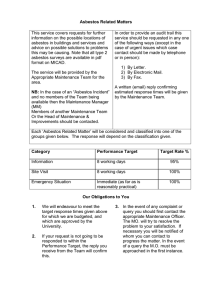

General Guidelines Asbestos RemovAl And disposAl

advertisement