Tensile Strength for Different Radii

advertisement

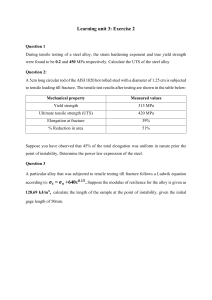

Page 1 Exam 4 Introductory Statistics for Engineers Spring 2012 /150 Name ________________________ 1. (60 points) A study of the effects of 2D and 3D weaving processes on the tensile strengths of synthetic fibers was carried out at the University of Delaware’s Center for Composite Materials. One part of the study was an investigation of the curvature of the weave as a source for the degradation of the mechanical properties of the fibers. A tow is an untwisted bundle of continuous filaments and Vectran is a Registered Trademark for a commercial multifilament yarn spun from a liquid crystal polymer. The data presented below gives the tensile strength of a Vectran tow calculated as the failure load (the mass required to break the fiber) in grams divided by the average linear density of the tow Each set of samples of tow were of a specific radius of curvature, which is stated at the top of the table. Tensile Strength for Different Radii Radius = 1 mm Radius = 2 mm Radius = 3 mm Radius = 5 mm 25.58 24.25 26.76 24.75 23.58 22.52 23.55 25.46 25.09 25.13 24.97 23.26 23.20 25.78 26.86 25.87 26.76 25.66 25.65 26.07 26.33 24.01 24.31 23.62 25.72 25.83 26.03 24.70 Test at a 5% level of significance whether there are any differences in fiber tensile strength associated with the different radii of curvature. State and explain your conclusion. Explain how you reached your conclusion. Compute and report the P- Value of your observed statistic. Now determine by a Bonferroni procedure which, if any, of the radii are significantly different from each other in their effect on fiber tensile strength. What assumptions are necessary for the above Single Factor ANOVA to be valid? Do these assumptions seem to be satisfied by this particular set of data? Explain your answer. Hand in your spreadsheet with the exam. Page 2 Exam 4 Introductory Statistics for Engineers Spring 2012 2. (90 points) Below a material’s elastic limit the relationship between stress (force per unit area) and strain Stress (fractional elongation) follows Hook’s Law. This is expressed by the equation: Strain = , E where E, the Young’s Modulus, is an intrinsic constant of the material. The elastic limit for nickel is about 20 MPa (the unit MPa is a Mega Pascal and is equal to 106 N/m 2 ). The following data was obtained at room temperature for a uniform thickness strand of nickel. Stress in MPa Strain ( Fraction of Elongation ) 1.50 6.391E-06 2.00 1.153E-05 2.50 1.275E-05 3.00 1.412E-05 3.50 1.736E-05 4.00 2.059E-05 4.50 2.273E-05 5.00 2.491E-05 5.50 2.811E-05 6.00 2.966E-05 6.50 3.276E-05 7.00 3.656E-05 7.50 3.779E-05 8.00 4.095E-05 8.50 4.350E-05 9.00 4.543E-05 The error in the applied stress is negligible, but the elongation measurements are subject to error. In Excel perform a linear regression analysis on this data. Your spreadsheet should contain two scatter plots. The first should display the data and the predictions of the linear regression model with the latter drawn as a continuous line. The second should display the residuals plotted versus the control variable. Calculate the lower and upper limits for the 95% confidence intervals requested below. 95% Confidence Interval for Population Slope β1 Population Intercept β 0 The mean strain at a stress of 10 MPa A single measurement of strain at a stress of 10 MPa correlation coefficient = coefficient of determination = Lower Limit Upper Limit Page 3 Exam 4 Introductory Statistics for Engineers Fill in the following Regression ANOVA table as shown below. Degrees of Source Sum of Squares Freedom Spring 2012 Mean Square Linear Model Error Total Observed F score ____________________ At a 5% level of significance, what conclusion do you draw from this ANOVA Table? Comment on how well the linear model fits this data. What does the pattern of residuals indicate about the theoretical model? At a 5% level of significance is it true that the regression intercept is different than 0? From this data construct a 95% confidence interval for the Young’s Modulus of Nickel.