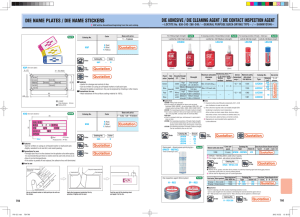

Product Selector

advertisement