Profinity eXact Protein Purification System Manual - Bio-Rad

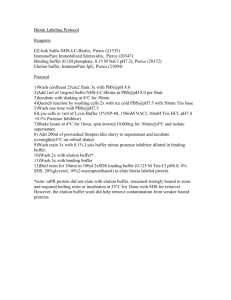

advertisement