Research on Misfiring Fault Diagnosis of Engine Based on Wavelet

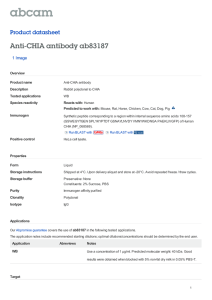

advertisement

May, 2015 Agric Eng Int: CIGR Journal Open access at http://www.cigrjournal.org Special issue 2015 259 Hydrated chia seed effect on wheat flour and bread technological quality Ivan Švec*, Marie Hrušková (Department of Carbohydrates and Cereals, University of Chemistry and Technology Prague, Prague 6, Czech Republic) Abstract: Commercial wheat flour was blended with hydrated white and brown chia seeds. Changes in chemical composition was described by common analytical proofs, and rheological properties of non-fermented as well as leavened dough was completely evaluated (within extensigraph and maturograph tests, respectively). Leavened bread and biscuits were prepared in a laboratory scale. Both chia type softly increased protein content and reversely their quality. Due to low amounts added, changes in dough viscoelastic properties were small. Consumer quality worsening of both tested products was also of low significance, but fibre content was increased about 50% compared to control. Keywords: composite flour, white and brown chia, fibre, dough rheology, leavened bread Citation: Švec, I., Hrušková, M. 2015. Hydrated chia seed effect on wheat flour and bread technological quality. Eng Int: CIGR Journal, Special issue 2015: 18th World Congress of CIGR: 259-263. 1 Introduction1 Chia seeds originate from Spanish specie of sage Agric of year 2012; the limit was increased to 10% recently (Regulation 2013/50/EU). (Salvia hispanica L.), annual plant bred mainly in South Depending on used chia level, quality parameters of American countries, and they are harvested as white or wheat flour composites are changed. Parameters of dark coloured variants. Name "chia" is derived from chia-enriched dough are solved in papers published by e.g. Aztec word "chian" meaning oily. The Mexican state Ixtaina et al. (2008), Capitani et al. (2012) or Chiapas belongs to the main producers of that plant Iglesias-Puig and Haros (2013). Inglett et al. (2013) material. Seeds were and still are eaten alone or blended describe behaviour of blend composed from barley and with cereals, in whole or milled into flour. Mixed with chia flour and state that addition up to 10% had no water, thick gel is formed in a few minutes, absorbing verifiable effect on both dough viscosity and elasticity. water up to 12-multiple of the own weight. Chia seeds were recognised as valuable food Chia addition into wheat flour causes gluten proteins dilution as well as bread volume decrease. raw-material (Reyes-Caudillo et al., 2008; Ayerza and Ortega-Ramirez et al. (2013) determined a diminishing up Coates, 2011; Ciftci et al., 2012; Luna Pizzaro et al., to 25% against non-fortified control, using 5% or 10% 2013), and nowadays it is already authorised novel food chia into recipe. Sweet bread structure containing 6% or ingredient (Directive 2009/827/EC). Considering bakery 12% of chia flour was described by image analysis product, addition level was allowed up to 5% to the end (Ferrera-Rebollo et al., 2012). Lower addition level did not proved in change of cell counts and sizes distribution compared to commercial sweet bread. The aim of presented paper was to evaluate an Received date: 2014-12-01 Accepted date: 2014-12-02 *Corresponding author: Ivan Švec, Department of Carbohydrates and Cereals, University of Chemistry and Technology Prague, Prague 6, Czech Republic. Email: Ivan.Svec@vscht.cz influence of whole white or brown chia seeds in hydrated form on chemical composition, rheological behaviour of non-fermented and fermented dough and on bread or 260 December, 2014 Agric Eng Int: CIGR Journal Open access at http://www.cigrjournal.org Vol. 23, No. 4 biscuits characteristics in blends with commercial fine form was used for analytical tests, while the whole wheat flour. hydrated seeds for rheological proofs and baking tests. 2 Materials and methods Before measurement, weighted amounts of 7.5 g or 15.0 g Wheat flour (WF) used as composites base was of commercial origin, obtained from the Czech industrial were allowed to hydrate in 150 ml of distilled water for 10 min. mill. Used chia samples involved both botanical variants Changes in chemical composition were evaluated by with white and dark seeds (Ch1 and Ch2) planted in analytical proves as the protein content according to Mexico, and bought in specialised food shop. With Kjeldahl method (ČSN ISO 1871, factor 5.7; abbreviation respect to EU legislation valid until 2012 year PRO), the Zeleny sedimentation value (baking quality of (258/97/ES), substitution levels were chosen as 2.5% and proteins, ČSN ISO 5529; ZT) and the Falling Number 5.0% on wheat flour base. Composites were signed by (estimation of amylose activity, ČSN ISO 3039; FN). combination of alternative flour type and its addition Nutritional benefit of chia was evaluated in terms of level, e.g. Ch2-5.0 means ratio of 95%/5% (w/w) of dietary fibre content (AOAC 985.29) using Fibertec wheat and Ch2 hemp flour, respectively. A dry milled apparatus and Megazyme assay kit. Table 1 Analytical parameters of tested flour composites Composite WF WF + Ch1 WF + Ch2 Chia addition, % 2.5 5.0 2.5 5.0 Proteins (f = 5.7, %) Zelenytest, ml Fallingnumber, s 10.73 10.97 11.21 10.98 11.21 41 33 31 33 31 327 347 377 348 377 WF: white fine wheat flour; Ch1, Ch2: hydrated white and brown chia seeds, respectively. Viscoelastic behaviour of tested composites was Effects of chia type and addition level were explored evaluated by using of the extensigraph (ČSN ISO 5530-2). by the Tukey HSD test (analysis of variance, ANOVA; p Maturograph proof, performed following the internal < 0.05) using the Statistica 7.0 software (Statsoft, Tulsa, procedure (Hrušková et al., 2003), describes changing USA). rheological properties of fermented dough within a 3 leavening stage. From a registered curve, the optimal 3.1 Flour composites analytical quality Results and discussion leavening time (time to reach a maximal dough volume) In the Table 1, amount of PRO in wheat flour standard in minutes, the maturograph resistance (maximal volume) reached a level common within the Middle Europa region and the maturograph elasticity of fermented dough in with good baking quality (10.7% and 41 ml, respectively). maturograph units (MU) are read out. Internal method of According to small amount added (2.5% and 5.0%), chia baking test was published earlier (Hrušková et al., 2006); wholemeal fortification demonstrated very slight increase both leavened and chemically fluffed up product (bread of PRO up to 11.2% by 5% of both chia samples. and cookie) were prepared. By using a rapeseed Alternative flour affected protein quality significantly, the displacement method and rectangular equipment, specific ZT was lowered about one-fourth independently to chia volume (ml/g) and product shape (height-to-diameter type or addition level. With respect to the FN ratio) were evaluated (abbreviations SBrV, BrS for bread repeatability (±25 s, ČSN ISO 3039), chia seeds did not and SBiV, BiS for biscuits, respectively). May, 2015 Hydrated chia seed effect on wheat flour and bread technological quality influence the parameter verifiably in spite of soft values Special issue 2015 261 3.3 Rheological behaviour of fermented dough increasing. In the Table 2, behaviour of fermented dough Figure 1 Viscoelastic characteristics of wheat and wheat-chia flour composites. WF: white wheat flour, Ch1, Ch2: white and brown chia seeds, respectively. EEN – extensigraph energy, ERA – extensigraph ratio (elasticity-to-extensibility); 30‘, 60‘: dough resting time. prepared 3.2 Rheological behaviour of non-fermented dough from test flour blends demonstrated As shown in the Figure 1, extensigraph test did not independence on both chia type involved and addition confirm a diminishing of protein quality evaluated by the level. A small drop in maturograph resistance (MRE) ZT. as recorded for the Ch1-2.5 sample had no impact on dough not elasticity, meaning similar dough machinability during Dough handling elasticity-to-extensibility ratio properties (ERA) were unequivocally changed similarly to extensigraph energy hand-made bread forming. (EEN). Longer resting time of dough led to soft growth of 3.4 Baking test results the extensigraph elasticity (Inglett et al., 2013), reflected As it was shown in the Figure 2, specific bread in the ERA increase. Between the chia types tested, any volume (SBrV) of the control sample WF (270 ml/100 g) significant differences were not found in composite corresponds to results of analytical and rheological tests. dough rheology. Owing to similar times of non-fermented dough resting and bread samples leavening (60 and 50 minutes), the Table 2 Rheological parameters of fermented composite dough composite WF WF+Ch1 WF+Ch2 Chia addition(%) LET,min MRE, MU MEL, MU 0 36 680 210 2.5 32 625 205 5.0 36 700 210 2.5 32 680 220 5.0 36 700 200 WF: fine white wheat flour; Ch1, Ch2: wholemeal LET: leavening time, MRE: maturograph dough resistance, MEL: maturograph dough elasticity;maturograph unit. 262 December, 2014 Agric Eng Int: CIGR Journal Open access at http://www.cigrjournal.org Vol. 23, No. 4 Figure 2 Influence of chia addition on bakery products size. WF: white wheat flour, Ch1, Ch2: white and brown chia seeds, respectively. SBrV – specific bread volume, SBiV – specific biscuit volume. Somewhat lower variation was observed in biscuit specific volumes (SBiV) – a difference of 21 ml/100 g highest volume was determined for the Ch1-2.5 only was calculated between the most enhanced Ch1-5.0 composite (rise about 50 units) as the highest EEN found and Ch2-5.0 samples. As was mentioned above, chia into during the extensigraph test. Volumes of further three mixture brings more elastic dough – it affected SBiV fortified bread were similar mutually as well as in relation prepared according to those recipes due to higher to control. On the other hand, Ortega-Ramirez et al. (2013) contraction of biscuit pieces after their cutting out from found a significant SBrV lowering (about 25%) by dough sheet. incorporation of 10% chia in dough recipe. Table 3 Dietary fibre content in tested flour composites Composite WF Ch1 Ch2 WF + Ch1 WF + Ch2 Chiaaddition, % 2.5 5.0 2.5 5.0 IDF, % 2.08 21.71 22.05 2.57 3.08 2.58 3.13 SDF, % 1.02 8.18 8.41 1.20 1.40 1.20 1.40 TDF, % 3.21 30.23 30.62 3.88 4.46 3.89 4.58 WF: white fine wheat flour; Ch1, Ch2: hydrated white and brown chia seeds, respectively. IDF, SDF, TDF – insoluble, soluble and total dietary fibre, respectively 3.5 Nutritional benefit of chia addition 4 Conclusions As in the Table 3, due to dietary fibre (DF) content White and dark chia seeds combined with common over 20% in both chia types, 30.23% in Ch1 and 30.62% fine wheat flour increased proteins content and lowered in Ch2 (in correspondence with Ayerza 2013), it’s usage their baking potential similarly. in wheat flour composites significantly enhanced Further, amylose activity as the Falling number was nutritional value of manufactured bakery product. In not significantly influenced. Regardless to that, terms of insoluble and total dietary fibre, their proportion physico-mechanical properties of non-fermented and was increased approximately about 50%. fermented dough with both chia types determined during May, 2015 Hydrated chia seed effect on wheat flour and bread technological quality the extensigraph and the maturograph tests were comparable to control wheat dough. Results of baking proof verified the findings, because specific volumes of all five tested bread samples were comparable one to each Special issue 2015 263 Farrera-Rebollo, R. R., M. Salgado-Gruz, J. Chanona-Perez, G. F. Gutierréz-Lopez, L. Alamilla-Beltran, and G. Calderon-Dominguez. 2012. Evaluation of image analysis tools for characterization of sweet bread crumb structure. Food Bioprocess Technol., 5: 474-484. other. In case of volumes of biscuits manufactured Hrušková, M., I. Švec, and I. Kučerová. 2003. Effect of malt flour manually, somewhat more important role was attributed addition on the rheological properties of wheat fermented to extensigraph elasticity-to-extensibility ratio; the higher dough. Czech J. Food Sci., 21: 210-218. Hrušková, M., I. Švec, and O. Jirsa. 2006. Correlation between ratio (a higher dough elasticity), the partially lower milling and baking parameters of wheat varieties. J. Food Eng., biscuit was determined. Regardless to that, total dietary 77: 439-444. fibre content was increased approximately about 50% by both types of chia used. Iglesias-Puig, E., and M. Haros. 2013. Evaluation of performance of dough and bread incorporating chia (Salvia hispanica L.). Eur. Food Res. Technol., 237: 865-874. Inglett, G. E., D. Chen, J. Xu, and S. Lee. 2013. Pasting and References rheological properties of chia composites containing barley flour. Internat. J. Food Sci. Technol., 48: 2564-2570. 2009/827/ES. http://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CEL EX:32009D0827&rid=1, download March 31, 2014. 2013/50/EU, http://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CEL EX:32013D0050&rid=1, download March 31, 2014. Ixtaina, V. Y., S. M. Nolasco, and M. C. Tomás. 2008. Physical properties of chia (Salvia hispanica L.) seeds. Industrial Crops Products, 28: 286. Luna Pizarro, P., E. Lopes Almeida, N. C. Sammán, and Y. K. Chang. 2013. LWT – Food Sci. Technol., 54: 73. Ortega-Ramirez, R., D. I. Leyva-García, R. M. Sanchez-Robles, Ayerza, R. 2013. Seed composition of two chia (Salvia hispanica and A. Morales-Ortega. Effect of addition of amaranth, chia L.) genotypes which differ in seed color. Emir. J. Food Agric., and wheat bran on bread: Impact on antioxidant activity. C&E 25: 495-500. Spring Meeting: Unlocking the full potential of cereals: Ayerza, R. and W. Coates 2011. Protein content, oil content and challenge for science based innovation, Leuven, Belgium, 29. - fatty acid profiles as potential criteria to determine the origin of 31. May 2013, Book of Abstracts (Brijs K., Gebruers K., commercially grown chia (Salvia hispanica L.). Industrial Courtin C. M., Delcour J. A., eds.), p. 127. Crops Products, 34: 1366-1371. Reyes-Caudillo, E., A. Tecante, and M. A. Valdivia-Lopez. 2008. Capitani, M. I., V. Spotorno, S. M. Nolasco, and M. C. Tomás. Dietary fiber content and antioxidant activity of phenolic 2012. Physicochemical and functional characterization of compounds present in Mexican Chia (Salvia hispanica L.) by-products from chia (Salvia hispanica L.) seeds of Argentina. seeds. Food Chem., 107, 656-663. LWT – Food Sci Technol., 45: 94-102. Ciftci, O. N., R. Przybylski, and M. Rudzinska. 2012. Lipid components of flax, perilla, and chia seeds. Eur. J. Lipid Sci. Technol., 114: 794-800.