This is a research initiative into lightweight thin

advertisement

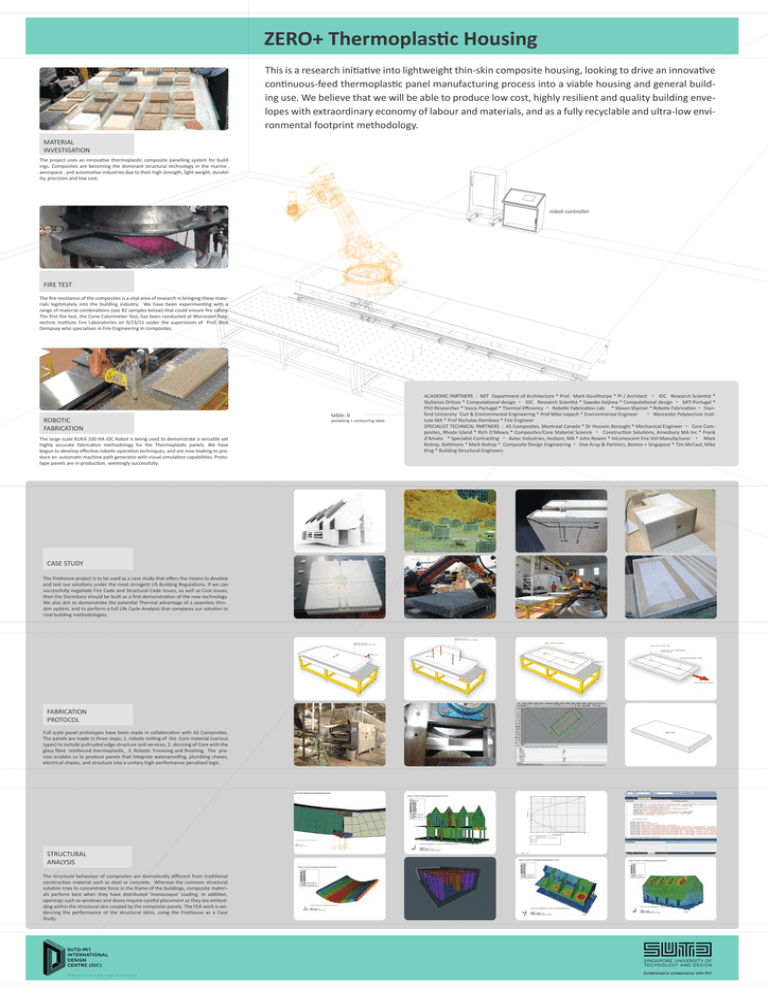

ZERO+ Thermoplastic Housing This is a research initiative into lightweight thin-skin composite housing, looking to drive an innovative continuous-feed thermoplastic panel manufacturing process into a viable housing and general building use. We believe that we will be able to produce low cost, highly resilient and quality building envelopes with extraordinary economy of labour and materials, and as a fully recyclable and ultra-low environmental footprint methodology. MATERIAL INVESTIGATION The project uses an innovative thermoplastic composite panelling system for buildings. Composites are becoming the dominant structural technology in the marine , aerospace , and automotive industries due to their high strength, light weight, durability, precision and low cost. robot controller FIRE TEST The fire resistance of the composites is a vital area of research in bringing these materials legitimately into the building industry. We have been experimenting with a range of material combinations (see 82 samples below) that could ensure fire safety. The first fire test, the Cone Calorimeter Test, has been conducted at Worcester Polytechnic Institute Fire Laboratories on 9/23/11 under the supervision of Prof. Nick Dempsey who specialises in Fire Engineering in composites. table: a trimming table ROBOTIC FABRICATION The large scale KUKA 100 HA IDC Robot is being used to demonstrate a versatile yet highly accurate fabrication methodology for the Thermoplastic panels. We have begun to develop effective robotic operation techniques, and are now looking to produce an automatic machine path generator with visual simulation capabilities. Prototype panels are in production, seemingly successfully. table: b pocketing + contouring table ACADEMIC PARTNERS : MIT Department of Architecture * Prof. Mark Goulthorpe * PI / Architect ・ IDC Research Scientist * Stylianos Dritsas * Computational design ・ IDC Research Scientist * Sawako Kaijima * Computational design ・ MIT-Portugal * PhD Researcher * Vasco Portugal * Thermal Efficiency ・ Robotic Fabrication Lab * Steven Shpiner * Robotic Fabrication ・ Stanford University Civil & Environmental Engineering * Prof Mike Lepech * Environmental Engineer ・ Worcester Polytechnic Institute MA * Prof Nicholas Dembsey * Fire Engineer SPECIALIST TECHNICAL PARTNERS : AS Composites, Montreal Canada * Dr Hossein Borazghi * Mechanical Engineer ・ Core Composites, Rhode Island * Rich O'Meara * Composites/Core Material Science ・ Construction Solutions, Amesbury MA Inc * Frank d'Amato * Specialist Contracting ・ Avtec Industries, Hudson, MA * John Rowen * Intumescent Fire Veil Manufacturer ・ Mark Bishop, Baltimore * Mark Bishop * Composite Design Engineering ・ Ove Arup & Partners, Boston + Singapore * Tim McCaul, Mike King * Building Structural Engineers CASE STUDY The Firehouse project is to be used as a case study that offers the means to develop and test our solutions under the most stringent US Building Regulations. If we can successfully negotiate Fire Code and Structural Code issues, as well as Cost issues, then the Dormitory should be built as a first demonstration of the new technology. We also aim to demonstrate the potential Thermal advantage of a seamless thinskin system, and to perform a full Life Cycle Analysis that compares our solution to rival building methodologies. FABRICATION PROTOCOL Full scale panel prototypes have been made in collaboration with AS Composites. The panels are made in three steps: 1. robotic milling of the Core material (various types) to include pultruded edge structure and services, 2. skinning of Core with the glass fibre reinforced thermoplastic, 3. Robotic Trimming and finishing. The process enables us to produce panels that integrate waterproofing, plumbing chases, electrical chases, and structure into a unitary high-performance penalized logic. Printed on: Wed Jul 20 15:51:37 Malay Peninsula Standard Time 2011 0.15 Thickness 0.10 0.05 0.00 −2.0 −1.5 −1.0 Transverse Shear TSHR23 Conventional CTSHR23 (Avg: 75%): True Dist. along ’Path−1’ XMIN −2253.910 XMAX 0.000 YMIN 0.000 STRUCTURAL ANALYSIS The structural behaviour of composites are dramatically different from traditional construction material such as steel or concrete. Whereas the common structural solution tries to concentrate force in the frame of the buildings, composite materials perform best when they have distributed ‘monocoque’ loading. In addition, openings such as windows and doors require careful placement as they are embedding within the structural skin created by the composite panels. The FEA work is evidencing the performance of the structural skins, using the FireHouse as a Case Study. SUTD-MIT INTERNATIONAL DESIGN CENTRE (IDC) Undertake the impossible, Design the unexpected YMAX 0.154 −0.5 0.0 [x1.E3]