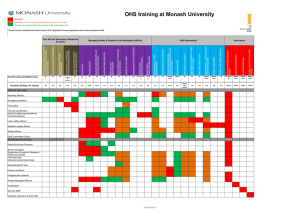

Physical Hazards: Non-Ionising Radiation

advertisement