Area Bonding Conductive Epoxy Adhesive Preforms for - ET

advertisement

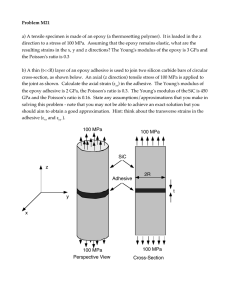

"Area Bonding Conductive Epoxy Adhesive Preforms for Grid Array and MCM Substrate Attach" by Justin C. Bolger, Merix Corp., 77 Charles St., Needham, MA 02194 and Ken Gilleo, Adv. Products Div., Alpha Metals Corp., Jersey City, NJ Abstract A new type of 2-axis epoxy tape adhesive, called an area bond conductive (ABC) adhesive, has been developed under ARPA contract to replace tin-lead solder for surface mounting grid array components. The ABC adhesive tapes contain discrete regions, or Idots", on pitch down to 0.2 min, of an electrically conductive epoxy within a high strength, high Tg , epoxy dielectric phase. The adhesives are supplied as die cut preforms, which match the size and bond pad pattern of the component to be attached. The preforms cure at 160-175 ° C and require no pressure during cure, in yield a shock resistant, voidfree area bond to any FR4 or other board surface. This paper presents bond strength, conductivity, dielectric strength, humidity and thermal shock results for daisy chain test circuits and other components attached to FR4 boards. Introduction ARPA contract #DAAH01-93-C-R322 to the group consisting of Merix, Auburn University and the University of Arizona, is intended to develop and demonstrate new polymeric materials to reduce the cost, improve the manufacturabilily and permit the customization and repair of MCM-L's. One of the materials being developed is a new type of z-axis adhesive, called an area bond conductive (ABC) epoxy adhesive preform. The ABC preforms consist of a high strength, thermally conductive epoxy tape adhesive, within which is formed columns or regions of a second, electrically conductive, epoxy adhesive. These adhesive preforms are intended to replace C-4 solder bumps for mounting flipped chips, and to replace solder paste and solder balls or columns for BGA, CGA, substrate and component attach. These adhesive preforms are now being made, in sample quantities, at Merix. The Alpha Metals Corp., now the largest supplier of solder paste and solder halls to the I.C. industry, has the exclusive license to manufacture and supply these preforms, in commercial quantities. The Alpha Advanced Products Division also supplies die attach adhesives and polymeric solder alternatives for board assembly and direct chip attach. Discussion of prior work Area array packaging is increasing rapidly in volume, both for attaching flipped I.C. chips, and for surface mounting BGA's, OMPAC's, and COA components (1). IBM's development of the C-4 solder bump process, 20 years ago, led to large volume use of area array bumped flipped chips. Recently, Motorola, Amkor, IBM, Compaq and others have begun volume production of I.C. packages with solderable bond pads arrayed in a grid on the bottom surface, to achieve smaller size, higher lead count and other performance advantages over QFP's or other fine pitch perimeter bonded packages. Although these BOA'S are now in volume production, some problems remain (I) (2) (3). These include "pop corning" (destructive release of absorbed moisture during solder mounting) and solder joint fatigue. Although BOA reduces thermal mismatch by mounting an FR-4 package on an FR-4 board, the die which is attached to the BOA circuit hoard appears to restrain movement, causing solder joint fatigue in the The ABC preforms are made by a new stencilling process, from art-work showing the size and location of the bond pads on the part to be bonded. The process can print down to 0.1 mm dots on 0.2 mm pitch. For cost reasons, the preforms are produced in sheet form, yielding many preforms per sheet, Fig. 1. In production, the sheets would contain multiple rows of 8 or more per row, which would then be slit and kiss cut to provide the strips shown in Fig. 2. die area (2). These fatigue problems frequently require the additional use of an underflow epoxy encapsulant to improve reliability. Conventional z-axis conductive adhesive films, which contain randomly distributed quantities of small (10 to 25 p dia) metal plated polymeric balls, have been considered for solder replacement in area array surface mounting, but give low electrical conductivity relative to solder. And became these z-axis films generally give final bond thicknesses less than 10 to 25 p, they have almost no tolerance for non-planarity and provide limited relief of interfacial stress. Fig. 3 shows a 50X Polaroid enlargement of the individual conductive dots plus a cross sectional drawing. Present standard ABC preforms are 50 to 75 p thick in the (black) dielectric epoxy regions with dot heights from 100 to 150p . Other, thicker preforms can be made, if desired, for non - planarity tolerance or stress relief purposes. The preforms also contain a fiberglass mesh, 30 p thick, for dimensional stability and to permit kiss cutting into the strips of Fig 2. In contrast to the previous random particle z-axis adhesives, the new preforms described in this paper are customized for each component to be mounted. Conductive adhesive areas are located only at bond pad locations and final thickness can be optimized and controlled between 25 and 250 p for planarity and stress relief purposes. This paper will describe preforms for attaching area array packages with grid pitch down to 1 mm. Future work under the ARPA contract will focus on preforms with pitch down to 0 2 mm for area bonding flipped chips. The two epoxy adhesive phases differ primarily in filler type. The conductive dots contain 85% by wt. of silver flake for high electronic conductivity. The region between the dots contains a high loading of oxide fillers for high thermal conductivity plus high electrical resistivity. Both epoxy regions are solvent free, Bstaged, non-tacky solids, with a melting point of about 70 ° C before cure. Both regions cure, with no volatiles or outgassing, to yield high T g , high strength adhesive bonds. T depends on cure time and temperature. g After 1 hour cure at 160 ° C, T E is about 150° C. After 1 ° hour at 175 C, Tg is about 16d° C. Description of product and assembly process Figs. 1 to 6 show several area bonding conductive (ABC) epoxy preforms. These are similar chemically and in form to the epoxy tape preforms which have been used for 20 years to bond hybrid substrates into military hermetic packages. In each case., an epoxy tape adhesive is die cut into customized shapes, "preforms", which match the size and shape of the part to he mounted. The preforms are normally sold in strips on a Mylar film carrier (Fig. 2), But whereas the previous mil-spec adhesives were insulating materials, intended only for high strength bonding, the present ABC preforms also contain a matrix of electrically conductive epoxy adhesive "dots". These conductive dots are Assembly Process. The ABC preforms are applied, cured and handled using the same methods as for previous (non-electrically conductive) tape adhesive preforms. Figure 4 shows how the BGA or other component is first tacked to one of the preforms on the Mylar carrier film of Figure 2. This is normally done by passing the carrier film across a heater block surface at 100-140 ° C, to warm the preform to about 80 ° C. When the BGA is pressed against the warm preform for 1-2 seconds at 2-4 psi, the preform bonds to the BGA surface. arranged in a customized pattern which corresponds exactly to the bond pad pattern on the bottom of the BGA or other component to be surface mounted. The BGA's may then be left attached to the carrier strip for shipment and/or storage, or may be lifted off the strip and tacked down on a heated mounting board by contacting for 2-3 seconds at 80 ° C and 2-4 psi pressure. The board is then oven cured for 30-60 minutes at 160 175 ° C. There are no volatiles released during the process and no pressure is required to hold the SGA's during cure. The figures show two different ABC preform sizes. The larger preform has a 11 x 11 = 121 dot pattern on 100 mil pitch. These were used for the humidity, bond strength, and other reliability tests discussed below. Fig. 1 shows higher density 15 x 15 = 225 dot preforms on 1.5 mm pitch which were made to fit present standard 1.5 mm BGA's and OMPAC's. - 2 Electrical Conductivity. Conductivity was measured using the daisy chain circuit patterns of Fig. 5. The circuit patterns were printed on FR-4, Kapton, alumina or glass substrates using a high T g , thermosetting epoxy PTF ink. When any two substrates were properly aligned and bonded with one of the 11x11 dot preforms, all 11 dots in each row were connected in series. The solid line at the left edge of the circuits in Fig. 5 is not contacted by the preform dots, and is used to factor out line resistance. Typical values for the daisy chain rows in Fig. 5 ranged from 1.6 to 2.0 ohms at 25 ° C and from 2.0 to 2.5 ohms at 130 ° C. Subtracting the circuit line resistance of about 1.2 ohms gave an average dot resistance of 0.03 to 0.06 ohms at 2.5 ° C and 0.04 to 0.08 ohms at 130 ° C. This is an order of magnitude higher conductivity than for previous random particle z-axis adhesives, and is comparable to conductivity through present BGA or CGA solder joints. Repair Procedure. The ABC adhesives form high strength bonds at ambient temperature, but soften when heated above T g . One inch square BGA's can be removed from board surfaces using present (1) torsion or lifting tools when (locally) heated to 180-200 ° C. This causes cohesive delamination, within the adhesive. If there were no glass mesh within the preform, this delamination would leave a hard-to-remove epoxy residue on both surfaces. But the ABC preforms are made such that the thin (30 it) glass internal mesh is directly against the release film side of the preform, Fig. 3. Bond failures above T galmost always occur just at the board-preform interface, leaving a relatively clean bond pad surface for the replacement BOA. When, occasionally, delamination occurs on the other side of the fiberglass mesh, the mesh allows the residue on the board to be peeled away, above T g , again leaving a reasonably clean surface for replacement. To minimize the possibility that one or more individual dots in a matrix will not make contact, the process for making the preforms minimizes deposition of dielectric epoxy on top of the dots. The dots are made (Fig. 3) to project above, and to have a much higher viscosity than the surrounding dielectric epoxy, to maximize pad contact. And an optical final inspection is used to reject preforms with undersized or missing dots. Thermal Stability and Solder Reflow. The cure temperature of 160-180 ° C in Fig. 4 will avoid the cracking and vapor release problems (pop-corn effect) now observed with solder paste mounted BGA's. Components attached with the ABC preforms may be exposed to reflow temperatures if other components are later soldered to the same board. This re-heating should not cause a problem, because the cured ABC adhesives retain enough hot strength to hold components in place at reflow temperatures, and because TGA data in air show no significant weight loss or adhesive decomposition below 300 ° C. Dielectric Strength and Silver Migration. Insulation between neighboring dots was measured by applying a DC voltage between adjacent lines of the assembled circuits of Fig. 5. Dielectric strength was tested after initial cure and also after water immersion and after pressure cooker or 85/85 humidity tests. Typically, after initial cure, adjacent lines showed over 10 6 ohms resistance and allowed no detectable current flow at V =120 volts. Results and discussion Bond strengths. Oxide filled adhesives are stronger in shear or tension than the same epoxies with a high loading of silver filler. The silver filled dots in these ABC adhesives (Fig. 3) occupy only about 5% of the volume, the remainder being the higher strength dielectric epoxy. Hence, the standard shear strength tests used for conductive adhesives, such as MIL 883B, Method 5011, can not be used with the ABC preforms because die fracture occurs before adhesive failure in shear. For example, 1.2x1.2 cm silicon dies, bonded to alumina substrates, failed by die fracture at about 30 kg shear force, leaving the adhesive and bottom half of the die intact. Tensile shear was therefore measured by a variation on ASTM D-1002, using 7" wide, 60 mil thick aluminum strips with a 1" overlap, bonded with the preforms of Fig. 5. After 1 hr cure at 165 ° C, overlap shear strength averaged 1650 lbs (750 kg) at 25 ° C. Because the silver filled epoxy regions are entirely encapsulated within a high Tg , low moisture absorption epoxy matrix, silver migration within the adhesive would not be expected to occur in a properly made, void free, joint. This was found to be true. Daisy chain circuits, Fig. 5, were tested after removal from the humidity chambers, while still saturated with water, by applying the Mil Std 20 volts D.C. between adjacent daisy chain lines. Present Mil specs require no shorting after 20 minutes at 20 volts. No migration failure was observed after 60 minutes at 20 volts for any of the 12 line pairs tested. 3 Humidity and Pressure Cooker Tests. Test samples were made with two substrate combinations using the 11x11 = 121 dot, 100 mil pitch, ABC preforms. For one set of 12 samples, Fig. 5, a daisy chain circuit on a 66 mil thick FR-4 board was attached to a second circuit on 2 mil thick Kapton. A second combination (10 samples) attached a 2.5 cm x 2.5 cm x 10 mil thick FR-4 square to the 66 mil FR-4 board. The laminated parts were first tested after initial assembly per Fig. 4 and then again after 50, 100 and 200 hours in humidity. refs. 2 and 3. After 10 cycles, all samples were inspected and tested for conductivity. No cracking or delamination was observed for any sample. All daisy chain lines on each assembly remained conductive, generally with less than 25% change from initial conductivity. While these reliability results have been encouraging to date, it is clear that considerable additional testing is needed. Future pressure cooker tests will use boards and substrates which will not themselves degrade in steam, to provide a test of the adhesive itself. Longer term, 85/85 humidity tests and thermal cycling tests, are also now in progress using the standard 1.5 mm pitch BGA packages and daisy chain boards shown in Fig. 6. Half of the samples were exposed to 85 ° C/85% RH. After 200 hours, none of these samples showed significant change or degradation. All daisy chain lines remained conductive and within 25% of initial resistivity. All boards continued to show >10 6 ohms between adjacent lines. The 85/85 tests were therefore discontinued in favor of a more severe test in pressure cooker, at 15 psig/121 ° C. Conclusions A new type of area bonding conductive (ABC) epoxy adhesive was developed to replace solder for surface mounting grid array chip carriers and other components. These adhesives are supplied as die-cut preforms, which match the size, shape and conductor pattern of the component to be attached. The preforms are applied by a conventional assembly process to yield high strength, shock resistant, void free area bonds to FR4 or any other board surface. Electrical conductivity of the individual epoxy dots is about equal to present solder ball joints. All of the circuit assemblies (6 FR-4/Kapton and 5 FR-4/FR-4 samples) inspected after 15 psig/121 ° C steam exposure showed severe degradation of the substrates, but not of the adhesive used to join the substrates. After 100 hours, the Kapton circuit films had hydrolyzed and had begun to flake apart, leaving an intact preform which was still bonded to the FR-4 board. After 200 hours, the FR-4 boards softened and lost insulation properties. Volume resistivity for the FR-4 boards decreased from an initial value above 10 7 ohms/sq to less than 500 ohms/sq when measured (while still saturated) after 200 hours. The cure temperatures of 160-175 ° C avoid pop-corn effects, and no external pressure is required during cure. Adhesive thickness can be varied from about 50 to 200 p for planarity and stress optimization. This paper showed encouraging bond strength, conductivity, humidity and thermal shock results using the preforms to attach Kapton or FR4 daisy chain circuits to 1'R4 boards. Additional longer term tests, using standard grid array chip carriers on FR4 daisy chain boards, are still in progress. These long term results will be presented at the conference in March. Although these substrate failures made it difficult to evaluate the ABC epoxy adhesive, it was clear that the epoxy did not soften or blister or suffer any adhesion loss at either 85/85 or in pressure cooker. At the end of the test, when the FR-4/FR-4 samples were dried and tested electrically, all daisy chain lines remained conductive, and there was no electrical contact between any adjacent lines. References Thermal Shock Tests. The cycle used was 30 minutes in a 150 ° C air oven, followed immediately by 30 minutes in a -20 ° C cold chamber, followed by inspection at room temperature. The test pieces were similar to the FR-4/FR-4 humidity samples described above (2.5 x 2.5 cm x 10 mil thick FR-4 squares, bonded to the 66 mil FR-4 board using the 100 mil pitch preforms) except that a silicon die, 0.480" square, had previously been attached to the top surface of the 10 mil FR-4 piece. This sample geometry was intended to duplicate the geometry and thermal shock conditions described in (1) Tuck, John. "BGA's: A Trend in the Making', Circuit Assembly, Dec. 1993. (2) Ejim T.I. et al. "Attachment Reliability of BGA Packages" VLSI Conf., Yorktown Hts, N.Y., Oct. 1993. (3) Mawer, A., et al. 'Calculation of Thermal Cycling and Fatigue Life of Plastic BGA Packages", p. 413-22, Nepcon East 1993 Proceedings. 4 'Figure 1. Two preforms (top right) with 15 x 15 conductive dots, on 1.5 mm pitch, cut from sheet of 4 units, left. The conductive areas correspond exactly to the bond pads on the EGA chip carrier, lower right. For production Figure 2. purposes, large sheets of epoxy adhesive arc slit into strips and then kiss-cut to provide the individual preforms in strips or rolls, pre-indexed on a Mylar release film carrier. EGA to be surface mounted at lower left Figure 3. The 50X Polaroid, top, shows the individual silver filled (85% silver by wt.) conductive 'epoxy dots. The black area is a 'high strength, T g = 160 ° C, oxide filled, electrically insulating, epoxy adhesive. Dielectric thickness can be varied from 30 to 200 A, with conductive dot height from about 100 to 300 p 4/ .2" Dot Height 4-5 mils ,/,/' (.7 — 2-3 mil Dielectric 2 mil Mylar Carrier Film Figure 4. Assembly Method. The preform is first tacked to the BGA or other component surface . by contacting for 1-2 seconds at 80-100 ° C. The BGA's may then be left on the carrier strip and stored for later mounting, or removed and attached to the motherboard surface by tacking in place and then oven curing at 160170 ° C. No pressure is required during cure. 80C 1 -2"eitt:' I transfer ABC Preform on Carrier Film 111111211211EMM- Surface Mount 80C 3 sec 111111111111011 Cure at 160C - Mother Board Figure 5. Daisy chain pattern on circuit boards used for pressure cooker and other reliability tests with the 100 mil pitch preforms. Various substrate combinationsi were used. This photo shows one circuit formed on FR-4 board . (left) and the second on Kapton (top center). After connecting the two circuits using the 11 x 11 dot preform (bottom center) all 11 dots in each row are connected in series (right). Figure 6. Standard 1.5 mm BGA's before (bottom right) and -after attachment to a FR-4 daisy, chain test board, using the 15 x 15 dot, 1.5 mm pitch, ABC preforms (top right).