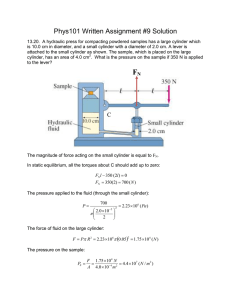

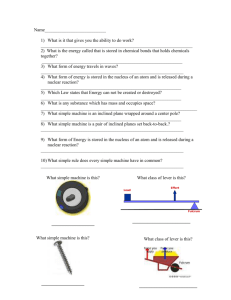

Falcon Locks

advertisement