Procedural Standard for Testing, Adjusting and Balancing of

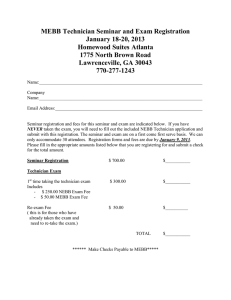

advertisement