DIRECTIONS FOR USE

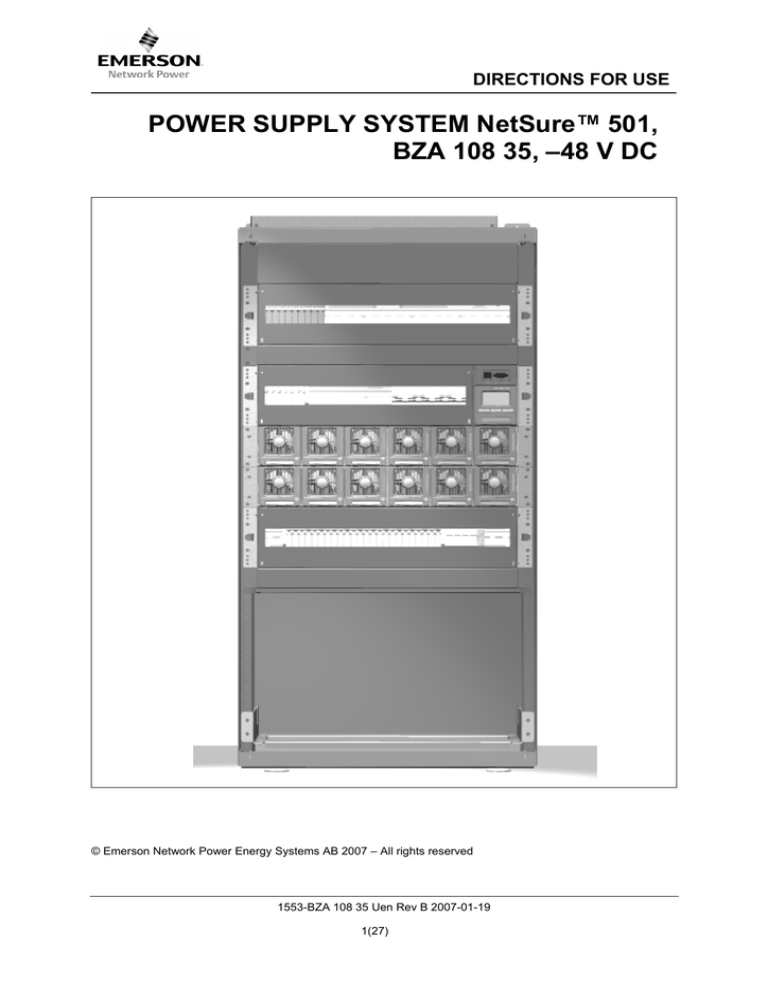

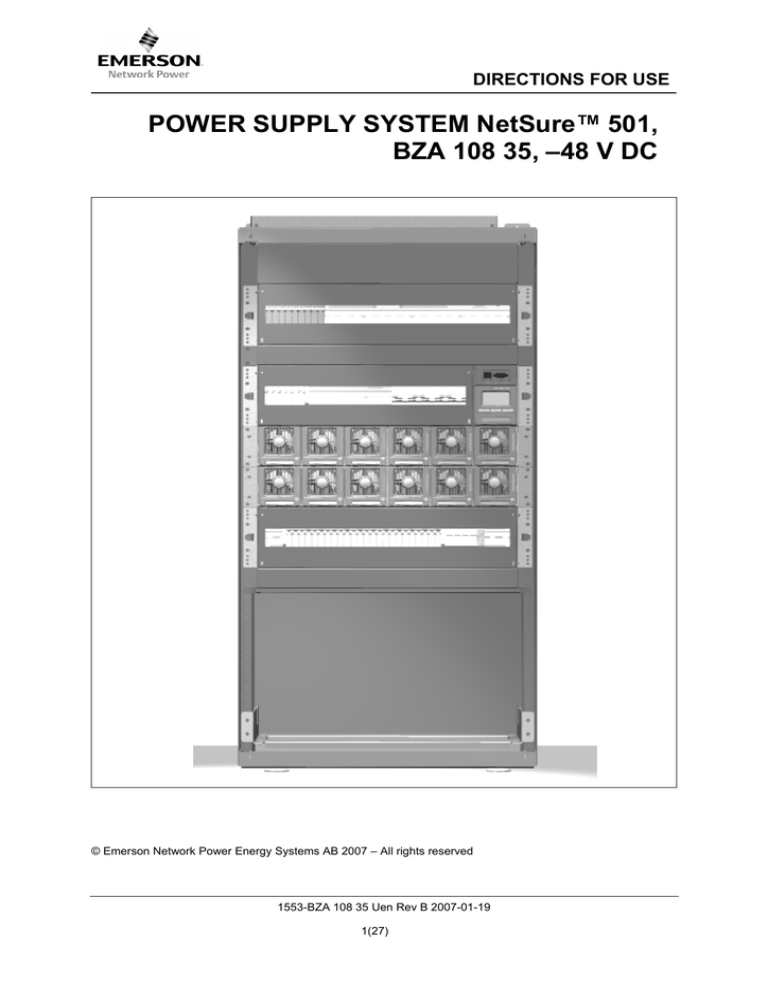

POWER SUPPLY SYSTEM NetSure™ 501,

BZA 108 35, –48 V DC

© Emerson Network Power Energy Systems AB 2007 – All rights reserved

1553-BZA 108 35 Uen Rev B 2007-01-19

1(27)

DIRECTIONS FOR USE – BZA 108 35

The contents of this document are subject to revision without notice due

to continued progress in methodology, design, and manufacturing.

Emerson Network Power Energy Systems AB

SE – 141 82 Stockholm

Sweden

Tel. +46 8 721 6000

Fax. +46 8 721 7177

www.emersonenergy.com

1553-BZA 108 35 Uen Rev 2007-01-19

2(27)

DIRECTIONS FOR USE – BZA 108 35

Contents

1

Introduction

4

2

Function

4

3

Configurations

5

4

Units in the system

8

4.1

4.2

4.3

4.4

4.5

4.6

Rectifier

Rectifier subrack

Control units

Multifunction unit

AC distribution

AC connection terminals

8

10

11

11

12

12

5

Technical data

13

5.1

5.2

5.3

System

Cabinet

Rectifier

13

13

13

6

Installation

14

7

Start-up and installation test

14

8

Maintenance

14

8.1

8.2

8.3

8.4

Safety

Scheduled maintenance

Alarms

Fault symptoms and trouble shooting

14

14

15

15

9

Exchange of units and parts

21

9.1

9.2

9.3

9.4

9.5

9.6

9.7

Exchange of rectifiers

Rectifier fan replacement

Exchange of distribution circuit-breaker

Exchange of contactor

Exchange of SCU/ACU

Exchange of connector board

Exchange of SCU/ACU supply fuses

21

22

23

24

25

25

26

10

Abbreviations used in this document

27

1553-BZA 108 35 Uen Rev 2007-01-19

3(27)

DIRECTIONS FOR USE – BZA 108 35

1

Introduction

The NetSure™ 501 –48 V DC power system consists of a stand-alone cabinet,

DC-distribution unit, maximum 12 rectifiers of 1700 W, battery connections

and a supervision unit.

2

Function

For the protection of the batteries during a power outage, the load is disconnected at a preset voltage or after a predetermined delay.

To prolong the service of some loads at a long power outage, the DC distribution is divided into two branches. One is for normal load and one for priority

load, so the disconnection can be made in two steps.

AC Mains

Subrack 2

DU, normal load

6 rect.

Priority Load

~

=

MFU

LVD 1

& ICU

Subrack 1

6 rect.

LVD 2

~

=

Shunt

AC terminals

CAN-bus

Batt.

CBs

SCU/

ACU

Figure 1.

Example of system topology.

1553-BZA 108 35 Uen Rev 2007-01-19

4(27)

Ext. Batts.

DIRECTIONS FOR USE – BZA 108 35

3

Configurations

The cabinets can be configured with different numbers of rectifiers, batteryand distribution- circuit-breakers. They are built for overhead cabling.

Extension

distribution unit

MFU and Control unit

Rectifier subrack

Rectifier subrack

AC distribution

unit (optional)

Figure 2.

Example of configuration with overhead cabling.

1553-BZA 108 35 Uen Rev 2007-01-19

5(27)

DIRECTIONS FOR USE – BZA 108 35

The Figure 3 and Figure 4 give examples of standard configurations.

Cover panel 2 U

AC terminals (if no ACD)

MFU (battery CBs,

S/A

LVDs, normal and

C/C

prio load CBs

U/U

R

R

R

R

R

R

ACD (optional)

(BMG 653 39/21)

Fire trap

Figure 3.

Configuration with single rectifier subrack.

Cover panel 2 U

AC teminals (if no ACD)

Extension distribution CBs

(normal load)

Cover panel 2 U

MFU (battery CBs,

S/A

LVDs, normal and

C/C

prio load CBs)

U/U

R

R

R

R

R

R

R

R

R

R

R

R

ACD (option)

(BMG 653 39/22)

Fire trap

Figure 4.

Configuration with double rectifier subracks.

1553-BZA 108 35 Uen Rev 2007-01-19

6(27)

DIRECTIONS FOR USE – BZA 108 35

Basic configuration:

•

•

•

•

•

Cabinet for overhead cabling

Maximum 12 rectifiers 1700 W

One or two rectifier subracks for maximum 6 rectifiers each

MFU including maximum four battery CBs, distribution CBs, LVD contactors, a standard control unit (SCU) and a battery shunt

AC terminal unit for maximum 12 rectifiers

•

Battery temperature sensor KET 103 06/1

Options:

•

•

•

•

•

•

•

•

•

•

•

Advanced control unit (ACU)

Cables for battery, distribution, earthing and signalling

Cabling materials (lugs, tie wraps, markings)

Internal AC distribution unit for maximum 12 rectifiers

External AC distribution units

Mains cable

Lifting eye bolts SAR 201 080/03

Cabinet anchoring material BMY 107 125/1

AC inlet pull-relief clamps

Room temperature sensor KET 103 06/1

Spare parts

1553-BZA 108 35 Uen Rev 2007-01-19

7(27)

DIRECTIONS FOR USE – BZA 108 35

4

Units in the system

4.1

Rectifier

The rectifier is voltage regulated of a constant power limitation type (1700 W)

and designed to meet the most stringent electrical requirements as well as

demands for high power density (fan cooling). It can work independently of the

control unit, and can share the load actively and control the system voltage.

LEDs

Figure 5.

Rectifier.

4.1.1 LEDs

The front panel has three indicator LEDs. The functions of the LEDs are listed

in the table below.

LED

Power indicator

(green)

Protection indicator (yellow)

Alarm indicator

(red)

Normal

ON

OFF

OFF

Abnormal

Cause of Abnormality

OFF

No AC Mains Supply

Flashing

Rectifier is under control by SCU/ACU

ON

AC input over/undervoltage, PFC

over/undervoltage and overtemperature

Flashing

Communication with SCU/ACU failure

ON

Output overvoltage

Flashing

Fan Failure

1553-BZA 108 35 Uen Rev 2007-01-19

8(27)

DIRECTIONS FOR USE – BZA 108 35

4.1.2 Features

•

Hot swappable. The rectifier is plug-and-play to live inputs and outputs.

•

Active load sharing. The rectifier uses advanced digital active load sharing

technology for minimum load difference between units.

•

Power derating by input voltage. The rectifier will go into power derated

mode if the input AC voltage is too low or too high.

•

Power derating by output load. The rectifier will limit its output power constant when the load exceeds the nominal output power.

•

Power derating by temperature. For high temperatures the output load will

be gradually reduced. See technical data.

•

Current limiting function. The rectifier has a current limiting function. The

current limit can be set from an SCU/ACU.

•

Foldback current limiting function. If a short circuit occurs on the rectifier

output terminals, the rectifier will keep its output current at a constant

value. When the short circuit fault is cleared, the rectifier will automatically

restore to normal operation.

•

Adjustable output voltage. The voltage can be set from an SCU/ACU.

•

Current walk-in. The rectifier can be set from an SCU/ACU to take load

gradually in order to reduce the stress on generators, fuses etc.

•

Fan control. The fan’s speed is controlled according to the rectifier internal

temperature. The fan is stopped completely at low temperature and at

very low or high input voltage.

4.1.3 Digital Signal Processor (DSP)

The rectifier has a built-in advanced DSP that monitors and controls the

operation of the rectifier. The DSP also communicates with an SCU/ACU

through a CAN bus.

•

The rectifier can receive commands such as turning on/off, current walk-in

on/off signal and high voltage alarm reset signal from an SCU/ACU.

•

An SCU/ACU can adjust the output voltage, overvoltage alarm point, current walk-in time and the current limit of the rectifier.

•

The rectifier reports its output voltage, output current, temperature, current

limit setpoint, overvoltage setpoint, on/off status and alarm information to

an SCU/ACU in real time.

•

By querying the DSP, an SCU/ACU can get the following data from the

rectifier: Input voltage, output voltage, output current, current limit setpoint,

temperature of rectifier, and overvoltage setpoint.

1553-BZA 108 35 Uen Rev 2007-01-19

9(27)

DIRECTIONS FOR USE – BZA 108 35

•

By querying the DSP, an SCU/ACU can get the following state information

from the rectifier: On/off, protect (input protect, inner DC bus voltage protect; overtemperature), fault (HVSD, fan failure), thermal derating, AC

derating, AC failure, and unbalance current.

•

An SCU/ACU can get the following unit information from the rectifier: Address, code, date, SW version and HW version.

4.1.4 Protection functions

4.2

•

Input over/undervoltage protection. The rectifier will shut down and its yellow LED will emit light if the input voltage is outside the range 80 to

305 V AC. An alarm will be sent to the SCU/ACU.

•

Output overvoltage protection. If the rectifier output voltage exceeds a limit

that can be set from the SCU/ACU, the rectifier will shut down. If output

over voltage occurs two times within 5 minutes, the rectifier can only be

restarted manually and its red alarm LED will emit light. An alarm will be

sent to the SCU/ACU.

•

Over-temperature protection. The rectifier will limit its power to 50% of

rated output power if its internal temperature is higher than 75 °C. If the internal temperature reaches 80 °C, the rectifier will shut down and its yellow LED will emit light. An alarm will be sent to the SCU/ACU.

The alarm will cease and the rectifier will restart when the temperature becomes normal.

•

Communication failure. At communication failure, the rectifier output voltage is reduced to a default value for protection of the battery. The yellow

LED will flash and alarm will be sent to the SCU/ACU.

•

Fan alarm. The red LED will flash at a fan fault and the rectifier will stop.

•

Unbalance of Rectifier Output Current. When the output current of the rectifiers in a DC power system is unbalanced, the rectifier that outputs unbalanced current will be identified automatically and its yellow LED will

emit light. An alarm will be sent to the SCU/ACU.

Rectifier subrack

Figure 6.

Subrack for six rectifiers.

The rectifier subrack has space for six rectifiers.

1553-BZA 108 35 Uen Rev 2007-01-19

10(27)

DIRECTIONS FOR USE – BZA 108 35

4.3

Control units

The control unit is placed in the multifunction unit. It controls, supervises and

communicates with the other units of the power supply system and manages

alarm handling, etc.

Two control units are available. The standard control unit (SCU) has an LCDdisplay, offers internal supervision and alarm handling, sends external alarm

signals over relays and communicates externally via modem with external

computer-based supervision systems (EEM, for example) that can be implemented for different maintenance activities.

The advanced control unit (ACU) has, in addition to the SCU features, an interface to communicate with supervision modules (SM) for supervision of

existing cabinets, AC mains and batteries, for example. It has a Web interface

for communication with MS Explorer.

For detailed information, refer to USER’S GUIDE 5/1553-BMP 903 050 Uen,

for the ACU and 5/1553-BMP 903 051 Uen, for the SCU.

4.4

Multifunction unit

+ terminals

LVD contactors

CB alarm

board

Connector

board

DIN bar for CBs

Figure 7.

MFU.

The unit combines normal and priority distribution circuit-breakers battery CBs,

a battery shunt (500 A) and one or two load disconnect contactors (125 and

500 A). The control unit (SCU/ACU) and the connector board are also

mounted here.

1553-BZA 108 35 Uen Rev 2007-01-19

11(27)

DIRECTIONS FOR USE – BZA 108 35

4.5

AC distribution

R1--------------------------------------------------------R12

Figure 8.

L1 L2 L3 N PE

Input terminal

AC distribution unit seen from front.

For cabinets with double rectifier subracks, an AC distribution unit is available.

It includes separate circuit breakers for each rectifier.

4.6

AC connection terminals

Figure 9.

Mains terminals.

A unit with maximum four terminal blocks can be delivered for the connection

of totally 12 rectifiers.

1553-BZA 108 35 Uen Rev 2007-01-19

12(27)

DIRECTIONS FOR USE – BZA 108 35

5

Technical data

5.1

System

Nominal DC voltage

–48 V

Maximum output current @ 48 V 212 A (with one rectifier subrack) or

425 A (with two rectifier subracks)

Operational temperature

–5 to +45 °C (with hydraulic magnetic

circuit-breakers)

–5 to +30 °C (with thermal/electro magnetic

circuit-breakers)

5.2

5.3

Storage temperature

–40 to +75 °C

Relative humidity

5 to 90%

Cabinet

Building practice

23”

Height (incl. top cover and feet)

1250, 1650, 1850, 2050 mm

Footprint (with x depth)

400 or 600 x 600 mm

Weight (fully equipped,

without batteries)

maximum 150 kg

Rectifier

See data sheet EN/LZT 145 280 RA

1553-BZA 108 35 Uen Rev 2007-01-19

13(27)

DIRECTIONS FOR USE – BZA 108 35

6

Installation

See INSTALLATION INSTRUCTIONS 1531-BZA 108 35 Uen.

7

Start-up and installation test

See TEST INSTRUCTIONS 1532-BZA 108 35 Uen.

8

Maintenance

Adequate knowledge of the power supply system is required. Refer to item 1

to 5 of this document.

8.1

Safety

The document SAFETY RULES 1550-1004 and local safety rules shall be followed when doing maintenance work in the power supply equipment. Measures that require work inside the cabinets or intervention in a unit shall always

be carried out by adequately trained personnel with adequate knowledge of

the power supply system. When in doubt about an action or how to carry it out,

always call for adequately trained personnel.

In case it is necessary to work on a live power supply system, the approval for

this type of work must be given, based on local regulations governing for example the following areas:

8.2

•

General rules for work on live equipment

•

Certification of operatives conducted by certified supervisor

•

Approved tools

•

Customer approval

Scheduled maintenance

•

Use a vacuum cleaner to remove dust from the air inlets of the cabinets.

•

Check and test the batteries according to the recommendations of the battery supplier.

•

A scheduled performance test according to the following table shall be

performed at least every two years according to item “Test of signals and

supervision” in the document TEST INSTRUCTIONS

1532-BZA 108 35 Uen. Settings according to the document TABLE OF

SET VALUES, shall be verified in this test.

A copy of the test result shall be kept in the logbook of the plant.

1553-BZA 108 35 Uen Rev 2007-01-19

14(27)

DIRECTIONS FOR USE – BZA 108 35

8.3

Alarms

8.3.1 Alarm categories

The different alarm categories used in the power supply system are Critical,

Major, Observation and No Alarm.

An alarm of category Critical requires immediate action, whatever the time of

day or night.

An alarm of category Major requires immediate action if it occurs during working-hours, otherwise as soon as the working-hours commence.

An alarm of category Observation is an alarm that indicates a temporary state

of operation and does not normally require any action. However, if the alarm

persists for more than 20 hours, it must be investigated.

If an alarm has category No Alarm it means that the alarm is deactivated and

will not be shown in the display of the SCU/ACU.

8.3.2 Procedure in case of alarm

Enter in the logbook of the power supply system all observations made at the

moment of failure, such as date, time, system voltage and rectifier load. Enter

also what alarm(s) are shown and any external disturbance such as thunderstorm or mains failure.

Trace activated alarms by means of the alarm survey of the respective unit

and the item, which describes what actions to take on the respective alarm.

8.4

Fault symptoms and trouble shooting

8.4.1 System alarms

For system alarms, see USER’S GUIDE 1553-BMP 903 051 Uen for the SCU

and 1553-BMP 903 050 Uen for the ACU.

Alarm on

the SCU

display

Alarm on

the ACU

display

Cause

Suggestion

The outgoing alarms are Check why before reconnecting the alarms.

blocked from the

SCU/ACU.

Alarms

Blocked

Alarm

Blocked

Load Fuse

Alarm

Fuse Alarm One or more distribution

circuit-breakers for the

load have tripped.

Rect Not

Respond

CAN

Comm

Fault

There CAN communication is broken.

Find out and eliminate the reason for the

tripped circuit breaker before resetting it.

Check the connectors and cables for the CAN

loop.

Exchange the rectifier that does not respond.

Exchange the SCU/ACU.

1553-BZA 108 35 Uen Rev 2007-01-19

15(27)

DIRECTIONS FOR USE – BZA 108 35

Alarm on

the SCU

display

LVD 1

LVD 2

Alarm on

the ACU

display

LVD 1 Disconnected

LVD 2 Disconnected

LVD 1/ LVD Contactor

2 Open

Fault

Cause

Suggestion

The contactor for the normal load is open because

the battery is too deep

discharged.

The batteries are disconnected at a preset level, in

order to protect them from

over-discharging.

If there is a mains failure, check that it is not

caused by broken supply fuses.

The contactor for the prioritised load is open because the battery is too

deep discharged.

See LVD 1

An LVD contactor is in a

wrong state.

Check the contactor functions.

If the rectifiers are working, the problem may

be that the system load is higher than the

rectifier capacity, causing the batteries to

discharge. If this is the reason, install more

rectifiers.

Batt Curr

High

Abnorm Bat The boost charging curCurr

rent exceeds the set max.

value.

Check the settings.

Batt Fuse

Alarm

Fuse Alarm

Indicates that one or more

battery fuses/circuit breakers have blown/tripped or

been removed.

If a battery fuse/circuit breaker has been

removed/tripped manually, check with the

person that removed/tripped it before reinserting/resetting it. Ensure that there is no

fault before doing that. The battery fuse

shall be reinserted by adequately trained

personnel.

If the battery fuse/circuit

breaker is blown/tripped,

the reason for the failure

probably is overload or

short circuit.

Find out and eliminate the reason for the

blown/tripped fuse/circuit breaker before

swapping/resetting it.

Exchange the SCU/ACU.

Self-detect

Err

ACU fault

SCU/ACU failure.

Manual

Mode

Manual

Mode

The battery monitoring has Check why before resetting it to automatic.

been set to “Manual

mode” in the SCU/ACU.

Non-Float

Status

Batt Discharge

The system is not in Float

Charge mode because of:

The boost charge is active.

The boost charge will stop automatically.

The battery test is active.

The discharge test will stop automatically.

The battery test is active.

The discharge test will stop automatically.

There is a mains failure.

Check that it is not caused by broken supply

fuses.

The system load is higher

than the rectifier capacity,

causing the batteries to

discharge.

Install more rectifiers.

1553-BZA 108 35 Uen Rev 2007-01-19

16(27)

DIRECTIONS FOR USE – BZA 108 35

Alarm on

the SCU

display

Curr Discrepancy

Alarm on

the ACU

display

Dis Curr Im

Short Test

Fail

Batt Test

Fail

Cause

Suggestion

Check the batteries.

The currents from two

groups of batteries are not

equal.

Note: There must be two

battery shunts in

the system to activate this function.

The short time battery test Check the batteries.

has failed.

Test Failure

The battery test has failed. Check the float charging level.

Check that the load is lower than the capacity of the rectifiers.

Check the battery according to the recommendations of the supplier.

Volt Discrepancy

Rect Over

Volt

Rectifier overvoltage

Mains Failure

Mains Failure

All rectifiers have stopped. Check if there is a general mains failure.

Check that it is not caused by broken supply

fuses.

Multi-Rect

Alarm

Multi-rect fail Two or more rectifiers

have stopped.

See item 8.4.2

Maintain

Alarm

Maintenance Alrm

The maintenance timer

gives alarm

Check the settings of the Maintenance Time

Delay

Rectifier

Lost

Rectifier

Lost

The SCU/ACU has detected a reduction in the

number of running rectifiers.

See item 8.4.2

If the lost rectifier is to be removed permanently, the alarm must be reset from the

SCU/ACU.

Load share

Alarm

The output current of a

rectifier is outside the average value for all rectifiers.

Check the rectifiers.

Rect HVSD

A rectifier output voltage

was higher than the rectifier HVSD setting and has

shut down.

Check the rectifier HVSD setting.

Rect AC Fail Rect AC

Failure

See item 8.4.2

Replace the rectifier.

AC input voltage outside

the normal range.

See item 8.4.2

Rectifier overtemperature

protection.

See item 8.4.2

Rect Failure Rectifier

Failure

Rectifier failure

See item 8.4.2

Rect Protect Rect Protected

Rectifier protection

See item 8.4.2

Rect Over

Temp

1553-BZA 108 35 Uen Rev 2007-01-19

17(27)

DIRECTIONS FOR USE – BZA 108 35

Alarm on

the SCU

display

Alarm on

the ACU

display

Cause

Suggestion

Rect Fan

Fails

Rect Fan

Fail

Rectifier fan failure.

See item 8.4.2.

Rect Derated

Rect Curr

limit

Rectifier overload.

If the batteries are being recharged, the

The load is higher than the alarm will cease by itself when the battery

rectifier capacity.

voltage has increased to the charging level.

If the system load is higher than the rectifier

capacity, the batteries will discharge. If this

is the reason, install more rectifiers.

If one or more of the rectifiers are out of

order, exchange the faulty rectifiers.

DC Volt

Low#1

Under Vol

The distribution voltage

has dropped below the

preset alarm level, usually

initiated because of mains

failure.

If there is a mains failure, check if some

load could be switched off in order to prolong the operating time of the plant.

If there is a rectifier failure, see item 8.4.2.

If the system load is too high related to the

rectifier capacity, install more rectifiers.

If the batteries are being recharged, the

alarm will cease by itself when the battery

voltage has increased to the charging level.

DC Volt

Low#2

Very Under

Vol

See DC Volt Low#1/DC Under Voltage

The distribution voltage

has dropped below the

preset alarm level, usually

initiated because of mains

failure.

DC Volt

High#1

Over Voltage

The system voltage exceeds the preset level.

Check the set float-, battery- and the overvoltage; if the limits are incorrect, find out

why they have changed and correct them.

DC Volt

High#2

The system voltage exceeds the preset level.

Check the set float-, battery- and the overvoltage; if the limits are incorrect, find out

why they have changed and correct them.

AC Voltage

Low#2

The mains voltage is too

low.

Check the mains voltage.

AC Voltage

Low#1

The mains voltage is too

low.

AC Voltage

High

The mains voltage is too

high.

Low Temp

Temp Alarm /Low Amb

Temp

The temperature on a

temperature sensor exceeds the set value.

Check the settings of the SCU.

See AC Voltage Low#2

Check the mains voltage.

Check the settings of the SCU.

Check the temperature.

Check the settings of the SCU/ACU.

If the temperature is OK, exchange the temperature sensor.

1553-BZA 108 35 Uen Rev 2007-01-19

18(27)

DIRECTIONS FOR USE – BZA 108 35

Alarm on

the SCU

display

Temp High

Alarm

No Temp

Sensor 1 or

2

Alarm on

the ACU

display

Cause

Suggestion

High Temp

Check the battery temperature.

The temperature on a

Check the settings of the SCU/ACU.

battery temperature sensor exceeds the set value. If the temperature is OK, exchange the temperature sensor.

Very hiTemp

The temperature on a

See High Temp alarm.

battery temperature sensor exceeds the set value.

High Amb

Temp

The temperature on a

room temperature sensor

exceeds the set value.

T Sensor

Fault

The temperature sensor

has a fault.

Plan BT

Planned battery test in

progress.

Wait for the test to stop automatically.

AC failure

BT

Mains failure.

See Mains Failure alarm.

Manual BT

Manual battery test in proWait for the test to stop automatically.

gress.

Short Test

Short battery test in progress.

Wait for the test to stop automatically.

Cyclic BC

Cyclic boost charge in

progress.

Wait for the boost charge to stop automatically.

Auto BC

Automatic boost charge in Wait for the boost charge to stop automatiprogress.

cally.

Manual BC

Manual boost charge in

progress.

Check the room temperature.

Check the settings of the ACU.

If the temperature is OK, exchange the temperature sensor.

Check the cable and the connector of the

temperature sensor.

Exchange the temperature sensor.

Wait for the boost charge to stop automatically, or stop it manually.

Charge Pro- The boost charge function The boost charge will be blocked by abnorhibit

is blocked.

mal conditions in the system.

Power Major

Indicates “Promt” alarm

(red LED)

Power Minor

Indicates “Main fail” alarm

(yellow LED)

High Load

Ab load curr

The system load is higher

than the set level.

Check the settings.

Indicate alarms on the

digital inputs 1-6.

Check the equipment connected to the corresponding input.

Over Power

Digital 1 (to

6)

DI 1 to DI 6

1553-BZA 108 35 Uen Rev 2007-01-19

19(27)

DIRECTIONS FOR USE – BZA 108 35

8.4.2 Rectifier

The usual fault symptoms of the rectifier include: power indicator (green) off,

protection indicator (yellow) on, protection indicator (yellow) flashing, alarm indicator (red) on, and alarm indicator (red) flashing.

Symptom

Power indicator (green) off

Cause

Suggestion

No input voltage

Make sure there is input AC voltage

Input fuse/circuit-breaker fault

Replace the fuse with a new one

of the same model or switch on

the circuit-breaker.

AC input voltage outside the normal

range

Check that the AC input voltage

is within normal range

PFC overvoltage

Replace the rectifier

Current sharing function is disabled

Replace the rectifier

Rectifier overtemperature protection, which is caused by:

Protection

indicator (yelRemove the obstacle that block

Fan blocked

low) on

the fan

Ventilation blocked: the inlet or outlet Remove the objects that blocks

blocked

the inlet or outlet

Ambient temperature too high or

rectifier inlet too close to a heater

Remove the heater, lower the

ambient temperature

Rectifier not completely inserted into

the slot

Insert the rectifier properly

Protection

indicator (yel- Rectifier communication failure

low) flashing

Exchange the rectifier for a new

one.

Alarm indicator (red) on

Remove the rectifier from the DC

power system and then reinsert

it. Exchange the rectifier for a

new one if the alarm continues.

Rectifier overvoltage

Alarm indicator (red) flash- Fan not running

ing

Replace the fan

When multiple rectifiers are in parallel connection and the unbalance of current sharing among them is higher than 3 %, check if the communication cables are correctly connected.

If the current sharing is still unsuccessful after the correction, replace the rectifier of which the current sharing is out of range.

1553-BZA 108 35 Uen Rev 2007-01-19

20(27)

DIRECTIONS FOR USE – BZA 108 35

9

Exchange of units and parts

To order spare parts, contact Emerson Network Power Energy Systems AB.

9.1

Exchange of rectifiers

1. Loosen the fixing screw of the handle of the faulty rectifier. The handle will

pop out and release the latch locking the rectifier to the subrack.

Fixing screw

Handle

Figure 10. Rectifier handle.

2. Pull out the rectifier unit and remove it.

3. Make sure the handle of the new rectifier unit is locked in its socket with

the fixing screw.

Latch

Figure 11. Locking latch.

4. Insert the new rectifier unit. Push it into its slot until the latch blocks the

way. The latch is set to block the way with the purpose of charging the

rectifier output filter slowly via a charging circuit, as the DC terminals may

get damaged by a spark at a direct connection.

1553-BZA 108 35 Uen Rev 2007-01-19

21(27)

DIRECTIONS FOR USE – BZA 108 35

5. Loosen the fixing screw of the handle, lift the handle, and the latch will withdraw into the rectifier.

6. Continue to push the rectifier into the slot completely.

7. Push the handle into its socket and fasten the fixing screw to lock the

rectifier. Now the rectifier is fixed to the slot by the latch.

The green LED emits light and the fan will start.

9.2

Rectifier fan replacement

If the fan does not work because it is faulty, exchange it for a new one.

1. Remove the rectifier according to item 9.1.

Fan cable plug

Fixing screw

and fan holder

Fan

Front cover

Fixing screws

Figure 12. Fan replacement.

2. Loosen the three screws fixing the front cover to the chassis.

3. Lift out the front cover from the chassis and observe the orientation of the

fan and its wires.

4. Unplug the power cable of the fan and remove the front cover with the fan.

5. Remove the fan from the front cover by removing its two fixing screws and

holders.

6. Replace the fan and fix it to the front cover with the two screws and holders.

7. Plug the fan power cable back into the corresponding socket.

8. Mount the front cover and fix it with the three screws.

9. Reconnect the rectifier according to item 9.1.

1553-BZA 108 35 Uen Rev 2007-01-19

22(27)

DIRECTIONS FOR USE – BZA 108 35

9.3

Exchange of distribution circuit-breaker

1. Open the distribution unit front.

2. Disconnect the distribution cable from the CB.

3. Loosen the CB fixing screw. See Figure 13.

4. Pull the locking device at the bottom of the faulty CB to release it from the

DIN-rail.

5. Lift the CB to release it from the connecting fork. See Figure 13.

3

CB fixing

screw

2

Figure 13. Releasing a distribution circuit-breaker.

6. Remove the CB according to Figure 14.

connecting fork

Figure 14. Removing a distribution circuit-breaker.

1553-BZA 108 35 Uen Rev 2007-01-19

23(27)

DIRECTIONS FOR USE – BZA 108 35

7. Mount a new CB in the reverse order.

8. Lock the new CB to the DIN-rail and switch it off.

9. Connect the distribution cable to the CB.

10. Mount the front to the distribution unit and fix it with the captive screws.

9.4

Exchange of contactor

Note:

The system has no backup during this work.

Figure 15. Exchange of contactor.

1. Take off metallic bracelets, rings or similar that may cause short circuits in

the equipment. Use insulated tools. Insulate the metal parts close to the

contactor with plastic and tape.

2. Open the connector for the signalling cables connected to the contactor.

3. Remove the plastic cover and two rectifiers placed below the contactor.

4. Use an insulated 13 mm U-socket key to loosen the four fixing nuts of the

contactor.

5. Hold the contactor and remove the four fixing nuts.

6. Pull the contactor straight down and remove it through the space in the

rectifier subrack.

7. Insert the new contactor and fix it with four nuts.

8. Connect the signalling cables to the contactor. If the voltage is OK it

should pull up.

9. Fit the plastic cover and two rectifiers below the contactor.

1553-BZA 108 35 Uen Rev 2007-01-19

24(27)

DIRECTIONS FOR USE – BZA 108 35

9.5

Exchange of SCU/ACU

Note:

An LVD contactor is in it’s OFF- position will reconnect when the

SCU/ACU is removed from a live system.

1. Unlock the control unit by pressing the handle so it pops out and pull out

the control unit from the subrack. See Error! Reference source not

found..

2. Insert the new control unit into the subrack, push it in completely and lock

it by pushing the handle into its socket.

9.6

Exchange of connector board

Connectors

Fixing screw

Figure 16. Connector board.

1. Remove the fixing screw, and then pull out the connector board from the

subrack to access the cable connectors. See Error! Reference source

not found..

Note:

Be careful not to damage the surface mounted components at the back of

the board when pulling it out.

2. Disconnect, insulate and mark the signalling cables connected to the terminals of the connector board.

3. Exchange the connector board for a new one.

4. Connect the signalling cables to the terminals of the new board.

Note:

An LVD contactor is in it’s OFF- position will reconnect when the connector board is reconnected to a live system.

5. Insert the connector board into the subrack, push it in completely and fix it

with a screw.

1553-BZA 108 35 Uen Rev 2007-01-19

25(27)

DIRECTIONS FOR USE – BZA 108 35

9.7

Exchange of SCU/ACU supply fuses

There are two fuses at the back-plane board of the SCU/ACU. See Figure 17.

If the display of the SCU/ACU is “dead”, the upper fuse (2 A) might have

blown.

The lower fuse (4 A) protects the supplies of the contactor coils.

2 A for SCU/ACU

4 A for contactors

Figure 17. Fuses for internal supplies.

1553-BZA 108 35 Uen Rev 2007-01-19

26(27)

DIRECTIONS FOR USE – BZA 108 35

10

Abbreviations used in this document

AC

ACD

ACU

BC

BT

CAN

CB

CENELEC

DC

DI

DSP

DU

EEM

EN

ESD

HVSD

ICU

LAN

LCD

LED

LVD

MFU

PE

PFC

R

SCU

SELV

SM

Alternating Current

AC Distribution

Advanced Supervision Unit

Battery Charge

Battery Test

Controller Area Network

Circuit Breaker

European Committee for Electrotechnical Standardization

Direct Current

Digital Input

Digital Signal Processor

Distribution Unit

Emerson EnergyMaster™

ENERGYMASTER is a registered trademark of

Emerson Network Power Energy Systems AB

European Norm

ElectroStatic Discharge

High Voltage Switch Down

InterConnection Unit

Local Area Network

Liquid Crystal Display

Light Emitting Diode

Low Voltage Disconnect

Multi Function Unit

Protective Earth

Power Factor Controller

Rectifier

Standard Supervision Unit

Safety Extra Low Voltage

Supervision Module

1553-BZA 108 35 Uen Rev 2007-01-19

27(27)