Long Term Assessment Trial on a Slow Speed Diesel Engine fuelled

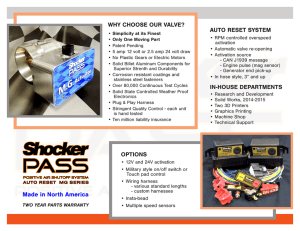

advertisement

Long Term Assessment Trial on a Slow Speed Diesel Engine fuelled with Straight Jatropha Oil PARTIAL REPORT (THIRD PHASE) October 2007 – January 2009 Submitted to The GAIA-Movement, International Environment House, 9 chemin de Balexert 1219 Châtelaine (Geneva) From Humana People to People India C-183, Madhuban, New Delhi – 110092, INDIA 1 1.Title of the Project : Development of Dual Fuel System and Long Term Assessment of Utilization of Straight Vegetable Oil in Diesel Engine Humana People to People India C-183, Madhuban, New Delhi – 110092, INDIA 2. Name of the Implementing : agency 3. Collaborating Institute, if any : 4. Project Commencement after : completion of formalities 5. Duration of the Project Delhi College of Engineering, Delhi, India September : 2008 Six Months 6. Objectives of the Project : • Carry out endurance test of another 512 hours on high speed diesel engine with pre-heating arrangement (The test rig was already developed during the second phase and 512 hours of trial was conducted on pre-heated JO which proved to be satisfactory. • Commissioning of a slow speed diesel engine for SVO application (dual fuel system without heating) • Endurance Test of diesel engine running on SVO with dual fuel system • Provision of heating arrangement through exhaust gases in slow speed diesel engine and carry out endurance test of 512 hours on pre-heated JO • Analysis of wear after the endurance test(s) and preparation of report 2 1.0 EXECUTIVE SUMMARY Jatropha activities are attractive because they are viable in adverse conditions and may help to counter drought, desertification, soil degradation, and climate change and to increase permanent crops and protection of biodiversity in tropical and subtropical developing countries. Additionally, jatropha undertakings provide a synergy of rural energy production, environmental protection and food security by erosion control, acting as a living fence to protect from water and wind, increasing income of rural dwellers, promoting women and providing renewable fuel. The fact that a huge amount of foreign exchange is used to import mineral fuels from oil exporting countries raises the demand for using an alternative, locally produced fuel as an extender or substitute to mineral diesel in developing countries. Furthermore, the high number of unpaved roads, particularly in remote areas, makes transporting petroleum products to rural areas very difficult. This increases the need for seeking a local fuel solution. The present study investigates doing a new 512 hours endurance test on a high speed diesel engine on pre-heated jatropha oil (a 512 hours of endurance test has already been completed during second phase) and conduct of 512 hours trial on a slow speed diesel engine on neat jatropha oil (unheated) using a dual fuel tank approach. Both the engines were run for 512 hours on neat jatropha oil (preheated and unheated) and analysis of wear of various vital engine parts during the endurance tests was carried. The results obtained on high speed diesel engine fuelled with pre-heated Jatropha Oil suggest that in longer term; even pre-heated jatropha oil has not performed that well. The ring sticking was found to occur. However, other features were satisfactorily. Therefore, in the light of two successive endurance tests of 512 hours each, it can be concluded that problems associated with neat vegetable utilization (with preheating) in high speed diesel engine have been delayed but not completely eliminated. The long term trial on slow speed diesel engine has been very encouraging and no untoward failure was encountered except heavy carbon deposits on engine parts. In the light of the endurance test of 512 hours, it can be concluded that problems associated with neat vegetable utilization are minimal in slow speed, IDI, diesel engine as compared to high speed diesel engine. 3 4.0 STATEMENT OF THE PROBLEM As Jatropha is becoming a sustainable source for diesel replacement in India, its high viscosity issue is resolved by adapting two strategies; first to modify the engine to adapt to the fuel and the second for processing the fuel to adapt to the engine. The literature suggests that modifying existing diesel engines to preheat Jatropha oil to reduce viscosity and could achieve the first strategy. The adaptation of Jatropha oil to the diesel engine could be done by blending the Jatropha oil with diesel or converting into biodiesel through transesterification process as a part of second strategy. As transesterification process requires expertise and equipments are not easily understandable to rural community and blending still require diesel, it shall be advisable to formulate the strategy in which neat Jatropha oil could be used in diesel engine with out detrimental effect on engine health. In this regard, it was found that very little quantum of work has been done on potential suitability of Jatropha oil in slow speed diesel engine and no work has been reported on assessing the aptness of neat Jatropha oil in slow speed IDI Engine. The following objectives have been set for the third phase of the project. • Carry out endurance test of another 512 hours on high speed diesel engine with pre-heating arrangement (The test rig was already developed during the second phase and 512 hours of trial was conducted on pre-heated JO which proved to be satisfactory. • Commissioning of a slow speed diesel engine for SVO application (dual fuel system without heating) • Endurance Test of diesel engine running on SVO with dual fuel system • Provision of heating arrangement through exhaust gases in slow speed diesel engine and carry out endurance test of 512 hours on pre-heated JO • Analysis of wear after the endurance test(s) and preparation of report 19 5.0 SYSTEM DEVELOPMENT 5.1 High Speed Diesel Engine Test Rig with pre-heating The high speed diesel engine test rig was developed during second phase of the project and the specification of the test engine is listed below in table 8. Table 8: Specifications of the Diesel Engine Make Kirloskar Model DAF 8 Rated Brake Power (bhp/kW) 8 / 5.9 Rated Speed (rpm) 1500 Number of Cylinder One Bore X Stroke (mm) 95 x 110 Compression Ratio 17.5:1 Cooling System Air Cooled (Radial Cooled) Lubrication System Forced Feed Cubic Capacity 0.78 Lit Inlet Valve Open (Degree) 4.5 BTDC Inlet Valve Closed (Degree) 35.5 ABDC Exhaust Valve Open (Degree) 35.5 BBDC Exhaust Valve Closed (Degree) 4.5 ATDC Fuel Injection Timing (Degree) 26 BTDC For conducting the desired set of experiments and together required data from the engine, it is essential to get the various instruments mounted at the appropriate location on the experimental setup. Apart from this, a dual fuel system has been developed for diesel and jatropha oil. The schematic diagram of the experimental setup with heat exchanger and along with all instrumentation is shown in Figure 6. Overall pictorial view of the test rig along with instrumentation used in the present investigations 20 is shown in Plate 1 & 2. Figure 6: Schematic Diagram of the Experimental Set Up Plate 1: Photograph of the Experimental Set Up 21 Plate 2: Photograph of Heat Exchanger Arrangement for Preheating by Exhaust Gases 5.2 High vs. Slow Speed Diesel Engine The high speed diesel engine used during the first & second phase of the project was a DI (Direct Injection) diesel engine. In this type of diesel engine, the fuel is squirted at a very high pressure into the combustion chamber (a bowl in the piston). The slow speed diesel engine used during the third phase of the project is an IDI (Indirect Injection) diesel engine. In IDI diesel engine, the fuel is not directly injected in to the combustion chamber. An IDI diesel engine delivers fuel into a chamber off the combustion chamber called a prechamber. The prechamber is carefully designed to ensure adequate mixing of the atomized fuel with the compressed heated air. 5.3 Selection of Engine Diesel engines play an indispensable role in agriculture and transportation sector and as such diesel consumption is expected to increase multi fold in future. The diesel engine continues to dominate the agriculture sector in our country in comparison to spark ignition engine and have always been preferred widely because of power developed, specific fuel consumption and durability. In India, almost all irrigation pump sets, tractors, mechanized farm machinery and heavy transportation vehicle are powered by direct injection diesel engines. However, they are 22 not considered suitable for vegetable oil adaptation on a long term basis. Considering the wide application of a small capacity diesel engine which has got great dominance in Indian agriculture sector, a slow speed, IDI, lister type, 4 stroke diesel engine was selected for the present study as the maintenance of this engine is very simple and due to its slow speed potential suitability of neat JO is more in this kind of engine. 5.4 Development of Experimental Test Rig The indirect injection (IDI) diesel engine used for this study is manufactured by Rolex Industries Engines Limited. It is widely used in India in agriculture for running the irrigation pump sets, running agriculture machinery and for driving different machines in industrial sector and shown in Plate 3. Plate 3: Slow Speed Diesel Engine It is a single cylinder, naturally aspirated, four stroke, vertical, water-cooled engine. It has a provision of loading electrically since it is coupled with single phase alternator through belt and pulley arrangement. The cylinder is made of cast alloy and fitted with a hardened highphosphorus cast iron liner. The lubrication system used in this engine is of splash type. The engine can be hand started using decompression lever and is provided with spring loaded 23 governor. The engine was started on diesel engine and after some time (10-15 minutes) it was switched on to the neat Jatropha mode. The detailed technical specifications of the engine are given in Table 9. Table 9: Specifications of the Lister type Diesel Engine Make Rated Brake Power (bhp/kW) Rated Speed (rpm) Number of Cylinder Bore X Stroke (mm) Compression Ratio Cooling System Lubrication System Cubic Capacity Inlet Valve Open (Degree) Inlet Valve Closed (Degree) Exhaust Valve Open (Degree) Exhaust Valve Closed (Degree) Fuel Injection Timing (Degree) Flywheel Dimension & Face Foundation Stud Hole Center Distance Crankshaft Center Dist. from Base Engine Total Height Rolex 5 / 3.725 600 One 114.3 x 139.7 18:1 Water Cooled Splash 1.43 Lit 5 BTDC 15 ABDC 45 BBDC 5 ATDC 20 BTDC 600 X 89 330 X 330 318 1016 For conducting the desired set of experiments and together required data from the engine, it is essential to get the various instruments mounted at the appropriate location on the experimental setup. Apart from this, a dual fuel system has been developed for diesel and Jatropha oil. The schematic diagram of the experimental setup along with all instrumentation is shown in Figure 7. Overall pictorial view of the test rig along with instrumentation used in the present investigations is shown in Plate 4. 24 Figure 7: Schematic Block Diagram of Engine Setup Plate 4: Photograph of the Test Rig 25 5.5 Installation of the Instrument Control Panel After finalizing the procedures for data collection and procurement of the desired instruments, they were put on a panel. A MS Control panel was fabricated and Instruments such as voltmeter, ammeter, watt meter, speed counter, six channels digital temperature display was mounted on the front side of the control panel (Plate 5). Electrical load bank, i.e. 16 bulbs each of 500 watts, were mounted on the rear side of the control panel which is shown in Plate 6 and their switches provided on the front side of the control panel. Plate 5: Control Panel Plate 6: Incandescent Bulbs on the Control Panel One 50ml burette with stop cocks was also mounted on the front side of the panel for fuel flow 26 measurements of either diesel fuel or Jatropha oil. The two fuel tanks were mounted on the rear side of the panel at highest position with stop cocks as shown in plate 7 & 8. Plate 7: Two Tanks System Plate 8: Valves for Controlling Supply of Jatropha Oil and Diesel A voltmeter, ammeter and wattmeter were connected between alternator and load bank. A nut was welded on the flywheel and the photo reflective sensor was mounted on a bracket attached to engine body. The thermocouples were mounted in the exhaust manifold to measure the exhaust temperature. The AVL 437 smoke meter and AVL Di Gas Analyzer were also kept in proximity for the measurements of various exhaust gas parameters. 27 Thus such a system was chosen to examine the practical utility of Jatropha oil in such applications. Besides being a single cylinder system it was light and easy to maintain. The engine was provided with suitable arrangement, which permitted wide variation of controlling parameters. Being a water cooled engine it was suitable for hot climate. Absence of radiator, water body and pump made the system more suitable for the tests. 5.6 Experimental Approach The high speed diesel was subjected to long term endurance test straight away since 512 hours of trial was already done on the engine on pre-heated Jatropha oil. For slow speed diesel engine, preliminary run was conducted at rated speed of 600 rpm to ensure that the engines is made trouble free for its exhaustive test run. This was done in accordance with IS: 10,000 Part V. During the preliminary run, engines are subjected to preliminary run of 49 hours at the operating temperature specified by the manufacturer, in a non stop cycles of seven hours each confirming to the following cycle pattern, the period of each run being a minimum of one cycle. Accordingly, after commissioning of the engine test rig, the engine was initially run for 49 hours on diesel fuel. The details of loading cycle are given in Table 10. Table 10: Loading cycle for preliminary run of constant speed engine Load (% of rated load) Running Time (hours) 25 1.5 50 2 75 1.5 100 2 After completion of preliminary 49 hrs test on the engine, long term endurance test was started on the slow speed diesel engine with Jatropha oil as a fuel in a dual tank operation method. The cycle adopted for long term endurance test is mentioned in Table 11. The total trial on the diesel engine has been kept as 8 hrs per day. The same cycle was also adopted for high speed diesel engine with preheated Jatropha oil. Table11: Test cycle for long term endurance test Load (% of rated load) Running time (hours) 100 2(including warm-up period for 0.25hours) 50 2 28 110 No load (idling) 100 50 0.5 0.25 1.5 1.75 6.0 Photograph Showing Results of the Long Term Endurance Test for High Diesel Engine Speed Plate 9: Cylinder Head of High Speed Diesel Engine after Completion of Endurance Test Plate 10: Upper Face of the Piston of High Speed Diesel Engine after Completion of Endurance Test 29 Plate 11: Photograph of the Piston of High Speed Diesel Engine after Completion of Endurance Test Plate 12: Piston Rings of High Speed Diesel Engine after Completion of Endurance Test Plate 13: Injector of High Speed Diesel Engine after Completion of Endurance Test 30 Plate 14: Fuel Filter of High Speed Diesel Engine after Completion of Endurance Test The long term trial 512 hours of endurance test was completed and a total of 512 hours was accumulated with pre heated jatropha oil as a fuel. The engine was opened on 09.01.2009 to assess the wear and tear of vital engine parts and condition of the fuel filter. Major findings after completion of trial are as follows: 1. It was found that sticking of top two compression ring have taken place. 2. The remaining third compression ring and two oil scrapping rings were found to be in good condition. As Jatropha oil has high viscosity and results in sticking of the piston rings. In the first phase of the project, the ring sticking occurred many times on neat Jatropha oil (without preheating). However, with the preheating the viscosity of Jatropha oil has been reduced and frequency of ring sticking has been drastically reduced. It is relevant to mention that ring sticking has been observed only after 1024 hours of endurance test. 3. The inlet and exhaust valves were in good condition. 4. Moderate carbon deposit was noticed at the upper face of the piston and cylinder head. 5. The space for the piston ring on the piston was found to be reduced. 6. Excessive carbon deposits were noticed at the tip of the injectors. However, all the holes of the injector were working satisfactorily. 7. The sedimentation was found on the fuel filter and housing. This is due to un-saturation and presence of wax in the jatropha oil. It is relevant to mention that preheating reduces viscosity. However; it has no control over unsaturation and wax particles. Therefore, 31 sedimentation is expected to occur even with preheating. 8. Some scratches on the cylinder were observed which are due to ring sticking. In the light of two endurance tests of 512 hours each, it can be concluded that problems associated with neat vegetable utilization (with preheating) in high speed diesel engine have been delayed but not completely eliminated. 7.0 Photograph of the New Piston & Piston Ring of Slow Speed Diesel Engine 32 8.0 Photograph Showing Results of the Endurance Test for Slow Speed Diesel Engine Plate 15: Cylinder Head of Slow Speed Diesel Engine after Completion of Endurance Test Plate 16: Upper Face of Piston Head of Slow Speed Diesel Engine after Completion of Endurance Test 33 Plate 17: Photograph of the Piston & Piston Ring of Slow Speed Diesel Engine after Completion of Endurance Test Plate 18: Injector of Slow Speed Diesel Engine after Completion of Endurance Test Plate 19: Fuel Filter of Slow Speed Diesel Engine after Completion of Endurance Test The long term trial 512hrs of endurance test was completed on Jatropha oil (unheated) as a 34 fuel in slow speed diesel engine. The engine was opened on 18.01.2009 to assess the wear and tear of vital engine parts and condition of the fuel filter. Major findings after completion of trial are as follows: 1. It was found that no ring sticking has taken place which was experienced in high speed diesel engine. 2. The slow speed of the diesel engine under investigation has actually given favorable results because due to slow speed more time was available for the combustion and very less fuel was unburnt. 3. The inlet and exhaust valves were in good condition. 4. Heavy carbon deposit was noticed at the upper face of the piston and cylinder head. 5. The piston was found in a good condition. It is relevant to mention that the piston used in high speed diesel engine is made up of aluminum alloy and that of slow speed diesel engine is of cast steel. Since, steel is stronger than aluminum therefore, no damage was found in slow speed diesel engine piston. 6. Excessive carbon deposits were noticed at the tip of the injectors. However, all the holes of the injector were working satisfactorily. 7. The sedimentation was found on the fuel filter and housing. This is due to un-saturation and presence of wax in the jatropha oil. In the light of the endurance test of 512 hours, it can be concluded that problems associated with neat vegetable utilization are minimal in slow speed diesel engine as compared to high speed diesel engine. 8.0 RECOMMENDATIONS Despite using preheating of Jatropha oil in high speed diesel engine, the results have not been very favorable in a longer term, whereas the endurance test on slow speed diesel engine (without preheating) has clearly established the suitability of adaptation of neat vegetable in slow speed, IDI, diesel engine. Therefore, the first part of the third phase advocates utilization of Jatropha oil in slow speed diesel engine either for rural electrification or driving many agriculture equipments. In the second part of the third phase, the long term suitability of preheated Jatropha oil (Using exhaust heat of the engine) shall be investigated. 35 REFERENCES: 1. BP Statistical Review of World Energy, 2008. 2. World Development Indicator Database; www.devdata.worldbank.org accessed on 4.2.2009 3. http://edugreen.teri.res.in/explore/glossary.htm accessed on 4.2.2009 4. http://www.grida.no/climate/vital/20.htm accessed on 4.2.2009 5. Petstat, Ministry of Petroleum and Natural Gas, Government of India, www.petroleum.nic.in/petstat.pdf accessed on 4.2.2009 6. www.eia.doe.gov accessed on 4.2.2009 7. http://mnes.nic.in, accessed on 4.2.2008 8. EIA- international energy outlook;2008 9. http://www.mnp.nl/en/service/pressreleases/2008/20080613ChinacontributingtwothirdstoincreaseinCO2 emissions.html, accessed on 4.2.2009 10. Report of the Committee on development of biofuels, planning Commission , Govt. of India , 2003 11. M S Graboski and R L McCormick; Combustion of fat and vegetable-oil derived fuels in diesel engines; Progress in Energy & Combustion Sciences; Vol. 24, pp.125–64, 1998 12. M Canakci and J H Van Gerpen; Comparison of engine performance and emissions for petroleum diesel fuel, yellow-grease biodiesel and soybean-oil biodiesel; Transactions of the ASAE; Vol. 46, pp. 937–944, 2003. 13 Crude Country Biofuels (CCB), Pure plant oil as transportation fuels 20.5.2005. 14 Alternative Fuels News; Alternative Fuels Data Center National Renewable Energy Laboratory; Vol. 5 ,No. 3 15 R Banerji, A R Chowdhury, G Misra, G Sudarsanam, S C Verma and G S Srivastava; Jatropha seed oils for energy; Biomass; Vol. 8, pp. 277–282, 1985 16 A Demirbas; Biodiesel from sunflower oil in supercritical methanol with calcium oxide. Energy Conversion and Management, Vol.48,pp. 937–941, 2006 17 A M Williamsons and Ossama Badr; Assessing the viability of using rape methyl ester (RME) as an alternative to mineral diesel fuel for powering road vehicles in the U.K.; Applied Energy, Vol. 59, IssueNo.2-3, pp. 187-214, 1998 36 18 A Demirbas; Biodiesel from vegetable oils via transesterification in supercritical methanol. Energy Conversion and Management, Vol. 43, pp. 2349–2356, 2002 19 N Kaushik, K Kumar, S Kumar and S Roy; Genetic variability and divergence studies in seed traits and oil content of Jatropha (Jatropha curcas L.) accessions; Biomass and Bioenergy, Vol. 31, pp. 497–502, 2007 20 Bhupender Chauhan studied the Potential Utilization of Jatropha oil in a dual fuel agriculture diesel engine, 2007 21 F K Forson, E K Oduro and E Hammond-Donkoh; Performance of Jatropha oil blends in a diesel engine; Renewable Energy, Vol. 29, pp.1135–1145, 2004 37