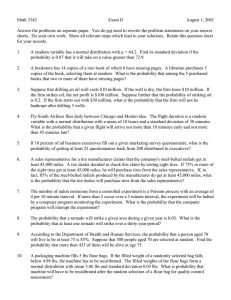

TIRE MAINTENANCE MANUAL - Goodyear Off-The-Road

advertisement