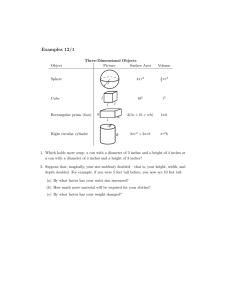

reference catalogue

advertisement