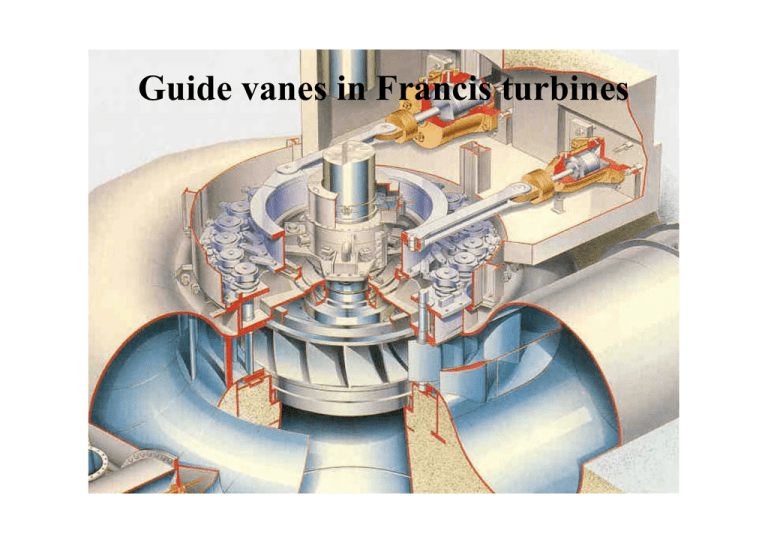

Guide vanes in Francis turbines

advertisement

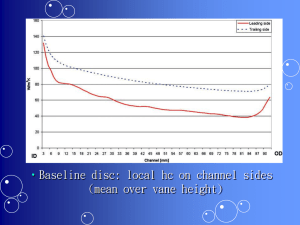

Guide vanes in Francis turbines El Cajon, HONDURAS Revelstoke, CANADA La Grande 3, Canada P = 169 MW H = 72 m Q = 265 m3/S D0 = 6,68 m D1e = 5,71m D1i = 2,35 m B0 = 1,4 m n = 112,5 rpm La Grande 3, Canada La Grande 3, Canada Guide vane cascade, Francis Guide Vane End Seals • • • High efficiency Less erosion Less leakage in closed pos. Guide vanes Main function: Adjust the turbine load The guide vanes consist of number of blades that can be adjusted in order to increase or reduce the flow rate through the turbine. The vanes are arranged between two parallel covers normal to the turbine shaft. Pressure distribution and torque L D L Torque D Arm Guide vanes in closed position π ⋅ D0 l= Z F0 = ρ ⋅ g ⋅ H ⋅ B0 ⋅ l Torque = M 0 = F0 ⋅ a 0 Guide vanes in open position Pressure distribution can be found using Bernoulli’s equation: c2 H=h+ + losses 2⋅g ⇓ Contour of the guide vane Trailing edge Trailing edge Pressure distribution along the contour of the guide vane: ξ ⋅ c2 c2 h=H− − ∑ ⋅ 2⋅g 2 g Pressure distribution along the contour of the guide vane: c2 2⋅ g StagnationPoint at Leading Edge Guide vane contour Small flow rate Large flow rate Variation of the torque when the guide vane opening changes: 2 ⋅ M ⋅ D0 Cm = = f (α 0 ) 2 ρ⋅Q α0 2 3 1 4 Sin α0 Horsepower ns = n ⋅ H5 4 cm1 c m1 Powerplant ns α0 Powerplant ns α0 Skjærka 66 12 Dynjafoss 208 27,5 Nedre Vinstra 69 12 Oltesvik 264 38,5 Hol I 72 13 Iverland 269 31,5 Mesna 78 13 Fiskumfoss 308 40,5 Røssåga 104 18 Fiskumfoss 308 36,5 Grønsdal 113 23 Gravfoss 346 37 Nore II 198 34 Solbergfoss 365 38 The guide vane maximum angle α0 at full load Powerplant ns α0 1 Skjærka 66 12 2 Nedre Vinstra 69 12 3 Hol I 72 13 4 Mesna 78 13 5 Røssåga 104 18 6 Grønsdal 113 23 7 Nore II 198 34 8 Dynjafoss 208 27,5 9 Oltesvik 264 38,5 10 Iverland 269 31,5 11 Fiskumfoss 308 40,5 12 Fiskumfoss 308 36,5 13 Gravfoss 346 37 14 Solbergfoss 365 38 NB: This is for Norwegian designed GE-turbines Guide vane angle Specific speed, ns ns = n ⋅ Horsepower H5 4 The servo’s work The servo has to: Take care of the torque from all guide vanes for all guide vane angles The torque consist of: Hydraulic torque Friction torque Hydraulic torque 2 ⋅ Cm ⋅ D0 M= 2 ρ⋅Q Cm = f (α 0 ) The hydraulic torque can be found from a CFD-analysis Friction torque µ ⋅ d ⋅ H ⋅ BD ⋅ DD M f = ±f f (Ω, α ) ⋅ Z ff (Ω,α)= empirical value µ = friction factor H = Head d Opening Friction Stroke Hy d Op e r au lic nin g High head Francis turbine Measurements of the servo’s work for ces Fully open Force in 1000 kg Cl os ing Horse shoe vortex damage Cavitation damage Sand erosion in the guide vanes Jhimruk Hydro Power Plant Head cover Head cover Head cover Guide kvane shaft Bottom cover The deflection of the head cover Z H = 435, P = 25 MW 1 2 Y Reduction of clearance Efficiency of repaired turbine [MW] H = 430 m Design of the Guide Vane Inlet Angle Cu inlet GuideVane ⋅ rinlet GuideVane = Cu inlet StayVane ⋅ rinlet StayVane • The inlet angle can be calculated by assuming a free vortex from the flow coming from the spiral casing Cm inlet GuideVane = B Q π ⋅ Dinlet GuideVane ⋅ B Dinlet Guide Vane rinlet Stay Vane Design of the Guide Vane Outlet Angle • The outlet angle can be calculated by assuming a free vortex from the flow in the gap between the runner and the guide vanes Cu 0 ⋅ ro = Cu1 ⋅ r1 Cmo B0 Q = π ⋅ D0 ⋅ B0 r1 D0 Design of the Guide Vanes How to choose the number of vanes • The number of guide vanes has to be different from the number of runner vanes. zGuide Vanes z Runner Vanes ≠ Integer Design of the Guide Vanes How to choose the number of vanes • The number of guide vanes has to be different from the number of runner vanes. zGuide Vanes z Runner Vanes ≠ Integer Design of the Guide Vanes How to choose the guide vane maximum angle α0 at full load α o = 4 ⋅ (− 4 ⋅ Ω 2 + 13 ⋅ Ω + 1) α Design of the Guide Vanes Overlapping of the guide vanes Design of the Guide Vanes Number of guide vanes Number of Guide Vanes 30 28 26 24 22 20 18 16 0,0 0,2 0,4 0,6 0,8 1,0 Speed Number 1,2 1,4 1,6 Design of the Guide Vanes Diameter of guide vane shaft 1,7 Diameter Ratio D0/D1 D1 D0 = 0,29 ⋅ Ω + 1,07 D1 1,6 1,5 1,4 D2 1,3 1,2 1,1 1,0 0,0 0,2 0,4 0,6 0,8 Speed number 1,0 1,2 1,4 1,6 Statement of Problem Givens Net head…………..….201.5m Flow rate…………...2.35m3/s Turbine speed….1000rpm Work out Design of Runner, Guide vanes, Stay vanes, Spiral casing andDraft tube Compare Design output with Jhimruk turbines Design Considerations Calculations - based on hydraulic principles only, Thickness of runner blades - neglected, Designs of components - done for the best efficiency point, Other several assumptions - mentioned locally in calculations. Design of Guide Vanes Chosen: Nos. of guide vanes z =20 1,7 Diameter of guide vane axis D0 = D1 (0.29 Ω+1.07) Ω = ω⋅ Q −− −− 2 ⋅π ⋅ n ω= 60 . ω = 1.66 −− Q = Q / 2 gH Q = 0.037 Ω = ω⋅ Q Ω = 0.319 −− −− D0 = 1.011m D D0 = 0,29⋅ Ω +1,07 D1 1 1,5 1,4 D 1,3 2 1,2 1,1 ω = ω / 2 gH −− −− Diameter Ratio D0/D1 1,6 −− 1,0 0,0 0,2 0,4 0,6 0,8 Speed number 1,0 1,2 1,4 1,6 Design of Guide Vanes Tangential and meridional velocities Assuming gap between runner and guide vanes 5% of the runner inlet diameter. C u ( gvo ) = C m ( gvo ) = Cu 1 1 . 05 C u ( gvo ) = 39 . 64 m / s Q ( z ∗ t gvo) [ ∗ − π B1 D gvo Cos (α 1) . C m ( gvo ) = 8.58m / s tan α(gvo) = Cm(gvo)/Cu(gvo) α(gvo) = 12.210 Value of αgvo in full guide vane open position is selected 180 Design of Guide Vanes L = 204 Velocities at outlet, axis and inlet of guide vanes (depending on varing values of α and t) Outlet Axis Inlet agvo=12.210 tgvo=5mm Cm(gvo) = 8.582 m/sec Cu(gvo) = 39.65 m/sec Cgvo = 40.56 m/sec agvc=28.040 tgvc=30mm Cm(gvc) = 9.521m/sec Cu(gvc) = 17.87 m/sec Cgvc = 20.25 m/sec agci=340 tgvi=15mm Cm(gvi) = 7.864 m/sec Cu(gvi) = 11.65 m/sec Cgvi = 14.06 m/sec . Cgvi=14.06 m/sec Cm(gvi)=7.86 m/sec Cu(gvi)=11.65 m/sec Cgvc=20.25 m/sec Cm(gvc)=9.521 m/sec Cu(gvc)=17.87 m/sec Cgvo=40.56 m/sec Cu(gvo)=39.65 m/sec Cm(gvo)=8.58 m/sec Design of Guide Vanes . Guide vane at Design Position = 12.21° Guide vane at Max. open Position = 18° Guide vane at closed position Runner inlet (Φ 0.870m) Guide vane outlet for designα) (Φ 0.913m) Closed Max. Opening Position Guide vanes Water particle Water from spiral casing R a d i a l R guide a d ivanes a l runner runner guide vanes v i e w v i stay e wvanes and and stay vanes