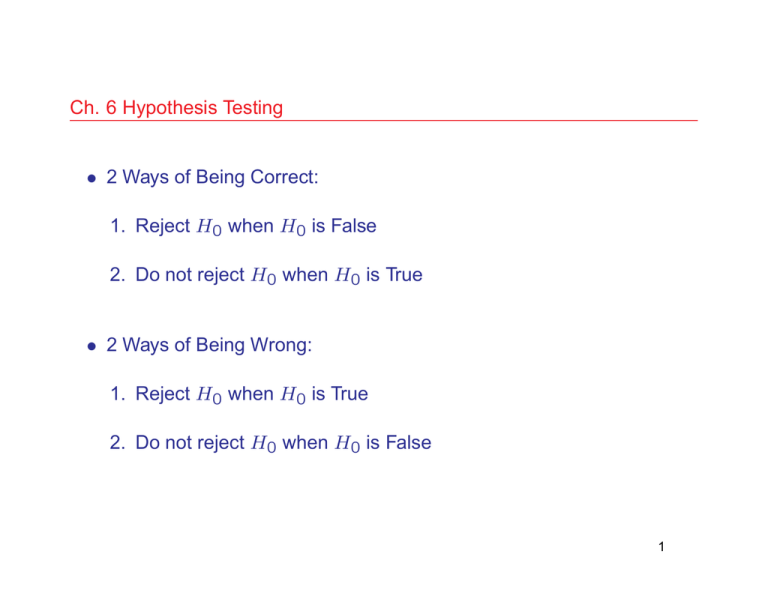

Ch. 6 Hypothesis Testing • 2 Ways of Being Correct: 1. Reject H0

advertisement

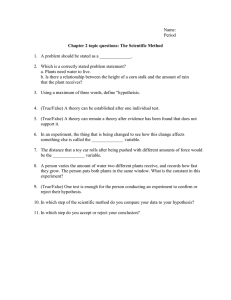

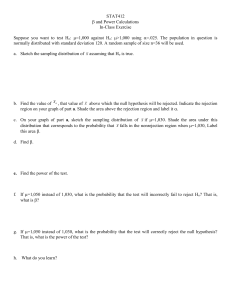

Ch. 6 Hypothesis Testing • 2 Ways of Being Correct: 1. Reject H0 when H0 is False 2. Do not reject H0 when H0 is True • 2 Ways of Being Wrong: 1. Reject H0 when H0 is True 2. Do not reject H0 when H0 is False 1 Type I Error and Level of Significance • A False Alarm. E.g., In quality control, a manufacturing process is monitored; it may be in control or out of control. If it is judged out of control when really in control, this is a Type I error. • α = level of significance α = P (Type I Error) This value is under the control of the experimenter, e.g. .05, .01, etc 2 Type II Error and Power • A Missed Signal. E.g., a manufacturing process is judged to be in control when really out of control. • β = 1 - power β = P (Type II Error) Note that β is often a function of a parameter, since the alternative hypothesis is not simple like the null hypothesis. 3 Type II Error and Power • Example. Single-Sample Acceptance Sampling Plans A simple random sample is selected from a lot for inspection. ◦ n = sample size. ◦ c = acceptance number. ◦ The number of defectives in the sample is denoted by D. ◦ If D > c, then the lot is rejected. ◦ Ideally, only acceptable lots would be accepted, and only unacceptable lots would be rejected. 4 Acceptance Sampling (cont’d) • An unacceptable lot is defined as one whose proportion defective is greater than p0. ◦ probability of accepting the lot: . β(p) = P (D ≤ c) = c X ! n j p (1 − p)n−j j=0 j ◦ p = true proportion nonconforming. • For p > p0, β(p) gives the probability of committing a Type II error. • Power = 1 − β(p) • α = 1 − β(p0). 5 Acceptance Sampling (cont’d) • Suppose an unacceptable lot is defined as one with more than 2% defective, n = 50 and c = 1. • Find the significance level α for the associated hypothesis test. • Find the probability of Type II Error if the true proportion defective is 3%. What is the power of the test for such a lot? 6 Control Charts • Measurements from an in control manufacturing process should be independent and identically distributed random variables with mean µ0 and variance σ 2. • Periodically, samples of size n are taken from a process, and the sample mean is computed. The sample mean should lie within σ µ0 ± 3 √ n most of the time. • If the sample mean lands outside the above control limits, then the process is said to be out of control. • H0 : process is in control • HA : process is out of control 7 Control Charts (cont’d) • α = P (Type I Error) = 1−P σ σ µ0 − 3 √ < X̄ < µ0 + 3 √ n n ! = 1 − P (−3 < Z < 3) = 1 − .9973 = .0027 [Z is standard normal] • Find the probability of Type II Error for the case where the mean has shifted upwards by .2σ (assume n = 9). • β(µ0 + .2σ) = P σ σ µ0 − 3 √ < X̄ < µ0 + 3 √ n n ! = P (−3.6 < Z < 2.4) = .9916 8 • Find P (Type II Error) if the mean has shifted upwards by .8σ. β(µ0 + .8σ) = P (−5.4 < Z < .6) = .7257