SENSOR PROPERTIES OF CADMIUM SULPHIDE (CDS) THIN

advertisement

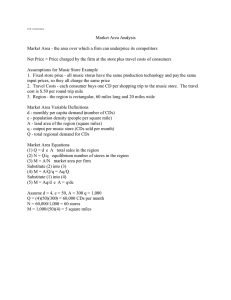

Molecular and Quantum Acoustics vol. 26, (2005) 273 SENSOR PROPERTIES OF CADMIUM SULPHIDE (CDS) THIN FILMS IN SURFACE ACOUSTIC WAVE SYSTEM - PRELIMINARY RESULTS Marian URBAŃCZYK, Wiesław JAKUBIK, Erwin MACIAK Institute of Physics, Silesian University of Technology ul.Krzywoustego 2, 44-100 Gliwice, POLAND murban@polsl.pl Presented here are the preliminary results concerning a cadmium sulfide(CdS) thin films investigations in a Surface Acoustic Wave dual-delay line systems. The CdS films has been prepared by an open-boat, physical vapor deposition (PVD) process using chemically prepared CdS powder as starting material. The thicknesses of the CdS films was about 115nm and 268nm. These CdS films have been investigated from the point of view their sensitivity towards: nitrogen dioxide, sulphur dioxide, ammonia and H2S gases with different concentrations in dry air. Keywords: cadmium sulfide film , surface acoustic wave, sensor properties 1. INTRODUCTION Conducting polymers are a new class of materials with a potent application in a number of growing new technologies, such as energy storage [1,2], molecular recognition [3,4] and opto-electronic devices [5,6]. All conducting polymers exhibit highly reversible redox behaviour with a distinguishable chemical memory and hence have been considered as prominent new materials for the fabrication of chemical sensors [7,8]. Cadmium sulfide, the mineral Greenockite, is an hexagonal, orange crystal with specific gravity of ~4.8g/cm3 and Mohs hardness of 3.8. Synthetic Cadmium pigments based on Cadmium sulfide are valued for their good thermal stability in many polymers, for example in engineering plastics. Cadmium sulfide has useful properties for optoelectronics, being used in both photosensitive and photovoltaic devices. Cadmium sulfide is an important II–VI semiconductor with a direct band-gap of 2.4 eV at room temperature, and it receives a wide range of research interest because of their unique properties and their wide variety of potential applications. For instance, for laser light-emitting diodes, solar cells, non-linear optical, 274 Urbańczyk M., Jakubik W., Maciak E. optoelectronic and electronic devices. The most important properties of CdS are shown in Table.1. Table.1 Properties of CdS Application fields: IR optics, polarizers, beamsplitters, λ /2 and λ/4 waveplates; substrates; Structure Density: Young’s Modulus: Coef. of Thermal Expansion (500 K): Wurtzite (Hexagonal) 4.825 g/cm3 45 GPa Specific Heat: Thermal conductivity (at 25 oC): Max. Transmittance (λ =2.5-15 µm): 0.47 J/gK 0.2 W/cmK Absorption Coef. (λ =10.6 µm): ≤ 0.007 cm-1 (including 2 surfaces) Refractive index (λ =10.6 µm): 2.2 Max. crystal diameter/length: ∅ α 1=6.26×10-6/K; α 3=3.5×10-6/K ≥ 71 % 40×30 mm During the past decades, various methods have been applied to fabricate cadmium sulfide nanocrystallines, such as electrochemically induced deposition , thermal decomposition , laser-assisted catalytic growth method , ultrasound irradiation, solvothermal method, and hydrothermal method [9]. In Institute of Physics SUT – vacuum evaporation technology have been applied for manufacturing of CdS thin films 115nm and 268nm (with yellow colour) in a SAW method. In this work, we report on sensor properties of as-deposited thin films of cadmium sulfide (CdS) by PVD technique at about 7000C from synthesized CdS powder. The investigations have been performed by SAW method from the point of view ofr sensitivity towards: nitrogen dioxide, sulphur dioxide, ammonia and H2S gases with different concentrations in dry air. 2. EXPERIMENTAL Surface Acoustic Waves (SAW) are very attractive due to their remarkable sensitivity in a specific configuration of the sensor structure, as well as their small size, low power consumption and frequency measurements [10-12]. The sensor structure in SAW method is shown in Fig.1. In such a sensor structure we can use both the acoustoelectric interaction ( between the electric potential associated with surface wave and the charge carrier in the CdS film) and the mass effects [13-15]. For rather high resistance CdS samples (even above 200 G Ω) we expect mainly the mass interactions. Molecular and Quantum Acoustics vol. 26, (2005) 275 Fig.1. The sensor structure with CdS thin film in a dual delay line configuration on piezoelectric lithium niobate substrate placed in a measuring chamber The experimental set-up for acoustic sensor is based on frequency changes in a surface acoustic wave dual delay line system, which is nowadays well known – Fig.2. On a piezoelectric LiNbO3 substrate, two identical acoustic paths are formed, using interdigital transducers. Next, a CdS thin film structure is formed in the measuring line in vacuum deposition processes. The second path serves as a reference and can compensate small variations of temperature and pressure. Both delay lines are placed in the feedback loop of oscillator circuits and the response to the particular gas of the active is detected as a change of the differential frequency ∆f, i.e. the difference between the two oscillator frequencies f and f0. 276 Urbańczyk M., Jakubik W., Maciak E. Fig.2. Schematic diagram of the experimental set-up The investigated CdS films with thicknesses of about 115 and 268 nm, were made by means of the vacuum-sublimation method, using a special aluminium mask and molybdenum boat. The source temperature was about 700 oC and the thickness was measured by the interference method. A copper-constantan thermocouple was used to control the temperature. The total flow rate of 1000ml/min was used during all the measurements. The volume of the measuring chamber was about 30cm3. The sensor was tested in a computer-controlled system. Gases of 99.999% pure hydrogen and 99.998% pure NO2, SO2, NH3 in dry air were mixed using mass flow controllers (Bronkhorst Hi-Tech). The temperature was measured using a thermocouple adjacent to the structure. Molecular and Quantum Acoustics vol. 26, (2005) 277 3. RESULTS Examples of interaction of the obtained CdS film with 115nm in SAW system in sulphur dioxide are shown in Fig.3, with NO2 in Fig. 4, with NH3 in Fig.5 and with H2S in Fig.6. 2004­12­20 C dS ~115nm heating T = 52oC dosing F3 (SO2) 600 s plik 2004-12-20d 211,5 60 58 211,0 56 temp 210,5 52 50 ∆f 210,0 48 Temperature [oC] Frequency [kHz] 54 46 20 15 209,5 44 10 5 ppm SO2 in air 42 209,0 0 600 1200 1800 2400 3000 3600 4200 4800 40 5400 Time [s] Fig.3. Interaction of CdS film (~115nm on LiNbO3 Y-Z substrate) with different concentrations of sulphur dioxide (SO2) in synthetic air at temperature (~520C) A very small interactions of the investigated film of CdS can be observed for the measurements with SO2 gas even at higher temperatures (~520C). The interaction is on the level of ~100Hz . The resistance of the sample is above of the range of the Electrometer Keithley 614 (200GΩ). So monitoring of the resistance cannot be performed. In Fig.4 we can observe an increase of differential frequency of the sample under the influence of various concentrations of NO2 in synthetic air (between 1000 and 5000 ppm). The regeneration of the sample at measurement temperature ~560C is quite good. The decrease of differential frequency of the sample (but for lower frequency mode) is observed for interaction with ammonia – Fig.5. The changes in frequency are between 250Hz for 1000ppm to 500Hz for 3000ppm NH3 in dry air. 278 Urbańczyk M., Jakubik W., Maciak E. plik 2004-12-21c 2004-12-21 CdS 115nm heating T = ~ 56oC dosing Doz1 (NO2) 600s 60 216,2 58 56 54 215,8 52 50 215,6 48 215,4 46 Temperatureo[C] Frequency [kHz] 216,0 44 215,2 42 1000 ppm NO2 w pow syntet 5000 2000 40 215,0 0 600 1200 1800 2400 3000 3600 4200 Time [s] Fig.4. Interaction of CdS film (~115nm on LiNbO3 Y-Z substrate) with different concentrations of NO2 in synthetic air at temperature (~560C) 60 38,4 58 56 temp. 38,2 54 38,0 50 48 37,8 46 ∆f 44 37,6 42 40 37,4 Temperature [oC] Frequency [kHz] 52 38 36 37,2 34 1000 ppm NH3 in air 0 600 1200 1800 32 3000 2000 37,0 2400 3000 3600 30 4200 Time [s] Fig.5. Interaction of CdS film (~115nm on LiNbO3 Y-Z substrate) with different concentrations of NH3 in synthetic air at temperature (~580C) Molecular and Quantum Acoustics vol. 26, (2005) 279 For interaction with H2S a lack of regeneration at lower temperatures and good regeneration but small interactions at higher temperatures is clearly observed – Fig.6. In Fig.7 an example of interaction of the second film of CdS (~268nm) with sulphur dioxide is shown. The changes in frequency ∆f are not great even for rather high gas concentrations – between 1000 – 5000 ppm in dry air. plik 2005-01-04a 50 48 46 46,4 42 38 46,2 36 34 46,1 32 30 46,0 o 40 Temperature C] [ Frequency [kHz] 44 46,3 28 26 45,9 24 10 ppm H2S in air 22 20 45,8 0 900 1800 2700 20 4500 3600 Time [s] 32,6 60 58 56 32,4 temp 54 Frequency [kHz] 50 48 32,0 ∆f 46 44 31,8 42 40 31,6 Temperature [oC] 52 32,2 38 36 31,4 34 10 ppm H2S in air 30 20 31,2 0 900 1800 2700 3600 4500 32 40 5400 6300 30 7200 Time [s] Fig.6. An examples of preliminary acoustic measurements for CdS 115nm with different concentrations of H2S at ~320C (upper) and ~530C (lower graph). 280 Urbańczyk M., Jakubik W., Maciak E. 40 plik 2005-01-12b 38 t 36 34 32 30 28 26 251.24 24 22 ∆f 251.22 2005-01-12 CdS 2 h~268nm 20 o T measurement ~ 34 C dosing Doz1 (SO2) 600s 16 Temperature [ oC] Frequency [kHz] 251.26 18 14 12 5000 2000 251.20 10 0 600 1200 1800 1000 ppm SO2 in Air 2400 3000 3600 4200 Time [s] Fig.7. Interaction of CdS film (~268nm on LiNbO3 Y-Z substrate) with different concentrations of sulphur dioxide (SO2) in synthetic air at temperature (~340C) 4. CONCLUSIONS The cadmium sulfide films has been prepared by an open-boat, physical vapor deposition (PVD) process using chemically prepared powder as starting material. The thicknesses of the CdS films was about 115 and 268 nm. These CdS films have been investigated from the point of view their sensitivity towards: nitrogen dioxide, sulphur dioxide, ammonia and H2S gases with different concentrations in dry air. Preliminary measurements of this two CdS films have been performed using an acoustic method with Surface Acoustic Waves. This method can be successfully used even when the resistance of the sample is very high – above 200GΩ. For CdS 115nm film, good and very repeatable interaction with NH3 at higher temperatures (above 500C) has been observed. Whereas for interaction with H2S lack of regeneration at lower temperatures and good regeneration but small interactions at higher temperatures is clearly observed. For the sample with a CdS thickness of 268nm an interaction with SO 2 on the level 50Hz is observed but only for higher concentrations. The best results were achieved after many cycles of interaction and at higher temperatures. Molecular and Quantum Acoustics vol. 26, (2005) 281 ACKOWLEDGEMENTS This work was sponsored by the Polish Committee for Scientific Research within the grant No. O T00A02726. REFERENCES 1. N.Li, Y.Lee and L.H.Ong, J.Appl.Electrochem. 22, 512 (1992). 2. F. Trinidad, M.C.Montemayer and E.Fatas, J.Electrochem.Soc. 138, 3186 (1991). 3. P.R. Teasdale and G.G. Wallace, Analyst, 118, 329 (1993). 4. N Bartlett and S.K.I Chung, Sensors and Actuators, 20, 287 (1989). 5. E.W.Paul, A.J.Ricco and M.S.Wrighton, J.Phys.Chem., 89,1441 (1985). 6. S.K. Dhawan and D.C. Trivedi, Poly. Inter., 25, 55 (1991). 7. A.Boyle, E.M. Genies and M.Lapkowski, Synth. Met. 28, C769 (1989). 8. H.Hu, M.Trejo, M.E. Nicho, J.M.Saniger and A.Garcia-Valenzuela, Sensors and Actuators B 82, 14 (2002). 9. B.Bostick, S.Fendorf, M.Fendorf, Geochimica et Cosmochimica Acta , 64, No.2, 247 (2000). 10. W. Jakubik, M. Urbańczyk, Journal of Technical Physics, 38, 3, 589(1997). 11. M.Urbańczyk, W.Jakubik, Electron Technology, 33,1/2, 161, Warszawa (2000). 12. W. Jakubik, M.Urbańczyk, S.Kochowski, J.Bodzenta, Sensors and Actuators B 82, 265, (2002). 13. W.Jakubik, M.Urbańczyk, S.Kochowski, J.Bodzenta Sensors and Actuators, B, 96, 321, (2003). 14. W. Jakubik, M. Urbańczyk, Sensors and Actuators B 106, 602 (2005). 15. W.Jakubik, M.Urbańczyk,J.Bodzenta, M.Pietrzyk, Sensors and Actuators, B,105, 340 (2005).