PDF Product Technical Guide for Ceiling Fastening Systems

advertisement

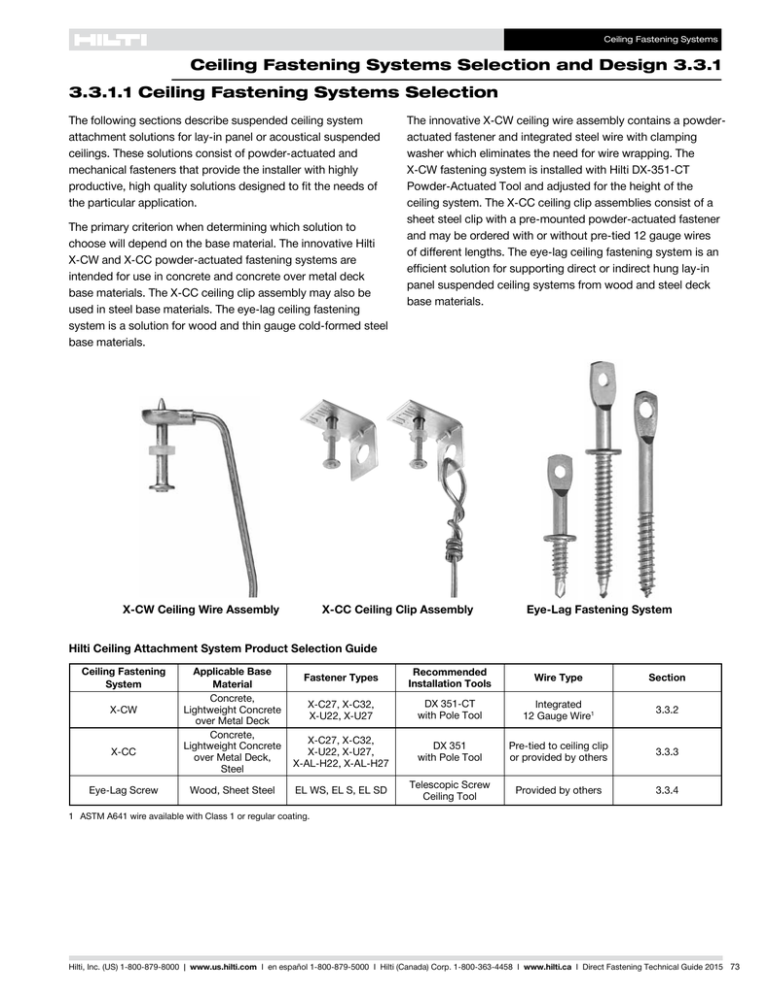

Ceiling Fastening Systems Ceiling Fastening Systems Selection and Design 3.3.1 3.3.1.1 Ceiling Fastening Systems Selection The following sections describe suspended ceiling system attachment solutions for lay-in panel or acoustical suspended ceilings. These solutions consist of powder-actuated and mechanical fasteners that provide the installer with highly productive, high quality solutions designed to fit the needs of the particular application. The primary criterion when determining which solution to choose will depend on the base material. The innovative Hilti X-CW and X-CC powder-actuated fastening systems are intended for use in concrete and concrete over metal deck base materials. The X-CC ceiling clip assembly may also be used in steel base materials. The eye-lag ceiling fastening system is a solution for wood and thin gauge cold-formed steel base materials. X-CW Ceiling Wire Assembly The innovative X-CW ceiling wire assembly contains a powderactuated fastener and integrated steel wire with clamping washer which eliminates the need for wire wrapping. The X-CW fastening system is installed with Hilti DX-351-CT Powder-Actuated Tool and adjusted for the height of the ceiling system. The X-CC ceiling clip assemblies consist of a sheet steel clip with a pre-mounted powder-actuated fastener and may be ordered with or without pre-tied 12 gauge wires of different lengths. The eye-lag ceiling fastening system is an efficient solution for supporting direct or indirect hung lay-in panel suspended ceiling systems from wood and steel deck base materials. X-CC Ceiling Clip Assembly Eye-Lag Fastening System Hilti Ceiling Attachment System Product Selection Guide Ceiling Fastening System X-CW X-CC Eye-Lag Screw Applicable Base Material Concrete, Lightweight Concrete over Metal Deck Concrete, Lightweight Concrete over Metal Deck, Steel Wood, Sheet Steel Fastener Types Recommended Installation Tools Wire Type Section X-C27, X-C32, X-U22, X-U27 DX 351-CT with Pole Tool Integrated 12 Gauge Wire1 3.3.2 X-C27, X-C32, X-U22, X-U27, X-AL-H22, X-AL-H27 DX 351 with Pole Tool Pre-tied to ceiling clip or provided by others 3.3.3 EL WS, EL S, EL SD Telescopic Screw Ceiling Tool Provided by others 3.3.4 1 ASTM A641 wire available with Class 1 or regular coating. Hilti, Inc. (US) 1-800-879-8000 | www.us.hilti.com I en español 1-800-879-5000 I Hilti (Canada) Corp. 1-800-363-4458 I www.hilti.ca I Direct Fastening Technical Guide 2015 73 Ceiling Fastening Systems 3.3.1 Ceiling Fastening Systems Selection and Design 3.3.1.2 Ceiling Fastening Systems Design Figures 1 and 2 illustrate the installation of a suspended ceiling system as described in ASTM C635. The ceiling systems shown are composed of ceiling panels which are supported by a suspension system of main runners, cross runners and wall moulding for direct hung ceiling systems. Carrying channels are part of indirect hung ceiling systems where the main runners are attached to carrying channels which are attached to concrete using Hilti ceiling fastening systems. The entirety of the suspended ceiling system depends on the Hilti ceiling fastening hangers which support the suspension system main load carrying members. The spacing between ceiling fasteners must be determined by the design architect or engineer of record based on the loads and building code requirements or as recommended by ceiling manufacturer (e.g. Armstrong/ WAVE). Hanger wires must be wrapped by the installer to the specific requirements at the point of installation to the main runner or channel members as shown in the figures below. The wires must be wrapped in a similar fashion at the wire hole for the X-CC ceiling clip assemblies. The innovative X-CW ceiling wire assemblies do not require wire wraps as the integrated ceiling wire and clamping washer is premounted to the head of the fastener. Hilti ceiling fastening systems should not be used for anchorage of seismic bracing channels and compression struts. Hilti recommends the use of ICCES AC193 qualified mechanical anchors, such as Hilti KB-TZ, for attachment of bracing for suspended ceiling systems. Reference Section 2.4 for more discussion on seismic considerations. Hilti Ceiling Attachment System Support Clip for Main Runners Wall Moulding Carrying Channel Acoustical Tile Cross Runners Figure 1: Indirect Hung Ceiling system (reference ASTM C635) Spline (Spanning Cross Runners) 12 ga. wire typ. Hilti Ceiling Attachment System Main Runners 3 tight turns in 1-1/2" Carry Channel or Main Runner typ. Acoustical Lay-in Panels Cross Runners (Spanning Main Runners) Wall Moulding Main Runners Figure 2: Direct Hung Ceiling System (reference ASTM C635) 74 Hilti, Inc. (US) 1-800-879-8000 | www.us.hilti.com I en español 1-800-879-5000 I Hilti (Canada) Corp. 1-800-363-4458 I www.hilti.ca I Direct Fastening Technical Guide 2015 Ceiling Fastening Systems Ceiling Fastening Systems Selection and Design 3.3.1 3.3.1.3 Ceiling Fastener Locations when Installing into Lightweight Concrete over Metal Deck Hilti Ceiling Fastening System 3000 psi Lightweight Concrete 12" min. 3-1/4" 3" 3-7/8" min. Form Deck Lower Flute Location Upper Flute Location Direction of combined 1-1/8" load on Min. Edge fastener Distance (Typical) Direction of tension load on fastener (Typical) 3-7/8" min. 7-1/4" min. Figure 3: Hilti Ceiling Fastening System Location in 3-in.-Deep Composite Floor Deck, Normal Deck Profile Orientation Hilti Ceiling Fastening System 6" 3000 psi Lightweight Concrete min. 2-1/2" 1-3/4" Form Deck Upper Flute Location Lower Flute Location Direction of combined load on fastener (Typical) Direction of tension 7/8" load on Min. Edge fastener Distance (Typical) 1-1/2" 2-1/2" 3-1/2" Figure 4: Hilti Ceiling Fastening System Location in 1-1/2-in.-Deep Composite Floor Deck, Normal Deck Profile Orientation Hilti Ceiling Fastening System 6" 3000 psi Lightweight Concrete Form Deck Upper Flute Location Lower Flute Location Direction of combined load on fastener (Typical) Direction 1-3/4" of tension Min. Edge load on Distance fastener (Typical) min. 2-1/2" 1-3/4" 1-1/2" 3-1/2" Figure 5: Hilti Ceiling Fastening System Location in 1-1/2-in.-Deep Composite Floor Deck, Inverted Deck Profile Orientation Hilti, Inc. (US) 1-800-879-8000 | www.us.hilti.com I en español 1-800-879-5000 I Hilti (Canada) Corp. 1-800-363-4458 I www.hilti.ca I Direct Fastening Technical Guide 2015 75