Low-VCE(sat)BJTs vs. MOSFETs: Cost

advertisement

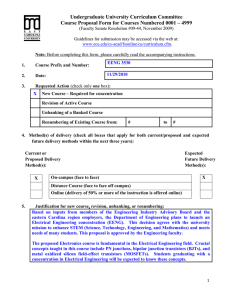

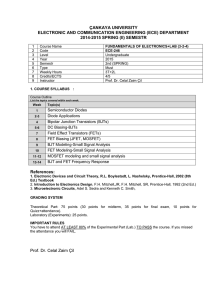

POWER SUPPLEMENT Low-VCE(sat) BJTs vs. MOSFETs: Cost considerations New low-VCE(sat) BJTs provide a viable low-cost alternative to planar MOSFETs in 500-mA to 5.0-A apps BY STEVE SHEARD ON Semiconductor Phoenix, AZ http://onsemi.com D potential savings of $0.05 to $0.20 compared with designs using MOSFETs. Low-VCE(sat) BJTs perform the same function as a MOSFET at a lower cost, and as an added bonus, in many cases provide for improved For this reason the designer needs to understand the current limitations of the PMU control circuits being used to determine the specific circuit requirements when designing with a low-VCE(sat) BJT. For example, if the BJT is to control a current of 1 A and has a worst-case gain of 100, then the base current will need to be a minimum of 10 mA to ensure that the BJT goes into saturation. The control pin must be able to supply the 10 mA for the BJT to be driven diFig. 1 rectly; otherwise an additional drive stage would be required. esigners of portable products, such as cell phones, digital cameras, digital camcorders, DVD players, MP3 players and PDAs, are under continuous pressure to reduce the cost of the bill of materials without any sacrifice in performance. This is a real challenge for the designer who is under continuing pressure to add features and not adversely affect battery life. The majority of portable products are moving toward an intepower consumption resulting in imCharging circuit example grated power management unit proved battery life. A review of a typical charging circuit (PMU) circuit designed specifically Some of the new devices are now X401ONSE0805 (see Fig. 1) in a portable product to control the different functions available with a saturation voltage at shows the pass transistor Q1 (power within the product. These may be 1 A of well under 100 mV. This MOSFET 2 A, 20 V, TSOP6 package) for the control of battery charging, equates to a forward resistance of and the blocking Schottky battery management, overdiode D1. voltage protection, backlight, All the control for chargvibrator, disc drives, and peing of the lithium ion batripherals power, such as camtery is embedded in a PMU. eras and flash units. The PMU control pin The circuits, for the control changes to high to turn on of currents under 500 mA, are the external pass transistor typically all embedded within Q1 and the charging current the PMU, including the final is set at 1 A. The series pass transistor. However, for Fig. 2 Schottky diode D 1 is rethe control of currents from quired to block any reverse 500 mA to 5 A, an external current from the battery. MOSFET pass transistor is the The typical power dissipated typical design of choice. An alternaunder 100 mV, and proves very through the pass transistor Q1 and tive to the MOSFET is to use a lowercompetitive against a higher-cost the reverse blocking diode D1 was cost low-VCE(sat) bipolar transistor, MOSFET. calculated as: which may also provide a powerX402ONSE0805 saving. Design considerations Q1 power = I2 x R, 1 A2 x RDS(on) The MOSFET is a voltage driven de(60 mV) = 60 mW New low-VCE(sat) BJTs vice, compared to the low-VCE(sat) D1 power = I x VF, 1 A x VF A new wave of low-VCE(sat) BJTs offer BJT being a current driven device. Reprinted from ELECTRONIC PRODUCTS POWER SUPPLEMENT 2005 P O W E R S U P P L E M E N T - LOW-VCE(SAT) BJTS Schottky (360 mV) = 360 mW Total power dissipated through Q1 and D1 = 420 mW The typical high-volume cost of the MOSFET and Schottky diode is $0.175 The charging circuit can be configured using a low-V CE(sat) BJT— such as the ON Semiconductor NSS35200 CF8T1G—to replace the MOSFET and the Schottky diode (see Fig. 2). The Schottky diode is not required because the BJT has this function inherent to its design. The control pin on the PMU is able to provide a maximum of 20 mA. The PMU would initiate a fast charge with the battery voltage of 3.0 V. With Q2 in saturation both the collector and emitter will be at approximately 3.0 V, thus the base would be 2.3 V. The base current required to drive the BJT, which has a minimum gain of 100, into saturation needs to be 10 mA for a 1-A charging current. Selecting a standard resistor value of 200 V for the base resistor will ensure the BJT is in saturation and that the limit for the drive pin is not exceeded. The typical power dissipated through the pass transistor Q2 and bias resistor R1 was calculated as: Q2 power = I x V, VCE(sat) (1 A, Beta 100 = 135 mV) = 135 mW R1 power = I2 x R, 0.011 A2 x 200 V = 24 mW Total power dissipated through Q2 and R1 = 159 mW The typical high-volume cost of the low-VCE(sat) BJT and resistor is $0.10 Charging circuit savings The savings resulting from exchanging the MOSFET bypass transistor and Schottky diode with a low-V CE(sat) BJT and bias resistor were $0.075 per unit. The exchange also resulted in a power dissipation savings of 261 mW making the thermal considerations of the portable product much simpler. VS. MOSFETS: COST CONSIDERATIONS More-complex circuits ICs designed specifically with an external bypass MOSFET may not have the ability to supply the required current to drive the lowVCE(sat) BJT into saturation directly. In these circuits an extra digital transistor or small general-purpose MOSFET can be used. The results are not quite as significant as the charging example. The cost savings is still $0.055 per unit. Power dissipation is the same. Additional advantages The BJT is less susceptible to ESD damage and thus a savings can be found in not having to provide extra ESD protection. In addition, the BJT has a lower turn-on voltage (typically 0.7 V) and thus an oscillator and charge pump—which are normally needed for a MOSFET— may be eliminated. Finally, the BJT is more efficient at switching medim um currents.