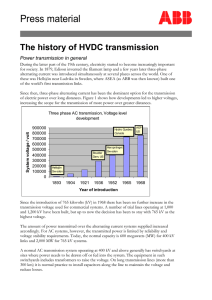

assessing the impact of an increasing penetration of hvdc

advertisement