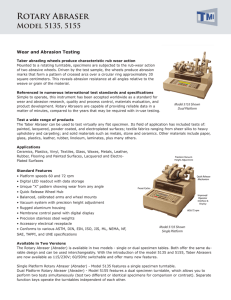

Abrasion Test Instrument Original TABER® ABRASER 352

advertisement

Abrasion Test Instrument Original TABER® ABRASER 352 GRIT FEEDER SCUFFING HEAD Abrasion Test Instrument Original TABER® ABRASER 352 G (Typ 5135) testing equipment for quality management DIN ISO DIN EN ASTM 352 G Mono 352 H Duo Purpose and Application Resistance to abrasion is one of the most significant mechanical properties of any surface. The use of the TABER® ABRASER is counted among the most commonly used and best-known methods for testing durability and resistance to wear. In numerous national and international standards specific reference is made to this test equipment. Abrasion resistance can be established by the following testing methods: vacuuming rate, are entered by way of a control panel with membrane keyboard. A digital display shows readings of either Weight loss method: The sample material is subjected to a specific number of test cycles. The abraded proportion of the specimen is established by differential weighing. . the current abrasion cycle rate (wear index) or . the remaining number of abrasion cycles. The Original TABER® ABRASER enables abrasion testing to be conducted on paint and other coatings such as rubber, paper, leather, ceramics, textile surface structures and metals. The equipment is suitable for use in research and development and for in-process and quality assurance controls. Visual end point method: The sample is subjected to abrasion until the substrate becomes visible. The number of test cycles is equivalent to the rate of wear. Depth of wear method: After a prescribed number of test cycles the depth of wear is measured using a micrometer. By using the Duo ABRASER 352 H (Type 5155), two abrasion tests with different specified parameters can be conducted simultaneously, yet independent of each other. Technical Data Test Principle The wearing action is caused by two abrasive wheels which are applied at a defined pressure to the material sample which has been mounted on a rotating specimen holder. One of the most outstanding features of this testing method is the X-shaped abrasion pattern (Fig. 1). 352 G (Type 5135) 352 H (Type 5155) 280 mm 500 mm Width: Description The TABER® ABRASER is a robust instrument suitable for table-top use. The accurate control and driving elements are contained in a sturdy aluminium housing with durable baked wrinkle enamel finish. The operating data, such as the number of test cycles and the Depth: 400 mm 350 mm Height: 250 mm 250 mm Weight (approx.): net 21 kg gross 45 kg 41 kg 60 kg Mains supply: 230V, 50Hz 230V, 50Hz (other voltages on request) Order Information Order No. Product Description 0352.09.51 Abrasion Test Instrument Original TABER® ABRASER 352 G (Typ 5135), including standard equipment (see below) 0352.10.51 Duo-Abrasion Test Instrument Original TABER® ABRASER 352 H (Typ 5155), including standard equipment (see below) Fig. 1 Standard Equipment The parameters to be specified for the testing method are: 1. the selection of the type of abrasive wheel, 2. the weight load with which the abrasive wheels are pressed onto the material, 3. counting of abrasive cycles (number of turntable revolutions). Description 352 G 352 H 503-0023 Auxiliary weight (1000 g/load) 2 (1 set) 4 (2 sets) 503-0022 Auxiliary weight ( 500 g/load) 2 (1 set) 4 (2 sets) E-100-125 Specimen holder, approx. 108 mm dia. 1 2 E-100-101 Hold-down ring for specimen holder 108 mm dia. ,for flexible specimen 1 2 100-237 Hex wrench for hold-down ring 1 1 S-11 Abrasive discs for refacing CALIBRASE wheels 100/pkg. 100/pkg. S-12 Long handled brush S-36 Self-adhesive discs, 4¼" x 4¼" (10,8 x 10,8 cm) 1 10/pkg. 1 10/pkg. CS-10 CALIBRASE wheels 1 pair 2 pairs H-18 CALIBRADE wheels 1 pair 2 pairs 5130-70 Vacuum unit with brush and hose 1 1 Instruction Manual 1 1 ACCESSORIES Specimen Holders The Original TABER® ABRASER can be used for numerous different applications. This is however conditional on having a suitable fixing device for the test material. Special specimen holders are available which include the following: . . . . . . . . . E 100-10, Transparent plastic specimen holder permits direct viewing of paper or textile samples E 140-15, Textile specimen holder with raised track to provide extra tension for fabric samples E 140-18, Rimmed textile specimen holder with initial tension for woven fabrics, for wet and dry testing E 140-19, "Drive pin" type specimen holder for rigid square specimens, such as glass or ceramic E 140-21, Threaded ring specimen holder for testing thin or warped specimens E 140-75, Rimmed specimen holder for testing under wet conditions S-21, Extension nut for rigid specimens measuring 6.3 - 12.7 mm (requires 9.6 mm bore) Extension screw for specimen thicknesses up to 26 mm (for 6 mm bore) E 100-102, Hold-down ring for thick textile specimens, 110 mm dia. (1.6 mm clearance) Abrasion Test Wheels/Sandpaper Strips The selection of the most appropriate abrasion wheels or sandpaper strips is a further important prerequisite for practice-oriented abrasion testing. There is a wide range of abraders available to suit the most varied specimen materials. CALIBRASE WHEELS* Order No. Type Description Application 0352.17.52 CS-10F brown, Light abrasion, for loads from 250 to 500 g Flexible plastics and coatings, paper 0352.07.53 CS-10 green, Medium abrasion, for loads from 500 to 1000 g (equivalent to manual pressuring) Medium hard plastics and coatings, cardboard, galvanic platings, leather, textiles 0352.60.52 CS-10W white, Medium abrasion, for loads from 500 to 1000 g (equivalent to manual pressuring) Medium hard plastics and coatings, cardboard, galvanic platings, leather, textiles 0352.18.52 CS-17 green, Coarse abrasion, for loads from 500 to 1000 g (equivalent to wear by tyres and footwear) Hard plastics and coatings, aluminium (anodized), ceramic, glazing, glass, insulated wires 0352.05.53 S-11 Abrasive paper discs, 150 grid For refacing CALIBRASE abrasive wheels *CALIBRASE WHEELS (= resiliently bonded abrasive material) CALIBRADE WHEELS* Order No. Type Description Application 0352.20.52 H-10 grey, fine abrasion, for loads from 500 to 1000 g Glass, aluminium (anodized), steel sheet, cardboard 0352.08.53 H-18 grey, medium abrasive, for loads of 250, 500 and 1000 g Glass, rubber, aluminium (anodized), steel sheet, wood, linoleum, cardboard, coarse textiles, floor-coverings 0352.21.52 H-22 grey, very coarse abrasion, for loads of 250, 500 and 1000 g Cement and concrete floors, wood, leather (shoe soles), linoleum, cardboard, rubber, coarse textiles, leather upholstery covers, floor-coverings, insulated wires 0352.22.52 H-38 tan, fine grain, for loads of 250 and 500 g Specifically for woven and coarse fabrics *CALIBRADE WHEELS (= ceramic-bonded abrasive material, non-elastic) Sandpaper Strips, Abrasive Wheels and Standardization Plates Order No. Type Description Application 0352.44.52 S-33 Sandpaper strips for abrasive wheels S-32, selfadhesive, grain size 63 - 100 µm, 70 - 100 g/m² Furniture surfaces, HP laminated sheet (HPL), Tests acc. to: DIN 53 799, DIN EN 438-2, ISO 4586-2 0352.43.52 S-42 Sandpaper strips for S-32 wheels, self-adhesive Furniture surfaces, HP laminated sheet (HPL) 0352.14.52 S-32 Abrasive wheels (= CS-0 wheels) Serves as a base for S-33 / S-42 sandpaper strips 0352.08.52 S-34 Standardization plates, material: zinc For controlling S-33 / S-42 sandpaper strips 0352.11.52 S-35 Tungsten carbide wheels with sharp, bevelled cut-outs, causes intensive abrasion Rubber, linoleum, leather 0352.57.52 S-45 Wheel tracking cards For use with Calibration Vertification Kit Calibration Vertification Kit TABER® GRIT FEEDER This enables the user to check the basicly correct functionality of his TABER® ABRASER regarding the observance of the right abrading trace area. Special test wheels, called ”Wear Trac” wheels (S-30), leave a typical interpretable pattern on a special test card, called ”Wheel Tracking Card” (S-45). The TABER® GRIT FEEDER, Model 155 an Model 255, is an attachment for the Taber Abraser. It was designed primarily to evaluate the resistance of various floor surface coatings to abrasion. Aluminium oxide grit is fed in as an abrader and special leather wheels are used instead of the regular abrasive wheels. With the attached Vacuum Gauge, the correct funktion of the vacuum device can be checked. Test Principle Order Information Order No. Product Description 0352.56.52 Calibration Vertification Kit 0352.57.52 Wheel tracking cards S-45 Diamond Wheel Refacer The Model 200 Diamond Wheel Refacer is a precision instrument which was specifically developed for dressing CALIBRADE abrasive wheels types H-10, H18, H-22 and H-38. This refacing equipment is also suitable for recentring CALIBRASE abrasive wheels which have become out-of-round. Order Information Order No. Product Description 0352.02.52 Diamond Wheel Refacer, Model 200, incl. diamond tool 133-60 with single diamond point Accessories/Spares Order No. Product Description Accessories/Spares ERICHSEN GmbH & Co. KG Am Iserbach 14 | 58675 Hemer | Germany | Quiet Cabinet The new TABER® Quiet Cabinet has been specially designed to accommodate the Original TABER® ABRASER. Apart from reducing sound levels by about 20 %, it also provides protection against the abraded material dust. The Quite Cabinet comprises two individual elements: . The TABER® ABRASER is fitted into the upper element of the cabinet. A plexiglass cover ensures that tests can be observed, even when the cover is closed. (W x D x H approx. 765 x 610 x 495 mm) . The lower cabinet element holds the abraser vacuum unit. (W x D x H approx. 765 x 610 x 840 mm - mains supply: 120 VAC, 60 Hz) Order Information Technical Data Order No. Product Description Dimensions (HxWxD): 610 x 380 x 150 mm Net weight: approx. 8 kg Mains supply: 230 V ~ / 50 Hz (other voltages on request) 0352.46.52 Quiet Cabinet complete set Standards Order Information Scuffing Head 0352.36.52 Scuffing Head 503-13 0352.41.52 Sieve S-40, acc. to VS Standard # 80 The complete attachment is easily mounted onto the Original TABER® ABRASER 352 G und 352 H. . The instrument can be easily positioned so that the course of both abrasive wheels can be closely observed. . The grit is fed onto the specimen at an even, constant rate as preselected on the operating element. . Continuous removal of abraded material and used grit. 0352.40.52 TABER® GRIT FEEDER, Model 155, Please indicate the voltage of the TABER ABRASER Order No. Product Description 0352.18.53 Grit S-41 Equipment Features Order No. Product Description Order Information 0352.16.53 Standardization plates, S-38, 100 x 100 mm, 6 mm bore Abrasion is caused when that part of the specimen which is turning horizontally passes the vertically rotating leather abrasive wheels. A vacuum pickup unit disposes of the abraded material together with any super-fluous aluminium oxide grit. 0352.04.52 Diamond Tool 200-62 with multiple diamond point The Ford Motor Company test method FLTM BN 108-04 is the standard procedure applied here. 0352.51.52 TABER® GRIT FEEDER, Model 255, adjustable heigths for adaption to the different specimen thicknesses The scope of supply includes: 1 pair of leather wheels S-39 Standardization plates S-38 S-41 grit (approx. 20 kg) Lead Instruction Manual Tel. + 49 (0) 23 72 - 96 83-0 | Fax + 49 (0) 23 72 - 64 30 Product Description 0352.16.53 Leather wheels S-39 The test sample is mounted on the specimen holder of the Taber Abraser. The Grit Feeder supplies the abrasion test surface with a constant flow of aluminium oxide grit. 0352.01.53 Diamond Tool 133-60 with single diamond point The 503-13 Scuffing Head Attachment is a Taber Abraser accessory for determining the scuff-resistance of materials such as vinyl, foils, leather and car floor mats. Ord.-No. | www.erichsen.de DIN 52 347 53 109 53 754 53 799 68 861-2 DIN EN 438-2 ISO 3444 3537 4586-2 5470 ASTM C 501 D 1044 D 3389 D 3884 D 4060 D 4158-82 F 362 F 510 Subject to technical modifications. Groupe 15 - TBE 352 - VI/2006 | info@erichsen.de