Foundry solutions for dust and fume extraction for safe

advertisement

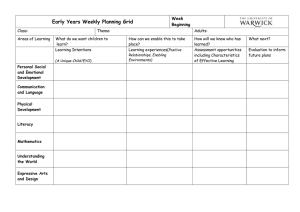

Foundry solutions for dust and fume extraction for safe, clean and efficient production in foundry industries Installation at Victaulic, Drezdenko, Poland Nederman offers a wide range of solutions for extraction and filtration in the foundry process FS/FD MJB MJB/A/H/G MJC FMC FMK MJC mini Silosafe Application All foundry applications incl. hot gases from the melting process All foundry applications incl. hot gases from the melting process Sand plants, and metal finishing Sand plants, metal finishing and downstream operations Sand plants, metal finishing and downstream operations Grinding and machining Designed specifically for silo and bin venting applications Air flow m³ / h 6,000 - 275,000 multiple units for higher air volumes 750 - 225,000 multiple units for higher air volumes 2,000 - 75,000 multiple units for higher air volumes 5,300 - 21,000 multiple units for higher air volumes 1,800 - 10,500 multiple units ¨for higher air volumes 250 - 2,000 1,250 Filter area 102 - 2,310 m² 7 - 1,870 m² 40 - 739 m² 32 - 128 m² 15 - 88 m² 4 - 40 m² 24 m² Placement In-/Outdoor In-/Outdoor In-/ Outdoor In-/Outdoor In-/Outdoor Indoor In-/Outdoor Heavy duty cleaning Nederman also offers high vacuum solutions for heavy duty cleaning, material transportation, collection of sand and fettling applications. We offer both stationary systems for multiple suction points and mobile units. 11 1 Stationary high vacuum system for cleaning 2 6 11 4 9 11 5 3 Nederman extraction and filtering solutions can be applied for all types of furnaces Grinding particles are safely collected by an extraction and filtration system Mobile vacuum system for cleaning FMC filters for shot blast machines 10 11 7 11 11 8 1. Sand preparation 2. Moulding line 3. Close capture hood for extracting hot fumes from the furnace during charging, melting and pouring 4. Ladle 5. Pouring line 6. Cooling line 7. Knock-out and cooling 8. Shot blasting 9. Recirculation of moulding sand 10. Vacuum cleaning system 11. Extraction of dust and fumes to filters Downstream operations Nederman also offers solutions for fettling, grinding, machining, cleaning, oil-mist filtering, swarf management, welding smoke, etc. Complete solutions for dust and fume extraction at all stages in the foundry process Extraction of fumes at the furnace Melting furnaces generate dangerous fumes. Extraction and filtration is necessary to make the production efficient, to protect workers from hazardous substances and to comply with statutory emission levels. Nederman has close capture hoods for collecting hot fumes from furnaces during charging, melting and pouring. Extraction of dust at moulding lines and sand management Our wide range of filters, fans and equipment are suitable for everything from single machines to whole processes with multiple extraction points. We ensure optimum collection of dust with the lowest possible air volume, which is vital for keeping the investment and operation costs to a minimum. Service & Spare Parts You can rely on Nederman for maintenance, spare parts and troubleshooting to ensure optimum performance throughout the lifecycle of your system. We also provide a 24 hour hotline to ensure trouble free operations. General cleaning Nederman offers stationary systems and mobile units for heavyduty cleaning throughout the foundry plant. Solutions for shot blast machines and fettling shops Nederman has solutions for extracting and filtering dust from shot blast machines, fettling tables, machining operations and other downstream operations. Nederman Sales companies Nederman Distibutors Assembly and logistic sites Through the acquisition of Dantherm Filtration in 2010 Nederman is now serving over 800 foundries world wide Nederman offers total solutions PRE-STUDIES PLANNING SYSTEM DESIGN INSTALLATION COMMISSIONING TRAINING MAINTENANCE The Nederman Group is one of the world‘s leading suppliers of products and solutions within the environmental technology sector, focusing on industrial air filtration and recycling. Nederman products and solutions contribute to reducing the environmental impact from industrial production processes and to creating a safe and clean working environment whilst boosting production efficiency. The Group´s offering covers everything from the design stage through to installation, commissioning and servicing. Nederman has subsidiaries in 29 countries and agents and distributors in over 30 countries. Nederman is ISO 9001 and 14001 certified. The Group develops and produces in its own manufacturing and assembly units in Europe, North America and Asia. In 2010 Nederman acquired Dantherm Filtration, thereby forming the world´s leading Group within industrial air filtration. www.nederman.com Nederman Sales companies in: Australia, Austria, Belgium, Brazil, Canada, China, Czech Rep. Denmark, France, Germany, Hungary, India, Indonesia, Ireland, Malaysia, Northern Ireland, Norway, Poland, Portugal, Romania, Russia, Slovak Republic, Spain, Sweden, Turkey, United Kingdom, USA, Thailand, Vietnam. Nederman Agents in: Bulgaria, Cyprus, Egypt, Estonia, Finland, Greece, Holland, Hongkong, Iceland, Iran, Ireland, Italy, Japan, Korea, Latvia, Lithuania, Malaysia, New Zealand, Philippines, Saudi Arabia, Serbia, Singapore, Slovenia, South Africa, Switzerland, Taiwan R.O.C, Thailand, Turkey, United Arab Emirates ENG 2011.10 Halmstad Tryckeri The Group is listed on Nasdaq OMX Stockholm.