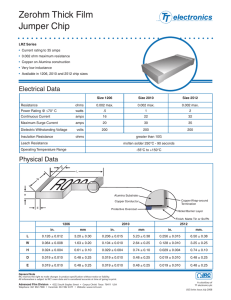

LR(F) - TT Electronics

advertisement

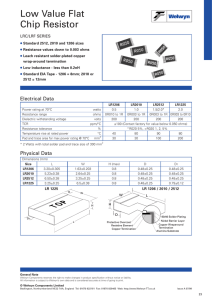

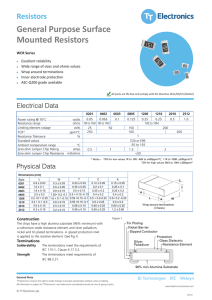

i o` J i oc | bKè ñÇ= = NOLOPLMQ= = NMWMT=^ j = = m~ÖÉ=N Low Value Flat Value LowLow Value Flat Flat Chip Resistor LowChip Value Flat Resistor Chip Resistor Welwyn Components Welwyn Components Chip Resistor Welwyn Components LRC/LRF Series Series •LRC/LRF Standard 2512, 2010 LRC/LRF Seriesand 1206 sizes Resistance Standard 2512, 2010 and2010 sizes •·LRC/LRF values down to1206 0.003 ohmssizes •Series Standard 2512, and 1206 ·•• Leach Resistance values down to 0.003 ohms resistant copper • Resistance values down to 0.003 ohms Standard 2512, solder-plated 2010 and 1206 sizes ·• wrap-around Leach resistant solder-plated copper termination • Leach resistant copper Resistance values downsolder-plated to 0.003 ohms wrap-around termination •• Low inductance - less than 0.2nH wrap-around termination Leach resistant solder-plated copper ·• AEC-Q200 AEC-Q200 Qualified wrap-around termination • Low inductance less than 0.2nH Qualified ·• RoHS compliant and SnPb variants Low inductance - less than 0.2nH • AEC-Q200 Qualified • AEC-Q200 Qualified Electrical Data Electrical Data Electrical Power rating @70°C Data LR1206 0.5 watts watts ohms % Power rating at 170°C Resistance range Resistance ranPgoewer rating at 70°C ohms Resistance tolerance1 nce range Power rating R ates7is0ta°C watts Dielectric withstanding voltage volts TCR ppm/°C Resistance ranDgielectric withstanding voltage ohms TCR ppm/°C Dielectric withTsCtaRnding voltage volts Dielectric volts Resistancewithstand tolerance % T C R p p m /°C Resistanrange ce tolerance Ambient temperature °C Temperature rise at rated power °C Resistance tolTeerm anpceerature rise at rated power % Values 2 Pad and tracerarea for tmax power rating @ 70°C mm Temperaturerise iseataand t ratrace epower d parea owerfor max power rating @°C70°C °C Temperature rated 40 Pad 2 2 Pad and trace max power rating @ 70°C mm300 30 2 Pad / trace area3area *2 Watts with totalfor solder pad and trace size of mm mm LR2010 LR2512 LR2010 LR2512 1 2 LR1206 0.5 1.0 LR2010 1.5/2.0LR2512 * wattsLR1206 0.5R003 to 1R0 1.0 1.5/2.0* LR2010 LR2512 0R010 to 1R 0R003 to 1R 0R003 to 1R <R01: 5, ≥R01: 1, 2, 5 ohms 0.5 0R010 to 1R 1.00R003 to 1R 1.5/0 2R .00*03 to 1R 2 0 0 2 0 0 200 ≥R05: ±100, R025–R047: <+200, R015-R024: <+300, vo0ltRs010 to 1R 200 200 20 0R003 to 1R 0R003 to 1 R0 ±1R01-R014: 00 (Conta<+500, ct facto<R01: ry for<+900 value below 0.050 ohms) ppm/°C 200 ±100 (200 Contact 2fa0c0tory for value below 02.00500 ohms) ≤R005 5%, >R005 1, 2, 5% tacttofa+150 c≤R005 tory fo5%, r valu>R005 e belo1, w 2, 0.0 50 ohms) % ±100 (Con-55 5% 40 80 90 2 ≤R005 5%, >R005 1, °C 40E24 802, 5% 90 preferred 30 30 100 80 90 90 100 mm2 40 30 80 30 30 30 2 100 300 100 LR1206 *2 Watts with total solder pad and trace size of 300 mm 2 Note 1: Contact factory value pad – tolerance combinations outside this range. Note 2: Many values = N x R001 and N x R005 up to N=10 are also *2 Watts with total for solder and trace size of 300 mm available. Note 3: Recommended minimum pad & adjacent trace area for each termination for rated dissipation on FR4 PCB Physical Data Data Physical Physical Data Dimensions (mm) Dimensions (mm) (mm) S ize SDimensions iz e L Size LR1206 LR1206 L LR1206 3.20±0.305 3.20±0.305 1.63±0.201.63±0.20 LR2010 LR2010 3.20±0.305 5.23±0.38 LR2512 LR2512 5.23±0.38 6.50±0.38 6.50±0.38 6.50±0.38 2.64±0.252.64±0.25 H (max) 0.8 0.8 0.8 0.84 3.25±0.253.25±0.25 0.84 LR2010 LR2512 D D D 0.48±0.25 0.48±0.25 0.48±0.25 0.48±0.25 0.48±0.25 0.84 2.64±0.25 0.84 0.84 3.25±0.25 0.48±0.25 0.48±0.25 0.48±0.25 0.48±0.25 0.84 LR 1206 L/R21021006//22501120 / 2512 W W W LR 1206 / 2010 / 2512 L LL H H H LRC/LRF Series H (max) H (max) W W 1.63±0.20 5.23±0.38 i o` J i oc | bKè ñÇ= = NOLOPLMQ= = NMWMT= ^ j = = m~ÖÉ= O Low Value Flat Chip Resistor W L D D D Solder Plating SolderPlating Plating Solder Nickel Barrier Layer Protective Overcoat NickelBarrier Barrier Layer Nickel CopperLayer Wraparound Copper Wraparound Termination Copper Wraparound Termination Alumina Substrate Termination Alumina Substrate ProtectiveOvercoat Overcoat Resistive Element Protective ResistiveElement Element Copper Termination Resistive Copper Termination Copper Termination Recommended Solder Pad Dimensions (mm) A Welwyn Components Alumina Substrate B C A LR1206 2.0 4.0 1.25 LR2010 3.05 6.5 1.5 B General Note General LR2512Note 3.7to make changes in product 7.75 specification without 1.5 Welwyn Components reserves the right notice or liability. Welwyn Components reserves the right to make changes in product specification without notice or liability. All information is subject to Welwyn’s own data and is considered accurate at time of going to print. General Note All information is subject to Welwyn’s own data and is considered accurate at time of going to print. Welwyn Components reserves the right to make changes in product specification without notice or liability. © Welwyn Components Limited · Bedlington, Northumberland NE22 7AA, UK All subject to Welwyn’s own data and is considered accurate at time of going © information Welwyn isComponents Limited · Bedlington, Northumberland NE22 7AA, UK to print. Telephone: +44 (0) 1670 822181 · Facsimile: +44 (0) 1670 829465 · Email: info@welwyn-tt.com (%) · Website: www.welwyn-tt.com Telephone: +44 (0) 1670 822181 · Website: www.welwyn-tt.com AEC-Q200 Table 7 · Facsimile: +44 (0) 1670 829465 · Email: info@welwyn-tt.com General Note Typ. Max. 100 Method © Welwyn Components Limited · Bedlington, Northumberland NE22 (add 7AA,R05) UK (@1R0) C A subsidiary of A subsidiary of TT electronics plc TT electronics plc A subsidiary of TT electronics04.10 plc 04.10 4 Temperature Cycling JESD22 Method JA-104 ©6TT electronics plc Resistance MIL-STD-202 Method 106 Moisture 7 Biased Humidity MIL-STD-202 Method 103 R% 0.25 0.1 R% 0.5 0.2 R% 0.5 0.2 Power Rating TTref electronics reserves the822181 right to·make changes specification without notice or liability. Test 04.10 Telephone: +44 (0) 1670 Facsimile: +44 in (0)product 1670 829465 · Email: info@welwyn-tt.com · Website: www.welwyn-tt.com 80 All3information isHigh subject to TT Exposure electronics’ own data and is considered at time 0.5 of going0.2 to print. Temp. MIL-STD-202 Method accurate 108 R% www.bitechnologies.com www.irctt.com www.welwyn-tt.com 60 40 2.14 23 23 23 Recommended Solder Pad Dimensions (mm) A LR1206 B C A Low Value Flat LR2010Resistor Chip 2.0 4.0 1.25 3.05 6.5 1.5 LRC/LRF Series LR2512 3.7 7.75 1.5 B C ref 3 Typ. (%) 100 R% 0.5 0.2 80 Max. (add R05) (@1R0) 4 Temperature Cycling R% 0.25 0.1 6 Moisture Resistance MIL-STD-202 Method 106 R% 0.5 0.2 7 Biased Humidity MIL-STD-202 Method 103 R% 0.5 0.2 JESD22 Method JA-104 8 Operational Life (Cyclic Load) MIL-STD-202 Method 108 R% 14 R% 0.5 Vibration MIL-STD-202 Method 204 15 Resistance to Soldering Heat MIL-STD-202 Method 210 16 1 0.5 0.05 R% 0.25 Thermal Shock MIL-STD-202 Method 107 J-STD-002 60 40 20 0 R% 0.25 0.05 70 25 Solderability 21 Board Flex AEC-Q200-005 R% 0.5 0.2 Terminal Strength AEC-Q200-006 R% 0.25 0.1 Short Term Overload 6.25 x Pr for 2s R% 0.5 Low Temperature Storage -65°C for 100 hours R% 0.5 Leach Resistance Solder dip at 250°C 90s minimum 150 (°C) Ambient temperature 0.1 18 22 Power Rating AEC-Q200 Table 7 Method Test High Temp. Exposure MIL-STD-202 Method 108 >95% coverage LRC 25 12 2 1 watt LRC 20 10 1 0.w 5 at wat t t LRC 12 06 0.5 25ww atat tt Note: 1. Although 2010 and 2512 sizes have passed temperature cycling and thermal shock, it is in general not recommended that ceramic chips this large be used on FR4 in a severe temperature cycle environment due to the possibility of solder joint fatigue. 2. Full AEC-Q200 qualification applies to ohmic values ≥R01. Ordering Procedure Ordering Procedure Example: LRF2512 at 10 milliohms (hence flip-chip mounted) and 2% tolerance on a reel of 1800 pieces This product has two valid part numbers: LRF2512–R01GW European (Welwyn) Part Number: LRF1206-R02FW (1206, 20 milliohms ±1%, Pb-free) Type Mounting L R F 1 2 0 6 R 0 Conventional (element up) Values > R025 1 2 Flip-chip (element down) Values < R025 3 F Size 1 Value (use IEC62 code) Type Tolerance (use IEC62 code) 2 T1 1206 or 2010 2512 All sizes 5 3 4 Size Value Tolerance Termination & Packing F = ±1% G = ±2% J = ±5% W Pb-free, standard packing T1 Pb-free, 1000/reel (non-standard) PB SnPb finish, standard packing Standard packing is tape & reel 1206 & 2010 3000/reel 2512 1800/reel 1%LR = Conventional orientation 1206 E24 = 3/4 (values >R025) 2% 2010 characters 5% LRF = Flip-chip orientation 2512 R = ohms (values ≤R025) Packing Tape W 4 2 F G J W F 3000/reel 1800/reel 1000/reel 5 Standard USA (IRC) Part Number: LRC-LRF1206LF-01-R020-F (1206, 20 milliohms ±1%, Pb-free) L R Components C L Limited R F Bedlington, 1 2 Northumberland 0 6 LNE22 F © Welwyn 7AA, UK 0 1 - R 0 2 0 - Telephone: +44 (0) 1670 822181 · Facsimile: +44 (0) 1670 829465 · Email: info@welwyn-tt.com · Website: www.welwyn-tt.com 1 2 3 4 5 F 6 7 04.10 1 2 3 4 5 6 7 Family Model Size Termination TCR Value Tolerance Packing F = ±1% G = ±2% J = ±5% Standard packing is tape & reel 1206 & 2010 3000/reel 2512 1800/reel LRC LR = Conventional orientation 1206 Omit for SnPb 01 = standard 4 characters (values >R025) R = ohms 2010 LF = Pb-free (±100ppm/°C values ≥R05) 2512 LRF = Flip-chip orientation (values ≤R025) General Note TT electronics reserves the right to make changes in product specification without notice or liability. All information is subject to TT electronics’ own data and is considered accurate at time of going to print. Electrical Data www.bitechnologies.com www.irctt.com www.welwyn-tt.com © TT electronics plc LR1206 LR2010 LR2512 2.14