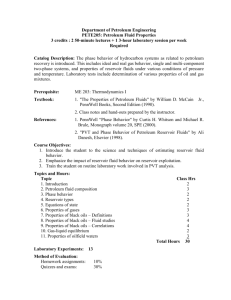

Complex Reservoir Fluid Characterisation

advertisement

SPE Workshop: Complex Reservoir Fluid Characterisation - Impact on Hydrocarbon Recovery and Production SUPER EARLY BIRD Register before 13 December 2015 13 - 16 March 2016 | Eastern & Oriental Hotel, Penang, Malaysia WHY SHOULD YOU ATTEND? ✓ Understand the key difference in complex fluids behavior. ✓ Advancement of complex fluid characterisations including data acquisition, phase behavior & PVT tests, EOS modelling and others. ✓ Understand and learn the key focus of complex reservoir fluids which are multi-stacked compartmentalised reservoirs with fluids faced large degree of compositional grading with depth and variation laterally; gas/oil fields with high percentage of CO2; fluid evaluation for the gas-based and chemical EOR processes. ✓ Understand the multidisciplinary data integration and fluid management. ✓ Learn from the FDP case studies on complex reservoir fluids. WHO SHOULD ATTEND? This workshop is designed for industry professionals who work with reservoir fluids and fluid data at various capacities, from hands-on data generation/handling to end-users of the data. Such professionals include but are not limited to reservoir engineers, petroleum engineers, production engineers, flow assurance engineers, geochemists, and process engineers. Experts from the laboratories are also welcome. Associated Training Course The Workshop will be preceded by a Training Course held on 12 – 13 March 2016 on Understanding the Complex Fluid Characterisation: A Critical Component in Improving the Hydrocarbon Recovery presented by Raj Deo Tewari, Custodian Reservoir Engineer and Rahim Masoudi, Custodian IOR/EOR Engineer of PETRONAS. For further information on this workshop, please visit www.spe.org/events/16ako2 SPE Workshop: Complex Reservoir Fluid Characterisation Impact on Hydrocarbon Recovery and Production 13 - 16 March 2016 | Eastern & Oriental Hotel, Penang, Malaysia Workshop Description Reservoir fluid phase behavior and PVT properties play a major role throughout the field life cycle from exploration, development, production and reservoir management up to EOR/IOR implementation. Complex reservoir fluids include the volatile oil, retrograde condensate, heavy oils, high impurities (such as CO2, H2S, etc.), high wax and asphaltenes content, fluids with high degree of compositional grading and variation, non-equilibrium fluids and also the change of phase behavior and composition through IOR/EOR processes. For instance, it is recognised that the phase and volumetric behavior of gas/oil system during gas injection had an important effect on ultimate recovery efficiency. Characterisation of the complex fluid which include obtaining reliable fluid samples, PVT data measurement and quality assurance/quality control (QA/QC), EOS tuning and fluid initialisation is a vital element to understand the hydrocarbon system and essentially the fluid characterisation integration with other reservoir data, particularly with rock characterisation, will assist in development decision and on-going reservoir management. Technology advancement and new methodologies in complex fluid characterisation result in a better and more accurate prediction of the phase behavior and volumetric properties of multicomponent system. More attention will be given on the following cases: multi-stacked compartmentalised reservoirs with hydrocarbon fluids having large degree of compositional and gravity variation, laterally and vertically; waxy/asphaltic crude development and production, gas/oil fields with acid gases contamination; deepwater development and fluid evaluation for gas-based and chemical EOR processes. Reservoir fluid characterisation also plays a key role in the design and optimization of production processes and facilities for efficient reservoir management. Thus, the challenges of characterising complex fluid streams for applications in different disciplines are worth extensive/elaborate discussion. Essentially, the discussion will address the overall risks and uncertainties and the impact of complex fluid characterisation from subsurface and surface perspective on the development concepts associated with gas/oil recovery and production, especially with respect to development capex and lifecycle opex. Workshop Objectives • Review and critique the latest technical advancements, associated reservoir fluid technologies, and management for the full E&P life cycle from exploration to EOR/IOR, with special emphasis on carbonate fluid systems and sour systems. • Share experiences via case histories. • Exchange/discuss ideas with fellow participants/experts from other companies, research institutes and universities. • Form a stronger network in the area of reservoir fluids/PVT, leading to future collaborative R&D/exchange of information at various levels. TECHNICAL PROGRAMME COMMITTEE Co-Chairpersons Handan Ramli General Manager PETRONAS Anthony Peacock Chief Reservoir Engineer Shell Malaysia Committee Members Abdul Halim Zainal Abidin Head of Subsurface Uzma Group www.spe.org/events/16ako2 Adil Pottayil Regional Manager (APAC) & Senior Consultant Calsep Asia Pacific Andry Halim VP Technical Support Pertamina Christopher Lenn Professor of Petroleum Engineering Universiti Teknologi PETRONAS Gunajit Das Principal - Halliburton Consulting Halliburton Workshop Advisor Technical Advisor Julio Herbas Head of Subsurface Io Oil and Gas Consulting Nagi Nagarajan Engineering Advisor Hess Corp. Rahim Masoudi Custodian IOR/EOR Engineer PETRONAS SPE Regional Technical Advisory Committee (RTAC) James Griffiths Senior Reservoir Engineer Santos Jan Bon Jr. Manager Petrolab Australia Kanthavel Renganathan Upstream Fluid Services Manager Petrotechnical Inspection Raj Deo Tewari Custodian Reservoir Engineer PETRONAS Carigali Sdn Bhd Nur Shazren Mohd Shah Senior Reservoir Engineer PETRONAS Scott Fey Principal Reservoir Domain Lead Schlumberger Md Nezam Mansor Head Production & Storage PETRONAS Carigali Sidhartha Sur Executive Director Chief Corporate Planning ONGC Michael E. Potts Region Manager for Software & Flow Measurement Weatherford Asia Pacific Vikas Bhushan Sarawak Asset Development Lead Shell Malaysia PRELIMINARY DAILY ACTIVITIES AND TECHNICAL AGENDA For updated technical information, visit www.spe.org/events/16ako2 Sunday, 13 March 2016 1500 1400 - 1600 1700 - 1900 1800 - 1900 1900 Hotel Check-in Final Programme Committee Meeting SPE Registration/Poster Setup Discussion Leaders and Session Chairpersons/Managers Briefing Welcome Reception/Dinner Monday, 14 March 2016 0830 - 1000 1000 - 1030 1030 - 1230 1230 - 1330 1330 - 1500 1500 - 1515 1515 - 1645 1645 - 1815 1815 - 1900 1900 Session 1: Introduction/Opening & Keynote Address Group Photo/Coffee Break Session 2: Advancement of Complex Fluid Sampling and Data Acquisition Samples of complex fluids can be collected from a wide range of locations covering topside facilities, the wellbore and the formation itself. Best practices for complex fluid sampling, the acquisition and reporting of data as well as the quality control of samples have advanced in recent years and will be discussed. The sampling program itself must ensure that the best methods are used to ensure that samples are taken under the best conditions. This is critical, for instance, in the case of gas/condensate reservoirs that may be at their saturation pressure. Sampling methods for heavy oils require the use special tools and sensors to obtain representative samples. Additionally the sampling of reactive or non-hydrocarbon components of complex reservoir fluids can be complicated through reaction or adsorption when in contact with the production tubing and even sample-bottle walls. Multiphase metering and the development of advanced methods such as isokinetic sampling now are having an impact on sampling programs. Developments in down-hole sampler technology, better designed equipment for reactive samples and the continued development of in-situ down-hole measurements and data acquisition continue to contribute to improvements in obtaining quality representative samples. Luncheon Session 3: Complex Fluids Characterisation - Phase Behavior and PVT tests Reservoir fluids naturally containing mixtures of complex hydrocarbons and non-hydrocarbons such as carbon dioxide, hydrogen sulphide, mercury, nitrogen etc. In-situ and laboratory tests of collected samples are required to determine their physical and chemical properties. This includes hydrocarbon type and the pressure, volume, temperature (PVT) phase behavior of the reserves in place. Complex fluids present an additional range of challenges in both their phase behavior and PVT measurement and properties. Gas-Condensates and near-critical volatile oils require careful analysis to capture their volatile, retrograde behavior and unique compositional changes. Inaccurate PVT analysis can result from small retrograde liquid volumes and underrepresented lean gases. Likewise the analysis of dense-phase hydrocarbons requires the collection of homogeneous samples prior to laboratory analysis. Close supervision of all field and laboratory experiments can ensure accuracy and validity of PVT tests. Results from the tests can be validated by the use of PVT software to determine the quality of the match between experimental PVT data and simulation. Coffee Break Session 4: Complex Fluids EOS Modelling The topic of the session will be targeted from two different angles. It will deal with complex phase equilibria exemplified through Asphaltene and wax precipitation. Modelling of those equilibria are further complicated by the fact that the key fluid components are heavy and not quantitatively analysed for. Common EoS modeling for multiple reservoir fluid compositions is another modelling challenge to be dealt with. What is the best practice for generating a Common EoS model and how large a span in fluid compositions can be handled? Session 5: Production & Flow Assurance Early identification of the potential for hydrates, wax, asphaltene and scale deposition to occur during production may be critical for field development planning. This session will focus on the flow conditions (temperature, pressure and salinity) which may cause these substances to form within the wellbore or surface network. Best practice methods for mitigation and remediation will also be discussed and illustrated via a case study. Poster Sesssion Group Dinner Tuesday, 15 March 2016 0830 - 1030 1030 - 1045 1045 - 1245 1245 - 1345 Session 6: Compositional Grading and Variation Significant compositional variations are common occurrence in large and high relief hydrocarbon reservoirs because of several reasons including gravitational segregation, thermal gradients, bio degradation, charge history and leaky seals. These variations highly influence development and production strategies. It is critical to reservoir management to capture these variations accurately in mathematical models. This session will focus on discussing the state-of-the-art technologies and evaluation methodologies. Coffee Break Session 7: Multidisciplinary Data Integration and Fluid Management Multidisciplinary data integration is one of the more important activities required to understand the fluid distribution in the reservoir, define fluid contacts, reservoir compartment, and other factors required to calculate the volumes of hydrocarbons in place, to estimate recovery factors and build a representative static models, which is fundamental for a dynamic model that would allow proper evaluation of well performance and define optimum field development plans. Multidisciplinary data integration involves wells, logs, cores, geology, seismic surveys, fluid samples, geochemistry studies, production tests, well geometries, completions, etc. its right integration is the unique way to enable the construction of a sound reservoir model, hence a optimum field development plan. Luncheon PRELIMINARY DAILY ACTIVITIES AND TECHNICAL AGENDA For updated technical information, visit www.spe.org/events/16ako2 1345 - 1545 1545 - 1600 1600 - 1800 Evening Session 8: Topside and Facilities Consideration, HSE and Economics The impact of reservoir fluid properties on the production system over the lifecycle of a field development can be very significant. The design assumptions and operating philosophy adopted in an initial Field Development Plan will both constrain the operating envelope of the facility, and put boundary conditions on potential new field developments that would utilize the same facility. These include the impacts of contaminants and fluid property changes over the production lifecycle. With uncertainties in the reservoir fluid phase behavior and PVT properties, impurities levels (e.g. CO2, H2S, wax, aspahltenes, etc.), water production, and other considerations over the lifetime of an installation, the impact on facilities design, production, HSE and field economics become very important considerations. This session will focus on these aspects of field development, and also on best practices in efficient facilities and reservoir management to optimize lifecycle opex and capex for safe production. Coffee Break Session 9: Regional Focus - High CO2 and Contaminants Gas Field Development and Sequestration This session is focusing on this region’s challenges in high CO2 and contaminants gas field development and sequestration. More than 90% of the high CO2 and contaminants gas field development and sequestration in the world are those in onshore and clastics. On the other hand, most this region’s high contaminants fields are those in offshore and carbonates. Thus, there are lack of case studies, experiences and on the shelves technologies readily available that can be taken advantage of by the upstream oil & gas player in the this region in developing their high contaminants gas fields. This further compounded by the rare experts on both surface facilities, engineering and subsurface related operations on the subjects. Reducing costs is another challenge. Dinner on own Wednesday, 16 March 2016 0830 - 1030 Session 10: Regional focus - Complex field development including rich gas condensate, oil rim, compositional variation, non-equilibrium cases, etc. This session will focus on field development challenges related to complex reservoir fluids frequently encountered in the South-Asian region. In the Malay basin, we encounter reservoirs with light oil, rich gas condensates sometimes associated with oil rims and multi-stacked compartmentalised reservoirs with both areal and vertical variations in fluid compositions. In this region, there has been recent focus on development of tight gas reservoirs often under HPHT conditions. We also observe issues related to waxy/high pour point crude production and related flow assurance issues. In this session, we will discuss specific cases and proposed solutions to mitigate these challenges from within the region. 1030 - 1045 Coffee Break 1045 - 1245 Session 11: FDP Cases with Complex Reservoir Fluids In this session, focus will be put on field developments of unique complex fluid reservoirs which include rich gas condensate, thin oil rim, reservoirs with high compositional variation, gas injection, EOR projects, high CO2 and/or contaminants, and others. Any of these fluids or processes can have profound impact on the phase behavior and fluid properties of a producing resource. The challenges faced with the complex fluid field development shall test the limits of industry resources, advance technologies and changing our practices to adapt to these challenging environments. This session will demonstrate best practices and lessons learned from data acquisition & sampling, complex fluids characterization, modelling technique, production & reservoir management within this region. 1245 – 1315 Session 12: Summary and Wrap-up 1315 – 1430 Luncheon 1430 Workshop Concludes Poster Solicitation and Information All participants are encouraged to prepare a poster for the Workshop. Posters will be presented at an assigned time and open to frank discussion and presentation of unconfirmed or partial results. Posters will be on display for the entire Workshop period. Presentations on both research and field experience are solicited. When preparing your poster: • Avoid commercialism. No mention of trademarks/product name. • Poster size should be approximately 0.8m x 1.2m (W x H) or size A0 in portrait layout. • Identify topic by title, presenter, affiliation, address, and phone number. • Include a brief abstract that summarizes the technology to be addressed. • Make the display as self-explanatory as possible. • Place the information sequentially; beginning with the main idea or problem, method used, result, etc. (Draw a plan keeping the size and number of illustrations in mind). • Keep illustrations simple by using charts, graphs, drawings, and pictures to create interest and visually explain a point. • Use contrasting colours. • Use large print for narrative materials. (We suggest a minimum of 24 points or 3" high letters for the title). Note that the Workshop Programme Committee will review all poster abstracts/materials prior to display, and reserves the right to refuse permission to display any poster considered by the committee to be commercial in nature. If you are interested in participating, please email your proposed topic with a short abstract (between 200- 300 words) to SPE Event Coordinator, Ruth Dass at rsdass@spe.org by 13 January 2016. SPE TRAINING COURSE: UNDERSTANDING THE COMPLEX FLUID CHARACTERISATION: A CRITICAL COMPONENT IN IMPROVING THE HYDROCARBON RECOVERY 12 – 13 March 2016 | Eastern & Oriental Hotel, Penang, Malaysia TRAINING COURSE SPE Training Course in Conjunction with SPE Complex Reservoir Fluid Characterisation - Impact on Hydrocarbon Recovery and Production Workshop Course Instructor Rahim Masoudi and Raj Deo Tewari Course Description This 2-day course deals on various aspects of complex fluids characterisation of oil and gas reservoirs. Significant complexities exist in oil and gas reservoirs in terms of reservoir architecture and fluids. Fluid complexities viz compositional gradation and variation, impurities and drastic spatial variations impact the recovery and production from the field. Many times these complexities are not understood and recognised in view of limited data and lack of analysis and appropriate tools used for capturing the data. These data are very crucial for reservoir engineering calculations in FDP, processing and flow assurance in wellbore and pipelines. This course is planned to introduce the topic in such way that candidates are able to understand basics of complex fluid characterisation and some of the differences from the conventional fluid studies, sampling of fluids in various types of reservoirs and in different conditions, planning of experiments for various recovery mechanisms viz. primary, secondary and tertiary stages. There will be special emphasis on modeling of PVT parameters which are important input in numerical simulation. Also a great deal will be covered on QA/QC of PVT data of laboratory studies and EOS modeling and PVT simulation as well as analysis and studies of compositional grading and variation. Generation of appropriate data for RE calculations in view of limited and unreliable data will also find special emphasis in the course. State of art techniques like downhole fluid analysis (DFA) and photophysics of reservoir fluids will also be introduced. Overall emphasis of the course is discussion of importance of PVT parameters for their practical application in reservoir simulation and management. Why You Should Attend? As globally recognised, among the main efforts to increase oil and gas production is comprehensive understanding of the fluid system and its behavior under difference scenarios of production, depletion and developments. Complex fluids and complex fields add more challenges to the conventional ways that the projects and studies are being done. As a petroleum engineer, it is important for you to understand the challenges, options and best practices dealing with the complex reservoir fluid systems both in the oil and gas assets. Who Should Attend? The course is designed for petroleum, reservoir and process engineers involving in various phases of technical and engineering studies and field development planning, and for those in resources management and investment for development of complex fields with complex fluids. CEUs Engineers are responsible for enhancing their professional competence throughout their careers. Licensed, chartered, and/or certified engineers are sometimes required by government entities to provide proof of continued professional development and training. Training credits are defined as Continuing Education Units (CEUs) or Professional Development Hours (PDHs). Attendees of SPE training courses earn 0.8 CEUs for each day of training. We provide each attendee a certificate upon completion of the training course. Rahim Masoudi has more than 18 years industrial and academic experiences and currently is Custodian IOR/EOR Engineer at Petroleum Resource Development in PETRONAS and an Adjunct Professor at University Technology PETRONAS. He was recognised /served as SPE Distinguished Lecturer in 2011-2012 seasons, received the 2012 SPE Northern Asia Pacific Regional Technical Award on Reservoir Description and Dynamics, appointed as a member of SPE Regional Technical Advisory Committee in Asia Pacific in October 2013, awarded the 2012 Line Trainer of the Year by PETRONAS PE Skill Group, published one book and more than 110 international journal, conference papers and 3 patents. He has supervised more than 40 MSc and PhD students in Petroleum/ Reservoir Engineering in various areas and carried out more than 50 reservoir studies. Raj Deo Tewari has more than three decades long career in oil & gas industry and currently working as Custodian Reservoir Engineer in Petronas Carigali Sdn Bhd. Dr Raj Tewari has extensive experience in light and viscous oil fields development, Gas and Gas Condensate field developments, Reservoir characterization and Simulation, EOR and Reservoir Management. He was responsible for field development and reservoir management of light and viscous fields producing more than 300 kbopd. He is currently actively involved in EOR studies and R&D projects for improving the recovery in Petronas. He has around 50 publications in international journals and conference proceedings. He has developed and is conducting number of training programmes on RE subjects in Petronas. He has received SPE Northern Asia Pacific Regional Technical Award on Production and Operation for the year 2015. SPE TRAINING COURSE: UNDERSTANDING THE COMPLEX FLUID CHARACTERISATION: A CRITICAL COMPONENT IN IMPROVING THE HYDROCARBON RECOVERY 12 – 13 March 2016 | Eastern & Oriental Hotel, Penang, Malaysia TRAINING COURSE Daily Agenda Day 1 (Saturday, 12 March 2016) Day 2 (Sunday, 13 March 2016) Session 1: Basic Petroleum Fluid Properties and Phase Behavior Concept • Fluid classification (Oil, Gas, Near Critical fluids, Complex Fluids) • Fluid properties and its role in the development studies • Formation water properties • Phase diagram and its application • Impurities and contamination concerns • Fluid properties required in reservoir studies Session 1: Flow Assurance Analysis and Studies (Part 2) • Fluid and chemical compatibility • Formation water • Flow assurance integrated studies • Planning of laboratory studies for mitigation Session 2: Reservoir Fluid Studies for Different Recovery Mechanisms • Scope of PVT study vs. drive mechanisms • Natural depletion • Water drive • Gascap drive • Gas recycling • Gaseous enhanced oil recovery • Gas and gas condensate reservoirs Session 3: Fluid Sampling and Planning for Laboratory Studies • Planning of sampling (Subsurface vs. Surface sampling) • Advantage and limitation of MDT/DST/cased hole sampling • Sample QC and contamination concerns • Compositional analysis and laboratory tests • Special phase behavior and PVT analysis - Equilibrium contact experiment - Multi contact experiment - MMP - slime tube experiment - Gas revaporisation experiment - IFT and Swelling Test Session 4: Flow Assurance Analysis and Studies (Part 1) • Fluid physico-chemical property change in hydrocarbon production path • Asphaltene precipitation • Wax formation/condition/location • Gas hydrate formation/condition/location • Mineral scale formation and precipitation Daily Training Schedule 08:00 - 08:30 a.m. Registration Opens 08:30 - 09:00 a.m. Welcome Coffee and Tea 09:00 - 10:30 a.m. Training Session 10:30 - 10:45 a.m. Coffee Break & Discussion 10:45 - 12:00 p.m. Training Session 12:00 - 01:00 p.m. Lunch Break 01:00 - 03:15 p.m. Training Session 15:15 - 15:30 p.m. Coffee Break & Discussion 15:30 - 17:00 p.m. Training Session Session 2: EOS and PVT Simulation and Regression • Selection of black oil and compositional model • Selection of EOS • Contamination analysis and correction • Expectation from PVT simulation • Plus fraction analysis and characterization • Integrated validation of the PVT model with the production behavior Session 3: Complex Fluids with Compositional Grading/Variation • Definition and the impact • Non-equilibrium concept • Geochemistry, finger printing and compartmentalisation analysis • Modelling of compositional grading Session 4: Fluid Characterisation with Limited Data • Deriving PVT parameters when limited data available • Properties from correlations • Impact of PVT parameters in STOIIP and GIIP estimates • Impact of PVT parameters in MB • Impact of PVT parameters in EOR SPE Workshop: Complex Reservoir Fluid Characterisation Impact on Hydrocarbon Recovery and Production 13 - 16 March 2016 | Eastern & Oriental Hotel, Penang, Malaysia GENERAL INFORMATION Workshop Venue: Eastern & Oriental Hotel Penang 10 Lebuh Farquhar, 10200 Penang, Malaysia T: +60 4 222 2000 F: +60 4 261 6333 Documentation: • Proceedings will not be published; therefore, formal papers and handouts are not expected from speakers. • Work in progress, new ideas, and interesting projects are sought. • Note-taking by participants is encouraged. However, to ensure free and open discussions, no formal records will be kept. Workshop Deliverables: • The committee will prepare a full report containing highlights of the Workshop discussions. This report will be circulated to all attendees. • PowerPoint presentation materials will be posted on a specific SPE URL site and made available to attendees after the Workshop. Provision of the materials by discussion leaders will signify their permission for SPE to do so. Commercialism: In keeping with the Workshop objectives and the SPE mission, excessive commercialism in posters or presentations will not be permitted. Company logos must be limited to the title slide and used only to indicate the affiliation of the presenter and others involved in the work. Attendance Certificate: All attendees will receive an attendance certificate attesting to their participation at the Workshop. This certificate will be provided in exchange for a completed Workshop Attendee Survey Form. Continuing Education Units: This Workshop qualifies for SPE Continuing Education Units (CEU) at the rate of 0.1 CEU per hour of the Workshop. Transportation/Visa: Delegates are advised to book their international / domestic airline tickets early from their country/city to Penang, Malaysia. Delegates travelling to Malaysia must be in possession of passports valid for at least six (6) months with proof of onward passage, either return, or through tickets. Contact your local travel agent for information on visa requirements to Malaysia prior to your departure. Dress Code: Casual clothing is recommended. The Workshop atmosphere is informal. Registration Policy: • Registration fee MUST be paid in advance for attending the Workshop. • Full fixed fee is charged regardless of the length of time registrant attends the Workshop. • Fixed fee cannot be prorated or reduced for anyone (Workshop chairpersons, committee members, speakers, discussion leaders, students and registrants). • Attendees are expected to attend all Workshop sessions and are not permitted to attend on a partial basis. • No refund will be issued if a registrant fails to show up at the workshop onsite. Refer cancellation policy on registration form. Notes: • Registration fee does not include hotel accommodation. However, SPE will provide hotel recommendations upon receipt of your registration. • Registration fees does not include meal costs for additional family member(s). • A discount fee of USD200 will be offered to registrants attending both SPE Workshop on ''Complex Reservoir Fluid Characterisation - Impact on Hydrocarbon Recovery and Production'' and SPE Training Course on ''Understanding the Complex Fluid Characterisation: A Critical Component in Improving the Hydrocarbon Recovery''. • If attendance is not sufficient for the Training Course by 26 February 2016, SPE reserves the right to cancel the course. • Substitutions will not be accepted without prior Programme Committee approval. • No refund will be issued if a registrant fails to show up at the Workshop and/or Training Course on-site. Attention Non-members Join Our Worldwide Membership! Non-member registrants are eligible for one (1) year SPE Membership at no additional cost. To take advantage of this offer, you must fill out the membership application form onsite. The Society of Petroleum Engineers (SPE) is a not-for-profit organisation. Income from this event will be invested back into SPE to support many other Society programmes. When you attend an SPE event, you help provide even more opportunities for industry professionals to enhance their technical and professional competence. Scholarships, certification, the Distinguished Lecturer programme, and SPE’s energy education programme Energy4me are just a few examples of programmes that are supported by SPE. SPE Workshop: Complex Reservoir Fluid Characterisation - Impact on Hydrocarbon Recovery and Production 13 - 16 March 2016 | Eastern & Oriental Hotel, Penang, Malaysia SPE Training Course:Understanding the Complex Fluid Characterisation: A Critical Component in Improving the Hydrocarbon Recovery 12 - 13 March 2016 | Eastern & Oriental Hotel, Penang, Malaysia SPE Member: £ Yes REGISTRATION FORM £ No Membership No. ______________________________________________ Name:_____________________________________________________________________________________________________________________________ (First / Forename) (Middle) (Last / Family Name) Position:___________________________________________________________________________________________________________________________ Company:__________________________________________________________________________________________________________________________ Address:___________________________________________________________________________________________________________________________ Town/City:_______________________ Zip/PostalCode:_____________________ Country: __________________________________________ Tel:_____________________________ Fax: _______________________________ Email: _____________________________________________ Would you be willing to give a brief (10-15 minutes) presentation _______(Yes/No)? If yes, please attach the topic with a short abstract of your proposed presentation. One of the Programme Committee members will contact you to discuss your presentation. Important: Registrants for SPE Workshops are accepted on the basis of information submitted by each registrant. Technical Disciplines (Check One) £ Drilling and Completions £ Production and Operations £ Health, Safety, Security, Environment and Social Responsibility £ Projects, Facilities and Construction £ Management and Information £ Reservoir Description and Dynamics Primary Responsibility (Check One) £ Drilling £ Economics £ Geology £ Geophysics £ Management £ Operation £ Production £ Reservoir £ Surveillance £ Other: ________________________________ List background and experience. (Use additional paper if required). List your expectation for the Workshop, so that the committee can tailor a portion of the Workshop to answering attendees’ concerns. (Use additional paper if required). Registration Fees: (Inclusive of 6% GST) Super Early Bird Registration on/before 13 December 2015 Early Bird Registration on/before 13 January 2016 Registration after 13 January 2016 Workshop Only (Fee includes all workshop sessions, workbook, certificate, 1 welcome reception, 1 group dinner, daily luncheons and coffee breaks). Registration does not include hotel accommodation. £ SPE Member £ Nonmember £ USD 1,750.00 £ USD 1,950.00 £ USD 1,850.00 £ USD 2,050.00 £ USD 1,950.00 £ USD 2,150.00 Training Course Only (Fee includes 2-day training course, training workbook, certificate, daily luncheons and coffee breaks). £ SPE Member £ Nonmember £ USD 1,300.00 £ USD 1,500.00 £ USD 1,400.00 £ USD 1,600.00 £ USD 1,500.00 £ USD 1,700.00 Workshop and Training Course (Fee includes all workshop sessions, 2-day training course, workbooks, certificates, 1 welcome reception, 1 group dinner, daily luncheons and coffee breaks). £ SPE Member £ Nonmember £ USD 2,850.00 £ USD 3,250.00 Payment by Telegraphic Transfer Bank details will be provided on the tax invoice £ U.S. Dollars £ Malaysian Ringgit Payment by Credit Card Credit Card Payment will be in U.S. Dollars only £ American Express £ MasterCard £ Visa £ Diners Club Card Number Expiration Date (mm/yy) Security Code (3 digits on back of card / 4 digits on the front of Amex) _______________________________________________________________ Credit Card Billing Address & Zip/Postal Code _______________________________________________________________ Name of Card Holder _______________________________________________________________ Signature Note: Forms will not be processed and space cannot be guaranteed unless accompanied by payment for total amount due. £ USD 3,050.00 £ USD 3,450.00 £ USD 3,250.00 £ USD 3,650.00 Cancellation Policy: a) A processing fee of US$150.00 will be charged for cancellations received before the registration deadline of 13 February 2016.. b) Cancellation received after the registration deadline of 13 February 2016, a 25% refund will be made to the registrant. c) No refund on cancellation received seven (7) days, 7 March 2016, prior to the starting of the Workshop date. d) Substitutions will not be accepted without prior approval from the Programme Committee. e) No refund will be issued if a registrant fails to show up on-site. This form may be used as a company invoice. Mail completed registration form with remittance and any supporting material to: Society of Petroleum Engineers Level 35, The Gardens South Tower, Midvalley City Lingkaran Syed Putra, 59200 Kuala Lumpur, Malaysia. Tel : 60.3.2182.3000 | Fax : 60.3.2182.3030 | Email : spekl@spe.org