percentage void contamination

advertisement

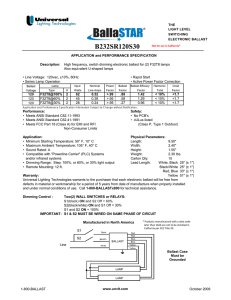

RTSA ALTERNATIVE TESTING METHOD FOR THE MEASUREMENT OF BALLAST FOULING: PERCENTAGE VOID CONTAMINATION Frank Feldman - Manager Ballast Cleaning and Formation, Program Maintenance Services, QR, Mackay Darryl Nissen - Bachelor of Engineering Technology (Civil), Infrastructure North, QR, Rockhampton SUMMARY Economic constraints are driving the need for Queensland Rail (QR) to obtain more cost effective maintenance methods such as better planning of proactive ballast-cleaning cycles. One means to achieve this would be implementing testing methods that quantify the measurement of ballast fouling. Existing tests do not realistically represent the extent of contamination. A contributing factor is that they are based on a sieve analysis test that measures the mass of particles passing different sieve sizes. The Percentage Void Contamination (PVC) is a volume based test, which measures the extent of void fouling for the depth of the ballast profile, and takes into account the different densities of the contaminants. This paper validates the PVC test by evaluating test results and comparing to existing test methods. The PVC is a percentage value calculated by measuring the volume of contaminants (fouling material passing 9.5mm sieve) and dividing by the volume of voids within the existing ballast (retained on 9.5mm sieve). Within QR's coal systems, it has been noted that most of the ballast fouling is due to coal infiltration and ballast breakdown. The volume ratio range of contamination is in the order of 70% - 95% coal and 5% - 30% ballast. Ballast cleaning is an efficient recycling maintenance activity used by QR to maximise ballast life and decrease overall maintenance costs. However, as the extent of fouling is predominantly based on visual inspections by track staff, ballast cleaning is not programmed as effectively as might be possible if it was measured more quantitatively. The volume of voids within new/clean ballast constitutes approximately 45% of the total volume of ballast within track. As ballast becomes fouled its functions are minimised until the level of contamination reaches the bottom side of the sleeper. At this stage ballast loses its resilience, void storage and drainage capabilities and the total substructure then starts to fail. For minimal adverse effects on the superstructure, a minimum live ballast depth of 100mm is required and the maximum limit of contamination should reflect this. When the extent of fouling has reached this limit, the ballast cleaning process needs to be initiated to maximise the cost effectiveness of track maintenance. Therefore the Percentage Void Contamination test needs to be implemented in existing ballast cleaning procedures as a quantitative measure of ballast fouling. 101 Conference on Railway Engineering Wollongong November 10-13 2002 & Darryl Nissen Frank Feldman Alternative Testing Method for the Measurement of Queensland Rail 1 Ballast Fouling : Percentage Void Contamination INTRODUCTION indication of the percentage of void fouling. The 3 density of ballast ranges between 2500kg/m and 3 2800kg/m and the density of coal is between 3 3 800kg/m and 900kg/m . This means that coal As stated by Selig and Waters' (1994), ballast is a select crushed granular material placed below and around the sleepers and performs the fines for the same mass as ballast can occupy following functions: three times the voids Resists vertical, lateral and longitudinal • forces applied to the sleepers to retain remain Provides some of the resiliency and energy absorption for the track; Facilitates maintenance surfacing and and thereby reducing its of the misrepresentation of void not frequently used to locate unacceptable fouled ballast rearrange ballast particles with tamping; locations within Inefficiencies Provides immediate drainage of water in Infrastructure districts. existing test methods have underlined the need for a simple test to measure falling onto the track; the percentage of void contamination for the Reduces pressures from the sleeper • profile, contamination, D-bar and Fouling Index tests are lining operations by the ability to • saturated Because fouling material in the ballast; • ballast bearing capacity. Provides appropriate voids for storage of • the ballast drainage also causes the formation to track in its required position; • in reducing drainage significantly. This reduction in existing ballast profile. This report outlines this bearing area to acceptable stress levels new for the underlying material. procedure and compares results with existing test methods. In a newly constructed state, the volume of voids within the ballast is approximately 45% of the total volume of ballast within track. As ballast becomes foul its functions are minimised until the level of contamination reaches the bottom side of the sleeper. At this stage the total substructure starts to fail. Selig and Waters (1994) have stated that ballast can become fouled from any of the following sources: • Ballast breakdown; • Infiltration from ballast surface; • Concrete sleeper wear; Infiltration • from underlying granular layers; Sub grade infiltration. • Within the coal systems of QR it has been noted that most infiltration of the and ballast ballast fouling is breakdown. by coal This ratio 95% coal to 5% - 30% ballast. Ballast cleaning is an SAMPLE LOCATIONS 2 range of contamination is in the order of 70% - 2.1 efficient NORTH COAST LINE recycling maintenance activity used by QR to maximise ballast life and decrease overall maintenance costs. Existing ballast cleaning programs are formulated by canvassing requirements from local Infrastructure Maintenance staff. The coal­ fouled locations are identified subjectively and therefore not located or justified as consistently as could be achieved by scientific means such as material testing. Existing ballast fouling test methods such as D­ bar and Fouling Index are determined from sieve analysis and are based on mass. These tests do not take into account the different densities of contaminants and therefore do not give a true Figure 2: Map showing Blackwater System 102 Conference on Railway Engineering Wollongong November 10-13 2002 Frank Feldman & Darryl Nissen Alternative Testing Method for the Measurement of Queensland Rail Ballast Fouling: Percentage Void Contamination Eight ballast samples were taken between Bajool No LOCATION FOUL CLEAN and Archer on the North Coast Line on the down SAMPLE SAMPLE track prior to undercutting. These eight locations DATE DATE 10/04/01 are listed below: These samples were tested for sieve analysis and percentage void contamination. Samples were also taken at six locations, shown below, after the Ballast-cleaning Machine (BCM) had screened the contaminated ballast. This testing was undertaken to ensure the efficiency of the BCM. No LOCATION . FOUL CLEAN SAMPLE SAMPLE DATE DATE 1 606.780kmDN 06/03/01 08/03/01 2 608.780kmDN 06/03/01 26/03/01 3 610.660kmDN 06/03/01 26/03/01 4 611.600kmDN 15/03/01 - 5 612.000kmDN 06/03/01 27/03/01 6 612.561kmDN 15/03/01 - 7 614.750kmDN 14/03/01 09/04/01 615.700kmDN 14/03/01 27/03/01 8 1 51. 226kmUP 09/04/01 2 52.050kmUP 09/04/01 10/04/01 3 53.122kmUP 09/04/01 10/04/01 4 54.000kmUP 09/04/01 10/04/01 5 60.305kmUP 19/04/01 20/04/01 6 61.000kmUP 09/04/01 20/04/01 7 77. 154kmDN 17/05/01 17/05/01 8 78.000kmDN 17/05/01 17/05/01 9 81.050kmDN 17/05/01 17/05/01 10 82.428kmDN 17/05/01 17/05/01 11 84.104km 29/05/01 29/05/01 12 103.011kmDN 23/04/01 09/05/01 13 103.011kmUP 23/04/01 30/04/01 14 113.659kmDN 09/05/01 09/05/01 15 114.482km 09/05/01 09/05/01 16 128.000km 09/05/01 17/05/01 Table 3: Sample locatIOns for Central lme 2.3 NEWLANDS BRANCH Samples were taken and tested for sieve analysis on Table 1: Fouled & clean ballast sample the Newlands Branch No Samples were taken and tested between Bajool - LOCATION Marmor at the following locations and dates: No . LOCATION 141.000km 17/05/01 - 143.000km 17/05/01 - 2 DATE DATE 596.418kmUP 07/06/01 - 2 597.399kmUP 07/06/01 - 3 598.402kmUP 07/06/01 - 4 601.740kmUP 29/05/01 - 5 602.769kmUP 29/05/01 - CLEAN SAMPLE DATE 3 1 FOUL SAMPLE - SAMPLE SAMPLE following 17/05/01 60. 000km CLEAN the DATE 1 FOUL at locations and dates: locations Table 4: Sample locations on Newlands branch Table 2: Fouled ballast samples 2.2 CENTRAL LINE Samples were taken and tested for sieve analysis on the Central Line at the following locations and dates: Figure 3: Map showing Newlands Branch 103 Conference on Railway Engineering Wollongong November 10-13 2002 Frank Feldman & Darryl Nissen Alternative Testing Method for the Measurement of Queensland Rail 3 Ballast Fouling : Percentage Void Contamination TESTING METHODOLOGY ballast-cleaning strategies. The Percentage Void Contamination is determined in a compacted 3.1 state to assimilate actual track conditions. CURRENT TEST METHODS There are currently two main methods for testing 3.2.2 the degree of fouling of ballast within the track, Referenced documents the D-bar and Fouling Index. Both methods are AUST STD calculated AS1141 from sieve analysis and therefore based on the mass of the ballast particles and METHODS Methods for sampling and testing aggregates contaminants. AS1141.1 Method 1: Definitions AS1141.2 D-bar 3.1.1 Method 2: Basic testing equipment AS1141.3.1 Method 3.1: Sampling Aggregates D-bar is a number that represents the weighted geometric average of particle sizes Table 5: Samplmg & testmg methods passing through grading sieves from a full sample. These grading sieves are based on the QR ballast 3.2.3 specification. A new Grading A ballast has a • typical D-bar = 36.60mm and ballast is deemed Apparatus A cylindrical water-tight measure made of steel to need replacement when D-bar ::; 10mm. and dimensions conforming - 251 to capacity, these 350mm diameter and 250mm depth; 3.1.2 • Fouling index Metal tamping rod, 16mm diameter, 600mm long with at least one tapered Fouling Index is the summation of the percentage end for a distance of 25mm to a spherical fines passing the 4.75mm sieve and 75 microns shape having a radius of 5mm; sieve (FI = P%4.75 + P% 0075)' fouling ranges for clean ballast (FI The degree of • Balance or scale - ± 5g; 1%) to highly • Sample divider - AS 1141.2; • Scope or shovel. < fouled ( F I � 30%). 3.2.4 Test portions A sample of ballast shall be obtained in accordance with AS 1141.3.1. The location of the selected sample is between the top of sleeper and formation level. Divide the sample by sieving through a 9.5mm sieve. 3.2.5 Procedure a) Sample retained on 9.5mm sieve (ballast) • Test portion sufficient to overfill measure • Determine mass M1 of ballast retained on • Fill one third and compact 25 blows with • Repeat the above step until measure is full • Determine mass M1/1 of ballast in the • Fill with water and determine mass of • Calculate volume of voids V1 by 10% ; 9.5mm sieve; ballast samples 3.2 tamping rod; PERCENTAGE VOID CONTAMINATION 3.2.1 then level the surface; measure; Scope The aim of this test method is to determine the ballast and water M2; percentage of void contamination of a ballast sample taken from the total depth of the ballast profile. This percentage value is calculated by dividing = (M2-M1/1) / density of water. b) Sample passing a 9.5mm sieve the volume of contaminates by the (contaminates) volume of voids within the ballast profile. The • percentage of fouled voids indicates the lack of Determine mass M3 of contaminates passing a 9.5mm sieve; drainage capabilities and loss of resilience of the ballast. This ratio can be used to formulate 104 Conference on Railway Engineering Wollongong November 10-13 2002 Frank Feldman & Darryl Nissen Alternative Testing Method for the Measurement of Ballast Fouling : Percentage Void Contamination Queensland Rail • particles must take place for the volume of Calculate revised mass of contaminants to be greater than the volume of contaminates M3/1 =(M1 /1 xM3)/M 1 ; • voids. Compact as above and determine volume of contaminates (M3/1), V2. The Contamination from the following strength equation: PVC = rate of return is also affected by the difference between the design ballast profile and the existing ballast profile. In areas with low c) Calculate Percentage Void been V2x100N1 soil formations, significantly ballast increased depths have to reduce the bearing pressures on the sub grade. By reducing the ballast depth to the design, the rate of spoil and rate of return are both maximised. Through the cleaning process the screens may reject a small quantity of useful ballast and this will impact upon the rate of return. Therefore the correct size, speed, throw, spacing, angle and flow into the screens must be evaluated to fully maximise the efficiency of the cleaning process. A co-efficient of cleaning efficiency (K) can be added to equation (1) to adjust for this variation. \obI r.1 "'lTf'ln II!d .11 ·lc.1'r.<1 (AQ,!) TI1JY,'!?pl); ..·:;u rre l: 4 In general, this co-efficient will have a value of 0.9 in dry, conditions Figure 5: Shows volume of clean ballast & slightly but fouled depends and on design the depth factors that influence the rate of return. voids versus volume of contaminants Therefore for fouled ballast with PVC less than 3.3 100% the rate of return is outlined in equation (1) RA TE OF RETURN below: The rate of return is the calculated percentage of ballast returned to the track after the ballast cleaning process has been completed. Rate of Return The rate = of return can be influenced by the following factors: • Moisture content of the ballast; • The extent of contamination; • When the fouled ballast has PVC greater than 100% then the rate of return is shown in equation (2): Difference in depth of ballast profile from design; • Rate of Return Efficiency of the ballast-cleaning screens. = the ballast effectively therefore K x (volume of ballast + (volume of ballast When the ballast is saturated the screens cannot clean K x volume of existing ballast profile ..........(1) total 3.4 renewal of the ballast profile may be the only + volume of voids)....(2) volume of contaminants) BALLAST LIFE PREDICTION The Percentage Void contamination will give a option. Theoretically, the volume of the ballast quantitative measure of ballast fouling for the profile should not change until the volume of depth of the ballast profile. contaminants is greater than the volume of voids. Given this measure of fouling, a limit of contamination, a time period When this happens the rate of return is equal to since undercutting and any changes in traffic the volume of ballast plus the volume of voids volume or type, a rate of contamination and a divided by the volume of ballast plus volume of ballast contaminants. life or ballast-cleaning cycle can be predicted for a track section or rail corridor. For QR, the effect of ballast strength on ballast life However as contaminants are concentrated at has been significantly minimised due to the high the bottom of the ballast profile through train source material standards outlined in the QR loading, resurfacing and rainfall, they may start to Ballast Specification. force the ballast particles apart even when the volume of contaminants is less than the volume Tests can be performed every two kilometres of voids. Therefore even in this case there still along a track section to calculate an average may be a slight variation in ballast profile volume PVC (PVCAVE) for any track section. A rate of after cleaning. This pushing apart of ballast contamination (ROC) can then be calculated by 105 Conference on Railway Engineering Wollongong November 10-13 2002 Frank Feldman & Darryl Nissen Alternative Testing Method for the Measurement of Ballast Fouling : Percentage Void Contamination Queensland Rail dividing the average PVC by the actual ballast life which is the maximum recommended limit for the (BLACT) since previous undercutting of the track section. indication of highly fouled ballast. ROC (%/yr) = PVCAVE/BLA CT. . . . .. . . . . . . . . . . . . . ....(3) 4.2 PERCENTAGE VOID CONTAMINATION The test This testing regime needs be completed in three year cycles for coal lines and six year cycles for for the Percentage Void These results show a comparison between PVC freight lines to monitor the rate of contamination. of contaminants passing the 4.75mm sieve and This cycle of testing will ascertain if any changes 9. 5mm sieve, 9.5mm sieve and 19mm sieve and in the rate of contamination are experienced. 19mm sieve and 26.5mm sieve. Testing was Given that the ballast depth under the sleeper is undertaken using the two sieve sizes to identify 250mm and the depth of crib ballast is 230mm, contaminants the maximum PVC at total fouling to the bottom side of sleeper is approximately 50%. results Contamination (PVC) are listed in Appendix A. in order to achieve a better comprehension of the relationship between the If the volume of voids and the volume of contaminants. minimum depth of live ballast under the sleeper for track stability is 100mm then the allowable PVC limit to initiate ballast cleaning is reduced to 4.3 30%. SIEVE ANALYSIS OF RECYCLED BALLAST Recycled ballast sampled from the BCM screens at the locations shown in Appendix B indicates that most particle size distributions are within the specification for a Grading A ballast. Heavily fouled areas show that screened ballast is outside specification but still give a D-bar greater than 26mm. 5 A = D-bar and the Fouling index are based on the Depth of sooper sieve = analysis and Figure 7 confirms the expected trend of D-bar decreasing and Fouling B = Deplh of ballast Umi of Contamination DISCUSSION OF RESULTS Index increasing. IB-l001x IOO/IA B) D-bar v's Figure 6: Shows the PVC Limit of Fouling Index Contamination The allowable ballast life (BLALd or � ballast cleaning cycle can be calculated by dividing the Ql 4 4.1 PVCALL/ROC ......... . .. . . . .. . 0 0 +-------j -g 20.0 +---���-----j Cl 15.0 +-----I-"�----­ I: "§ 10.0 +-----��._---.f 5.0 +------ln�'_F:--j contamination for the track section. = +------:.---j -; 25.0 allowable PVC limit (PVCALL) by the rate of BLALL (yrs) 35.0 -.----.-:----, 30.0 . ... (4) 0.0 +----,-----,---j 0.00 10.00 20.00 30.00 40.00 RESULTS D·bar (mm) SIEVE ANALYSIS OF FOULED Figure 7: Shows D-bar & Fouling Index BALLAST relationship Appendix A shows that all of the sieve analyses from the test sites are outside the particle size The trend between % passing 26.5mm sieve and distribution envelope outlined in the specification the D-bar indicates that as % passing 26.5mm for Grading A ballast. This grading limit failure increases the D-bar decreases. However for a D­ bar of 20mm, % passing 26.5mm sieve ranges indicates that all samples have some degree of fouling. The D -bars are all greater than 10, which have been the lower limit, from 19 to 56. The trend shown in Figure 8 was used for justifying anticipated, when comparing a number of particle cleaning. The Fouling Indices are all less than 30, sizes to just one. 106 Conference on Railway Engineering Wollongong November 10-13 2002 Frank Feldman & Darryl Nissen Alternative Testing Method for the Measurement of Queensland Rail Ballast Fouling : Percentage Void Contamination % Passing 26.5mm v's D_bar D·bar v's PVC 35.00 140.0.,------, 30.00 •• E 25.00 .§. 20.00 � 120.0 +---..... �A �� . 15.00 ----j ------- �. C 10.00 � � .�. • ii: o .a 100.0 +-------j 80.0 +----r-----;---1 60.0 +-------.--,--1 40.0 +---�-A-....hr_ . --- ---j .... 20.0 +------.IoIr-r--...k---j 5.00 0.0 +----,-----,---j 0.00 o 20 40 0.00 80 60 10.00 % Passing 26.5mm Figure 8: Shows general, % passing 26.5mm sieve & Figure 9 shows 20.00 30.00 40.00 D·bar (mm) Figure 10: Shows D-bar & PVC (9.5mm) D-bar relationship In (9.5mm) relationship that as D-bar Results in Appendix A show that two samples with similar particle distribution, D-bar and decreases the PVC increases. Figure 9 also shows that for PVC (9.5mm) of 35%, the D-bar Fouling Index, may have different PVC's by a ranges from 15 to 25mm. This range difference is factor of three. This indicates that the types of significant and can be justified by the variation in contaminates for the two samples are different densities of the fouling material. and this reflects in the make-up of their densities. This means that one sample has a large amount of broken down ballast in its fouling material while D-bar v's PVC � ;; 5: 400.0 350.0 300.0 250.0 200.0 150.0 100.0 50.0 0.0 the other may have a large amount of coal. -.---�.-----, +-----1 Results shown in Appendix B indicate recycled ballast is returned to track with D-bars in the +------=-.---l range between 26 and 36mm. +-------1 +-------'"'--1 +---..L...--e_-----I +----=-==-=__------1 +-------r-.... clean ballast in the range of 26 to 29mm show up to 37% 10.00 20.00 30.00 passing 26.5mm sieve but only 2% passing 9.5mm sieve. +---,----, 0.00 These results were foreseen, as the smallest screen on the Ballast-cleaning Machine is 30mm. D-bars of 40.00 D·bar(mm) .PVC (4.75mm) • PVC (19mm) a PVC (9.5mm) I PVC (26.5mm) Figure 9: Shows D-bar and PVC relationship The PVC passing 9.5mm sieve gave a more relevant perception of fouling as it compared reasonably well with visual inspections. Selig and Waters (1994) have previously validated that material passing 9.5mm sieve are considered to be contaminates. Results in Figure 10, which show PVC above 100 %, indicate that the ballast particles have been forced apart by contaminants. This may have occurred during the continuous process of compaction from loads and vibration from traffic and resurfacing operations. 107 Conference on Railway Engineering Wollongong November 10-13 2002 Frank Feldman & Darryl Nissen Alternative Testing Method for the Measurement of Ballast Fouling: Percentage Void Contamination Queensland Rail 6 It is known that when fouling reaches the bottom CONCLUSION side of sleeper (PVC The ballast sample was taken through the depth of the total ballast profile. This gives a greater starts to fail. Therefore the limit of contamination perception of how much of the ballast is fouled. must be less than 50%. Also the bottom side of For example, if only the ballast below the bottom sleepers will have much higher wear rate due to increased attrition between foul ballast and of sleeper is examined (sampled and tested) and it shows total contamination, one might consider sleeper. For minimal stability and operation of the that it has just been reached in time. However, if the whole profile contamination is depth is tested discovered then and one 50%, in concrete sleeper = track with 250mm of ballast) the substructure superstructure, 75% a minimum ballast depth of 100mm is required, reducing the allowable limit could for contamination or PVC to 30%. When the conclude that the section should have been and testing. extent of fouling has reached this limit, the ballast-cleaning process must be initiated to The BCM returns clean ballast to the track in maintenance. This allowable limit of PVC will undercut several years prior to initial sampling maximise that even in these highly a sieve realistic and relationship actual between void visual contamination. Sampling and testing should be completed every inefficiently at these locations. 9.5mm more inspection the BCM screener was processing fouled ballast on track selection compared with other sieve sizes. It has However D-bars below 30mm have a large % passing 26.5mm sieve. It can be concluded that PVC of The PVC on 9.5mm sieve is the most relevant contaminated areas, D-bars are still above 26. The effectiveness ballast depths. any short falls are always in highly fouled areas. show cost change for different track standards and different most cases in near specification limits, however Results the two kilometres in three year cycles for coal lines gives the and six year cycles for freight lines to fully best comprehend perception of fouling in the ballast. PVC of 50 % the rate of contamination and effectively predict ballast cleaning programmes. shows that the contamination has reached the bottom of sleeper and this compares reasonably FUTURE DIRECTIONS well with visual inspections in concrete sleeper 8 track with 250mm of ballast. Even though it must Continuous be taken into account from visual inspection, analysis over time will result in actual rates of data collection, correlation and contaminates in the top half of the fouled area contamination. are only loosely compacted and therefore this limits will produce better ballast life predictions ballast is still partially live. This is why PVC gives thus a more realistic measures the resurfacing perception of compacted fouling as it volume of rates contaminates. The assumption that material that passes the 9.5mm sieve are defined more of These efficient cycles. return will rates with ballast Further result appropriate cleaning investigation in more and into efficient utilisation of ballast contracts. as contaminates also agrees with Selig and Waters (1994). The PVC is a more relevant than existing test methods as it takes into account the different densities of contaminates, being a volume-based test. Some results of PVC show a percentage greater than 100. This implies that ballast particles must have been forced apart by train traffic vibration, resurfacing and rainfall. This mechanism starts at an early stage as contaminates migrate and concentrate at the bottom of the ballast profile. 7 RECOMMENDATIONS The Percentage Void Contamination test should be implemented into existing ballast cleaning procedures so that the amount and rate of ballast fouling can be measured and proactive ballast­ cleaning cycles is better predicted. 108 Conference on Railway Engineering Wollongong November 10-13 2002 Frank Feldman & Darryl Nissen Alternative Testing Method for the Measurement of Queensland Rail 9 Ballast Fouling: Percentage Void Contamination 3. Jeffs, T, August 1994, Assessment of Ballast REFERENCES 1. Selig, E.T. and Waters, J.M., Geotechnology Management, Telford SeNices Ltd, 4. London. Queensland Rail, BHP QR Civil Engineering, September 2000, Railway Ballast Specification No. - CT.147A 2. Ravitharan, S.S.S, June 1996, Assessment of 5. Ballast Perlormance for Queensland Rail Stage 2, for Research, Monash University, Melbourne. Substructure and Thomas Perlormance 1994, Track BHP Research, Monash QR Track Maintenance University, Formation Melbourne. Engineering, Guidelines and Drainage, April for 1999, Ballast, Workshop Guide Book. 109 Conference on Railway Engineering Wollongong November 10-13 2002 Frank Feldman & Darryl Nissen Alternative Testing Method for the Measurement of Ballast Fouling Percentage Void Contamination Queensland Rail APPEN DIX A 19mm 4.75mm 9.5mm - Sieve analysis and PVC test results 0.075mm O_bar LOCATION 63mm 53mm 37.5mm 26.5mm Maximum (Gradin!l A) 100 100 70 15 5 0.7 Minimum (Grading A) 100 95 35 0 0 0 10.00 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 100 97 98 97 100 99 99 99 99 99 100 100 96 97 100 99 100 99 99 99 99 100 100 100 100 100 100 99 100 100 100 100 96 71 60 54 89 68 64 79 64 71 84 87 60 64 97 89 94 94 72 63 96 97 94 97 78 64 74 77 74 84 93 86 77 27 26 15 67 34 28 38 30 26 47 55 18 28 42 41 43 40 28 29 47 66 56 53 28 29 35 37 29 40 67 56 50 3 0.2 1.3 6.4 2.9 21.95 29.60 29.17 10.88 18.40 26.03 21.86 23.41 27.69 17.03 13.23 28.24 21.95 22.95 24.33 21.06 22.37 22.61 19.77 17.07 9.90 14.55 17.90 21.34 24.66 17.60 20.61 21.23 17.37 11.74 19.92 19.70 596.418U-NCL 597.399U 598.402U 601.740U 602.769U 606.7800 608.7800 610.6600 611.6300 612.0000 612.5610 614.7500 615.7000 51.226U-CL 52.050U 53.122U 54.000U 60.305U 61.000U 77.1540 78.0000 81.0500 82.4280 84.10470 103.0110 103.011U 113.6590 114.4820 128.000 60.000-NB 141.000 143.000 16 9.6 8.1 40 21 12 17 15 9.5 26 30 9.5 16 10 11 14 12 15 21 19 40 28 20 14 15 23 20 15 21 44 29 29 - 10 3.5 5.7 23 17 6.8 9.5 10 4.3 15 20 6.3 12 4.4 4 7.6 6.4 9.8 16 13 30 17 11 12 8.5 20 11 12 15 22 8 11 8.6 2.5 5.2 21 15 4.7 5.7 8.2 3.1 11 16 5 9.8 3.5 3 6.1 5.2 8.7 14 11 26 15 9.4 11 3 14 9 12 13 15 3.4 _ 5.� _ 1 1.3 1.6 0.5 2.6 5.3 0.9 2.5 1.5 0.9 1.8 1.4 2.1 2.4 3.5 6.6 3.8 2.4 2 1 1.5 2 2.3 3.4 3.9 0.6 1 Fouling Index PVC (4.75mm) PVC (9.5mm) PVC (19mm) 13.0 32.7 20.0 122.5 72.2 23.2 173.2 79.4 PVC (26.5mm) ! 30.0 110 11.6 2.7 6.5 27.4 17.9 5.7 7.0 9.8 3.6 13.6 21.3 5.9 12.3 5.0 3.9 7.9 6.6 10.8 16.4 14.5 32.6 18.8 11.8 13.0 4.0 15.5 11.0 14.3 16.4 18.9 4.0 6.8 13.5 26.9 26.8 11.3 35.8 74.9 27.0 41.3 10.4 13.3 16.7 15.5 32.2 31.0 32.6 29.5 13.4 76.4 30.7 46.1 11.9 15.0 19.5 17.7 36.9 35.9 36.8 112.6 39.6 36.9 45.2 35.7 41.9 38.4 49.7 55.7 48.7 146.1 86.3 49.2 52.2 64.0 55.4 80.7 157.5 88.6 145.4 380.2 275.4 212.8 Conference on Railway Engineering Wollongong November 10-13 2002 Frank Feldman & Darryl Nissen Alternative Testing Method for the Measurement of Ballast Fouling Queensland Rail Percentage Void Contamination APPEN D IX B LOCATION - Sieve analysis for cleaned ballast 63mm 53mm 37.5mm 26.5mm O_bar Fouling Index 100 98 53 7 0 0 36.60 0.0 Minimum 100 95 35 0 0 0 10.00 5 arget 19mm 9.5mm 4.75mm 0.075mm Maximum 100 100 70 15 606.7800NCL 100 99 52 6.8 1 0.5 0.4 0.1 35.99 608.7800 100 96 44 7.4 1.4 0.7 0.7 0.3 36.72 1.0 610.6600 100 98 48 9.7 3.3 2.1 1.9 0.3 34.46 2.2 612.0000 100 96 59 14 3.9 2.2 1.8 1.6 31.20 3.4 614.7500 100 97 47 5.6 0.9 0.7 0.7 0.5 36.30 1.2 615.7000 100 96 52 12 2.8 1.4 1.1 0.2 34.57 1.3 51.226U-CL 100 100 79 20 3.2 1.1 1 0.5 30.11 1.5 52.050U 100 100 65 13 2 0.7 0.6 0.4 32.94 1.0 53.122U 100 100 80 18 1.6 0.6 0.6 0.4 30.87 1.0 54.000U 100 100 78 22 1.7 0.3 0.3 0 30.83 0.3 100 97 41 5 4 2.3 0.9 0.9 34.94 1.8 100 97 50 6 1.3 0 0 0 36.96 0.0 100 100 86 23 2.5 1.4 1.4 0.4 29.13 1.8 100 100 93 34 5.2 2.2 2.1 0.4 26.60 2.5 1.7 �0.350U p1.000U i77.1540 178.0000 �1.0500 0.7 30.0 0.5 100 100 92 34 5.5 1.6 1.4 0.3 27.07 82.4280 100 100 93 37 4.9 1.1 1 0.6 26.75 1.6 84.10470 100 100 60 9.7 2.5 1.2 0.9 0.1 33.85 1.0 103.011U 100 97 51 27 0.4 0.3 0.1 0 34.24 0.1 113.6590 100 100 50 6.2 0.8 0.4 0.4 0.2 36.20 0.6 114.4820 100 99 41 3.8 1.8 1.4 1.3 0.5 36.43 1.8 128.000 100 98 69 16 2.2 0.7 0.7 0.2 32.53 . 0.9 111 Conference on Railway Engineering Wollongong November 10-13 2002