Amorphous silicon/crystalline silicon heterojunctions

advertisement

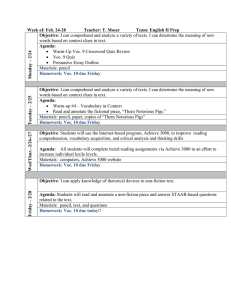

Amorphous silicon/crystalline silicon heterojunctions: The future of high-efficiency silicon solar cells Zachary Holman Arizona State University February 28, 2014 The importance of efficiency Goodrich et al., NREL/PR-6A20-50955 (2011). 2 Record efficiencies 3 Record efficiencies 4 Record efficiencies 5 Diffused-junction solar cells Diffused-junction solar cell No passivation Chemical passivation Front passivation is insulating; contact is made to the emitter by “spiking” the Ag through the passivation layer Field-effect passivation 6 Poor passivation at front and rear contacts limits Voc to ~650 mV Silicon heterojunction solar cells Heterojunction solar cell Chemical passivation Chemical passivation 7 a-Si:H provides excellent passivation of c-Si surface Charge can trickle through aSi:H layers; recombinationactive contacts are displaced from c-Si surface Voc and silicon heterojunction solar cells Lifetime > 1 ms; Voc > 730 mV Excellent Voc is trademark of heterojunctions Descoeudres et al., IEEE JPV 3, 83 (2013). 8 Getting to S-Q: Voc For 100-µm-thick c-Si wafer, S-Q predicts Voc, max = 760-770 mV Commercially available c-Si cells: Voc ≈ 650 mV Record-efficiency PERL c-Si cell: Voc = 706 mV Sanyo Si heterojunction cell: Voc = 750 mV! S. De Wolf, et al., Green 2, 7 (2012). 9 Voc: What next? Increase Voc by squeezing more charge into a smaller volume Can’t reduce recombination further, but can thin wafer, which helps because generation is mostly at the front Generation Generation Generation Recombination Recombination Recombination S.C Baker-Finch, et al., PIP 20, 51 (2011). 10 Voc: What next? τbulk=0.1 ms Voc improves with decreasing wafer thickness for surface recombination velocities < 100 cm/s Silicon heterojunctions best technology for thin wafers Voc (V) Surface recombination gains importance as wafer is thinned 0.74 0.72 0.70 0.68 0.66 0.64 0.62 0.60 0.58 0.56 τbulk=1 ms τbulk=10 ms sf=sb=1 cm/s 10 cm/s 100 cm/s 1000 cm/s 50 100150200 50 100150200 50 100150200 Wafer thickness (um) 11 Record-high Vocs, but… low Jsc and FF Current density (mA/cm2) 40 IMT heterojunction Voc = 727 mV 2 Jsc = 38.9 mA/cm FF = 78.4% Eff. = 22.1% 30 20 UNSW PERL Voc = 706 mV 2 Jsc = 42.7 mA/cm FF = 82.8% Eff. = 25.0% 10 0 0 200 400 600 Voltage (mV) A. Descoeudres et al., IEEE J. Photovoltaics 3, 83 (2013). 12 800 Where does the light go? 100-µm-thick wafer; 20.8% Holman et al., IEEE JPV (submitted). 13 Where does the light go? Reflection from Ag grid and TCO anti-reflection coating UV and blue parasitic absorption in front a-Si:H layers UV and IR parasitic absorption in front TCO; IR parasitic absorption in rear TCO Incomplete trapping of IR light 14 UV and blue parasitic absorption Holman et al., IEEE JPV 2, 7 (2012). 15 15 Parasitic absorption in the front a-Si:H layers 3 All light absorbed in a-Si:H p-layer is lost 70% of light absorbed in a-Si:H i-layer is lost 2 UV loss in TCO is small (0.2 mA/cm2) 1 i-la 12 ye 9 r th 6 ick ne 3 ss 0 (nm ) 16 Jsc loss (mA/cm2 ) 4 0 12 ) 9 m 6 ess (n 3 ckn i h t 0 yer p-la Thinner layers? Current decreases with p-layer thickness, but FF improves Current decreases with i-layer thickness, but Voc improves Overall trend is in favor of Jsc i-layer should be thick enough to provide passivation, but no thicker 0 5 10 15 20 p-layer thickness (nm) Efficiency (%) 74 73 0 5 10 15 20 p-layer thickness (nm) FF (%) 680 20.5 76 20.0 75 19.5 19.0 Jsc (mA/cm2) 690 Jsc = 38.0–0.16 tp-layer 0 5 10 15 20 p-layer thickness (nm) 77 75 700 36 35 76 710 17 37.0 0 5 10 15 i-layer thickness (nm) 0 5 10 15 i-layer thickness (nm) 20.5 74 73 0 5 10 15 20 p-layer thickness (nm) 37.5 36.5 Jsc = 37.9–0.10 ti-layer Efficiency (%) 715 37 FF (%) Voc (mV) 720 720 Voc (mV) Jsc (mA/cm2) 38 710 38.0 730 725 0 5 10 15 i-layer thickness (nm) 20.0 19.5 19.0 18.5 0 5 10 15 i-layer thickness (nm) More transparent materials? n and k both decrease as CO2 is added to plasma: a-Si:H → a-SiOx µc-Si has lower k than a-Si:H Growth is substrate dependent: hard to grow thin, highly crystalline layers on, e.g., a-Si:H FF falls very rapidly 18 18 IR parasitic absorption Holman et al., JAP. 113, 013107 (2013). Barraud et al. SolMat, 115, 151 (2013). Holman et al., SolMat. (in press). Holman et al., Light (submitted). Holman et al., IEEE JPV (submitted). 19 19 IR EQE and reflectance: From ideal to real 100 EQE EQE and and 1-R 1-R (%) (%) 80 60 40 20 0 900 Increasing parasitic absorption 1000 1100 Wavelength (nm) 1200 Parasitic absorption reduces both EQE and R Rsub (i.e., R @ λ=1200 nm) is metric of IR parasitic absorption that can be measured on insulating test structures 20 20 IR parasitic absorption 21 High-mobility hydrogen-doped indium oxide (IO:H) Replace front ITO with highmobility IO:H (µ > 100 cm2/Vs) Less (parasitic) free-carrier absorption for equivalent sheet resistance An ultrathin ITO layer is still required for good contact to screen-printed Ag fingers Koida et al., several papers between 2007-2013. 22 Optimized rear TCO layers 100 90 80 70 60 t 50 Rear ITO thickness (nm) 40 147 65 30 33 20 8 10 0 0 400600800 1000 1100 Wavelength (nm) EQE and 1-reflectance (%) EQE and 1-reflectance (%) 100 90 N 80 N 70 60 -3 ) (cm 50 Rear ITO carrier density 19 2.6 x 10 40 6.5 x 1019 30 1.0 x 1020 20 2.0 x 1020 10 3.0 x 1020 0 400600800 1000 1100 1200 Wavelength (nm) Ideal rear TCO layer is very transparent (to avoid FCA in the TCO), and … >150 nm thick (to supress plasmon excitation in the metal reflector) 23 1200 Record cells 24 Adding a low-refractive-index rear dielectric layer SiNx, 70 nm Si dielectric, variable t, nd Ag For a 300-nm-thick layer of air (nd = 1), only 4% of incident light is absorbed in the Ag layer (rr = 99.8%) 25 Really Rockin’ Rear Reflector (RRRR) 26 RRRR performance It’s really rockin’…but the old reflector was already very good. In industry, probably not worth the cost of the extra processing step. 27 RRRR and CheapRRRR performance Best rear reflector ever? 28 Summary 24 Acknowledgments A. Descoeudres, J. Wu, D. Rowe, D. Alexander, J. Seif, S. De Wolf, U. Kortshagen, C. Ballif European Union 7th Framework Program (FP7/2007-2013), Project '20plµs‘, #256695 Axpo Naturstrom Fonds, Switzerland 29 Sanyo 22 <100 µm 20 18 16 14 >200 µm IMT 2x2 10x10 12.5x12.5 200 0 200 2 200 4 200 6 200 8 201 0 201 2 Efficiency (%) a-Si:H provides excellent surface passivation and charge extraction; recombination-active metal contacts are removed from the wafer surface Heterojunction design enables Voc > 730 mV; further improvements only if wafer is thinned But…heterojunction design compromises FF, Jsc Reduce blue parasitic absorption in a-Si:H layers with thin layers, transparent materials, backcontacted design, or downshifters Reduce IR parasitic absorption with high-mobility TCOs, and “detached” rear metal reflector