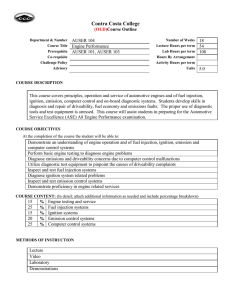

HFM-SFI

advertisement