energy benefits of different dedicated outdoor air systems

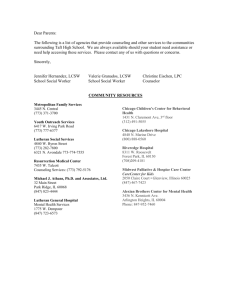

advertisement