Mid-Fire Raw Glazes for Studio Pottery: Thesis

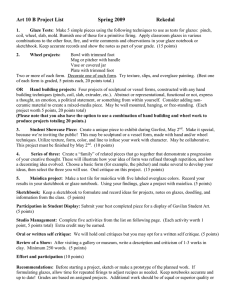

advertisement