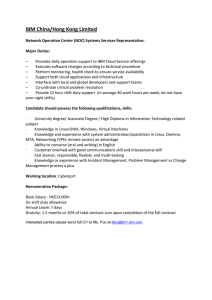

z13s IMPP

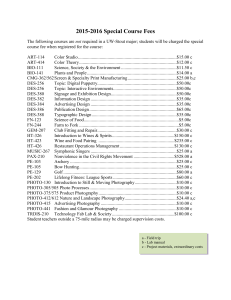

advertisement