High Temperature Superconductivity Market Readiness Review

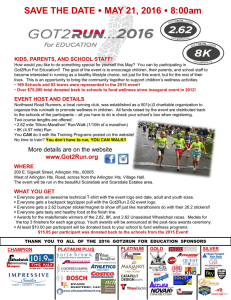

advertisement