Waveguide Simulation Walkthrough

advertisement

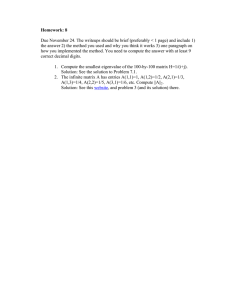

9/13/2016 EE 5303 Electromagnetic Analysis Using Finite‐Difference Time‐Domain Lecture #22 Waveguide Simulation Walkthrough These notes may contain copyrighted material obtained under fair use rules. Distribution of these materials is strictly prohibited Lecture 22 Slide 1 Lecture Outline • Optical Integrated Circuits • Walkthrough – – – – – – – – – – – – Step 0 – Problem Definition Step 1 – Define the problem in MATLAB Step 2 – Compute grid Step 3 – Build device on grid Step 4 – Compute source Step 5 – Initialize Fourier transforms Step 6 – Compute the PML Step 7 – Compute update coefficients Step 8 – Initialize FDTD data arrays Step 9 – Main FDTD loop Step 10 – Compute reflectance and transmittance Step 11 – Produce professional looking results • Results Lecture 22 Slide 2 1 9/13/2016 Optical Integrated Circuits Lecture 22 Slide 3 Integrated Optical Waveguides Stripe waveguide Diffused waveguide Buried‐strip waveguide Buried‐rib waveguide Rib waveguide Strip‐loaded waveguide Lecture 22 Slide 4 2 9/13/2016 Integrated Optical Circuits (Examples) Ginés Lifante, Integrated Photonics Fundamentals, (Wiley, 2003). Lecture 22 Slide 5 Another Fundamental Circuit Element… To interconnect multiple photonic elements within a single optical integrated circuit, it is necessary to turn waveguides. A critical design parameter is the minimum bend radius that will prevent scattering out of the waveguides. Rmin=? Lecture 22 Slide 6 3 9/13/2016 Fabrication of a Rib Waveguide (1 of 6) Typically, we start with a cleaned fused silica substrate. A 4” wafer is common in research labs. Fused silica has n = 1.52. flat 4” wafer Silica substrate Lecture 22 Slide 7 Fabrication of a Rib Waveguide (2 of 6) Second, a layer of high index material is deposited onto the silicon wafer. A common process is plasma enhanced chemical vapor deposition (PECVD). A common high index material is silicon nitride (SiN) which has n = 1.9. Silica substrate with SiN Lecture 22 Slide 8 4 9/13/2016 Fabrication of a Rib Waveguide (3 of 6) Third, a photoresist is spun onto the wafer using a spinner. A common photoresist is PMMA. Silica substrate with SiN and photoresist Lecture 22 Slide 9 Fabrication of a Rib Waveguide (4 of 6) Fourth, the resist is exposed to ultraviolet radiation through a mask in the pattern of the eventual optical integrated circuit. The exposed resist is then washed away leaving behind the unexposed resist. Silica substrate with SiN and developed photoresist Lecture 22 Slide 10 5 9/13/2016 Fabrication of a Rib Waveguide (5 of 6) Fifth, the wafer is etched using a plasma etching process. Both the resist and SiN are etched, but the remaining resist prevent etching of the SiN material directly underneath. Wafer after etching process Lecture 22 Slide 11 Fabrication of a Rib Waveguide (6 of 6) Sixth, the wafer is cleaned by removing the remaining resist. The optical integrated circuit (and our rib waveguide) is complete! Rib Waveguide Lecture 22 Slide 12 6 9/13/2016 Rib Waveguide Example 0 1550 nm w 775 nm h 775 nm a 310 nm neff 1.68 nair w nair 1.00 h a nSiN 1.90 nSiN nSiO2 1.52 nSiO2 Lecture 22 Slide 13 Effective Index Method n2 Vertically Polarized n1 neff,2 Hz mode Requires rigorous full‐vector model E neff,1 neff neff,2 We hope these are very similar results E Requires only a 1D slab model Ez mode Lecture 22 E neff,2 neff,1 neff,2 neff Slide 14 7 9/13/2016 2D Approximation of Optical Integrated Circuits It is possible to very accurately simulate an optical integrated circuit in two dimensions using the effective index method. n1,eff n2,eff Effective indices are best computed by modeling the vertical cross section as a slab waveguide. A simple average index can also produce good results. n1,eff n2,eff Lecture 22 Slide 15 Walkthrough Lecture 22 Slide 16 8 9/13/2016 Step 0: Problem Definition An optical integrated circuit is to be composed of stripe waveguides as shown below and operate at a wavelength of 1550 nm. Determine the minimum bend radius that ensures 90% through a 90° bend. y w x z SiN n 1.90 h Fused silica (SiO2) substrate n 1.52 y What device are you modeling? What is its geometry? What materials is it made from? What do you wish to learn? z ‐‐ stripe waveguide with 90° bend ‐‐ see above ‐‐ see above ‐‐ minimum bend radius for >90% transmission Lecture 22 Slide 17 Step 1: Define Problem – setup MATLAB Initialize MATLAB % Lecture22_bend.m % INITIALIZE MATLAB close all; clc; clear all; % UNITS meters centimeters millimeters inches feet seconds hertz kilohertz megahertz gigahertz = = = = = = = = = = 1; 1e-2 * meters; 1e-3 * meters; 2.54 * centimeters; 12 * inches; 1; 1/seconds; 1e3 * hertz; 1e6 * hertz; 1e9 * hertz; % CONSTANTS e0 = 8.85418782e-12; u0 = 1.25663706e-6; N0 = sqrt(u0/e0); c0 = 299792458 * meters/seconds; Lecture 22 Define Problem % SOURCE lam0 = 1.55 * micrometers; f0 = c0/lam0; k0 = 2*pi/lam0; % RIB nair nsub ncore WAVEGUIDE PARAMETERS = 1.0; = 1.52; = 1.9; w = 0.5 * lam0; h = 0.5 * lam0; x rbend = 20 * micrometers; % GRID nmax = NRES = BUF = NPML = PARAMETERS max([nair nsub ncore]); 10; 5*lam0 * [1 2 1 1]; [40 40 40 40]; z Slide 18 9 9/13/2016 Step 1: Define Problem – reduction to 2D Assumption #1: Effective index method n2 Performing a fully three dimensional simulation using standard FDTD is prohibitively computationally intensive. An alternative is to approximate the 3D circuit as a 2D circuit using the effective index method. For the stripe waveguide, there is no slab waveguide outside of the core. So instead of modeling a slab waveguide, we just estimate the effective by assuming 30% of the energy will reside I the air. nair n1 neff,2 neff,1 No slab! neff,2 No slab! neff,2 0.3nair 0.7 n1 x neff,1 1.7795 z neff,2 1.3640 neff,2 neff,1 neff,2 Lecture 22 Slide 19 Step 1: Define Problem – calculate effective n’s % COMPUTE SLAB GRID Sz = 7*h; dz = lam0/NRES/nmax; Nz = ceil(h/dz); dz = h/Nz; Nz = ceil(Sz/dz); %size of grid %initial resolution %snap grid to h %revised resolution %total number of cells n2 nair n1 % INITIALIZE MATERIALS TO FREE SPACE ERzz = ones(1,Nz); URxx = ones(1,Nz); URyy = ones(1,Nz); % COMPUTE POSITION INDICES nz1 = round(3*h/dz); nz2 = nz1 + round(h/dz) - 1; neff,2 neff,1 No slab! % CLADDING neff2 = 0.3*nair + 0.7*nsub; neff,2 No slab! x 0.3n 0.7 n2 % CORE SLAB ERzz = nair^2 * ones(1,Nz); eff,2 air ERzz(nz1:nz2) = ncore^2; ERzz(nz2+1:Nz) = nsub^2; [Ez,Hx,neff1] = ezmode(URxx,URyy,ERzz,k0*dz); n neff,2 Lecture 22 z neff,1 neff,2 Slide 20 10 9/13/2016 Step 2: Compute Grid – grid construction NPML 3 BUF 3 a x BUF 2 NPML 2 NPML 1 BUF 1 y BUF 4 NPML 4 Lecture 22 Slide 21 Step 2: Compute Grid – grid resolution Compute Initial Grid Resolution x N 10 nmax n2 1.90 y min 1550 nm min nmax N min nmax N 81.6 nm 81.6 nm % DEFAULT RESOLUTION dx = lam0/nmax/NRES; dy = lam0/nmax/NRES; Snap Grid to Critical Dimensions w 9.5 cells x w x 77.5 nm Nx N x w 9.5 cells y w y 77.5 nm Ny N y Lecture 22 round up make odd N x 10 % SNAP GRID TO CRITICAL DIMENSIONS Nx = ceil(w/dx); dx = w/Nx; Ny = ceil(w/dy); dy = w/Ny; round up N y 10 Slide 22 11 9/13/2016 Step 2: Compute Grid – grid size Determine Physical Size a rbend w 2 5.3875 m S x BUF 1 a BUF 2 11.5875 m S y BUF 3 a BUF 4 11.5875 m Calculate Number of Cells Sx NPML 2 230 x S x N x x 17.825 m N x NPML 1 N y NPML 3 3 Sy 2 NPML 4 230 y S y N y y 17.825 m % COMPUTE GRID SIZE a = rbend + w/2; Sx = BUF(1) + a + BUF(2); Nx = ceil(Sx/dx) + NPML(1) + NPML(2); Sx = Nx*dx; Sy = BUF(3) + a + BUF(4); Ny = ceil(Sy/dy) + NPML(3) + NPML(4); Sy = Ny*dy; Lecture 22 Slide 23 Step 3: Build Device – initialize grid Initialize Materials to Free Space xx x, y 1.0 yy x, y 1.0 zz x, y 1.0 % INITIALIZE MATERIALS TO FREE SPACE URxx = ones(Nx,Ny); URyy = ones(Nx,Ny); ERzz = ones(Nx,Ny); Compute Position Indices % COMPUTE START AND STOP INDICES OF BEND WINDOW nx = round(a/dx); nx1 = NPML(1) + round(BUF(1)/dx); nx2 = nx1 + nx - 1; ny = round(a/dy); ny1 = NPML(3) + round(BUF(3)/dx); ny2 = ny1 + ny - 1; x y Lecture 22 Slide 24 12 9/13/2016 Step 3: Build Device – construct bend Compute the Center of Curvature of the Waveguide Bend % COMPUTE CENTER OF CURVATURE x0 = nx2*dx; y0 = ny1*dy; x0 , y0 Construct the Bend % CONSTRUCT BEND [Y,X] = meshgrid(ya,xa); R1 = ((X - x0).^2 + (Y - y0).^2) <= (rbend + w/2)^2; R2 = ((X - x0).^2 + (Y - y0).^2) >= (rbend - w/2)^2; R = R1 .* R2; x y R R1 Lecture 22 R2 Slide 25 Step 3: Build Device – add I/O waveguides Clip the Center Window for a Single 90° Bend % CLIP BEND WINDOW R(1:nx1-1,:) = 0; R(nx2+1:Nx,:) = 0; R(:,1:ny1-1) = 0; R(:,ny2+1:Ny) = 0; Add Input Waveguide % ADD INPUT WAVEGUIDE nx = round(w/dx); nxa = nx1; nxb = nxa + nx - 1; R(nxa:nxb,1:ny1-1) = 1; x y Add Output Waveguide % ADD OUTPUT WAVEGUIDE ny = round(w/dy); nya = ny2 - ny + 1; nyb = ny2; R(nx2+1:Nx,nya:nyb) = 1; Lecture 22 Slide 26 13 9/13/2016 Step 3: Build Device – convert to materials Convert “Binary” Waveguide Structure to Materials in ERzz % BUILD MATERIALS ERzz = neff2^2 + (neff1^2 - neff2^2)*R; Lecture 22 x y Slide 27 Step 4: Compute Source – time step Compute Stable Time Step min min x, y t min 2c0 % COMPUTE STABLE TIME STEP dmin = min([dx dy]); dt = dmin/(2*c0); “Snap” Time Step so One Wave Cycle is an Integer Number of Time Steps % SNAP period Nt dt Lecture 22 TIME STEP SO WAVE PERIOD IS AN INTEGER NUMBER OF STEPS = 1/f0; = ceil(period/dt); = period/Nt; Slide 28 14 9/13/2016 Step 4: Compute Source – extract slab waveguide Determine Position of Source % COMPUTE nx1_src = nx2_src = ny_src = SOURCE POSITION NPML(1) + 1; Nx - NPML(2); NPML(3) + 2; x y Extract the Cross Section of the Waveguide % EXTRACT MATERIALS ACROSS INPUT SLAB WAVEGUIDE urxx = URxx(nx1_src:nx2_src,ny_src); uryy = URyy(nx1_src:nx2_src,ny_src); erzz = ERzz(nx1_src:nx2_src,ny_src); Lecture 22 Slide 29 Step 4: Compute Source – compute fundamental mode Analyze the Waveguide % ANALYZE WAVEGUIDE [Ez_src,Hx_src,neff,EZR,mref] = ezmode(urxx,uryy,erzz,k0*dx); emax = max(abs(Ez_src)); EZR Lecture 22 x y Ez_src & Hx_src Slide 30 15 9/13/2016 Step 4: Compute Source – other source data Compute Delay Between E and H t neff y t 2c0 2 % COMPUTE DELAY delt = 0.5*neff*dy/c0 + dt/2; Compute the Number of FDTD Iterations d S x2 S y2 prop nmax d c0 sim 2 prop % COMPUTE NUMBER OF TIME STEPS d = sqrt(Sx^2 + Sy^2); tprop = nmax*d/c0; tsim = 2*tprop; STEPS = ceil(tsim/dt); STEPS ceil sim t Compute Ramp Function 3 f0 t0 3 t t0 2 exp t t0 r t 1 t t0 % COMPUTE RAMP FUNCTION tau = 3/f0; t0 = 3*tau; ta = [0:STEPS-1]*dt; ramp = exp(-((ta - t0)./tau).^2); ind = find(ta>=t0); ramp(ind) = 1; Lecture 22 Slide 31 Step 5: Initialize Output – Fourier transforms Compute Kernel K 0 exp j 2 t f 0 % KERNEL FOR f0 K = exp(-1i*2*pi*dt*f0); reflection plane Initialize Steady‐State Field Arrays transmission plane % INITIALIZE STEADY-STATE FIELDS Eref = zeros(Nx,1); Etrn = zeros(1,Ny); Compute Position of Record Planes % POSITION OF RECORD PLANES nyref = NPML(3) + 1; nxtrn = Nx - NPML(2); x y Lecture 22 Slide 32 16 9/13/2016 Step 5: Initialize Output – output waveguide Extract Materials at Transmission Record Plane % EXTRACT MATERIALS ny1 = NPML(3) + 1; ny2 = Ny - NPML(4); nx = Nx - NPML(2); urxx = URxx(nx,ny1:ny2); uryy = URyy(nx,ny1:ny2); erzz = ERzz(nx,ny1:ny2); x y Analyze Output Waveguide % ANALYZE OUTPUT WAVEGUIDE [Ez,Hx,n,EZT,mtrn] = ezmode(urxx,uryy,erzz,k0*dy); Lecture 22 Slide 33 Step 6: Compute the PML Compute Size of 2× Grid % NUMBER OF POINTS ON 2X GRID Nx2 = 2*Nx; Ny2 = 2*Ny; Compute PML Parameters % COMPUTE sigx sigx = zeros(Nx2,Ny2); for nx = 1 : 2*NPML(1) nx1 = 2*NPML(1) - nx + 1; sigx(nx1,:) = (0.5*e0/dt)*(nx/2/NPML(1))^3; end for nx = 1 : 2*NPML(2) nx1 = Nx2 - 2*NPML(2) + nx; sigx(nx1,:) = (0.5*e0/dt)*(nx/2/NPML(2))^3; end % COMPUTE sigy sigy = zeros(Nx2,Ny2); for ny = 1 : 2*NPML(3) ny1 = 2*NPML(3) - ny + 1; sigy(:,ny1) = (0.5*e0/dt)*(ny/2/NPML(3))^3; end for ny = 1 : 2*NPML(4) ny1 = Ny2 - 2*NPML(4) + ny; sigy(:,ny1) = (0.5*e0/dt)*(ny/2/NPML(4))^3; end Lecture 22 x x 0 x 3 2t Lx y y y 0 2t Ly x 3 y x x x x Ly Lx Lx y y y y Ly Slide 34 17 9/13/2016 Step 7: Compute Update Coefficients ‐‐ Hx Compute Update Coefficients for Hx Extract the PML parameters from the 2× grid. % COMPTUE HX UPDATE COEFFICIENTS sigHx = sigx(1:2:Nx2,2:2:Ny2); sigHy = sigy(1:2:Nx2,2:2:Ny2); mHx0 = (1/dt) + sigHy/(2*e0); mHx1 = ((1/dt) - sigHy/(2*e0))./mHx0; mHx2 = - c0./URxx./mHx0; mHx3 = - (c0*dt/e0) * sigHx./URxx ./ mHx0; Compute the update coefficients mHx 0 i, j mHx 2 i, j H i, j 1 y t 2 0 mHx1 c0 1 mHx 0 i, j i, j xx mHx 3 i, j i, j 1 t 1 i, j mHx 0 H i, j y 2 0 H i, j c0 t x 1 mHx 0 i, j 0 xx i , j Lecture 22 Slide 35 Step 7: Compute Update Coefficients ‐‐ Hy Compute Update Coefficients for Hy Extract the PML parameters from the 2× grid. % COMPUTE HY UPDATE COEFFICIENTS sigHx = sigx(2:2:Nx2,1:2:Ny2); sigHy = sigy(2:2:Nx2,1:2:Ny2); mHy0 = (1/dt) + sigHx/(2*e0); mHy1 = ((1/dt) - sigHx/(2*e0))./mHy0; mHy2 = - c0./URyy./mHy0; mHy3 = - (c0*dt/e0) * sigHy./URyy ./ mHy0; Compute the update coefficients mHy 0 i, j mHy 2 Lecture 22 i, j H i, j 1 x t 2 0 c0 1 mHy 0 i, j yy i, j mHy1 mHy 3 i, j i, j 1 mHy 0 i, j H i, j x 2 0 H i, j c0 t y 1 mHy 0 1 t i, j 0 yy i , j Slide 36 18 9/13/2016 Step 7: Compute Update Coefficients ‐‐ Dz Compute Update Coefficients for Dz Extract the PML parameters from the 2× grid. % COMPUTE DZ UPDATE COEFFICIENTS sigDx = sigx(1:2:Nx2,1:2:Ny2); sigDy = sigy(1:2:Nx2,1:2:Ny2); mDz0 = (1/dt) + (sigDx + sigDy)/(2*e0) ... + sigDx.*sigDy*(dt/4/e0^2); mDz1 = (1/dt) - (sigDx + sigDy)/(2*e0) ... - sigDx.*sigDy*(dt/4/e0^2); mDz1 = mDz1 ./ mDz0; mDz2 = c0./mDz0; mDz4 = - (dt/e0^2)*sigDx.*sigDy./mDz0; Compute the update coefficients D i, j mDz 0 i, j mDz 2 i, j 1 x t yD 2 0 i, j t D i, j x D i, j y 4 02 c0 mDz 0 mDx1 mDz 4 i, j i, j i, j i, j i, j D i, j D i, j xD yD t 1 x y i, j 2 0 4 02 mDx 0 t 1 t D i , j D i, j x y i, j 2 mDz 0 0 1 Lecture 22 Slide 37 Step 7: Compute Update Coefficients ‐‐ Ez Compute Update Coefficients for Ez mEz1 i, j 1 zz i, j % COMPUTE EZ UPDATE COEFFICIENT mEz1 = 1./ERzz; Lecture 22 Slide 38 19 9/13/2016 Step 8: Initialize FDTD Data Arrays Initialize FDTD Data Arrays % INITIALIZE FIELDS Hx = zeros(Nx,Ny); Hy = zeros(Nx,Ny); Dz = zeros(Nx,Ny); Ez = zeros(Nx,Ny); % INITIALIZE CURL CEx = zeros(Nx,Ny); CEy = zeros(Nx,Ny); CHz = zeros(Nx,Ny); % INITIALIZE INTEGRATION TERMS ICEx = zeros(Nx,Ny); ICEy = zeros(Nx,Ny); IDz = zeros(Nx,Ny); Lecture 22 Slide 39 Step 9: Run FDTD (Main Loop) Compute Curl of E‐Field Correct Curl of E‐Field for TF/SF Update H Update H‐Field Integration Terms Update H‐Field Compute Curl of H‐Field Done? Finished! Correct Curl of H‐Field for TF/SF Update D‐Field Integration Terms Update D Update D‐Field Update E‐Field Update Fourier Transforms Visualize Simulation Lecture 22 Slide 40 20 9/13/2016 Step 9: Main Loop – Curl of E Compute the x‐Component of the Curl of E C E i , j 1 E i , j z t zt y i ,1 i,N y E z E z t t y E i, j x t % Compute CEx for ny = 1 : Ny-1 for nx = 1 : Nx CEx(nx,ny) = (Ez(nx,ny+1) - Ez(nx,ny))/dy; end end for nx = 1 : Nx CEx(nx,Ny) = (Ez(nx,1) - Ez(nx,Ny))/dy; end for j N y for j N y Compute the y‐Component of the Curl of E C yE i, j t E i 1, j E i , j z t z t x 1, j Nx , j E z E z t t x % Compute CEy for nx = 1 : Nx-1 for ny = 1 : Ny CEy(nx,ny) = - (Ez(nx+1,ny) - Ez(nx,ny))/dx; end end for ny = 1 : Ny CEy(Nx,ny) = - (Ez(1,ny) - Ez(Nx,ny))/dx; end for i N x for i N x Lecture 22 Slide 41 Step 9: Main Loop – Correct Curl‐E for TF/SF x Correct CEx for TF/SF Framework C E i , jsrc 1 x t E z i , jsrc t E z i , jsrc 1 t y 1 E y y src i , jsrc z t n y ,src 1 n y ,src We already calculated this. We just need to incorporate this correction term for all values of i. % TF/SF Correction ezsrc = ramp(T) * real(Ez_src*exp(-1i*2*pi*f0*T*dt)); CEx(nx1_src:nx2_src,ny_src-1) = CEx(nx1_src:nx2_src,ny_src-1) - ezsrc/dy; Lecture 22 Slide 42 21 9/13/2016 Step 9: Main Loop – Update H Update Integration Terms % Update Integration Terms ICEx = ICEx + CEx; ICEy = ICEy + CEy; Update Hx and Hy % Update Hx and Hy Hx = mHx1.*Hx + mHx2.*CEx + mHx3.*ICEx; Hy = mHy1.*Hy + mHy2.*CEy + mHy3.*ICEy; Lecture 22 Slide 43 Step 9: Main Loop – Curl of H Compute the z‐Component of the Curl of H CzH i, j t 2t H i , j H i 1, j H i , j H i , j 1 y t t x t t x t t y t 2t 2 2 2 x y H 1, j H N x , j H 1, j H 1, j 1 y t t x t t x t t y t 2t 2 2 2 x y i ,1 i 1,1 H y t H y t H x i ,1 t H x i , Nyt t 2 t 2 t 2 t 2 x y 1,1 N x ,1 1,1 1, N H y t H y t H x t H x yt t 2 t 2 t 2 t 2 x y for i 1 and j 1 for i 1 and j 1 for i 1 and j 1 for i 1 and j 1 % Compute CHz CHz(1,1) = (Hy(1,1) - Hy(Nx,1))/dx ... - (Hx(1,1) - Hx(1,Ny))/dy; for nx = 2 : Nx CHz(nx,1) = (Hy(nx,1) - Hy(nx-1,1))/dx ... - (Hx(nx,1) - Hx(nx,Ny))/dy; end for ny = 2 : Ny CHz(1,ny) = (Hy(1,ny) - Hy(Nx,ny))/dx ... - (Hx(1,ny) - Hx(1,ny-1))/dy; for nx = 2 : Nx CHz(nx,ny) = (Hy(nx,ny) - Hy(nx-1,ny))/dx ... - (Hx(nx,ny) - Hx(nx,ny-1))/dy; end end Lecture 22 Slide 44 22 9/13/2016 Step 9: Main Loop – Correct Curl‐H for TF/SF Correct CHz for TF/SF Framework C H i , jsrc z t t 2 Hy i , jsrc t 2t Hy i 1, jsrc t 2t x i , j 1 i, j H x t srct H x t srct 2 2 y 1 src i , jsrc 1 H x t t 2 y We just need to incorporate this correction term for all values of i. We already calculated this. n y ,src 1 n y ,src x y % TF/SF Correction hxsrc = ramp(T) * real(Hx_src*exp(-1i*2*pi*f0*(T*dt + delt))); CHz(nx1_src:nx2_src,ny_src) = CHz(nx1_src:nx2_src,ny_src) - hxsrc/dy; Lecture 22 Slide 45 Step 9: Main Loop – Update D and E Update Integration Term for D‐Field Update % Update Integration Term IDz = IDz + Dz; Update Dz % Update Dz Dz = mDz1.*Dz + mDz2.*CHz + mDz4.*IDz; Update Ez % Update Ez Ez = mEz1.*Dz; Lecture 22 Slide 46 23 9/13/2016 Step 9: Main Loop – Update Fourier Transforms Update the Fourier Transforms During Last Wave Cycle Eref f i , n y ,ref e 2t f e 2t f 0 j 2 f 0 t m Ez i , n y ,ref Ez nx ,trn , j m 1 f0 Etrn f nx ,trn , j 0 j 2 f 0 t m These are calculated at each frequency and at each point across the entire grid. m 1 f0 reflection plane transmission plane % Update f0 Fourier Transform if T>(STEPS-Nt) Eref = Eref + (K^(T-STEPS+Nt))*Ez(:,nyref); Etrn = Etrn + (K^(T-STEPS+Nt))*Ez(nxtrn,:); end Note: the constants are incorporated after the main loop is complete. % FINISH TRANSFORMS Eref = Eref * (2*dt/period); Etrn = Etrn * (2*dt/period); x y Lecture 22 Slide 47 Step 9: Main Loop – Visualize Simulation Draw the Field Superimposed on the Materials % Update Graphical Status if ~mod(T,10) % draw field draw2d(xa,ya,ERzz,Ez,NPML,0.5); axis equal tight; title([num2str(T) ' of ' num2str(STEPS) ]); x y % force MATLAB to draw graphics drawnow; end Graphics are very slow! This if statement only updates the visualization every 10 iterations. Lecture 22 Slide 48 24 9/13/2016 Step 10: Reflectance and Transmittance Compute Mode Amplitude Coefficients e z Va a V 1e z % CALCULATE MODE AMPLITUDES aref = EZR\Eref(NPML(1)+1:Nx-NPML(2)); atrn = EZT\Etrn(NPML(3)+1:Ny-NPML(4))'; e z reflected field transmitted field x y Compute Transmission and Reflection pref aref ainc 2 ptrn atrn ainc 2 % CALCULATE TRANSMITTANCE AND REFLECTANCE REF = abs(aref(mref))^2; TRN = abs(atrn(mtrn))^2; Lecture 22 Slide 49 Step 11: Report the Results % REPORT TRANSMISSION AND REFLECTION disp([' Reflectance: ' num2str(100*REF,'%4.1f') '%']); disp(['Transmittance: ' num2str(100*TRN,'%4.1f') '%']); Lecture 22 Slide 50 25 9/13/2016 Results Lecture 22 Slide 51 Convergence We first test for convergence with a small grid to determine an appropriate grid resolution for the remaining simulations. 4 T 74.4% 7 T 72.6% 10 T 74.4% NRES = 15: Good choice for doing multiple preliminary simulations. Lecture 22 15 T 69.0% 20 T 70.8% 30 T 74.0% NRES = 30: Good choice as a final simulation. Slide 52 26 9/13/2016 Minimum Bend Radius for 90% Transmission Given /15 grid resolution, we iterate bend radius to find the value that produces greater than 90% transmission. r 10 m T 93.0% Lecture 22 r 8.5 m T 89.9% r 8 m T 86.4% r 5 m T 69.0% r 9 m T 92.8% Slide 53 27