Easy Unplugger For more information, please contact a.gouldstone

advertisement

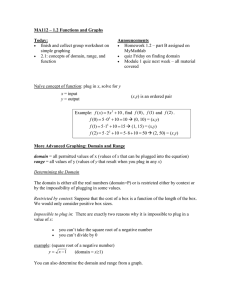

Easy Unplugger Design Team Drew Nathanson, Michael Notarangelo Mario Peritore, Matthew Sauter Design Advisor Prof. Andrew Gouldstone Sponsor N/A Abstract This report describes the design process for a mechanical or electro-mechanical device to allow remote unplugging of a cord from an electrical outlet. The primary motivation for the project is the increased usage of portable electronics, and therefore the increased number of times that device chargers or power cords are unplugged daily. Targeted users include travelers, commuters, or users disabled to the extent that unplugging is difficult or uncomfortable. From three initial mechanism ‘types’ (electronic, electro-mechanical, mechanical), an electromechanical design was decided upon leading to the development of more advanced and specific models. After choosing an electromechanical design, three different electromechanical (E-M) designs were decided upon leading to the development of more advanced and specific models. Three E-M designs were analyzed, using mechanisms such as springs and motors, solenoids, and actuators to eject a plug. Testing was done to determine the necessary force to remove a plug from an outlet, and to assess how long this force persists. Experimental data resulted in the final selection, a locking spring activated by a servomotor. This was modeled, constructed, tested, and analyzed for production cost. For more information, please contact a.gouldstone@neu.edu. The Need for Project The need for our research and The increased use of portable electronics such as laptops, cell proposed solution comes from phones and tablets has resulted in a drastic increase of plugging in and the increased use of portable unplugging standard electronic cords. This is a simple task for most electronics, resulting in an users under normal circumstances but for those users with physical increase of plugging and limitations, who are in a rush, or even just to simplify their lives, a unplugging electrical cords. device that could remotely release a plug would be of great benefit. The This product makes that action target audience includes travelers, elderly and students who rely on easier, quicker and safer for all electrical cords but do not want to reach down to unplug them every users. time they change charging stations. This device would have to meet the simple requirements of unplugging a cord from an outlet, be safe to use, simple to operate, reduce the amount of energy required to unplug and lastly not require user to physically approach the outlet. A product that meets all of these requirements would benefit a large percentage of the population allowing for proper unplugging techniques and minimizing the chance of electrical shock or damaged wires. The Design Project Objectives and Requirements The objective of the design Design Objectives was to create an The design objectives of this project involved creating a electromechanical adapter that device/method that would help alleviate the difficulty of unplugging an would unplug an appliance appliance from a standard outlet. Goals were laid out that would help remotely. accomplish the overall objective. These goals had to ensure that at the conclusion of the project, the main design objective was satisfied. This means the device would be simple to operate, primarily automated and not require more energy than actually unplugging from the wall. The design also had to not require the user to physically approach the outlet, which would lead to the design being remotely triggered. Design Requirements The design requirements entailed quantitative data about the metrics of the device. The final product would have to be small enough to only take up one socket from a standard American outlet. It would also have to successfully act as an adaptor meaning completing a circuit between an appliance and the outlet. Lastly this device must be comparable to many travel adaptors that are currently available and cost around $19.99. Design Concepts Considered The proposed designs include mechanical and electromechanical Five candidate design concepts were developed, of which two mechanisms. The purely mechanical design was conceptualized by the fully meet the requirements theory of bicycle brakes. The design would incorporate tension cables and required additional that would move a lever to push the plug out of the outlet. The planning and comparisons. electromechanical mechanism has the ability to be triggered remotely. The mechanism can use many different actuation mechanisms to unplug a plug. The actuation mechanisms that were investigated were a spring, a small linear actuator and a power screw. The preliminary designs were evaluated and the electromechanical adaptor was found to be the best approach to solve this problem. Factors that influenced this choice included the extended range of use provided by the remote controlled system, the added safety of the stationary prongs and finally the ease of resetting. Additionally, to developing designs that would force the plug out of the outlet, designs reducing the force it takes to unplug a plug from an outlet were developed. Removing friction between two surfaces that are being pulled or pushed reduces the required force to complete the action. Therefore if a lubricant is applied to the prongs of a plug it would require less force to unplug it from an outlet. However, applying a lubricant to the prongs of a plug would be hazardous and unrealistic. Research into this option has revealed studies in creating a mechanical lubricant. Studies show that applying a vibration to a moving body that is experiencing a normal force, reduces the force to move the body. Changing the prong sizes was researched to see if it would reduce the force to unplug a plug as well. Testing has revealed that in cases where prong dimensions have been changed it considerably decreases force required to unplug/plug into an outlet. Recommended Design Concept This design utilizes a simple (1) spring to provide the force Design Description The final design that was decided on is an electromechanical required for unplugging. adaptor that uses a spring and plunger to remove the plug from its Simple motors activate strong outlet. When the plug is inserted into the outlet the plunger will travel springs to minimize size. along a series of grooves, forcing itself to rotate and compress the spring and eventually hitting a flat surface. This surface will act as a hard stop, keeping the spring compressed and preventing the plunger from immediately ejecting the plug. This groove system is crucial to the design because without it and the flat stopping surface, the plug would be immediately ejected. When the user wants to eject the plug, a small servomotor connected to the plunger can then be activated using an infrared signal causing the plunger to rotate, releasing it from its hard stop. The spring will push the plunger along the grooves and eject the plug from the wall. When the user inserts the plug into the wall again for the next use, the spring will compress and the adapter will reset. (2) Experimental Investigations The first experiment that needed to be done was to determine the force that must be overcome to unplug a plug from an outlet. To accomplish this, a force gauge was used to remove different types of plugs from both an outlet and power strip. Once the force was determined, the spring necessary to overcome the force could be found. One of the most important experiments that had to be completed was determining the optimal spring to use in the adapter. To accomplish this, a mock-up adapter was made using a 3D printer. This mock-up had plungers with grooves to fit each spring being tested. There was no hard stop system, so the plunger would attempt to eject the plug as soon as it was released by the operator of the test. Using this test bed, two springs were determined that would accomplish the goals of the test. From here the final choice of spring was made. (3) Key Advantages of Recommended Concept The main advantage of this concept is that the plug can be removed remotely without the user having to walk over to the outlet. Existing products that were researched required the user to move across the room and unplug the cord at the socket. With the infrared transmitter, the user needs to only push a button to eject their device from the wall. Another key advantage is the cost of the adapter. Using a spring and piston allows the cost to be kept to a minimum. Although using a solenoid or linear actuator to push the plug out is possible, it is also expensive. Also, having the plunger travel along the system of grooves allows the adapter to reset itself every time the adapter is plugged in. This saves the user from taking a separate step of resetting the adapter before each use. Financial Issues The desired cost of $19.99 was The product should be similarly priced to current electric travel based on existing electrical adapters on the market. This means the price of the adaptor shall be adaptors currently on the around $19.99. This brings up concerns with the design to ensure that it market. does not use expensive parts. This means that the mechanism used in the design shall be inexpensive. This is a challenge because many of the mechanisms that were discussed had to be ruled out due to price. However, despite the desired price the design cannot be cheaply manufactured or contain poor quality parts, as it must accomplish the goal. Recommended Improvements To maximize the efficiency All prototypes created to date have utilized rapid prototyping to and minimize the price the create quick, effective and strong models of the design. These models final manufactured design shall were efficient for proof of concepts, product design and testing but will be injection molded. eventually be abandoned before the product is moved to manufacturing. To maximize cost and efficiency injection molding will be utilized for all pieces. This form of manufacturing will create a cheap, strong and precise set of parts to be assembled efficiently and cost effectively.