

engaged on the purlin and that the

module clamp is aligned with the module

frame.

•

Only for modules mounted in

portrait orientation.

•

When mounting modules, please observe

the clamping points specified by

module manufacturer.

•

Torque clamp bolts to 10.5 ft lbs.

•

Use of impact driver is not recommended.

Modules are secured to the purlins

23 mm max.

1.5 mm maximum

middle clamp to

module offset

5 mm max.

Allowable gaps between modules

ALITY

QU

ISO

N

9001:2008

CE

R T I F I C AT I O

© Schletter Inc • 1001 Commerce Center Drive • Shelby, North Carolina 28150 • Tel: (888) 608 - 0234 • Fax: (704) 595 - 4210

mail@schletter.us • www.schletter.us

I400223

072216

11/15

FS UnoTM Ground Mount Installation Manual

Optional Mounting Configurations

A. Rail Sharing Method

1. Position Modules

•

Purlins are positioned according to

module dimensions.

•

Position and secure clamp adapter on

purlin; refer to system specific drawings

to locate connection points.

•

End clamps are positioned approximately

20 mm from the end of the purlin.

Snap clamp adapter into place

as shown on image

20 mm

Position end clamps

approximately 20 mm

from end of purlin

B. Landscape

Secure clamp adapter with

self-drilling screw

Modules positioned using rail sharing method

1. Position Modules

•

Position and secure clamp adapter on

purlin; refer to system specific drawings

to locate connection points.

Modules positioned in landscape orientation

2. Secure Modules

•

•

When mounting modules, please observe

the clamping points specified by

module manufacturer.

•

Torque clamp bolts to 10.5 ft lbs.

•

Use of impact driver is

not recommended.

ALITY

QU

ISO

9001:2008

CE

R T I F I C AT I O

N

12/15

Verify that the module clamp is fully

engaged on the clamp adapter and is

aligned with the module frame.

Modules are positioned on purlins in landscape

according to specified dimensions

If adjustable end

clamps are

provided, slide

attachment on

to desired height.

© Schletter Inc • 1001 Commerce Center Drive • Shelby, North Carolina 28150 • Tel: (888) 608 - 0234 • Fax: (704) 595 - 4210

mail@schletter.us • www.schletter.us

1.5 mm

maximum

middle clamp

to module

offset

I400223

072216

FS UnoTM Ground Mount Installation Manual

Torque Specifications and Tolerances

Systems are specifically designed for each project. Please reference the specific project drawing for allowable tolerances and

recommended torque for each size of bolt used in the system.

In the event of deviation from approved drawings, contact Schletter immediately.

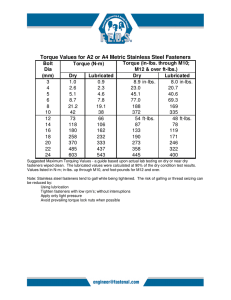

Torx Bolt for Rapid5K Module Clamps

14 N-M

10.5 FT-LBS

M6 and 1/4” Bolt

6 N-M

4.5 FT-LBS

M8 and 5/16” Bolt

14 N-M

10.5 FT-LBS

M10 and 3/8” Bolt

30 N-M

23 FT-LBS

M12 and 1/2” Bolt

50 N-M

37 FT-LBS

M16 and 5/8” Bolt

121 N-M

89 FT-LBS

M20 and 3/4” Bolt

244 N-M

180 FT-LBS

Note: Recommended speed for installation of self-drilling 1/4”

diameter is 1200-1800 RPMS.

Equipment Grounding

•

Many PV installations contain more than one mounting system. Such cases call for electrically bonding each of the different

manufacturers systems. Since individual racks are fully bonded units it is only necessary to connect individual racks together

from one single point to another single point.6 Only use stainless steel hardware when connecting harnesses or jumpers

to the mounting system. Take care to prevent copper wires from directly contacting aluminum surfaces as this will cause

corrosion. For this purpose, Schletter offers a bonding jumper (see page 10).

•

The PV INSTALLER of Schletter’s electrically bonded FS Uno must provide the components necessary for the final

connections to the grounding electrode system. Typically the installation will incorporate a grounding electrode (ground

rod), appropriately sized copper wire, rated wire connectors, and grounding lugs which are rated for this purpose. The PV

INSTALLER must follow all manufacturers’ installation literature. Installation must comply with all applicable NEC/CSA sections

including but not limited to; NEC 250 (Grounding and Bonding), NEC 690 (Solar Photovoltaic Systems), CSA 22.1 (Safety

Standard for Electrical Installations), and all other applicable state, and local electrical code requirements.

•

PV INSTALLER shall be fully responsible for all connections between Schletter’s bonded FS Uno and PV grounding electrode

system.

•

Equipment grounding conductors shall be no less than 14AWG (copper) or 12AWG (aluminum).

•

Equipment grounding conductors can be connected to any exposed metallic portion of rack system provided that:

a.

b.

c.

d.

•

Calculation for overcurrent protection device including but not limited to spacing and wire size is the responsibility of the

installer.

Schletter recommends two bonding jumpers to connect separate systems for redundancy.

ALITY

QU

ISO

9001:2008

CE

R T I F I C AT I O

N

6

connection area is sufficiently sized

dissimilar metals are not in direct contact

connection does not interfere with other components

connection is protected from damage

© Schletter Inc • 1001 Commerce Center Drive • Shelby, North Carolina 28150 • Tel: (888) 608 - 0234 • Fax: (704) 595 - 4210

mail@schletter.us • www.schletter.us

I400223

072216

13/15

FS UnoTM Ground Mount Installation Manual

Maintenance

•

Yearly inspection of system should be conducted to maintain optimal performance.

•

Visually inspect for signs of damage, wear, corrosion, or movement. Replace any affected components immediately.

•

Check for loose wiring

•

Mechanical details of the structure

•

At least 2% of bolted connections must be checked using a calibrated torque wrench. The torque wrench must have a display or be a click type torque wrench.

•

Torque wrench should be set at 50% of the intended tightening torque. Check is successful if the bolt cannot

be loosened.

•

If >10% of the checked bolted connections are loose, the check has to be increased by a factor of five.

•

If more than 10% of connections are still loose, all bolted connections much be checked.

•

Tighten to specified torques

•

Requirements per ASME B107 and AISC

•

WARNING: Risk of death by electric shock

•

Maintenance should only be performed by qualified personnel.

Safety Precautions

Follow proper installation and safety procedures at all times. Edges of parts may be sharp. Follow proper lifting procedures.

For More Information

For more information on the FS Uno, please see:

FS Uno Product Sheet

GAYK Hydraulic Ram Product Sheet

Torx® is a registered trademark of the Camcar Corp. division of Textron Industries.

ALITY

QU

ISO

9001:2008

CE

R T I F I C AT I O

N

14/15

© Schletter Inc • 1001 Commerce Center Drive • Shelby, North Carolina 28150 • Tel: (888) 608 - 0234 • Fax: (704) 595 - 4210

mail@schletter.us • www.schletter.us

I400223

072216

FS UnoTM Ground Mount Installation Manual

Approved Module Manufacturers

Bonding and Grounding

Canadian Solar

CS6X-310|315|320P

CS6X-P-FG

CS6K-P-FG

CS6K-M

CS6K-M AB

CS6P-P

CS6P-P-SD

CS6V-M

Yingli Green Energy

YL300C|295C|290C|285C|280C|275C-30b

YL290D|285D|280D|275D|270D-30b

YL340D|335D|330D|325D|320D|315D-36b

YL275P|270P|265P|260P|255P|250P-29b

YL260P|255P|250P|245P|240P-29b

YL325P|320P|315P|310P|305P|300P-35b

Hanwha Q Cells

Q.PRO BFR G4|G4.1|G4.3

Q.PLUS BFR G4.1

Q.PRO L G4.1

Q.PLUS L G4.1|G4.2

LG

LGxxxN1C-G4

LGxxxN1W-G4

LGxxxS1C-G4

LGxxxS1W-G4

LGxxxN1K-G4

LGxxxN2C-B3

LGxxxN2W-B3

SolarWorld

Sunmodule SW 80 MONO RHA

Sunmodule SW 150 POLY R6A

Sunmodule SW 150 MONO R6A

Sunmodule SW 100 POLY RGP

Sunmodule Plus SW 280-295 MONO

Sunmodule Plus SW 285-300 MONO (5-busbar)

Sunmodule Plus SW 280-290 MONO BLACK

(5-busbar)

Sunmodule Plus SW 275-290 MONO BLACK

Sunmodule Pro-Series SW 260 POLY WOB

Sunmodule Protect SW 275-280 MONO BLACK

Sunmodule SW 320-325|340-350 XL MONO

Trina

TSM-PD14

TSM-PD05

TSM-PD05.08

TSM-PD05.05

TSM-PEG5

TSM-PEG5.07

TSM-PEG14

TSM-PEG40.07

ALITY

QU

ISO

N

9001:2008

CE

R T I F I C AT I O

© Schletter Inc • 1001 Commerce Center Drive • Shelby, North Carolina 28150 • Tel: (888) 608 - 0234 • Fax: (704) 595 - 4210

mail@schletter.us • www.schletter.us

I400223

072216

15/15