Ill SLOTTED PRESSURE SCREENS

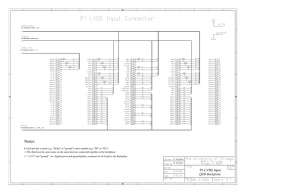

advertisement

. 'l Ill SLOTTED PRESSURE SCREENS Slot width and consistency need to be balanced BY C.M. VlTORl tial positive pulse generated by the leading edge of the foil will increase the passing velocity. The negative pulse generated by the trailing edge of the foil to back-flush the screen plate, results in 0 II Slot width VER THE PAST DECADE there has been a significant quality improvement in secondary fibre stock preparation systems by the use of fine slotted pressure screens. Further advances in screen plate designs over the past few years motivated a trend towards the use of progressively narrower slot widths. Slot widths as narrow as 0.15 mm (0.006 in.) now provide substantial improvements in stock quality, particularly with respect to stickies removal. As suppliers and paper mills strive to further advance stickies removal efficiency, new attention has been focused on fine slotted screens. Recently, particular attention has been directed towards the velocity at which stock passes through the screen slots, or passing velocity as it has been referred to. It is believed that as passing velocity increases, the tendency of conformable stickies to be extruded through the screen slots is also increased resulting in reduced stickies removal efficiency [ 1,2]. Passing velocity may at first be thought of as a process design characteristic. As flow through the screen is increased, it follows that the velocity at which the stock passes through the slots must also increase. However, passing velocity is greatly affected by the hydraulic actions of the rotating element which is designed to align contaminants for ease of removal and backflush the screen plate [ 3 ] . In the case of foil-type blades, the ini- 1441 4 stock being pulled back through the screen plate, creating a negative velocity. The complex hydraulic and mechanical interactions between the foil elements, screen plate, and the stock are II Open area 0.15 mm (0.006 in) 0.20 mm (0.008 in) 0.25 mm (0.010 in) 8,968 mm sq (1 3.9 in sq) 1 1,923 mm sq (1 8.48 in sq) 14,903 mm sq (23.1 in sq) 1550 P A ::: R C C N L T E I BIN 2 BIN 1 BIN 4 BIN 3 BIN 5 I E 100 F F I C % I E N C Y 0 1 2 3 4 5 VELOCITY (mls) PULP & PAPER CANADA 94:12 (1993) 109 not completely understood; therefore, passing velocity may be considered a theoretical or calculated average value based only on gross flow rates through the measured open area of the screen cylinder. A research program was designed to develop a method to compare stickies removal efficiency between various slot widths at various passing velocities. Particular attention was paid to efficiency based on particle sizes rather than just overall efficiency. When analyzing stickies removal, overall efficiency may be misleading if the furnish contains substantial quantities of large or small particles which tend to weight results. It was theorized that different ranges of particle sizes would be removed with different efficiencies as the passing velocity changed; therefore, it would be important to determine efficiency by particle size range. system was shut down and a screen cylinder with a different slot width was installed. The order in which each screen cylinder was tested was also random. Once testing was complete for the three different screen cylinders the feed stream was then diluted to 0.75% consistency and the tests were repeated. Note from the screen operating data listed in Table 11, that approximately Slot width Stock velocity 0.15mm 1 m/s 2 m/s 3 m/s 4 m/s 5 m/s 1 m/s 2 m/s 3 m/s 4 m/s 5 m/s 1 m/s 2 m/s 3 m/s 4 m/s 5 m/s 0.20mm OETHOD Furnish The furnish consisted of 100% overissue newsprint collected from a local publisher and contaminated by adding 4% by weight shredded pressure sensitive adhesive address labels. The furnish was pulped at 6% consistency and ambient temperature for 20 minutes. Pressure screen: A Black Clawson Model 12 centrifugal pressure screen having four foil-shaped rotating elements on the inlet side of the screen cylinder was used for screening stickies from the newsprint furnish. Contoured surface slotted screen cylinders with three different slot widths, 0.15 mm (0.006 in.), 0.20 mm (0.008 in.), and 0.25 mm (0.010 in.) were compared. The screen cylinders are listed in Table I along with their corresponding open areas. Theoretical stock velocities of 1, 2, 3, 4, and 5 metres per second (m/s) were compared at 0.75% and 1.25% screen feed consistency through each screen cylinder. Flow rates about the screen were derived based upon the desired velocity, screen cylinder open area, and a 15% volumetric reject rate from the screen. The screen runs were done first at 1.25% feed consistency in a closed loop by setting the proper feed, accept, and reject flow rates for the desired velocity through the slots based upon the installed screen cylinder’s slot size. Samples from the accept stream were then taken at each of the five stock velocities. The order of setting the flow rates for the different velocities was random. Feed stream samples were taken at the first, third, and fifth velocity settings. Reject stream samples were taken at the third velocity setting. Once sampling for a given screen cylinder was completed, the 110 25 mm equal capacity is obtained under the following conditions; 5 m/s with the 0.15mm slot, 4 m/s with the 0.20-mm slot, and 3 m/s with the 0.25-mm slot. This information helps in comparing efficiency at equal capacity between the three slot widths. Sample preparation: Observation sheets weighing 1 gram were prepared from all feed and accept samples in a Williams Feed flow L/min. Accept flow L/min. 632 1264 1896 2528 31 60 a40 1681 2525 3365 4205 1048 2104 31 57 4209 5257 Reject flow L/min. 537 1075 1612 21 50 2687 71 5 1431 2146 2861 3577 893 1790 2684 3577 4470 95 1 a9 284 378 473 125 250 378 503 628 155 314 473 632 787 ---- 0 0.15 mm Slot 0 0.20 mm Slot y 01 0 2 1 4 3 5 VELOCITY ( d o ) ---- 0 F ..-_.. A 0.25 mm Slot F I %C I E N C PULP & PAPER CANADA 94:12 (1993) 0.15 mm Slot 0 0.20 mm Slot 0 0 hm m v - 0 0 -*-- 4 T442 .I 200-mm x 200-mm sheet mold for image analysis. Great care was taken when removing the sheets from the mold so that the stickies would not be deformed. Very light pressure was used to couch the sheets onto blotter paper to remove them from the sheet mold. The sheets were then air dried instead of the common practice of using heat to dry. This prevented any thermal deformation or bleeding of the stickies within the observation sheets prior to image analysis. Image analysisequipment: A Cambridge Quantimet 520 Image Analysis System with macroscopic detection capabilities was used to count and classify the stickies particles by size. Procedure: Observation sheets from the screen feed and accept samples were analyzed by image analysis and compared to determine screening efficiency by particle size. Six sheets from each feed sample and eight sheets from each accept sample provided sufficient particle counts to be considered significant. As discussed, the feed stream samples were taken from the first, third, and fifth velocity settings for each screen cylinder test. Two observation sheets from each of these feed samples were grouped to form a set of six sheets representing the feed stream for each screen cylinder test. Counting bins for particle size based upon particle area were established to take into account the fact that different ranges of particle sizes were removed by each screen cylinder. The counting bins listed in Table I11 provided sufficient coverage of particle size ranges to compare efficiency based upon particle size between the three screen cylinder slot widths. Data were also compiled from the total black area (total area of the stickies) measured in the samples to compare efficiency on the basis of reduction of black area. Efficiencies were determined by comparing the number of stickies in each bin in the feed sample observation sheets per area measured to the number of stickies in each bin of the accept stream observation sheets per area measured. Calculations were then made according to TAPPI Technical Information Sheet TIS 003-4 to determine cleanliness efficiency, E,. 0 1 4 3 2 5 VELOCITY ( m k ) - 0 0.15 mm Slot - - - - - 0 0.20 mm slot I E loo 01 ___c_ I 0 3 VELOCITY (mls) 2 4 5 1 %loo E ......... A t3 F F F--r I C I .- % -. 0 0.25 mm Slot 0 ---D p-“= .?gA E I 0 3 2 4 5 VELOCITY (mls) 0ESULTS Furnish: Pulping of the newsprint and address labels resulted in a gray furnish containing conformable black sticky particles of various sizes and mostly nonround shapes. When viewed in observation sheets, the black stickies contrast sharply against the gray sheet, resulting in excellent detection by computerized image analysis. Figure 1 shows the average distribution of stickies particles in T443 4 Bin number 1 2 3 4 5 6 7 8 9 1 0 Particle 0.018- 0.071- 0.159- 0.283- 0.442- 0.636- 0.866- 1.130- 1.431- 1.767- Area 0.071 0.159 0.283 0.442 0.636 0.866 1.130 1.431 1.767 2.000 I I PULP & PAPER CANADA 94:12 (1993) 111 .. . the furnish. Particle count bins 6 through 10 (particles 0.636 mm sq. and larger) did not contain large enough quantities of stickies to be considered significant. Efficiency/size 0.75% feed consistency: At 0.75% feed consistency particles in bins 1 through 3 were not removed with any significant efficiency; however, particles in bins 4 and 5 were removed with measurable efficiency. Figures 2 and 3 show the difference in efficiencies between the three slot widths used. A slight trend of decreasing efficiency as velocity increases is evident from the data. The rate of decrease in efficiency is more significant on the larger particles in bin 5. Most significantly, the efficiency is always greater with the smaller slot widths even when compared at equal capacity. The efficiency of removal of particles in bin 4 is only slightly greater with the 0.20-mm slot than with the 0.25-mm slot; however, the efficiency decreases only slightly as the velocity increases resulting in equal or greater efficiency with the smaller slot width. 1.25% feed consistency: Only particles in bin number 1 were too small to be removed with measurable efficiency at 1.25% feed consistency, indicating increased efficiency at the higher consistency. Figures 4 through 7 illustrate the differences in efficiency amongst the three slot widths used for removal of particles in bins 2 through 5. Again, the data indicates a slight trend of decreasing efficiency as the passing velocity is increased. This trend tends to increase as the particle sizes become larger; however, a smaller decrease in efficiency as velocity increases is evident with the 0.15-mm slot than with the 0.20-mm or 0.25." slots. When compared at approximately equal capacities, again the efficiency is greater for the smaller slot widths except between the 0.20-mm and 0.25-mm slots on particles counted in bin number 5. The efficiency of removing the particles in bin 5 is approximately equal between the two slot widths and decreases significantly as the velocity increases. At 5 m/s velocity through the 0.20-mm slot and at 4 m/s through the 0.25-mm slot, capacities are approximately equal (points labelled A and B respectively in Fig. 7). Equal efficiency is obtained with the wider slot in this case; however, the 0.15mm slot still produced higher efficiency than both the other slot widths even when comparing this slot at 5 m/s to the other slots down to 1 m/s velocity. A comparison of the efficiency data for particles in bins 4 and 5 between 0.75% consistency and 1.25% consistency indicates that efficiency is substantially higher at the higher consistency. Efficiency/area: Efficiency as deter112 F 0 I ----. c l I I 0 0.20mm Slot - - .- - - - - F loo 0.15 mm Slot A 0.25 mm Slot 0 €l 0 1 2 0 3 VELOCITY (m/s) mined from the total black area in the samples was greatly affected by the lack of efficient removal of the large quantity of particles in bins 1 through 3 at 0.75% consistency and bin 1 at 1.25%. In fact 95% of the particles are in bins 1 through 3. The results from the 0.75% consistency runs are therefore not reported. The data from the 1.25% consistency run shown in Fig. 8 indicate these efficiencies are also heavily weighted by the large quantity of stickies from bin 1 that were not removed efficiently. The total black area data suffer from excess variance and do not appear to offer a suitable method of showing trends of reduced efficiency as velocity increases. OONCLUSlON Image analysis seems to provide a more informative method to evaluate the effects of screening system designs on efficiency. The technique removes the potential of efficiency data being weighted by too many large or small particles in the samples as can happen 0 4 5 when efficiency is evaluated by gravimetric means that measure only total efficiency. The data indicate that the most productive path to stickies removal efficiency is using a combination of the narrowest screen slot width and highest feed stock consistency practical for that slot width. Although increased passing velocities through the screen slot tend to reduce stickies removal efficiency, higher efficiencies are obtainable by using narrower slot widths at equal capacities even though the velocity may be much higher in the case of the narrower slot width. OEFERENCES 1. LEVIS, S. Removal of Contaminants From Recycled Fibre, High/Low Density Screening. Tech '91 Recycling & Deinking of Newsprint and Fine Papers Course, Technical Section, CPPA, Toronto, ON. February 1991. 2. HEISE, 0. Screening of Foreign Material and Stickies - A Critical Review. TAPPI Papermaker's Conference, Seattle, WA, April 1991. 3. MCCARTHY,C.E. Various Factors Affect Pressure Screen Operation and Capacity, Pulp &f Paper, September 1988. Abstract: Stickies removal efficiency is a primary concern in designing slotted screening systems for recycled paper fibres. A research program compared screening efficiencies based on slot widths and velocities through the slots. Specific attention was paid to the effects of consistencies, velocities, and slot widths on removal of particular particle sizes rather than overall efficiency. These tests were conducted under pilot plant conditions where particle sizes and stock velocities could be more precisely controlled. Reference: VITORI, C.M. Stock velocity and stickies removal efficiency in slotted pressure screens. Pulp Paper Con 94(12): T441-444 (December 1993). Paper presented at the 1st Research Forum on Recycling of the Technical Section, CPPA at Toronto, ON, on October 29 to 31, 1991. Not to be reproduced without permission. Manuscript received June 9, 1991. Revised manuscript approved for publication by the Review Panel March 17, 1993. Keywords: STICKIES, STOCK FLOW, SCREENS, RECLAIMED FIBRES, SCREENING. PULP & PAPER CANADA 94:12 (1993) 4 T444