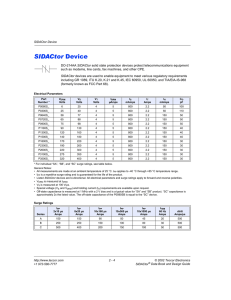

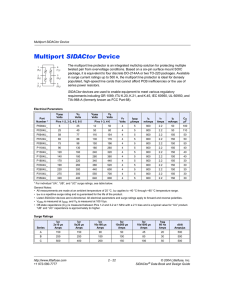

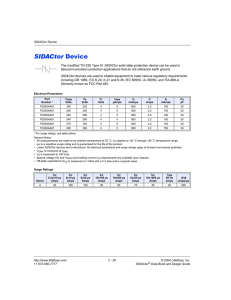

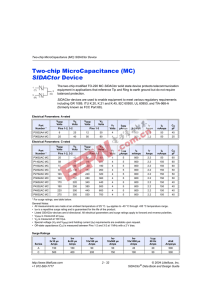

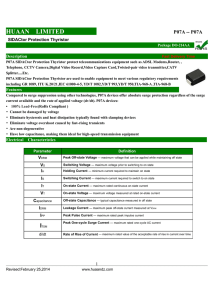

SIDACtor

advertisement