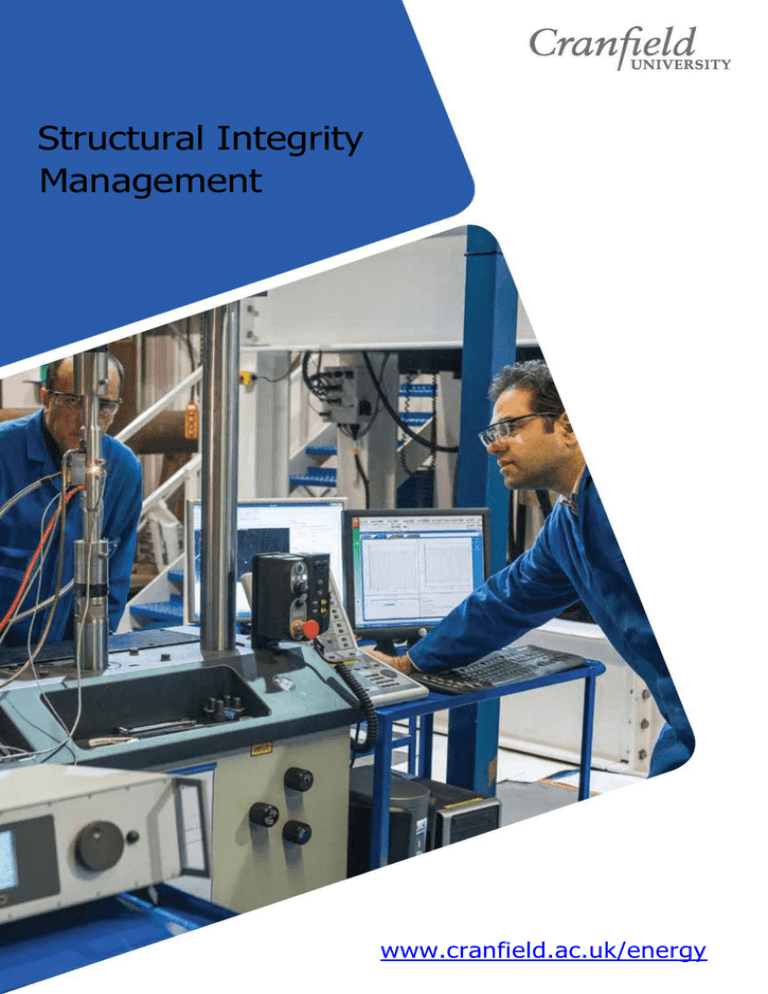

Structural Integrity Management

advertisement

Structural Integrity Management www.cranfield.ac.uk/energy Energy Cranfield University Cranfield University is a wholly postgraduate institution in the UK, with a global reputation for inspirational teaching and research, industrial-scale facilities and superior links with industry and commerce. Working in partnership with key players in the energy sector, Cranfield University enjoys an outstanding international reputation for the quality of its work, gained from many years of successful research, providing expert advice and consultancy on industrial projects both to Government and the private sector organisations. Our income earned from competitively won research grants and contracts is consistently in the top five UK universities. Cranfield is internationally renowned for its expertise in offshore structural integrity including inspection and testing. Our team is engaged in a diverse range of consultancy projects, research, teaching and bespoke CPD programmes that are supported by industrial scale facilities on campus. Your business can benefit from exploiting our unique knowledge and expertise, and our flexible consultative approach. You will be working with people who are passionate about knowledge transfer and improving the performance of your business. Consultancy projects can range from use of laboratory facilities to long-term change projects. Solutions might be based around improving the competitiveness of your company, such as improving product designs, quality or manufacturing processes, reducing costs, increasing efficiency or developing bespoke prototypes or analysis software programmes. 2 Cranfield University Energy Our capabilities in this area are: Offshore Structural Analysis: Failure Analysis Fatigue Testing of Materials and Components Fracture Mechanics Analysis Inspection Reliability Trials Engineering Criticality Analysis. The team conducts internationally leading research into the fatigue and damage modelling of large marine structures. This also involves the evaluation of suitable inspection and monitoring approaches and integrating results into appropriate fitness-for-service and Engineering Criticality assessments. Work carried out uses a combination of experimentally based and analytical/ numerical approaches. Energy Cranfield University Energy Asset and Integrity Management An energy asset refers to every structure, component or system employed in an energy installation be it for wind, tidal or a conventional energy structure such as pipelines or an offshore oil rig. The elements, whilst providing a source of energy, can wreak havoc on these costly installations – the earth, wind and water can corrode materials over time, whilst heat can distort structures with the intensity generated in power plants. Minimising maintenance costs and extending service life is essential for the energy industry not only due to the financial implications, but other drivers such as safety and loss of performance. Integrity management is therefore a critical activity for both conventional and renewable energy providers and manufacturers. Areas of expertise Fatigue and Fracture Analysis Structural Reliability Analysis Methods of assessment to test fitness for purpose and repair with minimal impact to overall performance. Providing design optimisation by systematic quantification of uncertainties and calibrating design standards. Requalification of Structures Composite Materials Extending the service life of installations by improving structural integrity. Determine the properties of new materials to optimise design and manufacturing.standards. Design of Structures and Components Corrosion Analysis Design, analysis and performance assessment of structures and structural details. Testing and characterization of new materials. Engineering for installation, manufacturing and large-scale production. With a focus on modern materials such as very thick plates where combined effect of fatigue and corrosion assessment is required. Reliability of inspection and monitoring systems; recent years have seen enormous activity in t he development of Integrity Monitoring equipment and systems. Advances in wireless communication, miniaturisation of electronics, increased processing and data storage have fuelled this explosion in sensor and system development that promises to provide high quality mechanical integrity information that will allow optimum use of facilities whilst improving safety and reliability. Systems based on technology that could in the past only be used under laboratory conditions are now frequently deployed in the field very often claiming accuracy and reliability commensurate with laboratory measurements. Monitoring is certainly an exciting prospect and has many advantages over traditional NDT; there are however, some very fundamental issues that must be resolved to benefit fully from these new technologies. Not least of these is providing the facilities manager with the appropriate understanding of the reliability of the inspection and monitoring techniques and how this information can be integrated into fitness-for-service and criticality assessments. 3 Energy Cranfield University Energy Cranfield University Facilities Structural Integrity Laboratory The Structural Integrity Laboratory has a range of servo-hydraulic materials and fatigue testing facilities, from 100kN to 2.5MN capacity, as standard test machines or as test rigs built about full or large-scale components. Loading of specimens and components is possible under unaxial tension-compression, bending and rotating bend arrangements. A pipe pressure-temperature rig is available and used for testing and verification of composite pipeline repair systems. A range of inspection/NDT equipment and structural health monitoring systems are used for crack and stress measurement. The laboratory specialises in the testing of non-standard specimens and components, development of fatigue design rules, acceptance testing and inspection reliability trials. Ocean Systems Test Laboratory (Wave-Towing Tank) The facility was specifically designed for model testing at the early stage of marine renewable projects. The combination of wave and towing capabilities in addition to a team having expertise in Hydrodynamics and Turbomachinery enable us to cater for the particular needs of the Marine Renewable Energy Industry (Wave, Tidal and Offshore Wind); In particular, dynamic response of support structures in wind-wave-current, turbine design and turbine performance assessment. The towing carriage features a bespoke design towing post capable of conducting resistance and stability tests in calm waters and waves. Dynamic response tests of a ship/yacht in a seaway can also be undertaken. The facility has the following characteristics: Tank Length: 30.0 m Tank Height: 1.8 m Wave height: 280mm peak to trough Max drag: 200 N Tidal turbine interaction test rig Accelerometers/Gyrometers Load Cells Full video recording equipment and editing facilities Fully equipped workshop. Multi-Component Balances from 30N - 2N.m up to 2500N - 400N.m. Tank Width: 1.5 m Water depth: 1.5 m Working frequency: 0.10Hz to 1.1Hz Max payload: 30 kg Tidal device deployment simulator Tension/Compression Ultrasonic and resistive wave gauges Adaptative towing post for ships and yachts Fully instrumented horizontal and vertical axis tidal turbine test rigs (motor and generator modes) Professional Development Short courses In addition to our postgraduate teaching Cranfield offers a variety of CPD and short courses in Energy, with the ability to tailor courses for industrial clients. Examples of our courses include: Advanced Control Systems Advanced Offshore Inspection & Evaluation Biofuels Process Technology Carbon Capture Technologies Carbon Transport Technologies Combined Heat and Power (CHP) Concentrating Solar Power (CSP) Corrosion in the Offshore Environment Cost Engineering in the Oil and Gas Industry Introduction Engineering Structural Integrity: Energy and Power Applications Environmental Management Fluid Mechanics & Loading Fundamental & Practical Offshore Inspection & Monitoring Gear Design Heat Transfer Industrial Heating Systems Materials in the Offshore Environment Multiphase Flows Offshore Inspection Offshore Pipeline Design and Installation Power Electronics & Machines Power Generation Systems Process Measurement Systems Process Plant Operation Process Simulation & Design Production Technology & Chemistry Pumps & Pumping Systems Reliability Engineering & Asset Risk Management Risk and Reliability Engineering Safety, Risk and Reliability Offshore Stress Analysis through Finite Element Modelling Subsea Oil & Gas Exploitations Testing & Routes to Certification Thermal Systems Operation & Design For further information on our cpabailities, facilities and training, please contact Professor Feargal Brennan at: f.brennan@cranfield.ac.uk SoE1443 Further information