diagnostic testing of generator insulation without

advertisement

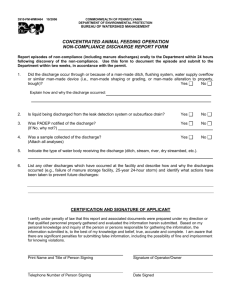

DIAGNOSTIC TESTING OF GENERATOR INSULATION WITHOUT SERVICE INTERRUPTION M. KURTZ and G.C. STONE, Ontario Hydro D. FREEMAN, V.R. MULHALL, and P. LONSETH, Canadian General Electric Co, Ltd (Canada) SUMMARY Coordinated efforts by the Canadian Electrical Association (CEA) and industry in Canada have led to the development of two new test methods which permit the evaluation of the condition of a generator’s stator insulation system with no or minimal service interruption. While both respond to partial discharges in the winding, one relies on coupling capacitors installed on the stator and the other, using an antenna mounted on the rotor, senses the presence of discharges in each slot as the antenna moves past. By employing these sensitive tests routinely, those generators experiencing insulation deterioration may be readily and inexpensively identified at an early stage. Thus, revenue loss, and the cost of maintenance inspection and repairs to the stator windings, if necessary, are minimized. The new approaches, which are insensitive to external high noise levels, are based on the measurement of electromagnetic disturbances related to individual partial discharge deterioration mechanisms. The detected pulses are analyzed by sophisticated electronic instruments, in order to extract all pertinent information including the degree and, sometimes, the location of insulation deterioration. Typical test data are given. The Paper explores the differences between the new diagnostic techniques and other methods developed in the past. Diagnostic Test, Generator, Partial Discharge, Slot Discharge, Stator Insulation. REPORT 1. INTRODUCTION The rate of occurrence and the consequences of service failures in high-voltage generator stator insulation systems can be reduced by the use of sensitive diagnostic tests designed to detect the early stages of insulation deterioration. Degradation processes include insulation delamination, shrinkage of wedges and/or side packing permitting vibration and abrasion, and loss of function of gradient control coatings. All these processes are almost invariably accompanied by partial discharges which increase in severity as the deterioration progresses, usually making an additional contribution to the insulation damage rate. Especially important with modem insulation systems are discharges occurring in the slot between the electrical shield of the stator bar and the core, usually referred to as slot discharge, which can attain levels of energy ( > 5 000 pC) sufficient to cause damage in times as short as several months [1,2]. Detection of discharges at the earliest practical stage, and proper interpretation of test results can permit corrective action to be taken before a winding deteriorates beyond the point of economic salvage, and particularly before the risk of a failure in service becomes unacceptably high. Reliable early warning from a suitable diagnostic test may permit relatively inexpensive repairs, such as re-establishing ground connections, side-packing, re-wedging or touch-up of stress grading paint, to be accomplished during a scheduled outage. In many power systems with mixed generation, hydraulic machines are reluctantly removed from service for discharge tests because of the relatively high cost of replacement fossil fuel energy. Thus, a diagnostic test that, at least for screening purposes, can be performed without service interruption, presents a distinct advantage. For large thermal machines, such a test also offers advantages in that the long time restraints for shedding and picking up load may be avoided. The new test methods described later in this Paper have been designed to respond to partial discharges originating in the stator insulation system, using signal- coupling techniques inherently insensitive to system noise. The signalto-noise ratio is further improved by electronic processing of the detected signals. To put into perspective the diagnostic tests described in this Paper, a review follows of the most widely employed tests to ascertain stator insulation condition. 2. REVIEW OF DIAGNOSTIC TEST TECHNIQUES 2.1. Measurable Quantities which Correlate with Damage Mechanical vibration, gaseous products and partial discharges are three quantities which can be monitored readily with negligible service interruption, while providing information with respect to the total stator insulation condition. The first two quantities have only relatively recently been under study and have yet to demonstrate their sensitivity and resolution, since data correlating measurements with visual inspections of stator condition are sparse. 2.2. Vibration If a bar or coil side loosens within a stator slot, vibration can cause ground wall erosion and wear, contributing to ultimate insulation failure. Hence, the presence of a vibrating bar indicates that the winding is loose and may eventually fail. By measuring the magnitude and rate of increase of these vibrations by means of accelerometers attached to the stator frame, the expected remaining useful life might be estimated. 2.3. Gaseous By-products Certain dielectrics, exposed to partial discharges or to heat, evolve various gaseous products. For insulations commonly used in stator windings of hydrogen-cooled units, some of these products can be readily distinguished against the background by gas chromatography or spectroscopy. The quantity of evolved gas car. indicate the degree of degradation [3,4]. 2.4. Partial Discharges 2.4.1. Tip-Up Test The “tip-up” test [5,6] provides a measure of the void content and partial discharge activity in a dielectric by measuring the change in dissipation factor between two discrete voltage stress levels, usually 50 percent and 100 percent of operating voltage. Unfortunately, this test tends to be insensitive to localized partial discharges because the loss component is averaged throughout the entire test sample, unless individual coils are isolated for test — an expensive procedure. Also, the end-grading material will distort results forin-situ measurements. The tip-up test requires an external supply to energize the winding, thus applying maximum voltage stresses to the entire winding which is not representative of operating conditions. 2.4.2. Dielectric Loss Analyzer The dielectric Loss Analyzer [7,8] reacts to the power loss in an insulation system as a function of voltage per cycle, thus indirectly measuring the presence and effects of partial discharge. This test method, through more sensitive than the “tip-up” test, can identify a number of weaknesses [9], but cannot detect the presence of a small number of intense discharge events in a background of many more moderate discharges. This test also requires an external supply, though the duration of the test outage may be comparatively short. 2.4.3. Inductive Probe Inductively coupled radio frequency probes have been employed to detect local discharges [10]. This test requires a lengthy service interruption and an external high-voltage supply, though it does have the capability of pin-pointing those bars or coil sides suffering the most intense internal or slot discharges. 2.4.4. Ultrasonic Detector Signals from an ultrasonic probe have been introduced into a conventional partial discharge measuring circuit with some success, especially for locating specific discharge sites [11]. This procedure does not provide any advantage over the Inductive Probe technique and is probably less quantitative. 2.4.5. Pulse Detection Detection of individual partial-discharge pulses by direct capacitive or inductive coupling to a machine winding, with the generator self-excited and thus supplying its own high voltage with normal voltage distribution, has been implemented in various measurement systems [12,13]. In this class of tests, the pattern of individual pulses can be displayed on an oscilloscope or quantified by a pulse-height analyzer. In the early days of this type of measurement, the high partial-discharge repetition rate from the many sites in a generator could result in the superposition of pulses since tests were often performed with “pulseshaping” circuitry to lengthen the duration of the individual pulses for easier observation. However, with modem wideband storage oscilloscopes and flat-response filters, it is observed that actual superposition of pulses rarely occurs. The rise times of partial- discharge pulses measured with such equipment are about 10 ns or less. Ringing frequencies, which depend only on generator winding parameters and the measuring system, vary from about 1 to over 50 MHz and are “second order” effects initiated by the original partial discharge event. Pulse durations, including ringing, are typically less than 1 psec., and consecutive partial discharges are rarely observed at intervals less than 10 psec. An inexpensive version of this test [13] has been in routine use within Ontario Hydro for more than 20 years, employing HV capacitors temporarily connected to the generator, a high-pass filter and an oscilloscope for display. This test has demonstrated that the condition of the stator groundwall insulation is correlated with the magnitude of the highest discharge pulse observed on the oscilloscope [14]. However, distinguishing between generator insulation partial discharges and external noise is sometimes difficult, requiring an experienced operator. Additional difficulties arise because of the nature of the partial-discharge pulses. Since these pulses are extremely rapid, the peak magnitude is difficult to determine at the slow oscilloscope sweep speeds required to recognize partial discharges by their phase position in the power frequency cycle, making the test highly subjective. A further drawback to the test is that, in practice, only the magnitude of the highest pulses is recorded. Information such as the number of pulses and the distribution of pulse magnitudes, that is, the relative abundance of large pulses compared to small pulses, can only be noted qualitatively. Yet, significant information about the nature and extent of insulation degradation must be present in the total pulse pattern. 3. IMPROVED GENERATOR TESTS Although the partial discharge test [14] is successful in quickly predicting stator insulation condition, the above limitations have restricted use of the test outside Ontario Hydro. As a consequence, CEA and one manufacturer began separately the development of more sophisticated procedures for observing and quantifying partial discharge activity in generator stator insulation systems. The test improvements described below comprise better methods of acquiring and treating partial discharge data with permanently installed coupling devices. The coupler or “antenna” is mounted on the rotor in one system, while couplers are installed on the stator in the system developed for CEA. Both coupling techniques respond to the highfrequency energy in an actual discharge. Means for reducing the influence of electrical noise are incorporated into both coupling techniques, thus permitting diagnostic testing while the generator is operating normally. Methods for quantifying the signals from either coupling system differ, although in principle both are based on pulse magnitude analysis. 3.1. Stater-Mounted Coupling System The partial discharge signals are acquired using rugged high-voltage capacitors of 50 to 100 pF which are solidly connected to the stator winding. The low-voltage sides of these couplers are connected to a convenient location external to the generator housing by terminated 50 ^l coaxial signal cable. The couplers are sensitive only to the highfrequency components of a discharge pulse. The placing and functioning of the couplers depends on whether the stator winding is in a hydraulic or a turbine generator. 3.1.1. Hydraulic Generators In hydraulic generators, the couplers are often placed at or close to the connection point of the circuit ring bus to each split or parallel of each phase in the winding. Since noise pulses entering the generator from the power system are first attenuated by surge capacitors and transformers and may be further reduced by impedance mismatches as the pulse travels along the circuit ring buses, a measure of external two capacitors installed on a hydraulic generator with a symmetrical winding. Referring to Figure 1 (a), when a noise pulse enters the winding, voltage pulses travel along the ring bus and reach both couplers about 25 ns, say, after signal injection. Since the response is the same at each coupler, if these two signals are combined in a differential amplifier there will be no output, at least not until pulse reflections within the generator winding start to build up. For partial discharges, which usually occur near the high-voltage end of each parallel, a net response is obtained since the signal reaches one coupler almost 50 ns before it reaches the other coupler in the pair (Fig. 1 (b)). This system works because the partial discharge pulse rise times are typically only 10 ns, much less than the pulse travel times along the transmission-line-like path of the circuit ring bus, (see paragraph 2.4.5.) Practical hydraulic-machine windings are rarely symmetrical about the terminals. Howewer, by the careful placement of the couplers and the use of delay lines, such permanent “differential” couplers can be installed on the majority of windings currently in use. More than twenty installations have been made in a number of Canadian utilities. These installations are usually on generators which either are difficult to obtain for test purposes because of outage restraints or are subject to a high degree of external noise interference. 3.1.2. Turbo-Alternators Because of the much smaller rotor radius involved, the type of differential coupling system described above is not possible for most turbo-alternators since the electrical length of circuit Figure 1: (a) Schematic diagram showing the response to an external noise source of a differential amplifier with inputs from a pair of balanced permanent couplers on two of the parallels. (b) This shows the response of the circuit to a partial discharge event within the winding. noise immunity is inherently present. Additional attenuation of noise, including power frequency and solid-state d.c. exciter noise, is afforded by connecting pairs of capacitive couplers to a differential amplifier in such a way as to cancel common-mode signals, taking into account the pulse travel time from the machine terminal to each coupler. For example, Figure 1 shows ring bus is often shorter than the discharge-pulse rise time. Sensitivity to external noise can be reduced, however, by the use of two permanently installed “directional” couplers per phase on the output bus of the generator (Fig. 2). External noise can be greatly attenuated by differential sensitivity to the direction of pulse travel on the bus, that is, either from the generator (assumed to be partial discharges) or from the power system (assumed to be noise). Retrofitting of the “directional coupler” can often be readily implemented on Isolated Phase Bus, since the inspection covers, which are regularly placed in the bus sheath, can provide sufficient capacitive coupling when grounded through a suitable impedance. 3.1.3. Electronic Analysis Partial Discharge Analyzers (PDA) have been constructed to process the voltage pulses from pairs of couplers into information about the repetition rate and magnitude of the discharges [15]. An analyzer consists of an 80-MHz bandwidth differential amplifier (Fig. 1 and 2) driving a single channel, dual polarity, pulse-height analyzer fabricated with ECL integrated circuits. The pulse-height analyzer is designed to handle generator partial discharges. Specifically, it responds to pulse rise times of less than 10 ns, ignores ringing, inhibits Figure 2: Directional coupler configuration. Pulses from the external system arrive simultaneously at the differential amplifier inputs, resulting in cancellation ; pulses from the winding arrive separated in time, resulting in a signal at V. the counting of pulse overshoots such as the negative overshoot of a positive pulse which can cause a false indication in the negative channel, ignores reflections in noise signals, and accepts consecutive discharge pulses more than 3 psec. apart. This single-channel pulse-height analyzer provides multichannel operation by sequential variation of the threshold levels. Fifteen 100-mV-wide channels with lower thresholds ranging from 100 mV to 1 500 mVhave been found satisfactory for completely determining pulse magnitude spectra. The PDA is controlled by a microprocessor which automatically steps the pulse height analyzer through the 15 voltage channels. The microprocessor also controls the counters which total the number of positive and negative pulses per second which occur in each channel and at the same time supervises a digital printer which provides the pulse magnitude spectra. Also produced is information on the generator’s operating voltage at the time of test, which is obtained from the 10-mV power frequency signal appearing on the couplers’s output. The source coupler of the partial discharges is identified automatically by comparing the polarity of the discharges with the phase of the power frequency voltage. Facilities are also included in the PDA for analyzing data from temporary couplers. These include requisite filters and a circuit which removes the very strong interference caused by thyristor excitation systems. Various versions of the PDA have been in use for more than 4 years and improvements are constantly being made. Several of the PDA’S described above have now been commercially manufactured and are in routine use by a number of Canadian utilities. 3.1.4. Test Results Test data on many operating hydraulic generators have shown that external noise and interference caused by thyristor excitation systems are reduced by more than 20 dB when the permanent couplers and the PDA are employed, whereas sensitivity to generator insulation partial discharges is maintained. Results are consistent with those obtained by skilled personnel using the “conventional” test [14]. Particularly the magnitude of pulses corresponding to a partial discharge repetition rate of about 10 Hz was found to correlate well with the magnitude of the peak discharge pulse observed from the oscilloscope trace in the conventional test. Figure 3 indicates pulse magnitude spectra observed on two of the parallels of a modern 200-MVA hydraulic generator. The stator winding in this machine has been visually examined and the parallel corresponding to the line on the right side of Figure 3 was found to be damaged by slot discharge deterioration. 3.2. Rotor-Mounted Coupling System A second system presently being developed has the ability to determine the location of slot discharge activity in an operating generator. Signals are processed on a slot by slot basis, providing detailed indication of the amplitude and location of partial discharge activity. The system also holds the promise of differentiation between various types of partial discharge activity because of the selectable frequency discrimination incorporated in the signal processing package. 3.2.1. System Description The system, as shown in Figure 4, consists of a specially designed “antenna” mounted on one or two field poles. This antenna does not interfere with the operation of the generator. As the antenna is carried by the rotor, a sample of discharge activity is received from each slot. Every slot is sampled in sequence during each revolution of the rotor. The antenna is is the occurrence of energy exchange from the broad band frequency spectrum in the actual discharge to specific harmonically related frequency components. When a partial discharge event occurs, the bars of the stator winding act as tuned circuits, producing energy in the 20 to 100 MHz region. Each bar acts as a structure for radiating electromagnetic energy directly from the front of each slot in the winding. These radiated signals are in the form of damped sine waves lasting approximately 1 jusec. for each slot discharge event. The higher harmonics tend to be restricted to the slot in which the discharge occurs because of reflections from the impedance discontinuity where the bar leaves the slot. Using the higher frequency components allows the monitoring system to resolve partial discharge activity on a slot by slot basis. Figure 3: Pulse magnitude spectra of the positive partial discharge pulses only, from two parallels on one phase of a 200-MVA hydraulic generator. located on a pole so as to maximize the probability of signal reception by being correctly positioned in front of each slot during the interval of the a.c. voltage cycle when discharges are expected to take place. The antenna has a bandwidth of 10 to 100 MHz. The received signals are passed by a balanced, matched transmission line to a specially designed matched radio frequency strip-line slip-ring coupling system located on the shaft below the rotor. These signals are then passed on to signal-conditioning electronics for analysis. To identify a specific source of slot discharge, a timing or synchronizing track is applied to the generator shaft near the location of the slip-ring coupler. 3.2.2. Theory of Operation The fundamental principle upon which the system is based 3.2.3. Signal Processing and Analysis The signal analysis electronics consists of a tuned radio frequency amplifier, envelope detector, high-speed logarithmic pulse amplifier and pulse stretcher. The timing signals from the shaft report the exact position of the antenna as a function of shaft rotation. Suitable counting circuits allow pulses from each slot to be studied individually or, alternatively, pulses from any or all slots may be displayed together. The data from each slot is then processed by pulse height analysis, giving statistical significance to the observed results. 3.2.4. Test Results Much of the work to date has been the solution of application problems. Results of field tests so far indicate that the theory upon which the system is based is generally correct. The Figure 4: Schematic diagram of rotor-mounted partial discharge monitoring system. full significance of many of the results is still not clear, although it is certain that the data reveal much detail about partial discharges which is unachievable by other detection systems. 4. CONCLUSION The two new systems described in this Paper illustrate the possibility of low-cost on-line monitoring of partial discharge activity in the stator windings of large generators. These tests may be performed on machines in their normal operating condition without an interruption to service, because they incorporate noise rejection. Test results are based on the direct measurement of partial discharge quantities, with none of the “dilution” effects inherent in other techniques. Both systems will identify the part of the winding, and one system the exact slot where the most significant discharge activity is located. Future developments must strive for the establishment of clear definitions of acceptable limits for damaging discharge in different machines. In particular: - It must be possible to positively identify high-intensity slot discharge so that it can be eliminated without delay. - The identification and measurement of surface or internal insulation discharges will permit the monitoring of any progressive increase in intensity throughout the life of the winding, as an indicator of insulation aging. Probably little can be done to reduce or eliminate internal discharge activity so that the usefulness of monitoring this mechanism lies mainly in making possible efficient scheduling of rewinding. Surface discharges may be reduced, when their intensity warrants, by suitable maintenance procedures. The greatest value from these diagnostic techniques will be obtained only after data from many different generators have been reviewed in relation to their design characteristics and their operating and maintenance histories, and correlated with the result of other more traditional diagnostic quality assessments of the bar insulation itself. To achieve this, continued close cooperation between manufacturers and users is essential. 5.REFERENCES [1] Johnson J.S. — “Insulation Failure Mechanisms on Large Rotating Machinery”, Electrical Insulation Conference, September, 1963, Paper AIEE, T-153-66. [2] Lonseth P. and Mulhall V.R. - “High Intensity Slot Spark Discharge, Its Cause and Cure”, IEEE International Symposium on Electrical Insulation, Montreal, 1976, 76CH1088- 4 -El, Paper C-4. [3] Burdulea C. and Chatelain J. — “New Method of Evaluation of Insulation Degradation in Electrical Machines”, Revue Generale de 1’Electricite, Vol. 83, No. 10, October, 1974, pp. 679-688. [4] Ryder D.M., Wood J.W. and Gallagher P.L. - “The Detection and Identification of Overheated Insulation in Turbogenerators”, IEE PES Summer Power Meeting, July, 1978, Paper F76 660-0. [5] Findley D.A., Brearly R.G.A. and Louttit C.C. “Evaluation of the Internal Insulation of Generator Coils Based on Power Factor Measurements”, AIEE Transactions (Power Apparatus and Systems), Vol. 78, June, 1959, pp. 268-279. [6] “IEEE Recommended Practice for Measurement of Power-Factor Tip-Up of Rotating Machinery Stator Coil Insulation”, IEE No. 286. [7] Dakin T.W. and Malinaric P. - “A Capacitance Bridge Method for Measuring Integrated Corona-Charge Transfer and Power Loss per Cycle”, AIEE Transactions (Power Apparatus and Systems), Vol. 79, October, 1960, pp. 648-653. [8] Simons J.S. — “Preventive Maintenance Testing of Large Machines : Recommendations for Insulation Test Procedures”, Digest No. 1975/3, Colloquium on Electrical Machine Insulation, IEE, London, England. [9] Simons J.S. — “Some Aspects of the Evaluation in the Laboratory and Field of the Serviceability of Micaceous Insulation for Rotating Machines”, Proceeding of the BEAMA International Electrical Insulation Conference, 1978, Brighton, England. [10] Dakin T.W., Works C.N. and Johnson J.S. - “An Electromagnetic Probe for Detecting and Locating Discharges in Large Rotating Machine Stators”, IEEE Transactions on Power Apparatus and Systems, Vol. PAS-88, March, 1969, pp. 251-257. [11] Wilson A. - “Discharge Testing on Site”, Proceeding of the BEAMA International Electrical Insulation Conference, 1978, Brighton, England. [12] Johnson J.S. and Warren M. - “Detection of Slot Discharge in High-Voltage Stator Windings During Operation”, AIEE Transactions, 1951, Vol. 70, Part II, pp. 1993-1997. [13] Kurtz M. — “A Partial Discharge Test for Generator Insulation”, Ontario Hydro Research Quarterly, Vol. 25, No. 4,1973 pi. [14] Kurtz M. and Lyies J.F. - “Generator Insulation Diagnostic Testing”, IEEE Transactions on Power Apparatus and Systems, Vol. PAS-98, Sept/Oct 1979, pp. 1596-1603. [15] Kurtz M. and Stone G.C. - “Discharge Testing of Generator Insulation - Part II”, Canadian Electrical Association Research Report, Contract RP76-17, September, 1979, (Available from Suite 580, 1 Westmount Square, Montreal, PQ, Canada). Extrait de la Conference Internationale des Grands Reseaux Electriques Session de 1980