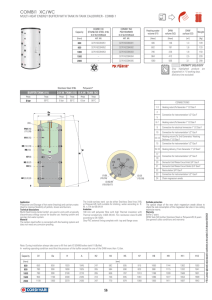

combi2 xc /wc

advertisement

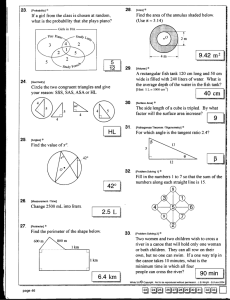

COMBI2 XC /WC MULTI-HEAT ENERGY BUFFER WITH 1 FIX COIL AND TANK IN TANK CALORIFIER - COMBI 2 Capacity COMBI2 XC STAINLESS STEEL 316L D.H.W.STORAGE COMBI2 WC POLYWARM® D.H.W.STORAGE Heating water volume (V1) DHW volume (V2) DHW surface (V2) Lower fix coil volume Lower fix coil Weight surface [liters] ART. NR. ART. NR. [liters] [liters] [m2] [liters] [m2] [Kg] 600 3270162284151 3270162284101 388 146 1,3 18 2,8 131 800 3270162284152 3270162284102 582 191 1,6 20 3,1 160 1000 3270162284153 3270162284103 681 226 1,8 24 3,7 184 1500 -- 3270162284104 952 412 2,5 32 4,9 267 2000 -- 3270162284105 1345 566 3,1 35 5,4 336 PROMPT DELIVERY Grey highlighted products are dispatched in 1-5 working days. (Delivery time excluded) Product component of a complete Sun Solution Solar Thermal System Please refer Sun Solution Cordivari catalogue Stainless Steel 316L BUFFER TANK (V1) CONNECTIONS Heating return/To Generator 1"1/2 Gas F 2 Connection for instrumentation 1/2" Gas F 4 Fix lower heat exchanger inlet 1" Gas F 5 Connection for instrumentation 1/2" Gas F 6-7 Heating return/To Generator 1"1/2 Gas F 8 Fix heat exchanger outlet 1" Gas F 9 Connection for electrical immersion 1"1/2 Gas F Connection for instrumentation 1/2" Gas F 12-13 Heating return/To 2nd Generator/ Heating Delivery 1"1/2 Gas F 15 Connection for instrumentation 1/2" Gas F 17 P.E.D. product planned and produced in conformity to the article 3.3 of directive 92/23/CE 19 Tmax Pmax Tmax Pmax Tmax 3 bar 99°C 6 bar 95°C 6 bar 90°C 12 bar 110°C De Df (24) H12 (16) (17) (18) H11 (15) H9 (12) (13) H8 (10) Heating delivery / From Generator 1"1/2 Gas F Domestic Cold Water Circuit Inlet 3/4" Gas F 21 Domestic Cold Water Circuit Outlet 3/4" Gas F 22 Recirculation 3/4” Gas F 23 Connection for instrumentation 1/2" Gas F 24 Chain magnesium anode V2 H7 (9) Connection for instrumentation 1/2" Gas F 20 EXCHANGER Pmax (19) (20) (23) H6 (8) H4 (5) (21) (2) (5) (9) (10) (15) (17) Application Production and Storage of hot water (heating) and sanitary water. Used to improve flexibility of pellets, stoves and burners. Technical descriptions Multi-Heat Energy tanks Combi2 are used in units with a typically discontinuous energy source for double use: heating system and sanitary hot water system. Material The carbon steel buffer is connected with the heating system and does not need any corrosion proofing. V1 H5 (6) (7) (22) (24) (1) (6) (12) (16) H 16-18 D.H.W. TANK (V2) Tmax A 10 D.H.W. TANK (V2) Pmax BUFFER TANKS 1-3 Polywarm® (3) (7) (13) (18) H3 (4) H2 (1) (2) (3) 0 (4) (8) The inside sanitary tank can be either Stainless Steel Inox 316L or Polywarm®, both suitable for drinking water according to D. M. n.174 del 06.04.04 Heat exchanger 1 fixed carbon steel heat exchanger Insulation 100 mm soft polyester fibre with high Thermal insulation with Thermal conductivity: 0.035 W/mK. Fire resistance class B-s2d0 according to EN 13501. Grey PVC external lining complete with top and flange cover. Cathode protection The special shape of the new chain magnesium anode allows to check the real consumption of the magnesium bar also in low ceiling technician rooms. Warranty Buffer 2 years DHW Tank (V2) (either Stainless Steel or Polywarm®) 5 years See general sales conditions and warranty Note: During installation always take care to fill first tank V2 (DHW) before tank V1 (Buffer). In working operating condition avoid that the pressure of the buffer exceed the one of the DHW more than 1,5 bar. Capacity Df De H A H2 H3 H4 H5 H6 H7 H8 H9 H11 H12 600 650 850 1920 1945 247 260 582 800 790 990 1890 1925 265 695 855 915 1060 1144 1382 1593 278 584 690 762 823 988 1115 1332 1000 790 990 2180 2210 1541 265 284 656 787 953 1013 1188 1309 1588 1500 950 1150 2300 1831 2345 313 336 736 845 1006 1061 1286 1377 1653 2000 1100 1300 2370 1909 2430 347 370 770 879 1001 1060 1300 1411 1687 1943 [liters] [mm] 57 COMBI 1 - 2 - 3 D.H.W. HEAT EXCHANGER TECHNICAL PERFORMANCES COMPLETE HEATED STORAGE VOLUME Capacity Heating Water Volume V1 DHW Volume V2 DHW exchanger surface Max sanitary water produced from 10°C to 45°C with storage at 65°C and boiler on [lt] [lt] [lt] [m2] [lt/min] 600 406 146 1,3 3,0 800 602 191 1,6 3,5 1000 706 226 1,8 4,1 1500 984 412 2,5 5,6 2000 1380 566 3,1 6,8 UPPER PART HEATED STORAGE VOLUME Max sanitary water produced from 10°C to 45°C with storage at 65°C and boiler off Max sanitary water produced from 10°C to 45°C with storage at 65°C and boiler on [lt] [lt/min] 10 lt/min: 239 lt 25 lt/min: 213 lt 10 lt/min: 320 lt 25 lt/min: 280 lt 10 lt/min: 389 lt 25 lt/min: 330 lt 10 lt/min: 753 lt 25 lt/min: 614 lt 10 lt/min: 1083 lt 25 lt/min: 852 lt Max sanitary water produced from 10°C to 45°C with storage at 65°C and boiler off [lt] 10 lt/min: 179 lt 25 lt/min: 160 lt 10 lt/min: 240 lt 25 lt/min: 210 lt 10 lt/min: 291 lt 25 lt/min: 250 lt 10 lt/min: 565 lt 25 lt/min: 461 lt 10 lt/min: 812 lt 25 lt/min: 639 lt 1,86 2,17 2,26 3,36 4,08 POWERS OF FIXED HEAT EXCHANGERS FOR COMBI 2 AND COMBI 3 Thermal output is given in both KW or kcal/h in terms of average temperature difference between primary and secondary circuit, all for a range of primary 3 m3/h. For example, a Combi2 of 1000 liters Capacity with a water flow of 3 m3/h at 80 °C inlet and outlet at 70 °C, has on the storage of water an average temperature of 60 °C, the mean difference of temperature will be (80 +70) / 20-60 = 15 °C and therefore you can exchange up to approximately 32 KW. Output of the lower heat exchangers COMBI 2 e 3 depending on the average DeltaT between primary and accumulation considering (considering flow rate at 3 m3/h) 120 2000 80000 1500 Output [KW] 80 1000 60000 60 800 600 40000 40 Output [KCal/h] 100 20000 20 0 0 0 5 10 15 20 25 30 35 Average Delta T [°C] Output of the upper heat exchangers COMBI 3 depending on the average Delta T between primary and accumulation (considering flow rate at 3 m3/h) 80 2000 70000 70 1500 60000 60 1000 50 50000 800 40 40000 600 30000 30 20000 20 10000 10 0 0 0 5 10 15 20 25 Average Delta T [°C] 59 30 35 Output [KCal/h] Output [KW] 90 BUFFER TANKS 100000