Surface & Coatings Technology 253 (2014) 8–13

Contents lists available at ScienceDirect

Surface & Coatings Technology

journal homepage: www.elsevier.com/locate/surfcoat

Coating substrate relationship after initial electrolyte contact in the

electrodeposition of zinc on steel

Thomas Greul a,b, Johann Gerdenitsch b, Christian Commenda b, Raffaela Sagl b, Martin Arndt c,

Jiri Duchoslav c, Achim Walter Hassel a,d,⁎

a

Institute for Chemical Technology of Inorganic Materials, Johannes Kepler University Linz, Altenberger Str. 69, 4040 Linz, Austria

Voestalpine Stahl GmbH, Voestalpine-Straße 3, 4020 Linz, Austria

Christian Doppler Laboratory for Microscopic and Spectroscopic Material Characterization, Center for Surface- and Nanoanalytics, Johannes Kepler University Linz, Altenberger Str. 69,

4040 Linz, Austria

d

CEST GmbH, Viktor Kaplan Str. 2, 2700 Wiener Neustadt, Austria

b

c

a r t i c l e

i n f o

Article history:

Received 27 August 2013

Accepted in revised form 29 April 2014

Available online 14 May 2014

Keywords:

Electro deposition

Zinc

Crystal growth

a b s t r a c t

Electron backscatter diffraction (EBSD) measurements show epitaxial electrochemical deposition of zinc on nondeformed and contrariwise random growth on deformed steel grains. Therefore, electrochemical investigations

on the differences of zinc electrodeposition on electropolished respectively on temper rolled low carbon steel

sheet of the same substrate are studied. These measurements show great differences in ECN (electrochemical

noise) investigations and the 1st cycle of a CV (cyclic voltammetry) only. It is found, that the immersion of the

substrate in the electrolyte prior to the measurements causes this behaviour. SEM, EDX, XPS (X-ray photoelectron spectroscopy), SAM (scanning Auger microscopy) and IRRAS (infrared reflection absorption spectroscopy)

measurements are used for surface characterisation and EBSD-measurements for determination of crystallographic orientation to reveal the influence on electrochemical growth. It is proven that zinc precipitates form

on the temper rolled substrate during immersion and cause a nucleation process prior to electrodeposition and

the subsequent change in electrocrystallisation as zinc is deposited on zinc instead of steel. The differences in

the electrochemical measurements are well described by this theory.

© 2014 Elsevier B.V. All rights reserved.

1. Introduction

Electrodeposition of zinc from acidic sulphate electrolytes is an

important industrial process for corrosion protection of steel strips

used in the automotive industry.

Various aspects such as the influence of pH, temperature and current

density on the electrodeposition of zinc from acidic sulphate electrolytes have been studied so far [1–3]. Furthermore deposition parameters like pulse deposition with [4] or without [5] an anodic pulse have

shown a remarkable influence on morphology and crystal size of

electrodeposited zinc. Even an external magnetic field applied to the

deposition cell shows changes in this system due to a micro-magneto

hydrodynamic convection [6].

The effects of inorganic impurities such as Ge [7], Pb [8], Cu, Ni, Co

[9], Sb [10], Sn [11] and Fe [12] and organic additives to acidic sulphate

electrolytes like sodium dodecyl sulphate, dodecyltrimethylammonium

bromide, octylphenolpoly(ethyleneglycolether)n, n = 10 [13] PEG

⁎ Corresponding author at: Institute for Chemical Technology of Inorganic Materials,

Johannes Kepler University Linz, Altenberger Str. 69, 4040 Linz, Austria. Tel.: +43 732

2468 8700; fax: +43 732 2468 8905.

E-mail address: achimwalter.hassel@jku.at (A.W. Hassel).

http://dx.doi.org/10.1016/j.surfcoat.2014.04.065

0257-8972/© 2014 Elsevier B.V. All rights reserved.

20000 [14], sodium lauryl sulphate, arabic gum [15] and tartaric acid

[16], and to chloride containing electrolytes [17–19] on current efficiency or the structure of the zinc layer were investigated thoroughly.

Another important aspect is the preparation of the surface and

therefore the microstructure of the surface to be coated which plays a

crucial role in the electrodeposition of zinc and the morphology and

texture of the deposited zinc layer [20].

Studies have shown that there is a relationship between the texture

of the steel substrate and the deposited zinc layer [21–23]. It was recently shown that zinc grows epitaxially on undeformed steel surfaces

whereas on deformed steel grains random crystal growth was found

[24].

One important influence which hasn't been studied so far is the influence of the initial electrolyte contact of a steel sheet before electrodeposition. In the industrial process the electrochemical potential is

applied simultaneously with the first electrolyte contact. On a laboratory scale on the other hand galvanostatic experiments are usually performed in flow cells with constant electrolyte velocity which results in

an electrolyte contact prior to electrochemical polarisation. In the used

flow cell this contact time is in the range of some seconds. Thus the

aim of this work is to study the influence of the contact of electrolyte

with a steel sample on the electrodeposition of zinc.

T. Greul et al. / Surface & Coatings Technology 253 (2014) 8–13

TRS (C1)

EPS (C1)

TRS (C4)

EPS (C4)

10

100

Fe

100

TRS immersed

EPS immersed

TRS cleaned

EPS cleaned

50

I / mA

20

9

80

0

-1.0

-0.5

0.0

60

0.5

Irel / %

I / mA

-50

-100

-1.5

E / V vs. NHE

0

40

TRS (C1)

EPS (C1)

-10

TRS (C4)

C

20

O

Zn

EPS (C4)

-20

-1.0

TRS immersed

EPS immersed

0

-0.8

-0.6

-0.4

-0.2

0.0

0.5

1.0

E / V vs. SHE

1.5

2.0

2.5

3.0

E / kV

Fig. 1. Comparison between temper rolled substrates (TRSs) and electropolished substrates (EPSs) in the 1st (C1) and 4th (C4) cycles of a cyclic voltammogram in ZnSO4

electrolyte.

Fig. 3. Comparison of temper rolled substrates (TRSs) and electropolished substrates

(EPSs) before and after immersion into Zn-electrolyte; energy dispersive X-ray (EDX)

measurements performed in a SEM.

2. Material and methods

2.1. Chemicals

2.3. Electrochemical measurements

The zinc electrolyte in use was an analytical grade sulphate electrolyte with 90 g L−1 Zn from ZnSO4 ∙ 7 H2O (p.A. from Roth) and 20 g L−1

Na from Na2SO4 (p.A. from Baker) as conducting salt with pH set at

1.55 at 55 °C with H2SO4 (p.A. from Merck).

For the electropolishing of the substrate prior to use Struers A2

(Struers, Ballerup, Denmark) electrolyte (perchloric acid in a mixture

of ethanol, 2-buthoxyethanol and H2O) was used. The substrate used

for the measurements was a low carbon steel sheet produced by

Voestalpine Stahl GmbH.

Electrochemical measurements were performed at room temperature in an EG & G PARC flat cell using an IM6e Potentiostat from

Zahner® electric (Kronach, Germany). A NPROBE CorrElNoise™ —

technology device from Zahner Messtechnik was used to enhance

ECN-measurement quality. Ag|AgCl|KCl (3 M) with a potential of

0.21 V vs. SHE was used as reference electrode. Cyclic voltammetry was

carried out from −1.2 to 0.3 V vs. SHE with a scan rate of 10 mV s−1.

2.2. Sample preparation

Before electroplating the samples were immersed in zinc electrolyte

for 20 s. Immersion was done in a flow cell at an electrolyte temperature

of 55 °C and an electrolyte velocity of 4 m s−1.

Electroplating was performed in the same flow cell. The electrolyte

was kept at the same conditions used during immersion and the current

density was set at 400 mA cm−2 with an EA-PS9036-240 galvanostat

(Elektro-Automatik GmbH & Co. KG Company, VIERSEN, Germany). In

order to simulate the Gravitel® process [25] with 12 cells, the current

Temper rolled steel samples, further called TRSs, were alkaline

cleaned with 10 g L−1 Ridoline C72 (Henkel, Germany) and electrochemically etched with 50 mA cm−2 in 10 g L−1 H2SO4 before further

investigations.

The electropolished samples, further called EPS, were produced from

mechanically polished TRS. Electropolishing was done using a Struers

LECTROPOL 5 unit at 30 V for 30 s. The sample was rinsed with analytical

grade ethanol after electropolishing.

2.4. Electroplating

100

8.5

8.0

75

Irel / %

7.5

I / mA

Fe

Zn

O

Fe

7.0

6.5

50

TRS

25

6.0

O

Zn

EPS

5.5

0

0

5.0

0

10

20

30

40

50

1000

1200

5

10

15

20

25

30

d / nm

t/s

Fig. 2. Electrochemical noise measurement of temper rolled substrates (TRSs) and

electropolished substrates (EPSs) in ZnSO4 electrolyte.

Fig. 4. Glow discharge optical emission spectroscopy (GDOES) depth profiles of temper rolled substrates (TRSs) after immersion into electrolytes with Zn-concentrations of

45 g L−1 (solid line), 25 g L−1 (dashed line) and 0 g L−1 (dotted lines).

10

T. Greul et al. / Surface & Coatings Technology 253 (2014) 8–13

De Nora (Milan, Italy) was used as an anode. The final thickness of the

zinc layer was 7.5 μm.

cleaned surface

etched surface

immersed surface

Zinc layer

Zn

Zn

2.5. Analytics

O

I/1

Zn

O

Zn

O

Zn

Zn

Zn

Fe

Fe

C

Zn

S

1400

1200

1000

800

600

400

S

Zn+Fe

Fe

200

0

BE / eV

electrodeposited-Fe surface

low carbon steel surface

dual phase steel surface

Zn

Zn

O

O

O

Zn

Fe

Fe

I/1

Zn

Zn Zn

Zn

C

S

Zn+Fe

Fe

S Zn

Surface measurements were performed with a Zeiss Supra 35 FEGSEM, an Oxford Channel 5 system for EBSD and an EDAX Smart Insight

system for EDX. Calculations for determination of the misorientation

angle were described in a previous work [24].

XPS (X-ray photo-electron spectroscopy)-measurements were

performed with a Theta Probe from ThermoFisher.

SAM (scanning Auger microscopy) was done using a JAMP-9500F

field emission Auger microprobe.

For AAS-measurements a HITACHI Z-8230 polarised Zeeman was

used downstream from a scanning droplet cell microscope (SDCM) [26].

GDOES (glow discharge optical emission spectroscopy)measurements were conducted on a GDA750 from SPECTRUMA

Analytic GmbH.

IRRAS (infrared reflection absorption spectroscopy) was done with a

FTIR-spectrometer tensor 27 from Bruker. An A513/3 grazing angle unit

was used to enhance the surface sensibility of the measurements.

3. Results

3.1. Cyclic voltammetry

1400

1200

1000

800

600

400

200

0

BE / eV

Fig. 5. XPS-measurements of steel surfaces after the different steps during electrodeposition (top) and comparison of different steel grades after immersion into electrolyte

(bottom).

was interrupted with 24 pulses (duty cycle: 1.7 s on, 1.0 s off). The temperature was kept at 55 °C using a Lauda PROLine RP855 thermostat. A

DSA (dimensionally stable anode) made from Ti coated with IrO2 from

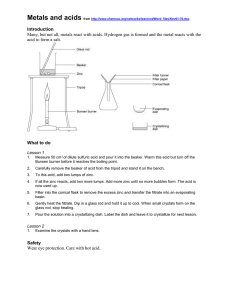

Previous EBSD-measurements showed differences in the

electrocrystallisation of zinc between EPSs and TRSs made of low carbon

steel. Therefore cyclic voltammetry was performed on these two substrates to determine their electrochemical behaviour (Fig. 1). Measurements of the 1st cycle of both substrates show a typical behaviour with

upd (underpotential deposition) of zinc from − 0.4 to −0.8 V vs. SHE

and slight differences of 10 mV in the starting potential of zinc bulk

deposition. Furthermore a crossover potential can be observed on TRS

whereas on EPS none was found.

Cyclic voltammetry was carried out till the dissolution of the steel

substrate, so that a fresh surface was generated in each cycle. Comparing later cycles of the different substrates most differences between

the two substrates disappear. There is a slightly higher limiting current

on the TRS in the upd regime compared to the EPS. But there is no indication why epitaxial growth occurs on EPS but not on TRS.

Fig. 6. Grazing angle infrared-reflection–absorption difference spectrum of an immersed and etched temper rolled substrate; the assignment to discussed substances is given in the inset.

T. Greul et al. / Surface & Coatings Technology 253 (2014) 8–13

3.2. Electrochemical noise (ECN) measurements

Due to the fact that the CV's have shown large differences between

the 1st and the following cycles and the fact that the samples were in

contact with the electrolyte at about 10–30 s prior to these measurements, it was concluded that the surface reactivity changes as a result

of the electrolyte contact. Therefore ECN in a Zn-electrolyte was

measured from first electrolyte contact on (Fig. 2).

On EPS a peak can be observed after 3 s, followed by a sharp drop to a

constant current. In comparison to EPS this peak can't be found on TRS.

A slightly higher dissolution current due to the surface roughness was

observed.

11

(Zn5(CO3)2(OH)6), or oxides and hydroxides of zinc. Both are typical corrosion products found on electrogalvanized steel sheets [27].

Quantification of the zinc precipitations with a flat flow cell with

downstream analytics to an AAS-system gives an amount of 5 mg m−2

3.3. Surface characterisation

In addition to the electrochemical measurements surface characterisation with SEM, EDX, XPS, SAM and GDOES was carried out to investigate the changes of surface chemistry/composition during electrolyte

contact.

Comparing the EDX spectra of the TRS with EPS taken after the

cleaning and etching procedures no differences can be found (Fig. 3).

Both substrates show C, O and Fe-peaks only, a typical result for low carbon steel sheets.

After immersion into the electrolyte the TRS shows a clear peak at

about 1 kV. After double-checking with the Kα-peak of zinc which can

be found at higher energies this peak can be assigned as the Zn-Lαpeak. That's a major difference compared to EPS, where no zinc peak

appears.

To discern whether or not the measured zinc signal is just an artefact

and to be sure that there is no superimposed Na-signal in the EDX

measurements, GDOES was performed on substrates immersed into

Zn-electrolytes with different Zn-concentrations (Fig. 4). To make sure

that the measured signal is not affected by the initiation of the plasma,

carbon was sputtered onto the samples before measurement.

The GDOES-measurements from Fig. 4 indicate a precipitation of

zinc on the TRS surface. Moreover the dependency of the amount of

Zn found on the substrates on the zinc concentration of the electrolyte

used is found. This means that the lower the zinc concentration in the

electrolyte is the lower is the signal found in the GDOES measurement.

This clearly indicates a reaction of the electrolyte with the surface and a

dependency of the reaction on the concentration of zinc.

XPS-measurements on TRS were performed to discern whether

or not the Zn-signal stems from residual ZnSO4. In Fig. 5 the XPSmeasurement on top shows the comparison of a cleaned, and etched

surface and a surface immersed into electrolyte. In addition a 7.5 μm

thick zinc layer produced from the same electrolyte used for immersion

was added to the graph. Cleaned and etched surfaces were measured to

form a reference for the interpretation of the immersed samples. Both

show neither impurities nor zinc contamination on the surface. Fe, C

and O were found on the cleaned surface whereas after etching small

amounts of sulphur are present on the surface due to the fact, that etching was performed in sulphuric acid. After immersion of TRS in electrolyte, Zn could be found besides Fe, C, O and small amounts of S. The

concentration of S found is too low to correspond to Zn being present

on the surface solely as ZnSO4. The fact that an Fe-signal was detected

indicates that the Zn-precipitate is either thinner than a few nm or

grows in islands.

Comparison between the precipitated layer and an electrodeposited

zinc with XPS shows that no metallic zinc can be found on the immersed

substrate. High-resolution measurements indicate that the Zn found on

the surface is either a carbonate or an oxide.

This is in good accordance to the IRRAS measurements done with a

grazing angle unit to achieve high surface sensitivity. The differences between the spectra of an etched and an immersed TRS surface (Fig. 6) indicate that the Zn found on the immersed surface is either hydrozincite

Fig. 7. Scanning Auger microscopy-mapping of a local deformation on an electropolished

surface; Zn-signal (upper) and S-signal (middle); and SEM-image (bottom).

12

T. Greul et al. / Surface & Coatings Technology 253 (2014) 8–13

Zinc

Steel

Fig. 8. IPF (inverse pole figure) map of a cross-section of a temper rolled substrate and corresponding zinc layer electrodeposited after immersion into zinc electrolyte.

of zinc, which refers to a zinc layer thickness of ~1 nm assuming a homogeneous film thickness.

It is assumed that although the transfer time of the freshly immersed

sample was kept at a minimum such a small layer would be readily

oxidised by the contact with air. This fact might explain why metallic

zinc can't be found on the immersed samples.

Currentless deposition of zinc on pure iron is thermodynamically

unfavourable; therefore immersion experiments with different steel

substrates and electrodeposited iron – representing the case of pure

iron – should reveal the influence of alloying elements on the precipitation of zinc.

XPS-measurements of these samples (Fig. 5 bottom) showed a

dependence of the amount of precipitated zinc on the steel grade. The

highest concentration of zinc was found on pure iron represented by

the electrodeposited iron surface. The concentration of zinc decreased

with increasing alloying additions of Cr and Mn so that the least zinc

was found on dual-phase steel surfaces. This indicates that the precipitation is not due to alloying additions but in the course of iron

dissolution.

The fact that there is no Zn precipitate on EPS but on TRS leads to the

assumption that deformation on the steel grains favours the precipitation of Zn on steel. To prove this assumption a local deformation was

produced on an EPS. The sample was thereafter immersed in the electrolyte and used for an Auger-mapping.

The mapping in Fig. 7 shows that more zinc is found in the deformed

area than that on the electropolished area. The sulphur signal in the

Auger-mapping is preferentially located on the electropolished area.

Therefore the zinc found in this area is most likely ZnSO4. It was concluded that the large amount of S and O found in this area is probably

a result of insufficient cleaning. The line with high sulphur concentration at the edge of the deformation is explained by drying of a droplet.

In the deformed area S can't be detected besides Zn.

3.4. Effect of immersion on electrodeposition

Fig. 8 shows the EBSD mapping of the cross-section of a zinc layer deposited on a TRS after immersion into electrolyte prior to electrodeposition. Determination of the misorientation angles between electroplated

zinc and iron of a steel sample after immersion into zinc electrolyte before electroplating gave an overall angle of 42° ± 4°. It can be seen that

only on highly deformed TRS grains the relation between zinc and steel

doesn't follow Burger's orientation relation. Comparing the relations of

the different zinc grains on one such deformed steel grain leads to a maximum standard deviation of 2.5° thus epitaxial growth can be assumed

anyway.

On steel grains with slight deformation zinc grows epitaxially

following Burger's orientation relation. Disregarding the steel grains

with high deformation leads to a misorientation angle of 43° ± 2°

which is the same as that previously detected on EPS [24]. The same

substrate without electrolyte pre-treatment shows a misorientation

angle of 34° ± 10°, thus random crystal growth.

4. Discussion

Electrochemical measurements show that there is an influence of the

immersion of a temper rolled substrate into the zinc electrolyte prior to

the measurements. During this time zinc precipitates on TRS whereas

on an electropolished substrate no such reaction occurs. This leads to differences in cyclovoltammetric scans. The absence of the current peak in

ECN measurements on the temper rolled substrate in combination

with the fact that zinc can be found on the surface, indicates that zinccementation is the precipitation reaction. Furthermore the difference in

charge between the temper rolled substrate and the electropolished substrate from the ECN measurements calculated by the missing peak can

explain the thickness of the Zn-layer determined by the AAS investigations. Although no metallic Zinc could be found on the steel surface by

XPS-measurements it is postulated that there is a cementation of zinc

on the deformed steel grains. It is shown by XPS measurements that

the zinc deposit doesn't consist of ZnSO4. The fact that there is about

5 mg m2 of zinc on the surface explains why after exposure to air only

corrosion products of zinc were detected.

The fact that this cementation happens even on electrodeposited

iron layers indicates that there is an anti-galvanic reduction similar to

the reduction of silver on a gold nanosystem [28]. No zinc precipitation

occurs on the electropolished surface but on electrodeposited and deformed surfaces as was shown with SAM-measurements. This indicates

that crystal deformation is necessary for this reaction.

It can be assumed that due to the deformation of the steel grains the

dissolution potential of the deformed grains is shifted to more cathodic

values than the potential of undeformed or electropolished grains. This

shift might be sufficient to reach a potential where underpotential deposition of zinc is possible. The fact that there might be a formation of

a Zn/Fe alloy, similar to the system Zn/Cu, involved can't be excluded

by the present results.

The resulting Zn deposit leads to a change in electrocrystallisation

and furthermore to a change in the electrochemical crystal growth.

Zinc is, after immersion of the TRS, deposited on a thin layer of zinc

instead of steel. This change in surface chemistry changes the electrochemical crystal growth of zinc from random to epitaxial growth mostly

following Burger's orientation relation, which is proven by the EBSD

measurements.

5. Conclusion

In the course of immersion of a temper rolled substrate into zincelectrolyte, the surface properties change. Zinc is deposited on iron in

T. Greul et al. / Surface & Coatings Technology 253 (2014) 8–13

an anti-galvanic reaction. This reaction is possible only on deformed steel

grains. Consequently this reaction is not observed on an electropolished

substrate. Such small amounts of zinc act as crystallisation seeds, and

lead to a complete change in the electrocrystallisation mechanism from

random to epitaxial since the zinc is deposited on zinc instead of iron.

Conflict of interest

There is no conflict of interest.

Acknowledgments

The financial support by the Austrian Federal Ministry of Economy,

Family and Youth (Christian Doppler Laboratory for Combinatorial

Oxide Chemistry COMBOX) and the National Foundation for Research,

Technology and Development (COMET K1 Center CEST) is gratefully

acknowledged.

References

[1] I. Zouari, F. Lapicque, Electrochim. Acta 37 (1992) 439–446.

[2] P. Guillaume, N. Leclerc, C. Boulanger, J. Lecuire, F. Lapicque, J. Appl. Electrochem. 37

(2007) 1237–1243.

[3] R.C. Salles, G.C. de Oliveira, S.L. Díaz, O.E. Barcia, O.R. Mattos, Electrochim. Acta 56

(2011) 7931–7939.

[4] T. Frade, V. Bouzon, A. Gomes, M. da Silva Pereira, Surf. Coat. Technol. 204 (2010)

3592–3598.

[5] D. Wang, Y. Wu, X. Zhong, W. Zhang, M. Li, J. Shen, Russ. J. Electrochem. 54 (2009)

291–295.

13

[6] M. Uhlemann, K. Tschulik, A. Gebert, G. Mutschke, J. Fröhlich, A. Bund, X.G. Yang, K.

Eckert, Eur. Phys. J. Spec. Top. 220 (2013) 287–302.

[7] D. Mackinnon, P. Fenn, J. Appl. Electrochem. 14 (1984) 467–474.

[8] R. Ichino, C. Cachet, R. Wiart, Electrochim. Acta 41 (1996) 1031–1039.

[9] M.M. Jakšić, Surf. Coat. Technol. 28 (1986) 113–127.

[10] D.J. Mackinnon, J.M. Brannen, J. Appl. Electrochem. 7 (1977) 451–459.

[11] T. Greul, J. Gerdenitsch, A.W. Hassel, Mater. Corros. 65 (2014) 410–415, http://dx.

doi.org/10.1002/maco.201307556.

[12] H. Nakano, S. Oue, S. Hisano, S. Kobayashi, H. Fukushima, ISIJ Int. 47 (2007)

1029–1033.

[13] A. Gomes, M. da Solva Pereira, Electrochim. Acta 52 (2006) 863–871.

[14] J. Ballesteros, P. Díaz-Arista, Y. Meas, R. Ortega, G. Trejo, Electrochim. Acta 52 (2007)

3686–3696.

[15] A. Recéndiz, I. González, J. Nava, Electrochim. Acta 52 (2007) 6880–6887.

[16] O. Aaboubi, J. Douglade, X. Abenaqui, R. Boumedmed, J. VonHoff, Electrochim. Acta

56 (2011) 7885–7889.

[17] M. Mouanga, L. Ricq, G. Douglade, J. Douglade, P. Berçot, Surf. Coat. Technol. 201

(2006) 762–767.

[18] M. Mouanga, L. Ricq, L. Ismaili, B. Refouvelet, P. Berçot, Surf. Coat. Technol. 201

(2007) 7143–7148.

[19] L. Morón, A. Méndez, F. Castañeda, J. Flores, L. Ortiz-Frade, Y. Meas, G. Trejo, Surf.

Coat. Technol. 205 (2011) 4985–4992.

[20] K. Raeissi, A. Saatchi, M. Golozar, J. Szpunar, Surf. Coat. Technol. 197 (2005)

229–237.

[21] K. Raeissi, M. Bateni, A. Saatchi, M. Golozar, J. Szpunar, Surf. Coat. Technol. 201

(2006) 3116–3122.

[22] H. Nakano, Trans. Nonferrous Met. Soc. China 19 (2009) 835–841.

[23] K. Raeissi, A. Saatchi, M. Golozar, J. Appl. Electrochem. 33 (2003) 635–642.

[24] T. Greul, C. Commenda, K. Preis, J. Gerdenitsch, R. Sagl, A.W. Hassel, Electrochim.

Acta 113 (2013) 797–802.

[25] M. Mascheck, K. Kösters, Galvanotechnik 80 (1989) 3790–3798.

[26] M. Voith, G. Luckeneder, A.W. Hassel, J. Solid State Electrochem. 16 (2012)

3473–3478.

[27] R. Autengruber, G. Luckeneder, A.W. Hassel, Corros. Sci. 63 (2012) 12–19.

[28] Z. Wu, Angew. Chem. 124 (2012) 2988–2992.