Fault-finding checks

advertisement

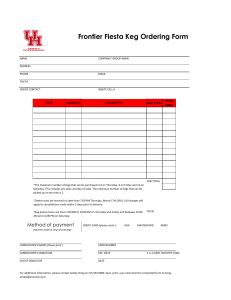

What tests are necessary to make sure your kegs are being cleaned, sanitized and filled correctly By Andrew J. Brewer andrew.brewer@petainer.com 636-388-9163 Kegs 1 1. 2. 3. 4. 5. 6. 7. Spear fitting. Valve. Hand hole Chime Rolling ring Spear tube Drain hole Barnes neck 7 2 3 4 5 Spear valve types: Quality testing areas to be covered Pre-production checks Checks during CIP and bringing the Beer down to the line. Running checks Making sure all services supplied within specification and checking all processes are working correctly. Fault-finding checks Additional checks that will help correct problems found. Fault-finding kegs A few good tips Simple things that can stop problems occurring. Pre-production checks During CIP or Sterilization of the line It is of upmost importance that prior to starting production that the Beer supply and the machine is clean. Often when micro problems are seen in the finished product one of the first questions is: “Was the CIP carried out correctly?” A simple check sheet that the operator can use to log the temperature and titration of the CIP solution, length of time taken etc. will help to answer this question. With additional notes on the procedure such as what valves to open and close etc. will assist an inexperienced operator preform the task correctly. Also prior to bringing the Beer onto the line, swabbing the filling head on the machine is also a good idea to prove the CIP worked. It is recommend prior to a CIP circulate cold water around the CIP routes and look for leaks and fix before staring the CIP. Pre-production checks Start up Base line tests Take micro samples of the Beer coming to the line and at any surge tanks, flash pasteurizers etc. Take CO2 in solution, Balling and DO of the Beer being supplied. If possible take this as close to the filling head on machine as possible prior to running the first keg. These Base line reading will help to see if changes to the Beer are occurring in the keg due to the washing and filling cycles. Running checks Services Make sure all services supplied to the line and machine are within the specifications agreed between you and the machines equipment suppliers. These include: Wash pressures Wash temperatures Wash titrations Purge gas pressures Back pressure settings during fill Beer pressure and temperature Surge tank top pressures Control air settings on cylinders and valves Though these reading can be automatically taken it is recommended that manual readings are also taken by the operator at various times during production using pressure and temperature gauges fitted where they can be easily and safely read. All Gauges should be calibrated regularly . Running checks CO2 in solution and DO tests If you have the equipment these tests will insure your product leaves the brewery at the specifications you require. Micro checks Use a sanitized coupler and clean all connections Running checks Occasional checks Internal keg inspection. To make sure the washing cycle you are using is keeping your keg float clean, take a keg off the machine that has processed through the machine but just prior to filling. Fully De-pressurize the keg and the using the correct equipment remove the spear valve and inspect the walls of the keg and its spear. Running checks Occasional checks Internal keg inspection. Running checks Occasional checks Checking on Spear washing If your equipment has spear washing it is important to make sure the flow rate is set correctly. Running checks Occasional checks Liquid carryover checks To make sure all the wash and or sterilizing agent has been removed out of the keg prior to filling, take a keg off the machine that has been processed just prior to filling. Place a coupler on the keg, then turn the keg neck down and push the coupler handle down and measure the amount of liquid that comes out of the gas ports. Chemical carryover checks To make sure all the chemicals has been removed out of the keg after sterilizing, take a keg off the machine after the sterilizing agent has been removed out of the keg. Note: If Steam is the sterilizing agent, first cool the keg. Place a coupler on the keg, then turn the keg neck down and push the coupler handle down and titrate the liquid that comes out of the gas ports. Fault-finding checks Micro problems Micro problems can be due to many areas: Beer supply or insufficient cleaning of the line prior to production. Taking samples from Beer supply and swabbing the head should help to find the problem area. Kegs that cannot be cleaned and sterilized. If the keg float is not getting cleaned, over time Beer stone and other residues can harbor bacteria that can not be removed or killed during sterilization. This where a regular sample internal inspection of the kegs helps. Note: Also damaged kegs, dents etc. can stop some of the kegs surfaces seeing any wash solutions and where steam is not used any sterilizing agent. Fault-finding checks Micro problems Kegs that cannot be cleaned and sterilized. Taking a keg off the machine just prior to the purge of the sterilizing agent, then with a sterilized coupler, de-pressurize the keg and turn it neck down and collect some of the sterilizing agent for micro sampling out of the gas ports. This may help to see if the washing and sterilizing cycle is working. Note: If Steam is the sterilizing agent, first cool the keg. If the above is okay taking a keg off the machine just prior to filling the keg, then with a sterilized “wide mouthed” coupler, de-pressurize the keg and introduce sterilized water into the keg. Then roll and shake the keg so all surfaces are touched by the water . Then turn it neck down and collect some of the water for micro sampling out of the gas ports. This may help to see if the problem is after the wash is due a dirty head or CO2.. Fault-finding checks Micro problems Micro problems can be due to many areas: CO2 supply This often a forgotten area for sampling and for cleaning. The CO2 should be supplied via sterile filter and during CIP the supply pipe work should be cleaned as far back as possible to that filter. Micro checking of the CO2 can be performed by bubbling the CO2 through sterile water and the plating it. Fault-finding checks DO and CO2 in solution problems These issues often go together and can be caused in problems in the Beer supply in not removing air traps in pipework etc. and with incorrect setting of top pressures in supply tanks. . DO problems can also be caused by not removing all air out of the keg prior to filling and by leaks in Beer or CO2 pipework that is pulling in air during flow by the Venturi effect. Check the CO2 pressure and purge times are at the correct settings and try increasing the purge time to correct the problem. For Venturi problems, circulate cold water around the system and check for leaks. Fault-finding checks DO and CO2 in solution problems DO2 pick up and CO2 loss or pick up problems are often caused by turbulent filling during the Beer fill and can be caused by Beer pressure problems or more likely by problems controlling the Back-pressure. To check if the Back-pressure control system is working correctly allow a keg to process through the machine but turn off the Beer supply. Allow the keg to think it is Beer filling and then take it off the machine and conduct a head pressure test. If the Back-pressure control system is working correctly the pressure should be within 1 to 2 PSI of it’s set point. Fault-finding kegs Keg with window and pressure and temperature gauges For safety reasons this test keg should be purchased from a keg manufacturer and certified for this use and not a home built device. Also all gauges should be able to take full vacuum. Fault-finding kegs Automatic test keg This keg will allow you to automatically log all the pressure , temperature and fill information for the keg throughout the complete process. Profamo Inc. - www.profamo.com Fault-finding kegs Automatic test keg A few good tips Monitor all services and utilities If you do not have pressure gauges fitted, fit them! CO2 Keep the CO2 supply and pipe work as clean as possible. Learn all the machines processes Find out from the machines manufacturer what checks are made in the program to insure all processes are carried out correctly. Do not let any one change the machines program Monitor your keg float One-way kegs Acknowledgements Andres Jensen www.jenrey.ca 416-670-8897 Jeff Gunn www.iddeas.com 805-529-9890 Chris Nimptsch www.profamo.com 941-284-7990 I would like to thank all the above for providing information and pictures for this presentation. Questions?