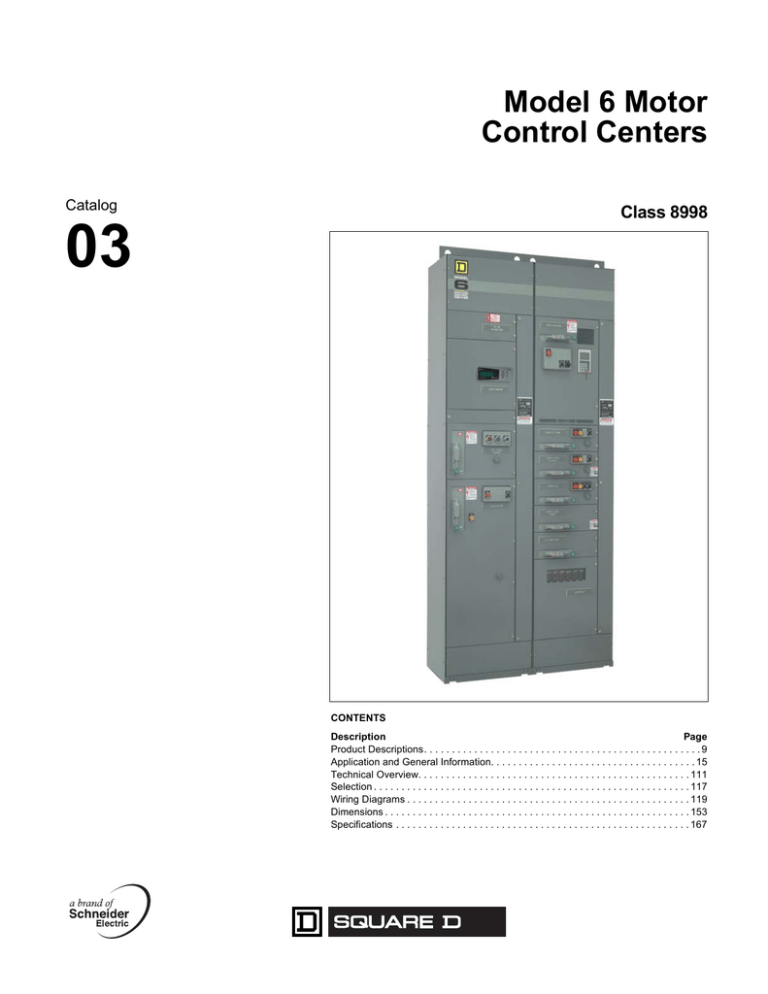

Model 6 Motor

Control Centers

Catalog

Class 8998

03

CONTENTS

Description

Page

Product Descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Application and General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Technical Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Model 6 Motor Control Centers

Table of Contents

Section 1—Product Description .............................................................................................................9

Introduction ........................................................................................................................................9

Features...........................................................................................................................................10

Codes and Standards ......................................................................................................................11

NEMA/EEMAC Wiring Classes and Types ......................................................................................11

Class 1- Independent Units..........................................................................................................11

Class 2 - Interconnected Units.....................................................................................................11

Type A..........................................................................................................................................11

Type B..........................................................................................................................................11

Type B-D......................................................................................................................................11

Type B-T ......................................................................................................................................11

Type C .........................................................................................................................................11

Enclosure Types ..............................................................................................................................12

NEMA 1........................................................................................................................................12

NEMA 1 Gasketed (NEMA 1A) ....................................................................................................12

NEMA 3R .....................................................................................................................................12

NEMA 12......................................................................................................................................12

Shipping Weights .............................................................................................................................12

Altitude Ratings................................................................................................................................12

Motor Control Center Heat Dissipation ............................................................................................13

Structure Steel Gauge Information ..................................................................................................13

Section 2—Application and General Information .................................................................................15

Structures and Bussing....................................................................................................................15

Structure ......................................................................................................................................15

Bussing Options and Modifications..............................................................................................15

Structure Options and Modifications ............................................................................................16

Special Structures ........................................................................................................................16

Model 5 to Model 6 Transition Section.........................................................................................17

Switchboard to Model 6 Transition Section..................................................................................17

Bus Duct Connection ...................................................................................................................17

Model 4 to Model 6 Transition Section.........................................................................................18

Incoming Devices.............................................................................................................................19

Main Lug Compartments..............................................................................................................19

Main Circuit Breakers...................................................................................................................20

Main Fusible Switches .................................................................................................................21

Standard Wire Lug Ranges (Mechanical) ....................................................................................22

Three Phase/Four-Wire Wye Systems with Grounded Neutral ...................................................23

Four-Wire Examples ....................................................................................................................24

PowerLogic® Circuit Monitor ........................................................................................................25

PowerLogic Power Meter.............................................................................................................26

PowerLogic Ethernet Gateways...................................................................................................28

Ethernet Hubs ..............................................................................................................................28

Transparent Ready™ Factory Configurations .............................................................................29

Analog Metering Options On Mains .............................................................................................29

Transient Voltage Surge Suppressor (TVSS) Units for MCC Incoming Mains ............................30

Model IMA TVSS (120kA Surge Rating) ......................................................................................33

Model IMA TVSS (160kA Surge Rating) ......................................................................................33

Model IMA TVSS (240kA Surge Rating) ......................................................................................33

Additional Options ........................................................................................................................33

Branch Feeder Units ........................................................................................................................34

Circuit Breaker Branch Feeder Units ...........................................................................................34

Fusible Switch Branch Feeder Units............................................................................................35

Combination Starter Units................................................................................................................36

Full Voltage Non-Reversing (FVNR) Starters with Mag-Gard® Circuit Breakers ........................36

Full Voltage Non-Reversing Vacuum Starters with Circuit Breakers ...........................................37

Application-Rated Compac 6 Units – Full Voltage Non-Reversing Starters with Circuit Breakers....... 37

Full Voltage Reversing (FVR) Starters with Mag-Gard® Circuit Breakers...................................38

Full Voltage Reversing Vacuum Starters with Circuit Breakers ...................................................38

11/03

© 2003 Schneider Electric All Rights Reserved

3

Model 6 Motor Control Centers

Table of Contents

Application-Rated Compac 6 Units – Full Voltage Reversing Starters with Circuit Breakers.......39

ProductStarters

Description

Reduced Voltage Autotransformer (RVAT)

with Thermal Magnetic Circuit Breakers.....40

Reduced Voltage Autotransformer Vacuum Starters with Circuit Breakers .................................40

Reduced Voltage 2-Step Part-winding (RVPW) Starters with Mag-Gard® Circuit Breakers ........41

Full Voltage 2-Speed 1-Winding Starters (Consequent Pole) with Mag-Gard Circuit Breakers...41

Full Voltage 2-Speed 2-Winding Starters (Separate Winding) with Mag-Gard Circuit Breakers..42

Full Voltage 2-Speed Reversing Starters with Circuit Breakers ...................................................42

Wye-Delta Closed Transition Starters with Thermal-Magnetic Circuit Breakers (Non-UL Listed)43

Wye-Delta Open Transition Starters with Thermal-Magnetic Circuit Breakers (Non-UL Listed) ..44

Full Voltage Non-Reversing (FVNR) Starters with Fusible Switch Disconnects ..........................45

Full Voltage Non-Reversing Vacuum Starters with Fusible Switch Disconnects .........................45

Application-Rated Compac 6 Units – Non-reversing with Fusible Disconnects ...........................46

Full Voltage Reversing (FVR) Starters with Fusible Switch Disconnects.....................................46

Full Voltage Reversing Vacuum Starters with Fusible Switch Disconnects .................................47

Application-Rated Compac 6 Units – Full Voltage Reversing with Fusible Disconnects..............47

Reduced Voltage Autotransformer (RVAT) Starters with Fusible Switch Disconnects ................48

Reduced Voltage Autotransformer Vacuum Starters with Fusible Switch Disconnects ...............48

Reduced Voltage 2-step Part-winding (RVPW) Starters with Fusible Switch Disconnects

(Non-UL Listed) .......................................................................................................................48

Full Voltage 2-Speed 1-Winding Starters (Consequent Pole) with Fusible Switch Disconnects..49

Full Voltage 2-Speed 2-Winding Starters (Separate Winding) with Fusible Switch Disconnects.49

Full Voltage 2-Speed Reversing Starters .....................................................................................49

Wye-Delta Closed Transition Starters with Fusible Switch Disconnects (Non-UL Listed) ...........50

Wye-Delta Open Transition Starters with Fusible Switch Disconnects (Non-UL Listed)..............50

Unit Options .....................................................................................................................................51

Unit Nameplates...........................................................................................................................51

Control Circuit Variations..............................................................................................................51

Pilot Devices.................................................................................................................................52

Pilot Lights....................................................................................................................................53

LED Pilot Lights............................................................................................................................54

Overload Relays...........................................................................................................................55

Motor Logic® Solid State Overload Relays (SSOLR) ..................................................................56

Overload Trip Function.................................................................................................................56

Phase Loss / Phase Unbalance Relays .......................................................................................56

Motor Logic Plus Solid State Overload Relays.............................................................................57

Auxiliary Electrical Interlocks ¿ ................................................................................................................................... 58

Circuit Breaker Options ................................................................................................................58

Fusible Switch Options.................................................................................................................59

Ground Fault Options ...................................................................................................................59

Wiring Options..............................................................................................................................60

Miscellaneous Units .........................................................................................................................61

Distribution Transformers .............................................................................................................61

Single Phase Distribution Transformers 120 V or 240 V Secondary................................................61

Three-Phase Distribution Transformers 208Y/120 V Secondary ................................................62

Distribution Panelboards ..............................................................................................................62

Factory Installed Panelboard Branch Circuit Breakers.................................................................63

Empty Mounting Units ..................................................................................................................64

Full Section Empty Mounting Units (Relay Section).....................................................................64

Blank Cover Plates.......................................................................................................................64

Master Terminal Compartment For NEMA/EEMAC Class I or II, Type C ....................................64

Power Factor Correction Capacitors ............................................................................................65

Altivar® AC Drive Units in MCCs ......................................................................................................66

General Information......................................................................................................................66

Application....................................................................................................................................66

Variable Torque Loads .................................................................................................................66

Constant Torque Loads................................................................................................................67

Constant Horsepower Loads........................................................................................................67

Impact Loads................................................................................................................................68

Selection ......................................................................................................................................68

4

© 2003 Schneider Electric All Rights Reserved

11/03

Model 6 Motor Control Centers

Table of Contents

Altivar® 58 TRX AC Drives...............................................................................................................69

MCC Package Features...............................................................................................................69

Factory Options............................................................................................................................70

Monitoring and Indication.............................................................................................................70

AC Drive Options .........................................................................................................................71

Drive Power Circuit ......................................................................................................................71

Space Requirements ...................................................................................................................72

Power Contactor Options .............................................................................................................74

Pilot Devices ................................................................................................................................75

Miscellaneous Options.................................................................................................................75

Wiring Diagrams ..........................................................................................................................77

Altistart® 48 Soft Start Units.............................................................................................................79

General Information .....................................................................................................................79

Benefits of Altistart 48 Soft Starts ................................................................................................79

MCC Packaging ...........................................................................................................................80

Features Included: .......................................................................................................................80

Starting and Stopping ..................................................................................................................82

Monitoring and Indication.............................................................................................................82

Options.........................................................................................................................................83

Application ...................................................................................................................................83

Standard Duty Application ...........................................................................................................83

Severe Duty Application...............................................................................................................83

Selecting the Starter ....................................................................................................................83

Standard Duty Altistart® 48 Soft Starts with Circuit Breaker Disconnects

(Pumps, Fans, Lightly Loaded, or Unloaded Starting Applications) ........................................85

Standard Duty Altistart® 48 Soft Starts with Fusible Switch Disconnects

(Pumps, Fans, Lightly Loaded, or Unloaded Starting Applications) ........................................86

Altistart® Unit Power Options ......................................................................................................88

Altistart Unit Control Circuit Variations .........................................................................................88

Altistart® Unit Control Options .....................................................................................................89

Automatic Transfer Switches with Microprocessor Control Panel ...................................................91

Standard Features .......................................................................................................................91

Model 6 OMNI Center ......................................................................................................................94

OMNI Basic ..................................................................................................................................94

Control Power Distribution ...........................................................................................................94

PLC Connections in the MCC ......................................................................................................94

Quantum™ PLC...........................................................................................................................95

Premium™ PLC ...........................................................................................................................95

Momentum™ PLC .......................................................................................................................95

Micro PLC ....................................................................................................................................96

Nano PLC ....................................................................................................................................96

Compact PLC...............................................................................................................................96

Twido™ Ultra-Compact PLC........................................................................................................96

Model 6 OMNI Center-Flex ..........................................................................................................97

Benefits ........................................................................................................................................97

Connectivity .................................................................................................................................97

OMNI Basic with Data Acquisition ...............................................................................................98

Features/Options .........................................................................................................................98

Model 6 OMNI Center-Enhanced.................................................................................................98

Information Available ...................................................................................................................98

Motor Logic® Plus Displays .........................................................................................................99

Motor Logic Plus Overload Central Monitoring Display ...............................................................99

Motor Logic Plus Motor Management System Display ................................................................99

Thermal Overload Relay Unit Selection.........................................................................................101

Melting Alloy Overload Selection Tables for All Types of Combination Starter Units Except

Part-Winding Starter Units ........................................................................................................101

Size 1 .........................................................................................................................................101

Size 2 .........................................................................................................................................102

11/03

© 2003 Schneider Electric All Rights Reserved

5

Model 6 Motor Control Centers

Table of Contents

Size 3 .........................................................................................................................................102

Product Description

Size 4 .........................................................................................................................................102

Size 5 .........................................................................................................................................103

Size 5 with CT Type Overloads and Circuit Breakers................................................................103

Size 5 with CT Type Overloads and Fusible Switch Disconnects..............................................103

Size 6 .........................................................................................................................................103

Melting Alloy Overload Selection Tables for Part Winding Combination Starter Units Only ..........104

Size 1 .........................................................................................................................................104

Size 2 .........................................................................................................................................104

Size 3 .........................................................................................................................................105

Size 4 .........................................................................................................................................105

Size 5 .........................................................................................................................................105

Size 5 with CT Overload with Circuit Breakers ..........................................................................106

Size 5 with CT Type Overloads and Fusible Switch Disconnects..............................................106

Ambient Compensated Bimetallic Overload Relay Selection Tables for All Types of Combination

Starter Units Except Part-Winding Starter Units .......................................................................107

Size 1 .........................................................................................................................................107

Size 2 .........................................................................................................................................107

Size 3 .........................................................................................................................................107

Size 4 .........................................................................................................................................108

Size 5 .........................................................................................................................................108

Size 6 .........................................................................................................................................108

Ambient Compensated Bimetallic Overload Relay Selection Tables for Part Winding Combination

Starter Units Only......................................................................................................................109

Size 1 .........................................................................................................................................109

Size 2 .........................................................................................................................................109

Size 3 .........................................................................................................................................109

Size 4 .........................................................................................................................................110

Size 5 .........................................................................................................................................110

Section 3—Technical Overview .........................................................................................................111

Short Circuit Current Ratings .........................................................................................................111

Interrupt Rating ..........................................................................................................................111

Bus Bracing or Withstand Rating ...............................................................................................111

Integrated Equipment Rating .....................................................................................................111

Series Connected Short Circuit Current Ratings .......................................................................111

Short Circuit Current Rating.......................................................................................................111

UL Listed Short Circuit Current Ratings .....................................................................................112

“Self-Certified” Short Circuit Current Ratings .............................................................................112

Section 4—Selection Guide ...............................................................................................................117

Layout Instructions.........................................................................................................................117

Unit Designation Chart for Planning .............................................................................................118

Section 5—Wiring Diagrams..............................................................................................................119

Introduction ....................................................................................................................................119

Submittal Drawing Cover Sheet.....................................................................................................119

Full Voltage Non-Reversing, Size 1–4 with Control Power Transformer ...................................120

Full Voltage Non-Reversing, Size 1–4 with Separate Source....................................................121

Full Voltage Reversing, Size 1–4 with Control Power Transformer ...........................................122

Full Voltage Reversing, Size 1–4 with Control Power Transformer (cont.) ................................123

Full Voltage Reversing, Size 1–4 with Control Power Transformer (cont.) ................................124

2-Speed, 1-Winding, Constant or Variable Torque, Size 1–4 with Separate Source and

Remote Control .....................................................................................................................125

2-Speed, 1-Winding, Constant Horsepower, Size 1–4 with Separate Source and

Remote Control .....................................................................................................................126

2-Speed, 1-Winding, Constant or Variable Torque, Size 1–4 with 120 Vac Control Power

Transformer, Start/Stop Push Buttons, Red “High,” Red “Low,” Green “Off” Pilot Lights, and

Auxiliary Interlocks ................................................................................................................127

6

© 2003 Schneider Electric All Rights Reserved

11/03

Model 6 Motor Control Centers

Table of Contents

2-Speed, 1-Winding, Constant Horsepower, Size 1–4 with 120 Vac Control Power

Transformer, Start/Stop Push Buttons, Red “High,” Red “Low,” Green “Off” Pilot Lights,

and Auxiliary Interlocks .........................................................................................................128

2-Speed, 1-Winding, Constant or Variable Torque, Size 1–4 with Separate Source, Start/Stop

Push Buttons, Red “High,” Red “Low,” Green “Off” Pilot Lights, and Auxiliary Interlocks .....129

2-Speed, 1-Winding, Constant Horsepower, Size 1–4 with Separate Source, Start/Stop

Push Buttons, Red “High,” Red “Low,” Green “Off” Pilot Lights, and Auxiliary Interlocks .....130

2-Speed, 2-Winding (Separate Winding), Size 1–4 with 120 Vac Control Power Transformer

and Remote Control ..............................................................................................................131

2-Speed, 2-Winding (Separate Winding), Size 1–4 with Control Power Transformer, Start/Stop

Push Buttons, Red “High,” Red “Low,” Green “Off” Pilot Lights, and Auxiliary Interlocks .....132

2-Speed, 2-Winding (Separate Winding), Size 1–4 with Control Power Transformer, Remote

Control, Red “High,” Red “Low,” Green “Off” Pilot Lights, and Auxiliary Interlocks ...............133

2-Speed, 2-Winding (Separate Winding), Size 1–4 with Separate Source and Remote Control....... 134

2-Speed, 2-Winding (Separate Winding), Size 1–4 with Separate Source, Start/Stop Push

Buttons, Red “High,” Red “Low,” Green “Off” Pilot Lights, and Auxiliary and Operator Interlocks 135

2-Speed, 2-Winding (Separate Winding), Size 1–4 with Separate Source, Remote Control,

Red “High,” Red “Low,” Green “Off” Pilot Lights, and Auxiliary and Operator Interlocks ......136

Reduced Voltage Auto Transformer, Size 3–4 with Control Power Transformer and Remote

Start/Stop Push Buttons........................................................................................................137

Reduced Voltage Auto Transformer, Size 3–4 with Control Power Transformer, Start/Stop

Push Buttons, and Red “On” and Green “Off” Pilot Lights ....................................................138

Reduced Voltage Auto Transformer, Size 3–4 with Control Power Transformer,

Hand-Off-Auto Selector Switch, and Red “On” and Green “Off” Pilot Lights.........................139

Reduced Voltage Auto Transformer, Size 3–4 with Separate Source, Start/Stop Push

Buttons, and Red “On,” Green “Off” Pilot Lights ...................................................................140

Reduced Voltage Auto Transformer, Size 3—4 with Separate Source, Hand-Off-Auto

Selector Switch, Red “On,” Green “Off” Pilot Lights, and Melting Alloy Overload Relay.......141

Reduced Voltage Auto Transformer, Size 5 with Control Power Transformer and Remote

Start/Stop Push Buttons........................................................................................................142

Reduced Voltage Auto Transformer, Size 5 with Control Power Transformer, Start/Stop

Push Buttons, and Red “On,” Green “Off” Pilot Lights ..........................................................143

Reduced Voltage Auto Transformer, Size 5 with Control Power Transformer,

Hand-Off-Auto Selector Switch, and Red “On,” Green “Off” Pilot Lights...............................144

Reduced Voltage Auto Transformer, Size 5 with Separate Source, Start/Stop Push Buttons,

and Red “On,” Green “Off” Pilot Lights..................................................................................145

Reduced Voltage Auto Transformer, Size 5 with Separate Source, Hand-Off-Auto Selector

Switch, Red “On,” Green “Off” Pilot Lights, and Melting Alloy Overload Relay .....................146

Reduced Voltage Auto Transformer, Size 6 with Control Power Transformer, Remote

Start/Stop Push Buttons, and Melting Alloy Overload Relay.................................................147

Reduced Voltage Auto Transformer, Size 6 with Control Power Transformer, Start/Stop

Push Buttons, Red “On,” Green “Off” Pilot Lights, and Melting Alloy Overload Relay ..........148

Reduced Voltage Auto Transformer, Size 6 with Control Power Transformer, Hand-Off-Auto

Selector Switch, Red “On,” Green “Off” Pilot Lights, and Melting Alloy Overload Relay.......149

Reduced Voltage Auto Transformer, Size 6 with Separate Source, Start/Stop Push Buttons,

Red “On,” Green “Off” Pilot Lights, and Melting Alloy Overload Relay .................................150

Reduced Voltage Auto Transformer, Size 6 with Separate Source, Hand-Off-Auto Selector

Switch, Red “On,” Green “Off” Pilot Lights, and Melting Alloy Overload Relay .....................151

Section 6—Dimensions......................................................................................................................153

General ..........................................................................................................................................153

Quick Finder for Conduit Entry Drawings.......................................................................................153

NEMA/EEMAC 1, NEMA/EEMAC 1 Gasketed, or NEMA/EEMAC 12 Enclosures ........................154

Standard Sections—15 in. Deep....................................................................................................156

Relay Sections—15 in. Deep .........................................................................................................157

Standard Sections — 20 in. Deep..................................................................................................158

Relay Sections—20 in. Deep .........................................................................................................160

Main/Branch Devices and Relay Sections—20 in. Deep ...............................................................161

Relay Sections—20 in. Deep/50 in. Wide ......................................................................................162

11/03

© 2003 Schneider Electric All Rights Reserved

7

Model 6 Motor Control Centers

Table of Contents

Standard Sections—15 in. Deep....................................................................................................163

Product Description

Relay Sections—15 in. Deep .........................................................................................................163

Standard Sections—20 in. Deep....................................................................................................164

Relay Sections—20 in. Deep .........................................................................................................165

Section 7—Typical Specifications......................................................................................................167

Regulatory Requirements ..............................................................................................................167

Packing and Shipping ....................................................................................................................167

Storage ..........................................................................................................................................167

Warranty ........................................................................................................................................167

Materials ........................................................................................................................................167

Structures.......................................................................................................................................167

Standard Paint ...............................................................................................................................168

Special Paint (Customer-Specified) ...............................................................................................168

Wireways .......................................................................................................................................168

Barriers ..........................................................................................................................................168

Bussing ..........................................................................................................................................169

Typical Unit Construction ...............................................................................................................169

Components...................................................................................................................................170

A. Combination Starters.............................................................................................................170

B. Control Terminal Blocks ........................................................................................................170

C. Nameplates ...........................................................................................................................171

D. Pilot Device Panel .................................................................................................................171

Six-Inch Unit Construction .............................................................................................................171

Components for Six-Inch Units ......................................................................................................172

Six-Inch Combination Starters ...................................................................................................172

Terminal Blocks for Six-Inch Units .............................................................................................172

Nameplates ................................................................................................................................172

Pilot Device Control Panel .........................................................................................................172

Quality Control ...............................................................................................................................173

Physical Inspection ....................................................................................................................173

Electrical Tests...........................................................................................................................173

Markings/Labels.........................................................................................................................173

8

© 2003 Schneider Electric All Rights Reserved

11/03

Model 6 Motor Control Centers

Introduction

Product Description

SECTION 1—PRODUCT DESCRIPTION

Introduction

Motor control centers (MCCs) provide the most suitable method for grouping electrical motor control,

automation, and power distribution in a compact and economical package. Motor control centers consist

of totally enclosed, dead front, free-standing structures bolted together. These sections support and

house control units, a common bus bar for distributing power to the control units, and a network of wire

trough and conductor entrance areas for accommodating incoming and outgoing load and control wires.

The control units consist of components such as combination motor starters, branch feeder devices, AC

drives, soft starts, or lighting panelboards. Each unit is mounted in an individual, isolated compartment

having its own door. Standard MCC dimensions are 20 in. wide (including a 4 in. vertical wireway trough)

by 90 in. high (add 1.5 in. base channel and a 3 in. removable top lifting channel) by 15 or 20 in. deep.

Larger sections are often required for mounting larger equipment, or for providing room for customermounted devices.

Two package styles are available: Standard and Industrial. These Model 6 feature packages allow you

to custom design the MCC to fit your specific requirements. The Standard package lets you tailor the

MCC by selecting only those options that you need for an individual project, guaranteeing the optimal

cost/value balance. The Industrial package includes options most often requested and specified by

industrial customers. Offering the options as part of a package reduces the possibility of leaving out

common industrial features. See the following table for a comparison of the two packages.

Option

Standard Package

Industrial Package

Vertical ground bus material

Steel

Copper

Horizontal bus material

Tin-plated aluminum ➀

Tin-plated copper

Fishtape barriers

Optional

Included

Gray

White

Structure Features

Unit Features

Interior color

Nameplates

Optional

Included

X1 and X2 wired to terminal blocks

Optional

Included

➀

Exceptions: 1600-2500 A are tin plated copper.

All features of the industrial package can be added individually to the standard version.

11/03

© 2003 Schneider Electric All Rights Reserved

9

Model 6 Motor Control Centers

Product Description

Features

Features

Product Description

• Section dimensions are 20 in. W x 90 in. H x 15 in. or 20 in. D.

• Horizontal power bus is located at the top of the structure for easy installation, inspection, and

maintenance without having to remove units.

Quarter-Turn Fasteners

• Constructed with 12-gauge steel frame and welded corner channels for exceptional structural rigidity.

• A durable, ANSI 49 acrylic/alkyd baked enamel exterior finish is standard on all Model 6 MCCs.

• Captive, four-bolt, horizontal splice bars with self-contained nuts and hardware make installation

easy and reduce the possibility of splice bar loss.

Captive Horizontal

Splice Bars

• Vertical bus barriers and wireway openings, when supplied, are built in 3 in. increments. This feature

allows more flexibility when mounting units and reduces wasted space in the enclosure.

• Vertical ground bus is located in each section. This bus mates with ground stabs on the rear of each

plug-on unit to create a positive ground connection, with first make/last break operation.

• Iridescent chromate-plated exterior hardware increases corrosion resistance.

• Quarter-turn fasteners on unit and wireway doors expedite closing and opening.

• A full-depth vertical wireway maximizes the wire pulling area. The Model 6 MCC has the largest vertical

wireway in the industry.

• L-shaped unit door hinge pins are easily removed with a screwdriver for general maintenance.

Horizontal Bus Located

Behind the Wireway

• Each Industrial package unit is fully compartmentalized, with solid side, back, and bottom plates. This

feature allows more mounting space for components and confines any potential faults within the

individual unit.

• A hinged, or fold-down, unit bottom plate on the Industrial package MCC allows additional space for

wiring and maintenance.

• Leveling notches in the base channel provide a means of aligning the section during installation.

Iridescent Chromate Plated Exterior Hardware

• Non-conductive, two-piece, sliding, horizontal bus barrier provides convenient access for splicing

and maintenance without the need to remove the panels.

Vertical Ground Bus

L-shaped Hinge Pins

12-Gauge Steel Frame and

Welded Corner Channels

10

© 2003 Schneider Electric All Rights Reserved

11/03

Model 6 Motor Control Centers

Codes and Standards

Product Description

Codes and Standards

®

®

Model 6 Motor Control Centers are manufactured to NEMA (National Electrical Manufacturers’

Association) Standard ICS 18-2001 and EEMAC (Electrical, Electronic Manufacturers’ Association of

Canada) standards. Model 6 MCCs are also manufactured to Underwriters Laboratories Standard 845

and bear the “UL Listed” label, where applicable. The “UL Listed” mark is applied to vertical sections

and units that are installed within those sections. It should be noted that sections and installed units are

independently listed devices. Thus, it is possible to have non-UL Listed units installed in UL Listed

vertical sections.

All sections and units listed in this catalog are UL Listed, unless otherwise noted. The Model 6 MCC

meets CSA (Canadian Standards Association) specification standards and can carry the CSA label.

NEMA/EEMAC Wiring Classes and Types

Class 1- Independent Units

Class 1 motor control centers consist of mechanical groupings of combination motor control units,

branch feeders, other units, and electrical devices arranged in a convenient assembly. The

manufacturer completes wiring between components within each unit. Wiring between units is not

required.

Class 2 - Interconnected Units

Class 2 MCCs are the same as Class 1 MCCs with the addition of manufacturer-furnished electrical

interlocking and wiring between units as specifically described in the overall control system diagrams

supplied by the purchaser.

Type A

User (field) wiring connects directly to device terminals internal to the unit. Type A wiring is provided

only on Class 1 MCCs.

Type B

User (field) control wiring connects to unit terminal block(s) in or adjacent to each motor control unit.

User load (power) wiring for Size 3 or smaller combination motor control units connects as follows:

Type B-D

User load (power) wiring connects directly to the device terminals, which are located immediately

adjacent to, and are readily accessible from, the vertical wireway.

Type B-T

User load (power) wiring connects to factory-wired power terminal blocks located in or adjacent to

each unit.

User load (power) wiring for Size 4 or larger combination motor control units and branch feeder units

connects directly to the unit device terminals.

Type C

User (field) control wiring and load wiring on Size 3 or smaller motor control units connects to master

terminal blocks mounted at the top or bottom of those vertical sections containing control units. Unit

control wiring and load wiring on Size 3 or smaller units are factory-wired from unit-located terminal

blocks to the master terminal blocks. User load (power) wiring for Size 4 or larger units connects directly

to the device terminals. As an option, user load (power) wiring for all sizes of motor control units may

connect directly to the device terminals within the MCC units. See page 60 for load wiring options.

11/03

© 2003 Schneider Electric All Rights Reserved

11

Model 6 Motor Control Centers

Product Description

Codes and Standards

Enclosure Types

Product Description

NEMA 1

Intended for indoor use only. NEMA 1 enclosures are designed primarily to provide protection against

contact with energized equipment inside. They are to be used in locations where normal service

conditions exist.

NEMA 1 Gasketed (NEMA 1A)

Intended to restrict the entrance of dust and falling dirt into NEMA 1 enclosures. NEMA 1 Gasketed

enclosures are not dust-tight. Neoprene gasketing is the standard material used.

NEMA 3R

Intended for outdoor use only. NEMA 3R enclosures are designed primarily to provide protection against

falling rain and sleet and remain undamaged by the formation of ice on the enclosure. They are not intended

to provide protection against conditions such as dust, internal condensation, internal icing, or extreme heat

or cold. The Model 6 NEMA 3R enclosure is built with galvannealed steel, which provides a high level of

resistance to corrosion when compared to standard hot or cold rolled steel with the same paint finish.

NEMA 12

Intended for indoor use only. NEMA 12 enclosures are designed primarily to protect against dust, falling

dirt, light splashing, and dripping of non-corrosive liquid. They are not intended to provide protection

against conditions such as internal condensation.

Shipping Weights

One, two, or three vertical sections can be shipped together on a pallet. Larger MCCs are split into

shipping blocks of three sections maximum. The following table lists typical approximate shipping

weights for a normal mix of MCC equipment. Some sections, based on installed devices and width of

the section, may vary from values shown in the table.

Approximate MCC Shipping Weights

Enclosure Type

Depth (inches)

1 Section (lbs)

2 Sections (lbs)

3 Sections (lbs)

NEMA 1, 1A, 12

NEMA 3R Non-Walk-In

15

600

1200

1800

15 ➀

(27.2 in. overall)

900

1800

2700

20

750

1500

2250

20 ➀

(32.2 in. overall)

1050

2100

3150

NEMA 1, 1A, 12

NEMA 3R Non-Walk-In

➀

See the NEMA 3R dimensions drawing on page 155.

Altitude Ratings

The following table lists the MCC derating factors necessary at altitudes of 6,600 ft (2,000 m) and higher.

Altitude

6,600 ft (2,000 m)

①

Altitude Rating Correction Factors ①

Full Load Current

System Voltage

Ambient Temperature

1.0

1.0

1.0

8,500 ft (2,600 m)

0.99

0.95

1.0

13,000 ft (3,900 m)

0.96

0.80

0.95

14,000 ft (4,300 m)

0.95

0.80

0.90

15,000 ft (4,600 m)

0.93

0.80

0.85

For variable frequency drives or solid state reduced voltage starters, Altitude Rating Correction Factors may differ. Contact your

local Schneider Electric field sales office.

12

© 2003 Schneider Electric All Rights Reserved

11/03

Model 6 Motor Control Centers

Product Description

Motor Control Center Heat Dissipation

The following table lists the approximate heat dissipation of various MCC units. This information is often

requested by engineers who are sizing HVAC equipment to cool and ventilate equipment rooms. Values

include an estimate of heat dissipated by the MCC Power Bus. To use, add the values for each of the

units in the MCC. Values are given in BTUs per minute or watts. To provide BTUs per hour, multiply the

BTUs per minute by 60.

The values given are for “typical” applications, and include an adjustment for power bus contribution.

Make the following adjustments for special situations:

Add 10–20 percent to the total heat dissipation for MCCs that make extensive use of relays, timers,

and other control devices.

Add 10 percent to the total heat dissipation for MCCs with 1200–1600 A main bus.

Add 20 percent to the total heat dissipation for MCCs with 2000 A main bus.

Typical Heat Dissipation Values ➀

Description

Size/Rating

1

Combination Starters (Circuit Breaker or Fusible

Disconnect)

Heat Dissipation

BTUs/min

Watts

4.5

79

2

6

106

3

12

210

4

24

420

5

40

700

FA (15–100 A)

4.5

79

KA (110–250 A)

12

210

Main and Branch Feeder Breakers

LA (300–400 A)

13

230

MA (500–600 A)

22

390

30 A

2.1

37

46

60 A

2.6

100 A

4.7

85

200 A

13

230

400 A

17

300

600 A

22

390

Main and Branch Feeder Switches

➀ For variable frequency drives, solid state reduced voltage starters, and programmable logic control, unit heat dissipation can be

significant. Contact your local Schneider Electric field sales office for the heat dissipation of these devices.

Structure Steel Gauge Information

Model 6 MCCs are totally enclosed, dead front, free standing assemblies. All steel is in compliance with

UL 845 / CSA requirements:

Part Description

12

Back Plates: 20–30 in. wide

16

35 in. wide

End Closing Plates

Unit Doors

11/03

Thickness (Gauge)

Corner Channels

14

16 (NEMA 3R: 12 gauge)

14 and 16 (NEMA 3R: 12 gauge on outer door)

Side Channels

11

Top and Bottom Frame

12

Top and Bottom Plates

14

Base Channels

10

Lifting Angle

7

© 2003 Schneider Electric All Rights Reserved

13

Model 6 Motor Control Centers

Product Description

Product Description

14

© 2003 Schneider Electric All Rights Reserved

11/03

Model 6 Motor Control Centers

Structures and Bussing

Application and General Information

SECTION 2—APPLICATION AND GENERAL INFORMATION

Structures and Bussing

Structure

Each section provides 72 in. of vertical mounting space for MCC units. Special sections are required for

selected units such as autotransformer starters and some main breakers. Structures include vertical

ground bus, with a 42,000 A bus withstand rating.

NEMA/EEMAC Enclosure Type

Depth

General Purpose NEMA 1

General Purpose NEMA 1 Gasketed (often referred to as NEMA 1A)

15 in. - Standard

20 in. - Available

Industrial Duty NEMA 12

Outdoor Duty NEMA 3R Non-Walk-In

Outdoor Duty NEMA 3R Walk-In (Contact the Project Support and Engineering Center.)

Main Bus Amps and Material ➀

Horizontal Bus

600 A tin-plated aluminum

1200 A silver-plated copper

600 A tin-plated copper

1600 A tin-plated copper (20 in. deep only)

600 A silver-plated copper

1600 A silver-plated copper (20 in. deep only)

800 A tin-plated aluminum

2000 A tin-plated copper (20 in. deep only)

800 A tin-plated copper

2000 A silver-plated copper (20 in. deep only)

800 A silver-plated copper

2500 A tin-plated copper (20 in. deep only) ➁

1200 A tin-plated aluminum

2500 A silver-plated copper (20 in. deep only) ➁

1200 A tin-plated copper

For 3PH4W systems, see page 23.

➀ Ratings shown based on 149° F (65° C) max. temperature rise per UL 845. Consult your local Schneider

Electric field sales office for current density ratings.

➁ Not available in NEMA 12 or 3R enclosures.

Bussing Options and Modifications

Description

Bus bar surge protection (Requires main disconnect. Installed in 6 in. unit and will be located as close as possible to

the main device.) Not for use on ungrounded systems. Note: Capacitor unit is not needed for surge protection.

Steel or copper vertical ground bus (INCLUDED AS STANDARD)

300 A vertical bus – tin-plated copper (INCLUDED AS STANDARD)

Substitute 600 A vertical bus – tin-plated copper

Substitute 600 A vertical bus – silver-plated copper

4 bolt splice (captive) on main/horizontal bus (INCLUDED AS STANDARD)

42,000 A rms

Bus Withstand Rating

(Modifications to increase the bus system withstand rating to meet available fault current

requirements.) Does not increase individual unit ratings.

65,000 A rms

85,000 A rms

100,000 A rms ➀

Tin-plated copper horizontal ground bus - 1/4 in. x 1 in. (INCLUDED AS STANDARD)

Substitute tin-plated copper horizontal ground bus - 1/4 in. x 2 in.

Optional 2 in. main/horizontal bus – tin-plated copper

Optional 2 in. main/horizontal bus – silver-plated copper

➀ 480 V maximum

Required on 2500 A horizontal bus

11/03

© 2003 Schneider Electric All Rights Reserved

15

Model 6 Motor Control Centers

Application and General Information

Structures and Bussing

Structure Options and Modifications

Description

12 in. high pull box

18 in. high pull box

Two-piece top plate

Bottom plate for NEMA/EEMAC 1 Gasketed

Drip hood (Not available with 2500A horizontal bus)

Strip heater (200 Watts at 120 V) (Not available in sections with Size 6 RVAT, bottom feed main lugs, bottom feed mains and

branches over 600 A, or distribution transformers)

Thermostat for control of strip heater (6 heaters maximum)

Rear doors (20 in. deep sections only)

9 in. wide vertical wireway (sections 25 in. wide.This option applies only to sections with plug-in units.)

Wire tie retainers in vertical wireway

Automatic Vertical Bus Shutters

White unit interiors (included with Industrial package)

NEMA/EEMAC 1,

1 Gasketed, or 12

Non-standard exterior color (includes one coat of Schneider Electric selected paint.)

NEMA/EEMAC 3R

Fishtape barrier (included with Industrial package) (Prevents rising of bottom-entering fishtapes into wireway.)

Rodent barriers (Standard)

GFI receptacle (NEMA/EEMAC 3R Non-Walk-In)

Fluorescent light (NEMA/EEMAC 3R Non-Walk-In)

Reduced height construction:

Structure height including base channels (without lifting

angles):

79.5 in.

73. 5 in.

67.5 in.

Available unit mounting space:

60 in.

54 in.

48 in.

Amount section shortened:

12 in.

18 in.

24 in.

Application - Not available on back-to-back, corner, NEMA 3R, or sections with neutral bussing. Reduced height construction

reduces the section’s unit mounting space and does not reduce either the top or bottom horizontal wireway.

Special Structures

(Not available in NEMA/EEMAC 3R Construction or Reduced Height Sections)

Description

Application

Back-to-back splice transition section

2500 A Max.

Through-the-back splice ➀

1200 A Max.

Corner Sections

2500 A Max.

➀

Tin plated copper splice standard.

20.00

508

or

20.00

12.00

508

305

25.00

635

20.00

508

or

31.00

25.00

787

or

635

41.00

1041

1.00

15.00

1.00

381

or

25

Between

Sections

Back-To-Back Transition Section

Top View

➀ Not available with neutral bus or relay sections.

20.00

508

Through-the-Back Splice

Top View ➀

Dual Dimensions =

25

Between

Sections

INCHES

millimeters

15.00

381

or

Front

20.00

508

Corner Section

Top View

16

© 2003 Schneider Electric All Rights Reserved

11/03

Model 6 Motor Control Centers

Structures and Bussing

Application and General Information

Model 5 to Model 6 Transition Section

A Model 6 MCC can splice directly to a Model 5 MCC, provided the Model 5 structure was manufactured

after May 1992.

If the Model 5 MCC was manufactured before May 1992, custom splice plates (NEMA/EEMAC 1 and

1A) or an adapter kit (NEMA/EEMAC 3R) is required and supplied with the appropriate section in the

Model 6 lineup.

Switchboard to Model 6 Transition Section

Square D brand switchboards can be provided with bussed transitions to Model 6 Motor Control Center

lineups. The transition section will be supplied as part of the switchboard lineup. Contact your local

Schneider Electric field sales office for additional information.

Bus Duct Connection

I-Line® feeder busway compartments must always be located at the top of the section. A 12 in. high pull

box is required. I-Line Busway should be positioned edgewise A, B, C, left-to-right as shown in the

figure. To facilitate installation, both front and side accessibility is recommended. NO ADDITIONAL

MOUNTING SPACE IS REQUIRED.

Must be “I-Line II Feeder End” Style; Qwik Flange™ is not available. NEMA/EEMAC 3R is not available.

Bus duct connections are not UL Listed in MCCs. Contact the factory for 2500 A applications.

W

W/2

A

B

C

D

CL

Typical

MCC

Section

D/2

CL

Front

Top View

No Main Disconnect ➀

MCC Bus Width Depth

Ampacity (In.)

(In.)

➀

➁

➂

11/03

C/B Disconnect

➁

Fusible Main Disconnect ➁

Conn

MCC Mains

Ampacity

Width

(In.)

Depth

(In.)

Conn

MCC Mains

Ampacity

Width

(In.)

Depth

(In.)

Conn

600 A

800 A

1200 A

20

15

or

20

Bus

110A–600 A

20

15 or 20

Cable

200 A–600 A

20

15 or 20

Cable

1600 A

2000 A

25 ➂

20

Bus

800 A–1200 A

25

20

Bus

800 A–1200 A

25

20

Bus

—

—

—

—

1600 A–2000 A

30

20

Bus

1600 A–2000 A

30

20

Bus

With no main disconnect, connection from busway to horizontal bus is done with main bus. A main lug compartment is not

required.

With a main disconnect, connection from busway to disconnect is done with either cable or bus depending on ampacity.

A 25 in. wide section is a standard section with a 9 in. wireway and will accept plug-on units. A 72 in. unit mounting space is

available.

© 2003 Schneider Electric All Rights Reserved

17

Model 6 Motor Control Centers

Application and General Information

Structures and Bussing

Model 4 to Model 6 Transition Section

(Not Available In NEMA/EEMAC 3R Construction)

Provides transition from an existing Model 4 to a new Model 6 MCC. The transition requires a 12 in.

extension on the first section of the Model 6 lineup. A transition section does not affect the space

calculation when estimating the number of sections during pricing. The transition section must be

ordered with at least one Model 6 section and cannot ship separately. The ampacity of the Model 6

horizontal bus must be equal to or exceed the ampacity of the Model 4 horizontal bus.

NOTE: Splice bars are included with the transition section.

The transition section will match the depth of the Model 6 MCC, and can be used to splice to an existing

back-to-back Model 4 MCC (20 in. deep). The transition section will be rear aligned with both the Model

4 and the Model 6 sections. On 3-phase 4-wire systems, the 3-phase bus bars will splice together, but

the Model 4 neutral bus bar will not be carried through in the Model 6.

NOTE: When ordering a Model 4 to Model 6 transition section, you must provide the original Model 4

factory order number.

Basic Transition ➀

Model 4 on left and Model 6 on right

Model 6 on left and Model 4 on right

➀

Includes 12 in. wide structure with 800 A bus as standard.

Transition Bussing Modifications

Model 4 Bus

600 A Aluminum or Copper

Model 6 Bus

600 A Copper

800 A Aluminum

800 A Copper

1000 A Aluminum (2) 2 in.

1200 A Copper

1200 A Aluminum (2) 3 in.

1200 A Copper

1000 A Aluminum (1) 4 in.

1200 A Copper

1200 A Copper (2) 2 in.

1200 A Copper

1000 A Copper (1) 3 in.

1200 A Copper

1200 A Copper (1) 4 in.

1200 A Copper

1400 A Aluminum (2) 4 in.

1600 A Copper

1600 A Copper (2) 3 in.

1600 A Copper

1800 A Copper (2) 4 in.

2000 A Copper

2000 A Copper (2) 4 in.

2000 A Copper

18

© 2003 Schneider Electric All Rights Reserved

11/03

Model 6 Motor Control Centers

Incoming Devices

Application and General Information

Incoming Devices

Incoming or main devices are used to connect power to the motor control center. In the majority of MCC

applications, the system is rated as 480 V, 3PH3W. If a neutral wire connection is required, a neutral kit

can be supplied (see “Three Phase/Four-Wire Wye Systems with Grounded Neutral” on page 23).

Typically, one of three devices is used to connect power to the MCC: main lugs, main circuit breaker, or

main fusible switch. One of these devices is connected to the horizontal or main bus with cable or hard

bus. Cabled or bussed branch devices or cabled starter units (those with an L, M, or P frame circuit

breaker disconnect, or 600 A or larger fusible switch disconnect) cannot be installed in the same section

as a main device. As with all electrical equipment rated 600 V or less, incoming cables must be rated

using the 75° C (167° F) chart in the National Electrical Code (NEC). The incoming lugs are 90° C

(194° F) lugs and 90° C (194° F) cable can be used, however the cable must be applied to the 75° C

(167° F) ratings.

All main devices must be top or bottom located.

Main Lug Compartments

• Main lug compartments must be specified in the absence of other incoming line provisions.

• 3PH4W main lugs include neutral assembly for cable connection to other units with solid neutrals.

• Main lug units short circuit current ratings to 100,000 A are available.

Top Located Main Lug Compartments

System

Main Lugs

3-Phase 3-Wire

Amps

Space (Inches)

600

800

6

1200

12

1600 ➁

2000 ➁

Horizontal Bus Connection

Bussed

72

2500 ➁

3-Phase 4-Wire

600

800

9

1200 ➀

12

1600 ➁

2000 ➁

Bussed

72

2500 ➁

➀

➁

25 in. wide section with 9 in. wireway

30 in. wide by 20 in. deep section

Bottom Located Main Lug Compartments

System

Amps

Space (Inches)

600

18

1200 ➀

3-Phase 3-Wire

1600 ➁

2000 ➁

Horizontal Bus Connection

36

Bussed

72

2500 ➁

600

1200 ➀

3-Phase 4-Wire

1600 ➁

2000 ➁

18

36

Bussed

72

2500 ➁

➀

➁

11/03

25 in. wide section with 9 in. wireway

30 in. wide by 20 in. deep section

© 2003 Schneider Electric All Rights Reserved

19

Model 6 Motor Control Centers

Application and General Information

Incoming Devices

Main Circuit Breakers

• Main circuit breaker units are located in 20 in. wide by 15 in. or 20 in. deep sections, except where

noted. Mains must be top or bottom located.

• All main breakers include a high-interrupting thermal magnetic circuit breaker.

• All units are for 3PH3W systems. 3PH4W applications may require additional space (“Three Phase/

Four-Wire Wye Systems with Grounded Neutral” on page 23).

Top Located Main Circuit Breakers

Frame

Type

Maximum

Amperes

AIC

240 V

480 V

600 V

Space

(inches)

Connection

Molded Case Breakers

KH

250

65,000

35,000

25,000

15

KI

250

100,000

100,000

65,000

21

Plug-on

LH

400

65,000

35,000

25,000

21

LI

600

100,000

100,000

65,000

27

MH

600

65,000

50,000

25,000

24

800

65,000

50,000

25,000

24

800

65,000

65,000

25,000

72 ➀

Cabled

Main Circuit Breaker

MH

MH

1000

65,000

65,000

25,000

72 ➀➂

1200

100,000

100,000

65,000

72 ➁

2000

100,000

100,000

65,000

72 ➁

PH

Bussed

Electronic Breakers

LX

400

100,000

65,000

50,000

27

MX

800

65,000

50,000

25,000

24

Cabled

➀

➁

➂

MX

800

65,000

65,000

25,000

72 ➀

PX

2000

100,000

100,000

65,000

72 ➁

Bussed

25 in. wide by 20 in. deep

30 in. wide by 20 in. deep

Ground fault option requires 30 in. wide by 20 in. deep section

Bottom Located Main Circuit Breakers

Frame

Type

Maximum

Amperes

AIC

240 V

480 V

600 V

Space

(inches)

Connection

Molded Case Breakers

KH

250

65,000

35,000

25,000

15

KI

250

100,000

100,000

65,000

21

LH

400

65,000

35,000

25,000

27

LI

400

100,000

100,000

100,000

27

LI

450–600

100,000

100,000

65,000

36

MH

600

65,000

50,000

25,000

36

800

65,000

50,000

25,000

36

800

65,000

65,000

25,000

72 ➀

Plug-on

MH

MH

1000

65,000

65,000

25,000

72 ➀➂

1200

100,000

100,000

65,000

72 ➁

2000

100,000

100,000

65,000

72 ➁

PH

➀

➁

➂

Cabled

Bussed

25 in. wide by 20 in. deep

30 in. wide by 20 in. deep

Ground fault option requires 30 in. wide by 20 in. deep section

20

© 2003 Schneider Electric All Rights Reserved

11/03

Model 6 Motor Control Centers

Incoming Devices

Application and General Information

Bottom Located Main Circuit Breakers (continued)

Frame

Type

Maximum

Amperes

AIC

240 V

480 V

600 V

Space

(inches)

Connection

Electronic Breakers

LX

400

100,000

65,000

50,000

30

MX

800

65,000

50,000

25,000

36

Cabled

➀

➁

➂

MX

800

65,000

65,000

25,000

72 ➀

PX

2000

100,000

100,000

65,000

72 ➁

Bussed

25 in. wide by 20 in. deep

30 in. wide by 20 in. deep

Ground fault option requires 30 in. wide by 20 in. deep section

Main Fusible Switches

• Main fusible switch units are located in 20 in. wide by 15 in. or 20 in. deep sections, except where

noted. Mains must be top or bottom located.

• All main switches use automatic molded case switches in series with Class R or L fuse clips as

standard. Unit short circuit current ratings to 100,000 A are available.

• All main switches listed are for 3PH3W systems. 3PH4W applications may require additional space

(“Three Phase/Four-Wire Wye Systems with Grounded Neutral” on page 23).

Top Located Main Fusible Switches

Unit Type And Amps

➀

➁

➂

➃

➄

Space (Inches)

250 V Max.

600 V Max.

200

200

400

400

45

600

600

54 ➄

Connection to Bus

24

800 ➀

800 ➀

72 ➁

1000 ➀➃

1000 ➀➃

72 ➁

1200 ➂

1200 ➂

72 ➁

1600 ➂

1600 ➂

72 ➁

2000 ➂

2000 ➂

72 ➁

Cabled

Bussed

25 in. wide by 20 in. deep section

Requires single shipping split.

30 in. wide by 20 in. deep section

Ground fault option requires 30 in. wide by 20 in. deep section.

3PH4W applications require 60 in. of mounting space.

Bottom Located Main Fusible Switches

Unit Type And Amps

➀

➁

➂

➃

➄

➅

11/03

Space (Inches)

250 V Max.

600 V Max.

200

200

400

400

54

600

600

66 ➃

Connection to Bus

24

Cabled

25 in. wide by 20 in. deep section

Requires single shipping split.

30 in. wide by 20 in. deep section

3PH4W applications require 72 in. of mounting space.

Ground fault option requires 30 in. wide by 20 in. deep section.

3PH4W applications require 60 in. of mounting space.

© 2003 Schneider Electric All Rights Reserved

21

Model 6 Motor Control Centers

Application and General Information

Incoming Devices

Bottom Located Main Fusible Switches

Unit Type And Amps

250 V Max.

800 ➀

1000 ➀➄

➀

➁

➂

➃

➄

➅

600 V Max.

Space (Inches)

800 ➀➄

72 ➁

➀➄

1000

Connection to Bus

72 ➁

1200 ➂

1200 ➂

72 ➁

1600 ➂

1600 ➂

72 ➁

2000 ➂

2000 ➂

72 ➁

Bussed

25 in. wide by 20 in. deep section

Requires single shipping split.

30 in. wide by 20 in. deep section

3PH4W applications require 72 in. of mounting space.

Ground fault option requires 30 in. wide by 20 in. deep section.

3PH4W applications require 60 in. of mounting space.

Standard Wire Lug Ranges (Mechanical)

Mechanical set-screw type lugs are supplied as standard for Model 6 MCC main, branch, and neutral line

and/or load connection. Compression crimp type lugs are available (see “Wiring Options” on page 60).

Main Lugs