PFC-based Control Strategies for Four Switch VSI fed BLDC Motor

advertisement

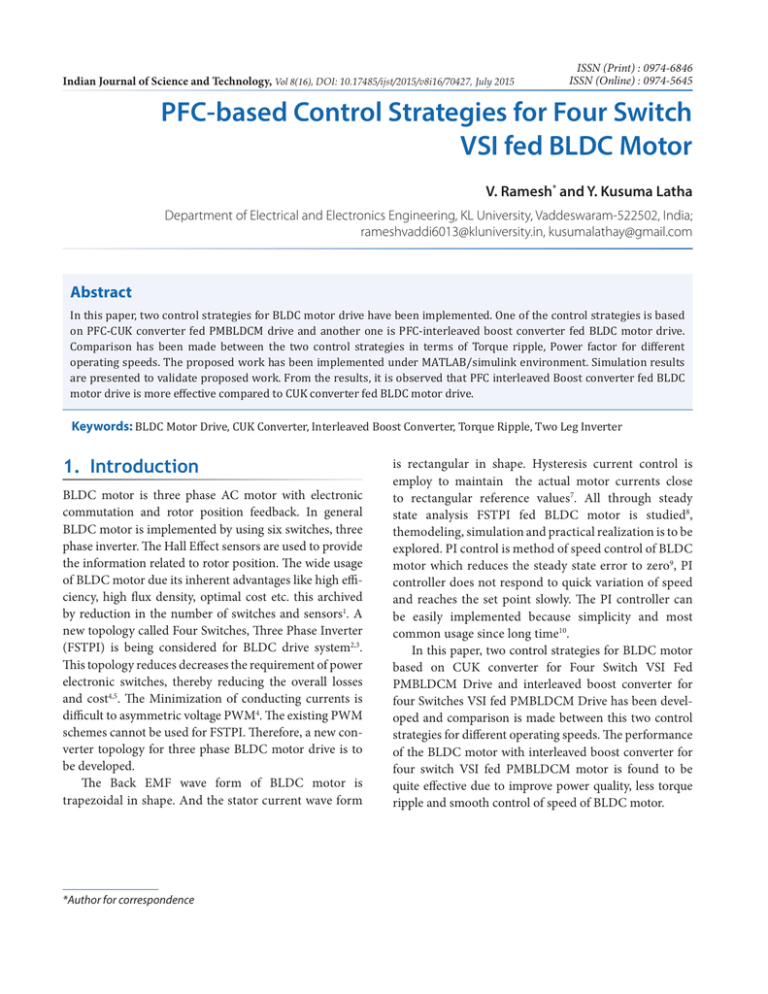

Indian Journal of Science and Technology, Vol 8(16), DOI: 10.17485/ijst/2015/v8i16/70427, July 2015 ISSN (Print) : 0974-6846 ISSN (Online) : 0974-5645 PFC-based Control Strategies for Four Switch VSI fed BLDC Motor V. Ramesh* and Y. Kusuma Latha Department of Electrical and Electronics Engineering, KL University, Vaddeswaram-522502, India; rameshvaddi6013@kluniversity.in, kusumalathay@gmail.com Abstract In this paper, two control strategies for BLDC motor drive have been implemented. One of the control strategies is based on PFC-CUK converter fed PMBLDCM drive and another one is PFC-interleaved boost converter fed BLDC motor drive. Comparison has been made between the two control strategies in terms of Torque ripple, Power factor for different operating speeds. The proposed work has been implemented under MATLAB/simulink environment. Simulation results are presented to validate proposed work. From the results, it is observed that PFC interleaved Boost converter fed BLDC motor drive is more effective compared to CUK converter fed BLDC motor drive. Keywords: BLDC Motor Drive, CUK Converter, Interleaved Boost Converter, Torque Ripple, Two Leg Inverter 1. Introduction BLDC motor is three phase AC motor with electronic commutation and rotor position feedback. In general BLDC motor is implemented by using six switches, three phase inverter. The Hall Effect sensors are used to provide the information related to rotor position. The wide usage of BLDC motor due its inherent advantages like high efficiency, high flux density, optimal cost etc. this archived by reduction in the number of switches and sensors1. A new topology called Four Switches, Three Phase Inverter (FSTPI) is being considered for BLDC drive system2,3. This topology reduces decreases the requirement of power electronic switches, thereby reducing the overall losses and cost4,5. The Minimization of conducting currents is difficult to asymmetric voltage PWM4. The existing PWM schemes cannot be used for FSTPI. Therefore, a new converter topology for three phase BLDC motor drive is to be developed. The Back EMF wave form of BLDC motor is trapezoidal in shape. And the stator current wave form *Author for correspondence is rectangular in shape. Hysteresis current control is employ to maintain the actual motor currents close to rectangular reference values7. All through steady state analysis FSTPI fed BLDC motor is studied8, themodeling, simulation and practical realization is to be explored. PI control is method of speed control of BLDC motor which reduces the steady state error to zero9, PI controller does not respond to quick variation of speed and reaches the set point slowly. The PI controller can be easily implemented because simplicity and most common usage since long time10. In this paper, two control strategies for BLDC motor based on CUK converter for Four Switch VSI Fed PMBLDCM Drive and interleaved boost converter for four Switches VSI fed PMBLDCM Drive has been developed and comparison is made between this two control strategies for different operating speeds. The performance of the BLDC motor with interleaved boost converter for four switch VSI fed PMBLDCM motor is found to be quite effective due to improve power quality, less torque ripple and smooth control of speed of BLDC motor. PFC-based Control Strategies for Four Switch VSI fed BLDC Motor 2. Proposed Control Schemes of Four Switches VSI fed PMBLDCM Drive 2.2 CUK Converter for Four Switch VSI fed PMBLDCM Drive 2.1 Interleaved Boost Converter for Four Switches VSI fed PMBLDCM Drive The Figure 1 shows the interleaved boost converter for four switches VSI fed BLDC motor drive system. The control scheme employs hysteresis current control. For each phase of 3-hystersis current controller, four power electronic switches are used and hence low cost and less switching losses and also reductions in torque ripple, as well as voltage stress and improved dynamic response. The variable DC output of bridge rectifier is fed to interleaved boost converter. The output of the interleaved boost converter is fed two leg VSI inverter which drives BLDC motor. The power factor correction control scheme is based on the principle of current multiplier approach. This involves the presence of current loop inside speed control loop, in case of continuous conduction of the converter. The control loop starts with processing of speed obtained by comparing the actual, speed with the desired reference speed. The error is fed to the PI controller to obtain the reference torque and compared with actual torque of BLDC motor. The resultant torque error is multiplied with suitable constant and amplified is order to provide input to reference current block. The reference current is compared with phase a current which is gives to hysteresis current control. The hysteresis current controller generates pluses for operation of two leg inverter and a rate limiter is introduced, which limits the current within specified limits. Interleaved Boost Converter L1 The Figure 2 shows the block diagram of CUK converter for four switches VSI fed BLDC motor. The performance of the motor is enhanced due to less ripple content in torque wave form, reduced voltage stress on the power electronic switches and improved dynamic response. The AC supply is given to the diode bridge rectifier. The variable DC output of bridge rectifier is fed to CUK converter. The output of CUK converter goes to three leg inverter which drives BLDC motor. The power factor correction control scheme is based on the principle of current multiplier approach. Involves in the presence of current loop inside speed control loop in case of continuous conduction of the converter. The control loop starts with processing of speed error obtained by comparing the actual speed with the desired reference speed. The error is fed to the PI controller to obtain the reference torque and compared with actual torque of BLDC motor. The resultant torque error is multiplied with suitable constant amplified is order to provide input to reference current block. The reference current is compared with phase currents fed to BLDC motor which is fed to hysteresis current control. The hysteresis current controller generates pluses for operation of two leg inverter for current control of BLDC motor drive. A rate limiter is introduced, which limits the current within specified limits. CUCK Converter L1 2LEG Inverter L0 C1 S1 SW 2 LEG Inverter D S1 D2 S3 Cd S2 C1 S2 S1 S2 S4 C2 BLDC MOTOR Position encoder + i a* Tref Reference Speed + - G PI Gain Te ib* ia i c* - + ib + ic - Vol 8 (16) | July 2015 | www.indjst.org BLDC MOTOR Position encoder + i a* Tref Reference Speed + - G PI Gain Te - Figure 1. Interleaved Boost Converter for four switches VSI fed PMBLDCM drive. 2 C2 Hysteresis Current controller Diode Bridge Rectifier Hysteresis Current controller S4 Diode Bridge Rectifier Vs C0 C1 r D1 L2 S3 Vs ib* ia - + ib i c* + ic - Figure 2. CUK converter for fourswitchesVSI fed PMBLDCM drive. Indian Journal of Science and Technology V. Ramesh and Y. Kusuma Latha 3. Description and Implementation of Proposed Control Schemes Table1. Operting modes Switching tates and output phase voltage of BLDC motor Switching sequence Figure 1 and Figure 2 show the schematic diagrams of two leg inverter fed PMBLDC drive with CUK converter and Interleaved Boost converters respectively. The actual speed of BLDC motor and reference speed is compared to obtain error in speed and gives as input to PI controller. The output of PI controller is reference torque which is compared with actual torque. The magnitude of reference currents is obtainedwith the help of torque and appropriate gain values. The hysteresis current control is employed to control 2 leg inverter fed BLDC motor. 3.1 Speed Controller The reference torque is given by Tr (n) = T (n − 1) + K Psc We (n) − We (n − 1) + KiscWe (n) (1) Where Kpsc = Speed controller Proportional Gain Kisc = Speed controller of the Integral Gain I ref = K te ∗ Tr (2) Where Tr = Reference Torque Kte = Constant Torque The Iref is compared with actual motor current and the error is fed hysteresis current controller to produce pulses for 2-Leg inverter 3.4 Two Leg Inverter V Van = dc ( 4SW1 − 2SW 2 − 1) 3 (3) Vdc ( −2SW1 + 4SW 2 − 1) 3 (4) Vol 8 (16) | July 2015 | www.indjst.org 2Vdc 3 –Vdc Vdc 0 0 Vdc –Vdc 0 1 Vdc 3 Vdc 3 0 0 1 1 1 − Vdc 3 − − Vdc ( −2SW1 − 2SW 2 + 2) 3 2Vdc 3 (5) Van Vdc vbn = 3 Vcn 4 −2 SW1 Vdc −2 4 SW 2 + 3 −2 −2 −1 −1 2 (6) The various operating modes and corresponding output voltage of BLDC motor are presented in Table 1. The BLDC motor is modelled using differential equations given by di p dt ( ) = v p − i p R a − E p / (Ls + M ) (7) Where a, b, c phases Four electronic power switches Sw1, Sw2, Sw3 and Sw4 constitute 2 leg inverter. The two legs of the inverter are connected to 2 phase of BLDC motor while the third phase of two capacitor Vbn = Vdc 3 0 Van 3.5 PMBLDCM Drive 3.3 Hysteresis Controller Vcn SW2 Where Van, Vbn, Vcn are terminal voltage of BLDC motor The equations can be rewritten is matrix form as 3.2 Reference Current Single (Iref): The current reference signal is given by Vbn SW1 Vcn = Output phase voltages dω r P = ( Tm − Tl ) / J 2 dt (8) Back EMF of BLDC motor is terms of rotor angle position (θ) is given by Ep = kb fp (θ) ωr (9) fp (θ) Is similar to induces EMF which is trapezoidal in nature is given by Indian Journal of Science and Technology 3 PFC-based Control Strategies for Four Switch VSI fed BLDC Motor f p (θ ) = 1 for 0 < q < 2p / 3 6 f p (θ ) = ( π − θ ) − 1 π for 2p / 3 < q < p (11) f p (θ ) = −1 for p < q < 5p / 3 6 f p (θ ) = (θ − 2 π ) + 1 π (10) (12) for 5p / 3 < q < 2p (13) The equation of the electronic torque Tm is expressed in equation from as ( ) Tm = K b fa (θ) ia + fb (θ) i b + fc (θ) i c the BLDC motor fed CUK converter, the current reaches to 1.8 Amp and gradually decreases to 1.6 Amps. Figure 4 represents Back EMF wave form of BLDC drive system with interleaved boost converter and CUK converter. In case of interleaved boost converter, the back EMF is maintained at 38V where as in case of CUK converter the value is 42V. During dynamic response the EMF value reaches to 55.2V in case of interleaved Boost ­converter where as the value is 58V for CUK converter. E lec tromagnetic Torque (Nm) 60 (14) 40 Stator Voltage(Volts) 20 4. Results Discussion 0 -20 -40 4.1 Interleaved Boost Converter and CUK –converter Four Switches VSI fed PMBLDC Motor 0 0. 1 0. 2 0. 3 0. 4 0. 5 Time in S ec s 0. 6 0. 7 0. 8 0. 9 1 (a) E lec tromagnetic Torque (Nm) 60 40 20 0 -20 -40 -60 0 0. 1 0. 2 0. 3 0. 4 0. 5 Time In S ec s 0. 6 0. 7 0. 8 0. 9 1 (b) E lec tromagnetic Torque (Nm) 10 -80 Stator Voltage(Volts) Figure 3 shows the stator current of proposed BLDC motor drive system with interleaved boost converter and CUK converter. The current raises gradually to 1.4 Amps initially t = 0.01secs. During the dynamic response of BLDC motor the current value rapidly rises to 1.5 Amps and falls to 1.4 Amps. In case of CUK converter fed BLDC motor, the current is 1.8Amps and gradually reaches a steady value 1.6Amps.During the dynamic response of -60 8 Figure 4. Back EMF wave form one of the phase of BLDC motor, (a). Interleaved Boost Converter and (b). CUK Converter. Current(Amps) 6 4 2 0 -2 -4 0 0. 1 0. 2 0. 3 0. 4 0. 5 Time in S ec s 0. 6 0. 7 0. 8 0. 9 1 (a) 2 1.5 1 Current(Amps) 0.5 0 -0.5 -1 -1.5 -2 0 0.1 0.2 0.3 0.4 0.5 Time In S ecs 0.6 0.7 0.8 0.9 1 (b) Figure 3. Stator Current wave form one of the phases of BLDC motor, (a). Interleaved Boost Converter and (b). CUK Converter. 4 Vol 8 (16) | July 2015 | www.indjst.org Figure 5 shows torque wave form of BLDC motor fed by interleaved boost converter and CUK converter respectively. The torque is 1.75N-m in case of interleaved boost converter where it is 2.2N-m CUK converter. During dynamic response of BLDC motor in case of interleaved boost converter the torque fluctuates between 2N-m to 2.2N-m and finally reaches a steady state value of 2 N-m torque increase to 2.2N-m for certain instant of fixed change but reaches the steady state value of 2 .2 N-m. Figure 6 shows the speed response of BLDC motor fed by interleaved boost converter as well as CUK converter. The speed value is 300rpm in case of interleaved boot whereas 300rpm in case of CUK converter. On observation of dynamic response of the drive for the interleaved topology the speed changes instantaneously from 300rpm Indian Journal of Science and Technology V. Ramesh and Y. Kusuma Latha to 750rpm.Whereas increase the CUK converter ­topology. The speed change 300rpm to 750rpm gradually. Method Torue R es pons e 14 Table 2. Performance of CUK converter fed PMBLDCM drive and interleaved boost converter for speed control & torque ripple Speed in Rpm Torque Ripple (N-m) CUK converter Four Switch VSI fed BLDC Drive 300 0.18N-m 750 0.22N-m Interleaved Boost converter Four Switch VSI fed BLDC Drive 300 0.12N-m 750 0.20N-m 12 10 Torque(N-m) 8 6 4 2 0 -2 -4 0 0. 1 0. 2 0. 3 0. 4 0. 5 Time in s econds 0. 6 0. 7 0. 8 0. 9 1 (a) 5. Conclusion E lec tromagnetic Torque (Nm) 3 2. 5 Torque(N-m) 2 1. 5 1 0. 5 0 -0. 5 0 0. 1 0. 2 0. 3 0. 4 0. 5 Time In S ec s 0. 6 0. 7 0. 8 0. 9 1 (b) Figure 5. Torque output wave form at speed corresponding to 300 rpm ad 750 rpm, (a). Interleaved Boost Converter and (b). CUK Converter. S peed R es pons e 1000 900 In this paper two PFC based control strategies have been developed for four switches VSI fed PMBLDC motor drive. The two control strategies one is based on Interleaved Boost Converter and another one based on CUK converter topology, both control strategies have been applied to BLDC motor drive for different operating speeds to ensure unity power factor under wide rangeof speed and supply voltages. Comparison has been made between the two proposed control strategies of the BLDC motor and it is found that interleaved boost converter based control strategies proved to be the best compared to CUK converter based control strategy of BLDC motor. 800 700 6. References Speed in RPM 600 500 400 300 Motor Actual S peed Motor R ederence S peed 200 100 0 0 0.25 0.5 0.75 1 1.25 Time in s ec (a) R otor s peed (rpm) 800 700 600 Speed(Rpm) 500 400 300 200 100 0 -100 0 0. 1 0. 2 0. 3 0. 4 0. 5 Time In S ec s 0. 6 0. 7 0. 8 0. 9 1 (b) Figure 6. Speed output wave form of the drive at constant load torque variable300 rpm and 750 rpm, (a). Interleaved Boost Converter and (b). CUK Converter. Vol 8 (16) | July 2015 | www.indjst.org 1. Lee BK, Kim TH, Ehsani M. On the feasibility of four-switch three-phase BLDC motor drives for low cost commercial applications: topology and control. IEEE Transactions on Power Electron. 2003 Jan; 18(1):164–72. 2. Puviarasi R, Dhanasekaran D. Interleaved boost converter fed DC machine with zero voltage switching and PWM technique. Indian Journal of Science and Technology. 2015 Feb; 8(4):376–82. 3. Pushpavalli M, Abirami P, Vasanth K. Performance of fuzzy controlled negative KY boost converter. Indian Journal of Science and Technology. 2014 Aug; 7(8):1049–59. 4. Subramanian K, Kumar VKS, Saravanan EM, Dinesh E. implementation of one cycle control technique in DC-DC buck converter. Indian Journal of Science and Technology. 2015 Jan; 8(S2):200–6. 5. Krishnan R. Selection criteria for servo motor drives. Proceedings of IEEE IAS Annual Meeting; 1986. p. 301–8. Indian Journal of Science and Technology 5 PFC-based Control Strategies for Four Switch VSI fed BLDC Motor 6. Jahns TM. Torque production in permanentmagnet synchronous motor drives with rectangular current excitation. IEEE Transactions on Industry Application. 1984 Jul/Aug; IA-20(4):803–13. 7. Pillay P, Krishnan R. Modeling, simulation and analysis of permanent-magnet motor drives. II. The brushless DC motor drive. IEEE Transactions on Industry Applications. 1989 Mar/Apr; 25(2):274–9. 8. Lin C-L, Jan H-Y, Shieh NC. GA-based multiobjective PID control for a linear Brushless DC motor. IEEE Transactions on Mechanical. 2003 Mar; 8(1):56–65. 6 Vol 8 (16) | July 2015 | www.indjst.org 9. Nasri M, Nezamabadi-Pour H, Malihemaghfoori. A PSObasedoptimization of PID controller for a linearBLDC motor. Proceedings of World Academy of Science Engineeringand Technicalogy; 2007 Apr; 20. 10. Ang K, Chong G, Li Y. PID control system analysis, design and technology. IEEE Transactions on Control System Technology; 2005 July; 13(4):559–76. Indian Journal of Science and Technology